Environmental-friendly door plank manufacturing method

A manufacturing method and door panel technology, applied to veneer presses, manufacturing tools, plywood presses, etc., can solve problems such as difficult precise positioning of stamping positions, misalignment, and easy damage to components, and achieve the effect of strengthening the fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

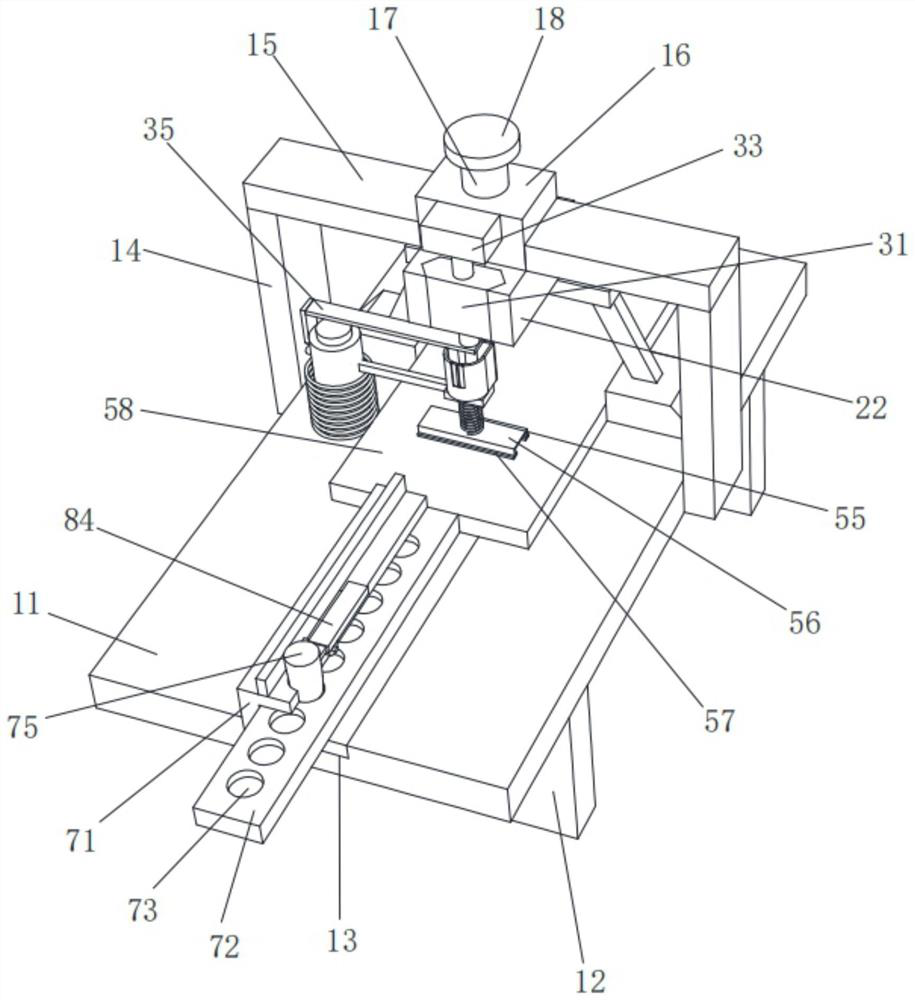

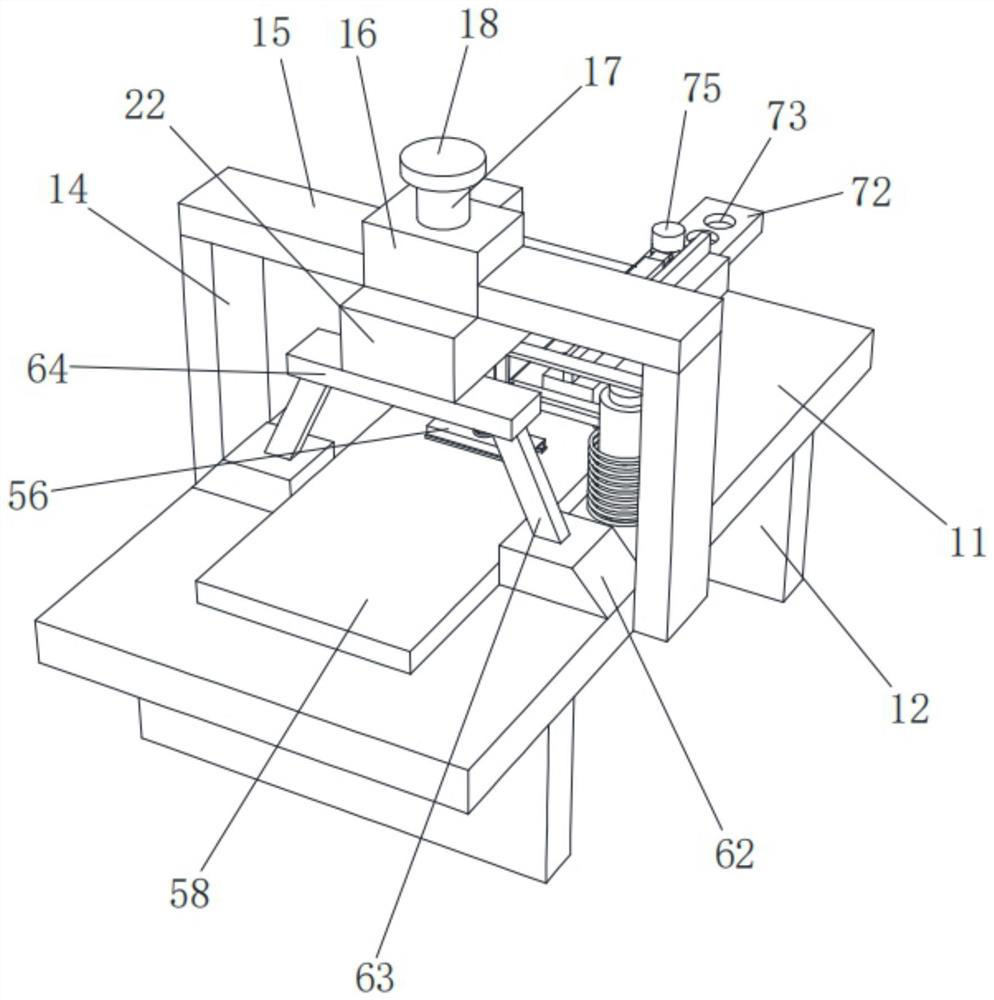

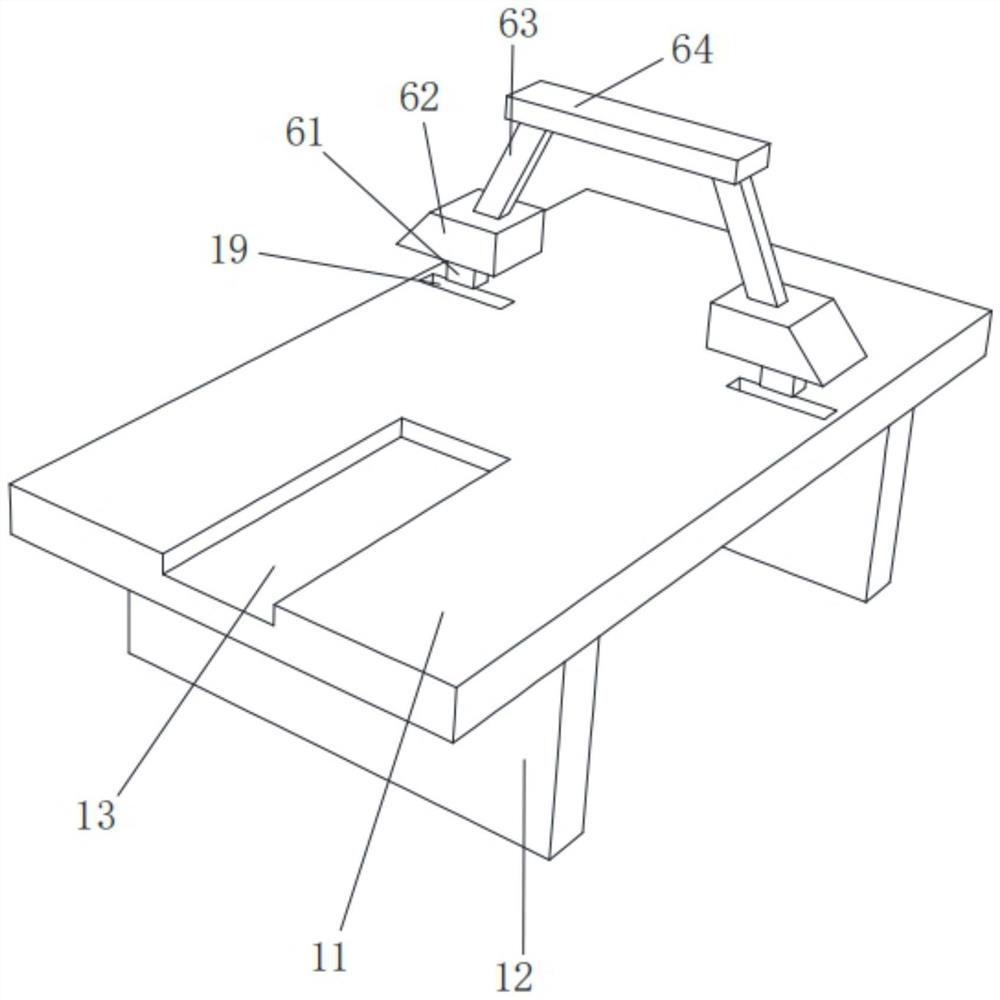

[0052] Example 1: See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11 , a method for manufacturing an environmentally friendly door panel, comprising the following steps:

[0053] 1) Wood drying: Put the wood in a 4t / h coal-fired steam boiler for drying. Generally, the time for spraying steam is about 15 minutes, and the time for heating and drying is about 25-30 days. The moisture content of the dried board is about 10-14%;

[0054] 2) Blanking: When rough cutting, increase the length and width by 10mm. If the material is combined, indicate the material of the veneer and indicate the combination of the door type;

[0055] 3) Hot pressing: Clean the hot pressing plate and the workpiece, confirm that there are no impurities, set the hot pressing temperature and pressure, and slowly put the door panel in to ensure that the thickness of each layer of the plate is the same as the cladding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com