Cloth sample cutting mechanism

A sample and fabric technology, applied in the field of fabric sample cutting mechanism, can solve the problems of irregular cutting, affecting carrying, easy to form burrs, etc., to achieve neat and smooth cutting edges, improve appearance effect, and not easy to burr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

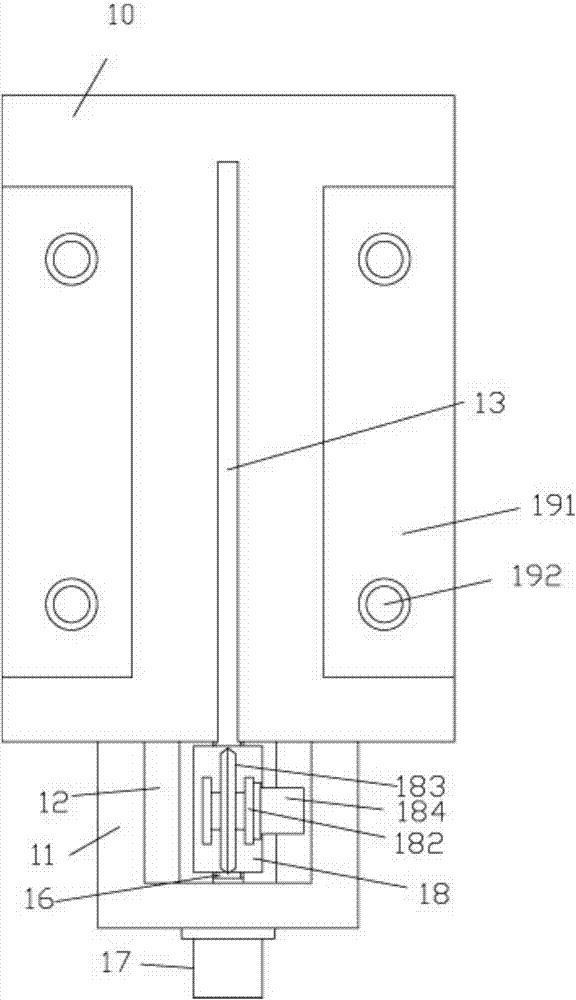

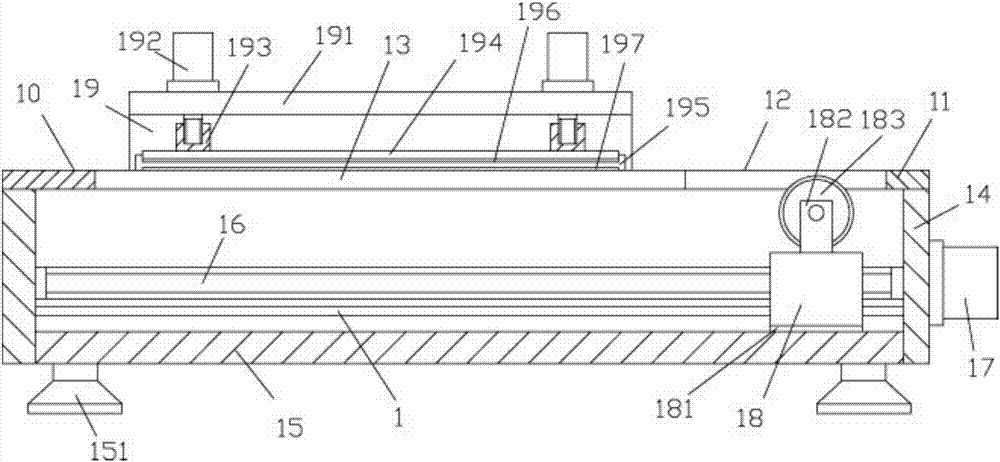

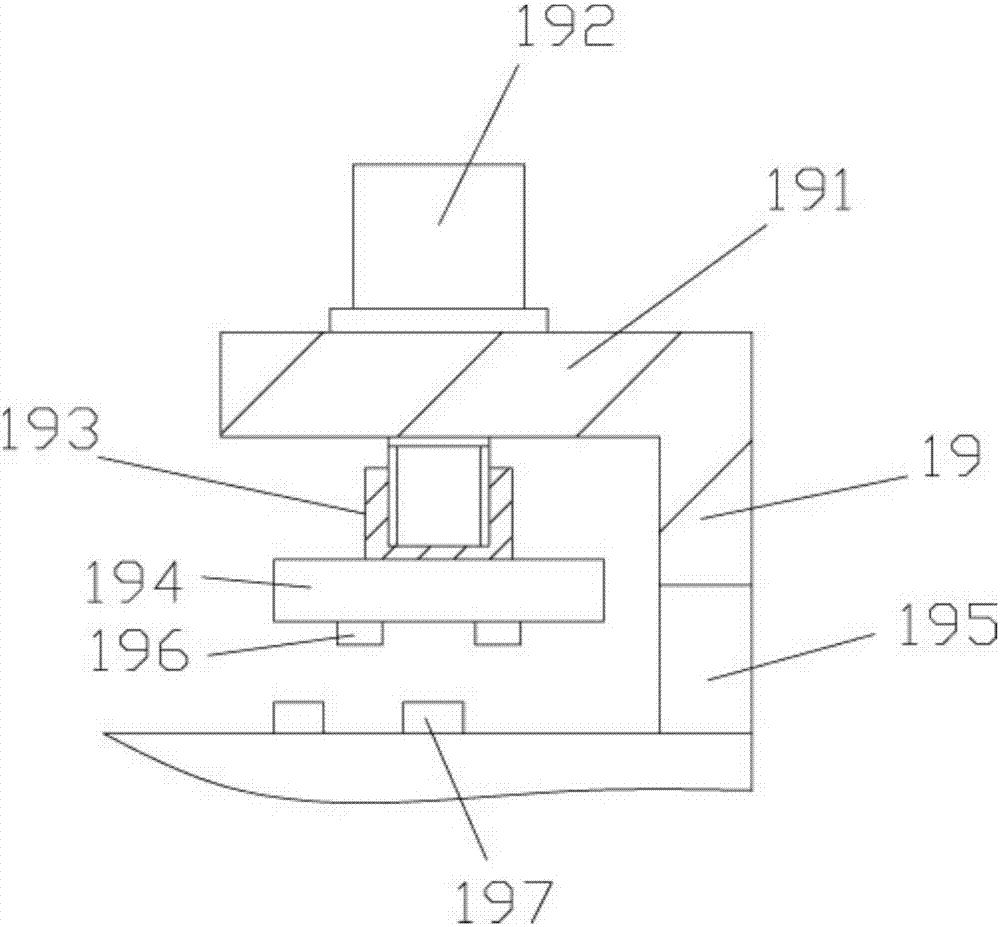

[0022] Examples, see e.g. Figure 1 to Figure 3 As shown, a cloth sample cutting mechanism includes a main support plate 10, a transition plate 11 is fixed in the middle of the rear side wall of the main support plate 10, and the middle portion of the transition plate 11 has an empty groove 12, which is connected to the main support. The right end of the intermediate separation groove 13 formed in the middle of the plate 10 communicates, the left bottom surface of the main support plate 10 and the right bottom surface of the transition plate 11 are fixed with a vertical support plate 14, and the two ends of the bottom plate 15 are fixed on two vertical supports. On the straight support plate 14, the transmission screw rod 16 is above the bottom plate 15, and the two ends of the transmission screw rod 16 are respectively hinged on the corresponding vertical support plate 14, and a drive motor 17 is fixed on the outer wall of one of the vertical support plates 14, The output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com