Assembly type adjustable lamp strip rear-mounted structure and mounting method

An adjustable and assembled technology, applied in lighting devices, lighting auxiliary devices, components of lighting devices, etc., can solve the problems of inconvenient operation, many steps, and not suitable for replacing strip light strips, etc. The installation process is convenient and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

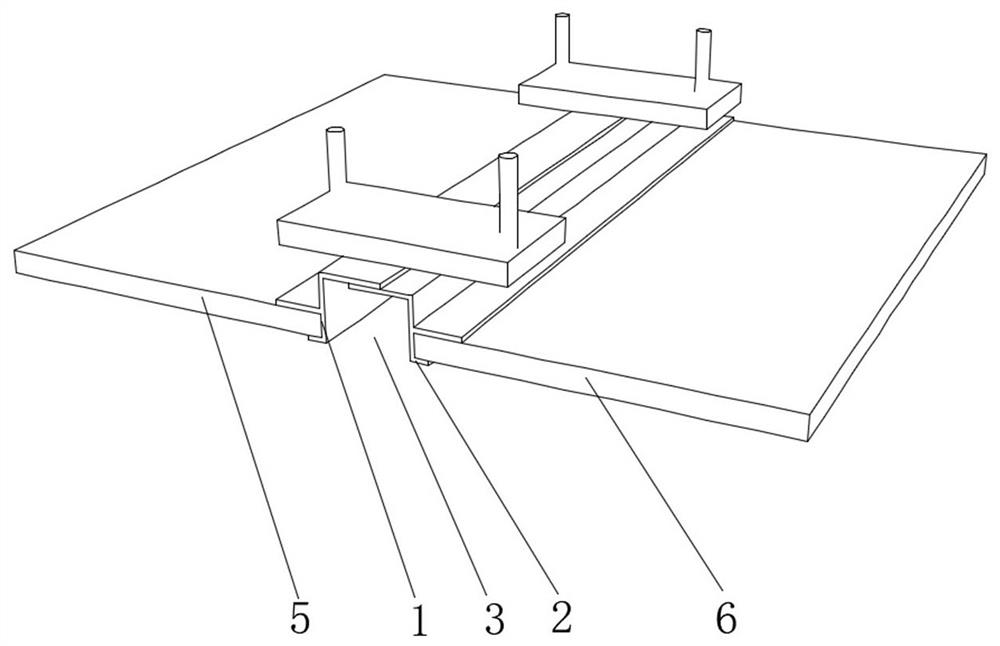

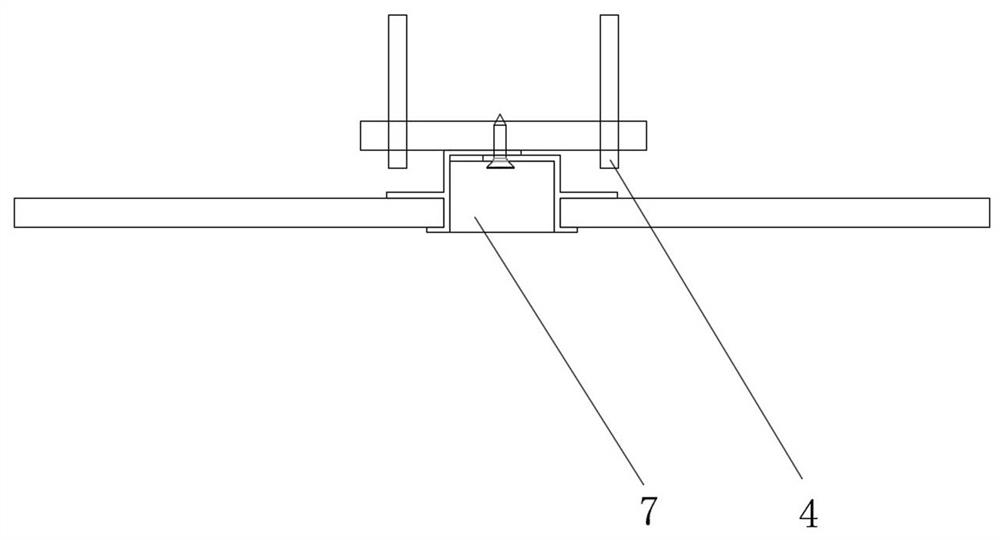

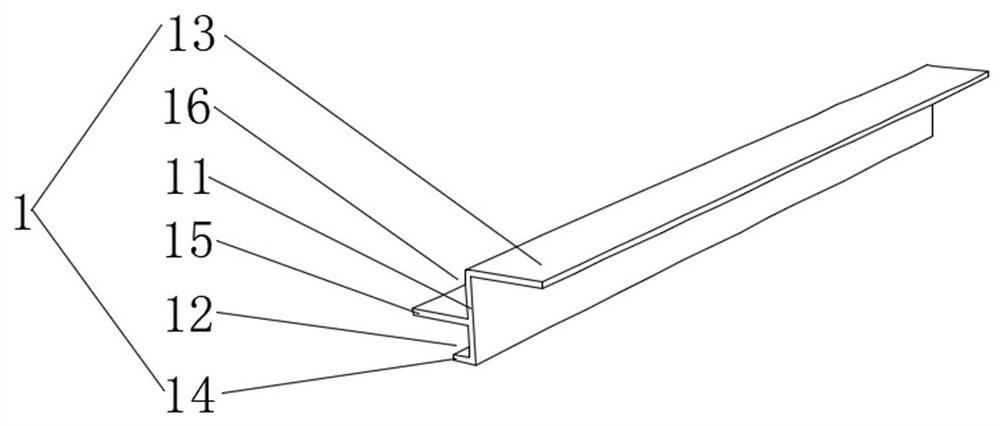

[0033] like Figure 1-2 As shown, an assembled adjustable light strip rear structure includes a component A and a component B. An outward left cavity 12 is formed under the component A, and the top of the component A extends inward from a supporting plate 13; An outward right cavity 22 is formed, component A is stacked on top of component B through the support plate 13, and the lower part of component A and component B overlaps to form a light strip cavity 8, which carries a light strip 7 in the light strip cavity 8, and component A 、Component B is fixed under the nail-holding plate 3 by screws, expansion bolts 4 are installed on both sides of the nail-holding plate 3, the nail-holding plate 3 is installed on the floor through the expansion bolts 4, and the left cavity 12 is provided with a left ceiling plate Face 5, right cavity 22 inner sleeves are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com