Small diameter reflector supporting structure

A mirror-supported, small-diameter technology, used in installation, optics, instruments, etc., can solve the problems of cumbersome operation, sensitive to temperature changes, uneven adhesive strength, etc., and achieve the effect of reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

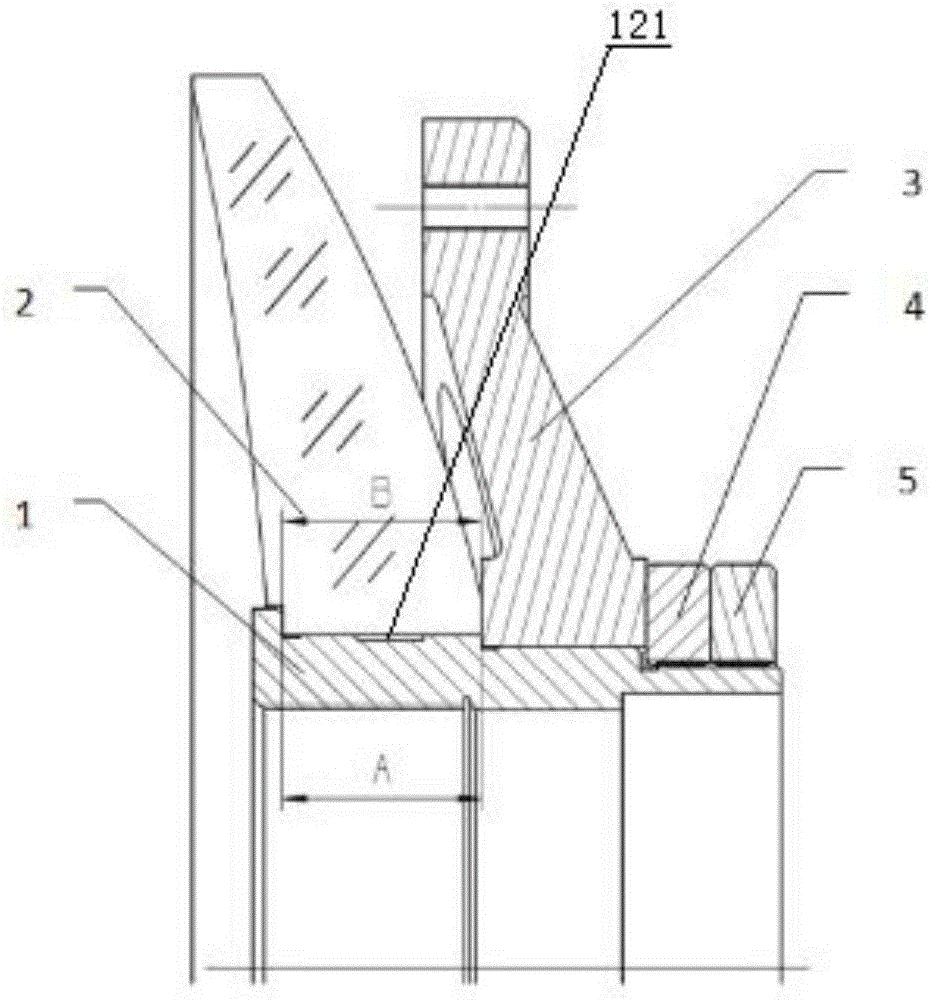

[0041] Such as Figure 4 As shown (the symmetrical structure is omitted in the figure), the small-diameter reflector support structure of the present invention includes a mandrel 1, a back plate 3, a first locking nut 4, a second locking nut 5, a pressing plate 6, a silicone pad 7 and Backing ring 8.

