Plastic hollow board ultrasonic wave indentation method

A plastic hollow board and ultrasonic technology, which is applied in the field of ultrasonic indentation of plastic hollow boards, can solve the problems of short service life, easy burrs, thin and damaged surface layer, etc., and achieve long service life, thin indentation thickness and rebound force small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: thickness 6mm (1600g / m 2 ) The specific indentation process of hollow plate products will position the cut product plate on the ultrasonic equipment platform, using a semi-circular die head,

[0024] 1. Indentation length: 120mm; indentation thickness: 1.4±0.2mm The specific parameters of the ultrasonic equipment are: the distance between the upper and lower dies is 0.8mm; the compressed air pressure is 7kg; welding time: 2.2s; delay time: 0.6s; holding time: 2.5s.

[0025] 2. Indentation length: 100mm; indentation thickness: 1.4±0.2mm The specific parameters of the ultrasonic equipment are: the distance between the upper and lower dies is 0.8mm; the compressed air pressure is 7kg; welding time: 1.9s; delay time: 0.6s; holding time: 2.3s.

[0026] Start the ultrasonic equipment to make traces formed on the plate of the product and the pressing part of the die head.

Embodiment 2

[0027] Embodiment 2: thickness 5mm (1000g / m 2 ) The specific indentation process of the hollow plate product is the same as in Example 1, the selected die head is a semicircular die head, the indentation length is 150mm, and the indentation thickness is 0.6mm; the specific parameters of the ultrasonic equipment are: the distance between the upper and lower dies 0.6mm, compressed air pressure 7kg, welding time: 1.2s, delay time: 0.3s, holding time: 1.6s.

Embodiment 3

[0028] Embodiment 3: thickness 4mm (700g / m 2 ) The specific indentation process of hollow plate products is the same as above, the selected die head is a semicircular die head, the indentation length: 150mm, and the indentation thickness: 0.6mm; the specific parameters of the ultrasonic equipment are: the distance between the upper and lower dies is 0.6mm, Compressed air pressure 7kg, welding time: 1.0s, delay time: 0.3s, holding time: 1.3s.

