Perforating device for laser thermoprint bend-resistant clothing hangtag

A punching device and bending-resistant technology, applied in metal processing, surface polishing machine tools, metal processing equipment, etc., can solve the problem that the punching effect of non-laser hot stamping bending-resistant clothing tags is not ideal, and the holes are prone to burrs. and other problems, to achieve the effect of not easy to flash, to ensure the polishing effect, and to ensure the punching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

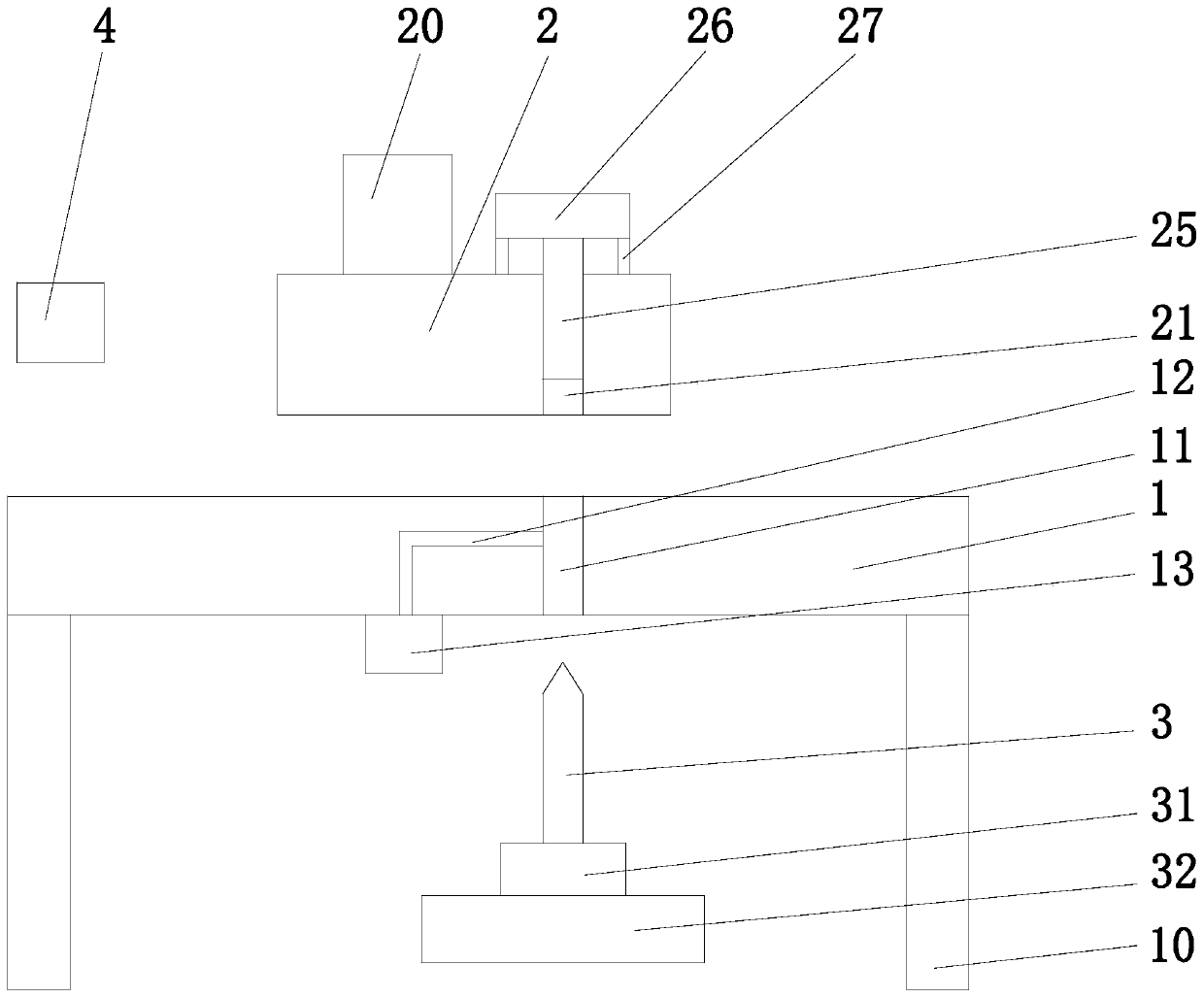

[0020] refer to figure 1 , a punching device for laser hot stamping anti-bending clothing tags of the present invention, comprising a punching table 1, a pressing plate 2, a punching rod 25, a first pressing device 20, a second pressing device 26, a lifting device 32, Polishing rod 3, control device 4, a pressing plate 2 is arranged on the top of the punching table 1, the pressing plate 2 is connected with a first pressing device 20, and a vertically arranged first through hole 21 is provided on the pressing plate 2 , the first through hole 21 is inserted with a punching rod 25, the punching rod 25 is connected with a second pressing device 26, the second pressing device 26 is fixed with the pressing plate 2, and the punching table 1 is provided with A vertically arranged second through hole 11, the second through hole 11 runs through the upper and lower ends of the punching table 1, the second through hole 11 is located directly below the first through hole 21, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com