High-frequency reciprocating motion die cutter device

A technology of reciprocating motion and punching knife, which is applied in metal processing and other directions, can solve the problems of untidy trimming, large material deformation, and low precision, and achieve the effect of small material deformation, large cutting force and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0029] Example.

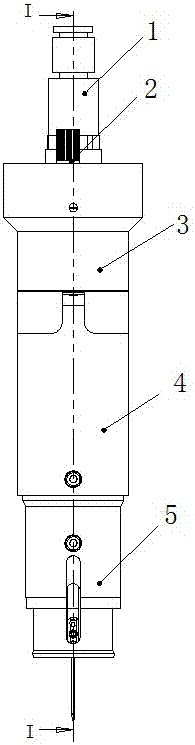

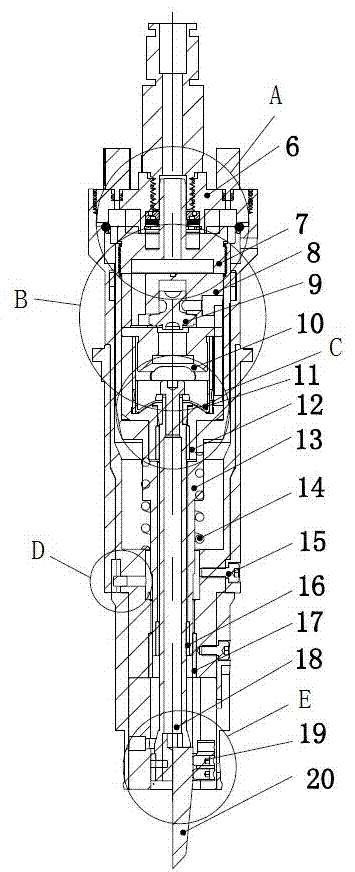

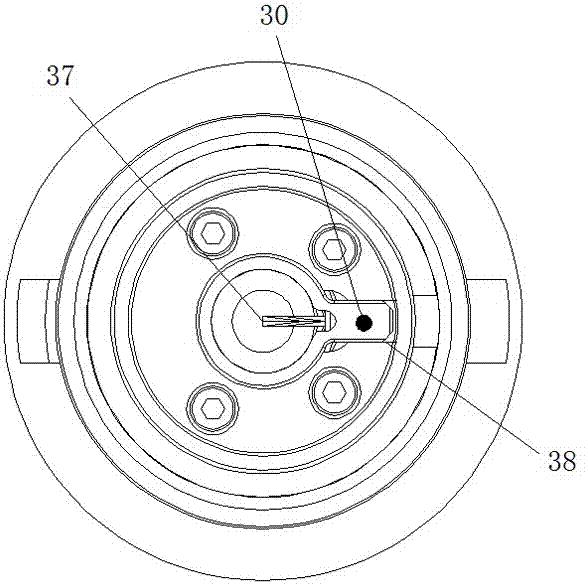

[0030] see Figure 1 to Figure 8 , the high-frequency reciprocating knife punching device of this embodiment mainly includes a pneumatic joint 1, a mounting seat 3, an adjustment sleeve 4, a knife cover 6, an air intake seat 7, a ventilation seat 8, a vibrating core 9, a breathable seat 10, and a piston sleeve 11. Vibration cylinder 12, vibration box 13, vibration bar 18, blade 20 and limit seat 31.

[0031] The pneumatic joint 1 in this embodiment is installed on the knife cover 6, and the bottom of the knife cover 6 is provided with a sealing ring 1 22, a gasket 23 and a retaining spring 24, and a sealing ring 2 25 is installed on the outer circle of the knife cover 6, and the air intake seat 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com