High-molecular composite boundary medium preparation process and use method thereof

A preparation process and polymer technology, applied in coatings, pre-treated surfaces, magnetic coatings, etc., can solve problems such as low life expectancy, easy oxidation of the boundary medium, and impact on strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

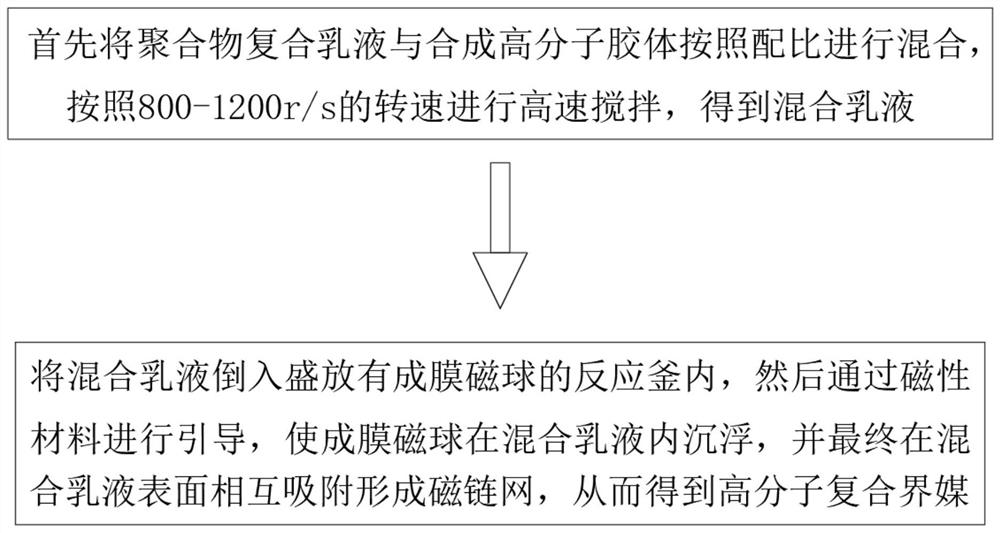

[0049] see figure 1 , a polymer composite intermediary preparation process and using method thereof, the polymer composite intermediary includes a polymer composite emulsion and a synthetic polymer colloid, and the preparation process includes the following steps:

[0050] S1, first mix the polymer composite emulsion and the synthetic polymer colloid according to the proportion, and perform high-speed stirring at a speed of 800-1200r / s to obtain a mixed emulsion;

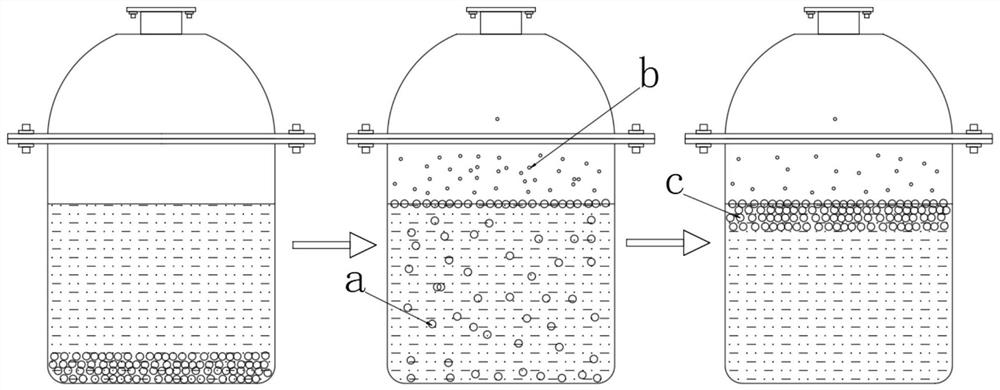

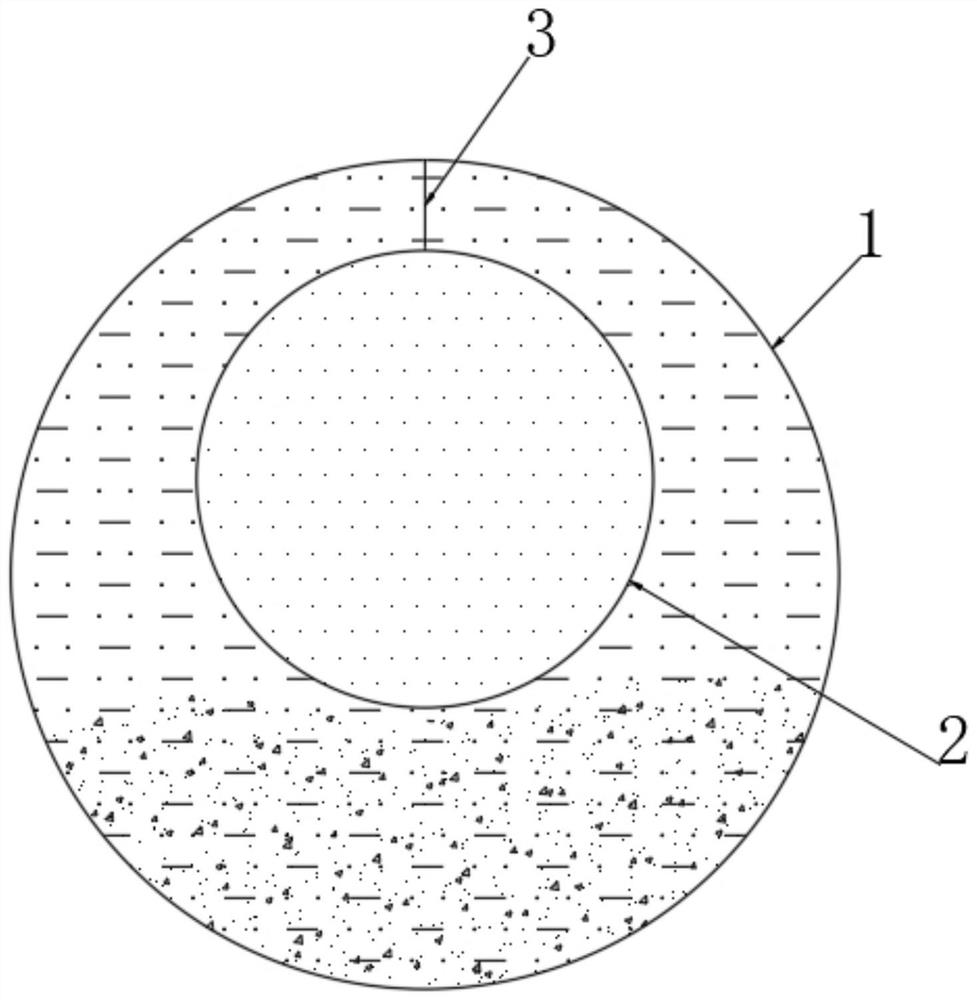

[0051] S2. Please refer to figure 2 In the figure, a represents the film-forming magnetic ball, b represents the overflowing air bubbles, and c represents the magnetic chain net. The ball sinks and floats in the mixed emulsion, and the bubbles can be effectively cut during the sinking and floating process, so that the air content in the formed polymer composite intermediary is low, thereby effectively improving its quality, and finally adsorbing each other on the surface of the mixed emulsion to form a magnetic ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com