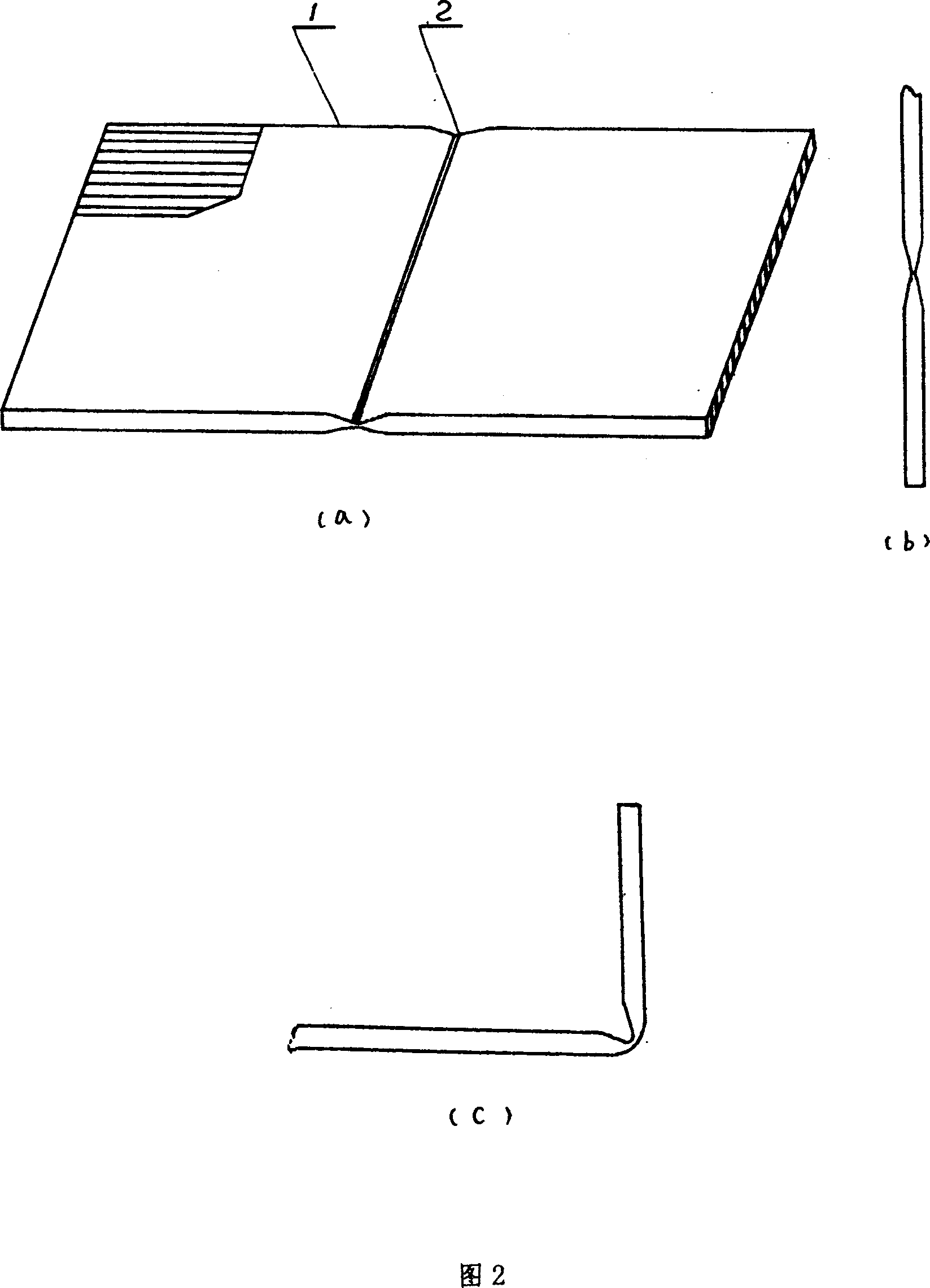

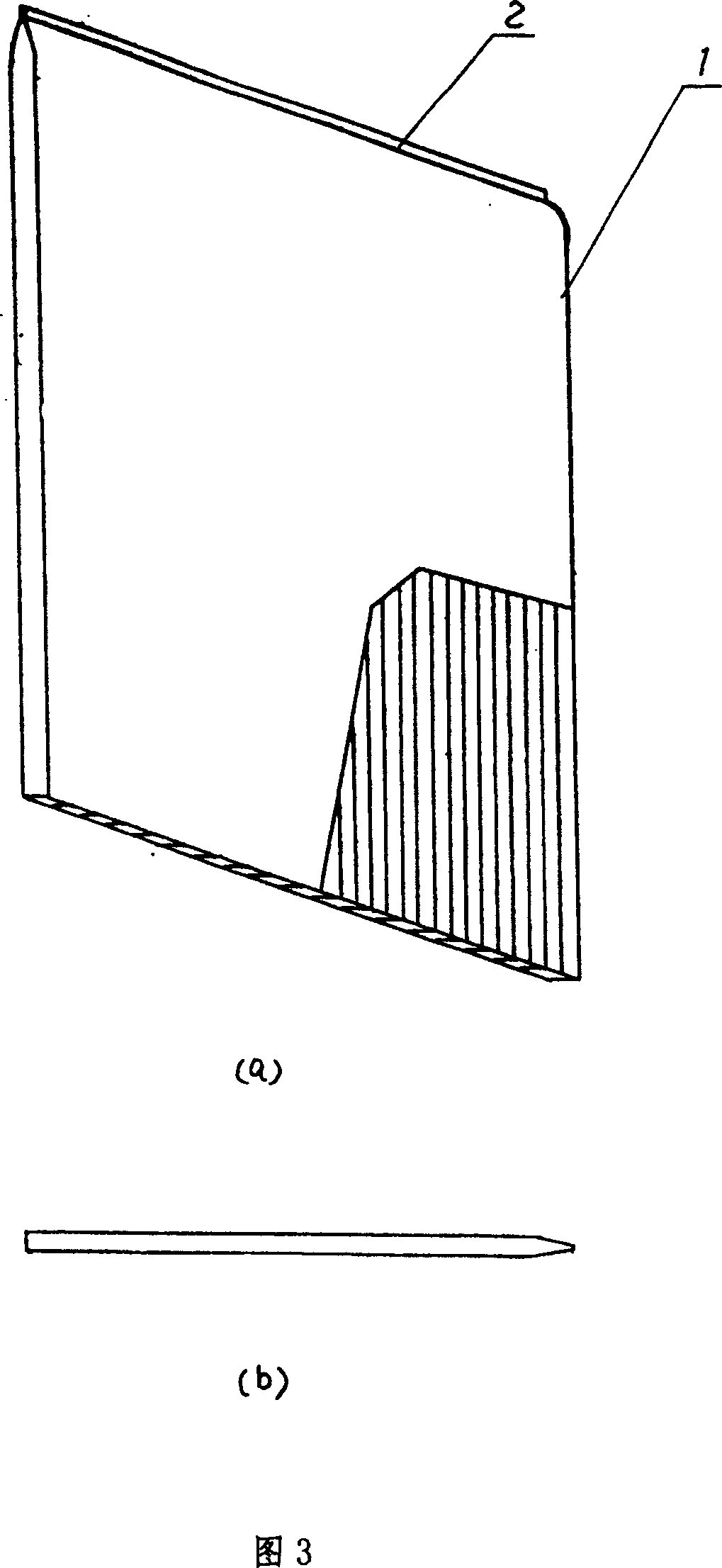

[0029] Fig. 2a, b, c are schematic diagrams of hollow plates indented by the method of the present invention. A semicircular die is used to indent the hollow plate 1 under pressure. The ribs and surface layer of the plastic hollow plate are fused together under high temperature and high pressure to form the indentation 2 shown in Figure 2a. The thickness of the indentation is 0.2-2.5mm (see Figure 2b), the indentation thickness is thin, easy to bend or fold, can be folded 180 degrees (see Figure 2c), and the rebound force is small. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com