Short-sleeve shirt and cutting method

A short-sleeved, shirt technology, applied in shirts, clothing, applications, etc., can solve the problems of insufficient aesthetics, weak layering, and poor windproof performance of the placket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

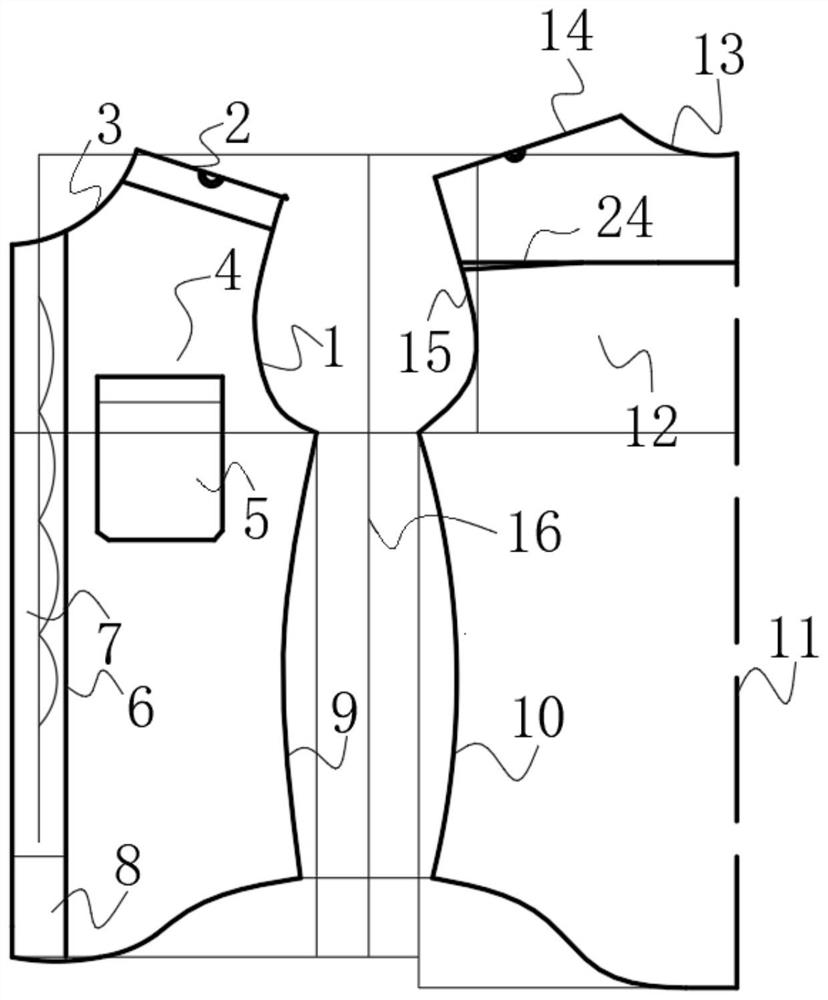

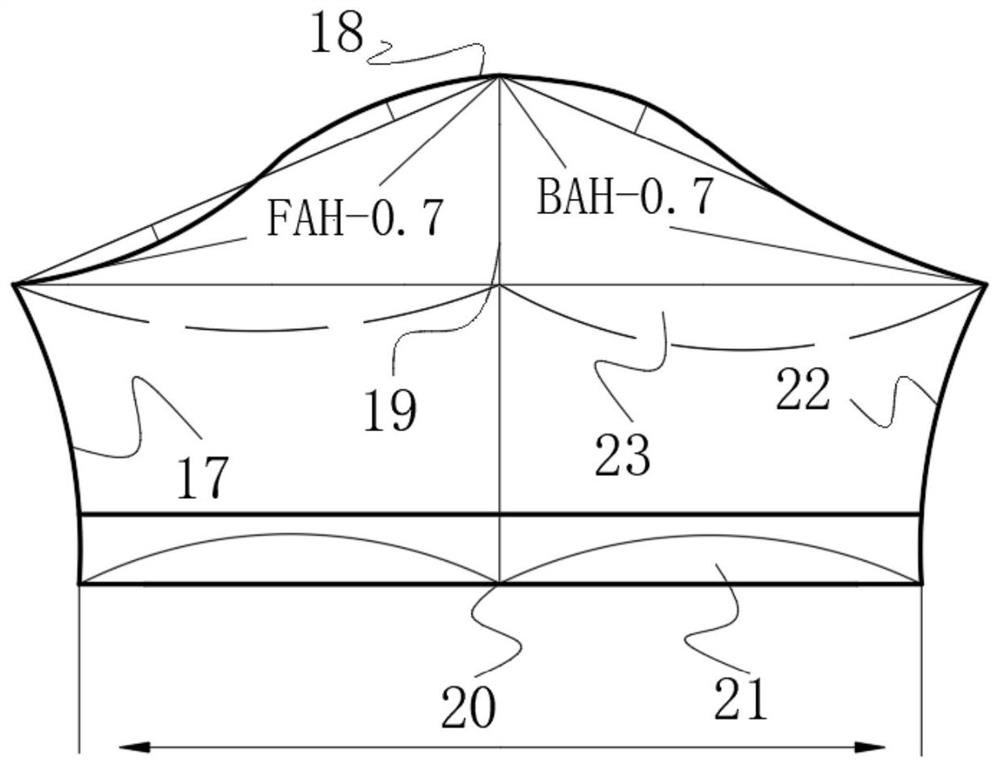

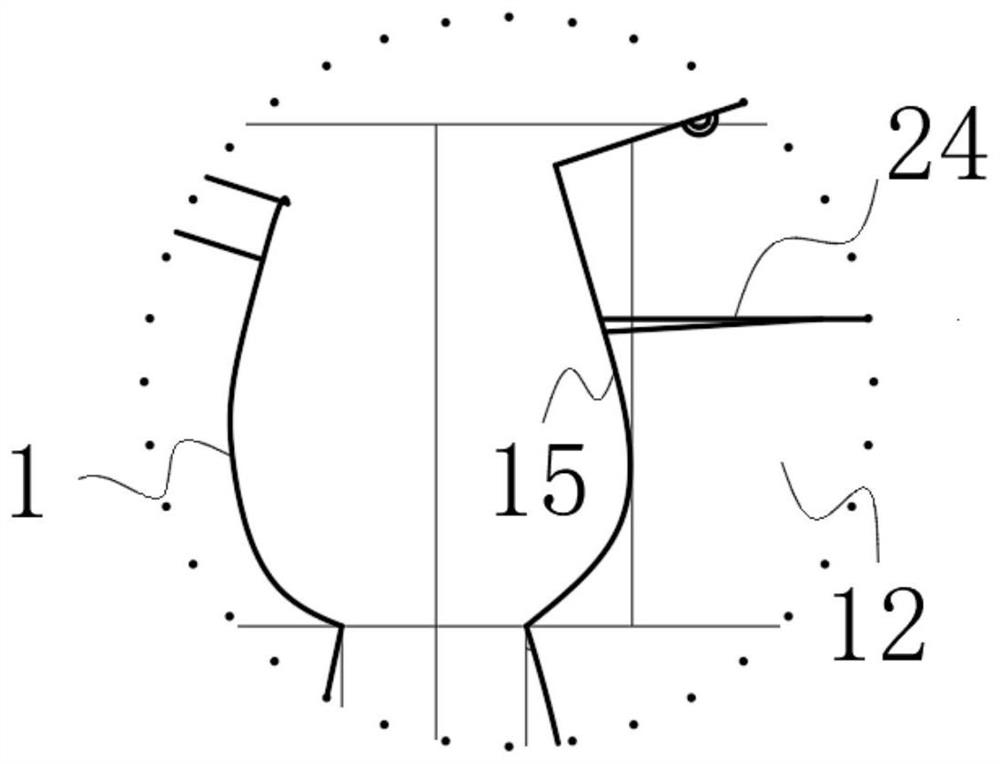

[0037] Such as Figure 1-4 As shown, the present invention provides a short-sleeved shirt, comprising a left front armhole arc 1, one end of the left front armhole arc 1 is connected with a front shoulder seam edge 2, and one end of the front shoulder seam edge 2 is connected with a front neckline 3. The lower end of the front neckline 3 is connected with the left chest piece 4, one end of the left chest piece 4 is connected with the pocket patch 5, one end of the pocket patch 5 is connected with the welt contour line 6, and the welt contour line 6 One end is connected with a laminated fly 7, the lower end of the laminated fly 7 is connected with a placket bottom 8, one end of the placket bottom 8 is connected with a front side patch 9, and one end of the front side patch 9 is connected with a rear side Side patch 10, one end of rear side patch 10 is connected with track line 11 in the back, the upper end of track line 11 in the back is connected with left back piece 12, and t...

Embodiment 2

[0047] A cutting method for a short-sleeved shirt, the steps of the cutting method are as follows:

[0048] Step 1: Determine the structural size of the clothing style according to the anthropometric data. First, determine the position of the front shoulder seam edge 2 according to the left front armhole arc edge 1, and cut out the front shoulder seam edge 2, and use the front shoulder seam edge 2 to determine the position of the front neckline 3, and cut out the front neckline 3, determine the position of the left chest piece 4 by 3cm to 4cm from one end of the front neckline 3, and cut out the left chest piece 4;

[0049] Step 2: Cut a pocket patch 5 at a distance of 3cm to 4cm from one end of the left chest piece 4, the upper end of the pocket patch 5 is 34cm to 5cm from the front neckline, and the lower end of the pocket patch 5 is 87cm to the back of the placket 8cm, the left end of the pocket patch 5 is 2cm to 3cm away from the laminated placket, the right end of the poc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com