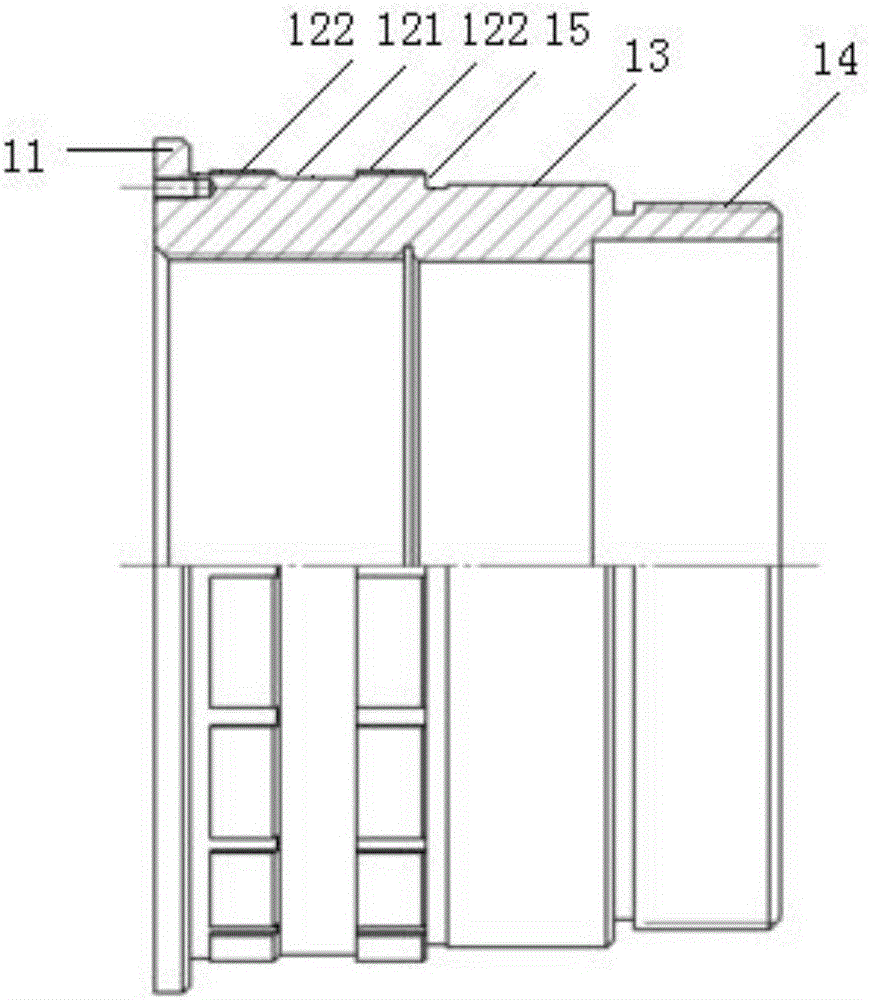

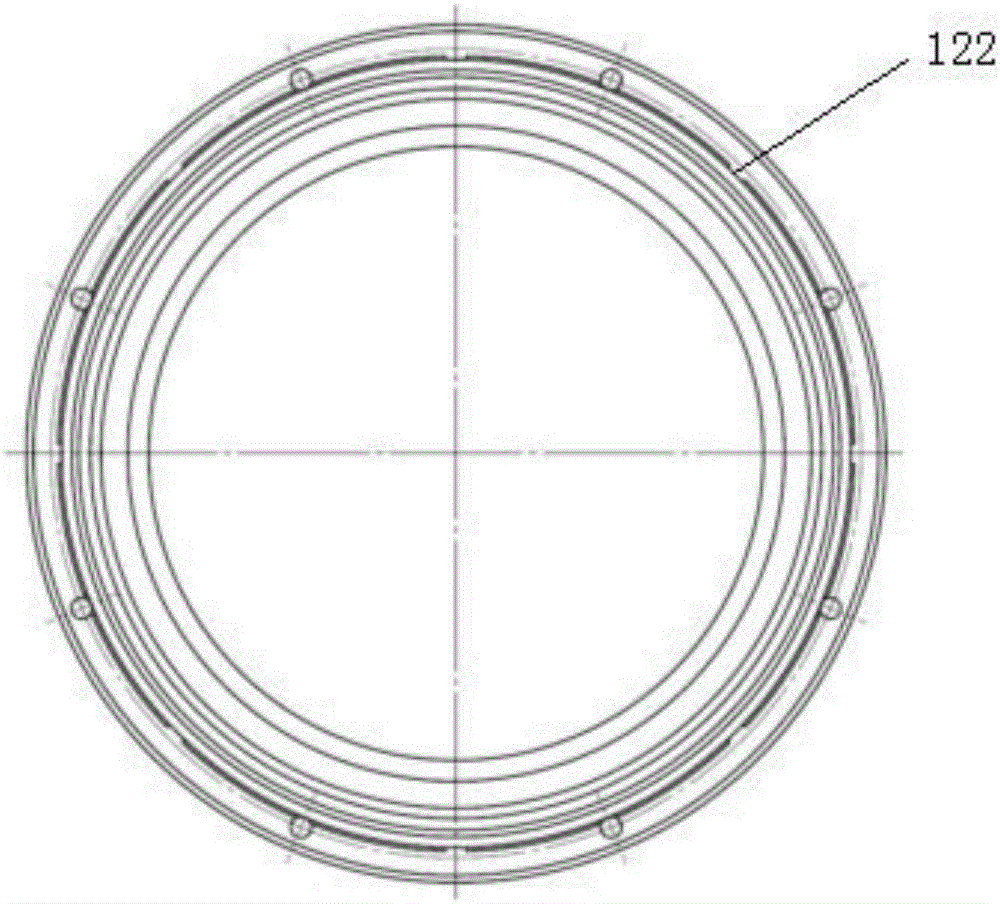

[0042] Among them, such as Figure 5 and Figure 6 As shown, the outer wall of the mandrel 1 is provided with a first endless belt 12, a second endless belt 13 and a third endless belt 14 in sequence from front to back, and the first endless belt 12, the second endless belt 13 and the third endless belt 14 The outer diameter decreases successively.

[0043]The length of the first annular band 12 is slightly less than the length of the through hole of the reflector 2; the edge circumference of the front end face of the first annular band 12 is uniformly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com