Longitudinally reinforced cured in place liner and reinforced coating

An in-situ curing and lining technology, applied in other household appliances, mechanical equipment, pipe components, etc., can solve problems such as difficulty, weakening circumferential stretching of CIPP installation, difficulty in dipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

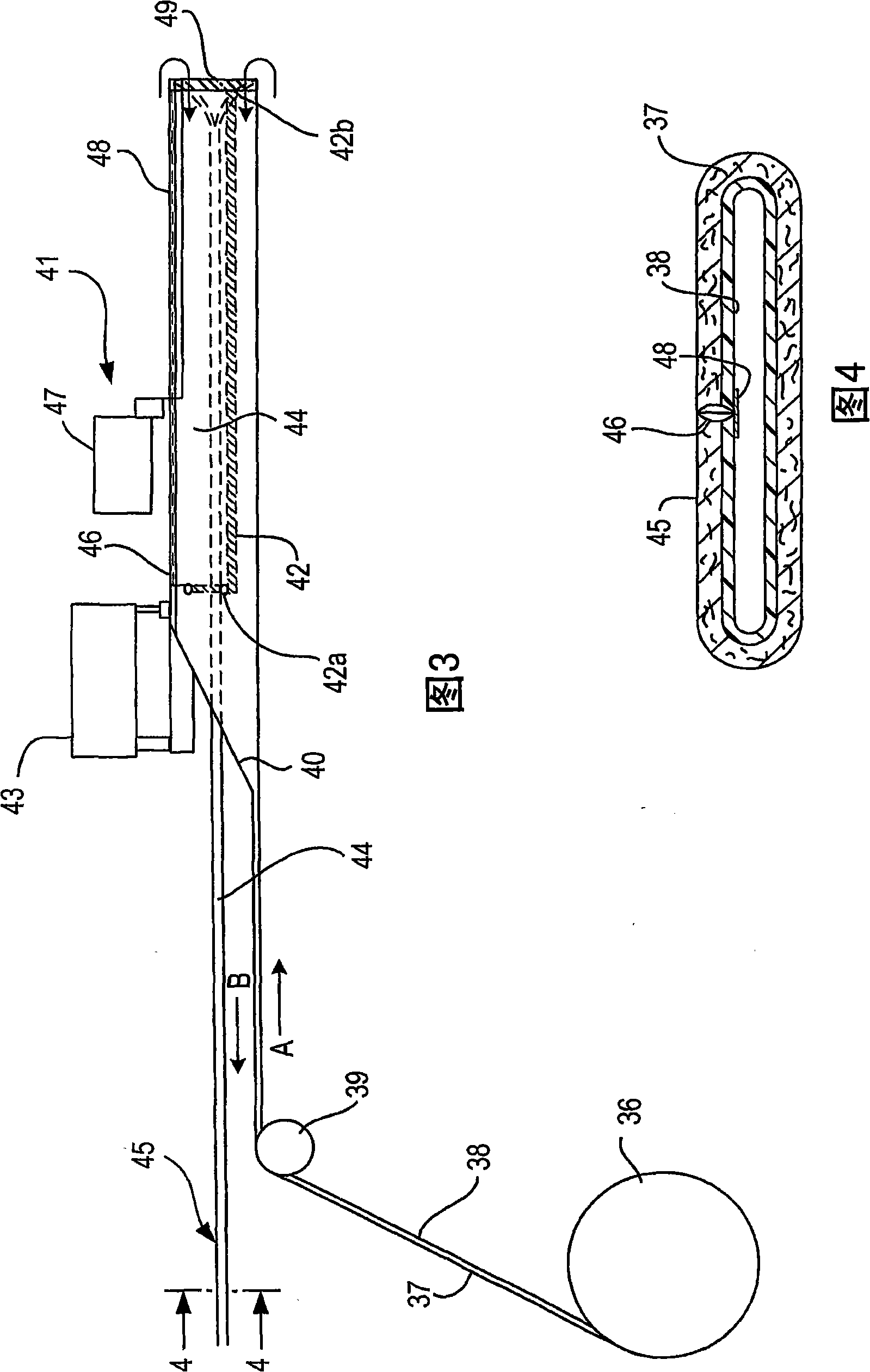

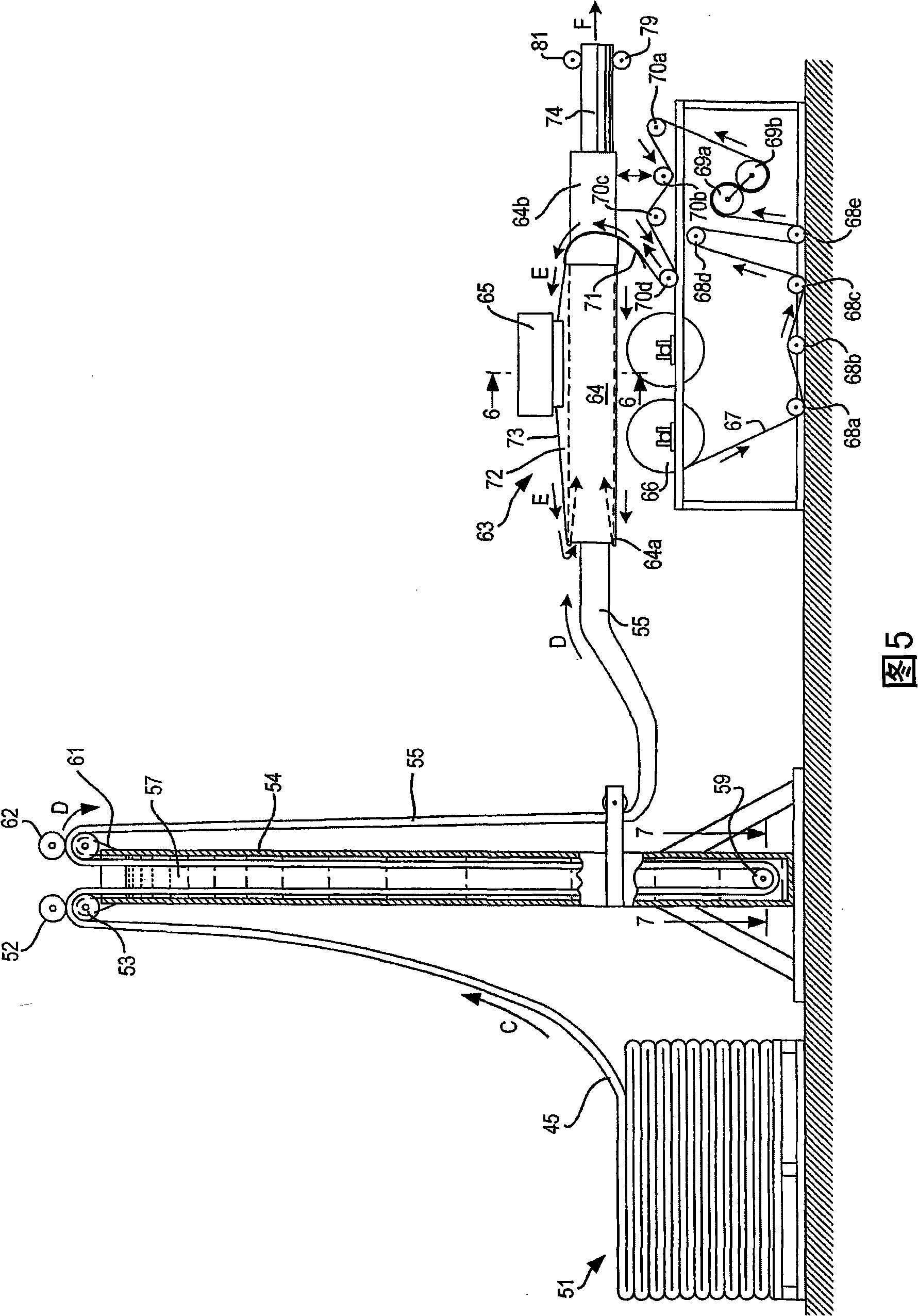

[0038] A resin-impregnated cured-in-place inner liner prepared according to the present invention has a longitudinally reinforcing fabric cover as the outer impermeable layer. When prepared with an integral inner impermeable layer, the liner can be installed by pull-in inflation and expanded and cured by heating a fluid without the need for inflatable bladders. A continuous length of liner may be prepared having an internal impermeable longitudinal reinforcing fabric cover. Given the extra effort necessary to impregnate a flattened liner with resin absorbable material between the inner and outer cladding using conventional vacuum impregnation techniques, the liner can be impregnated after assembly.

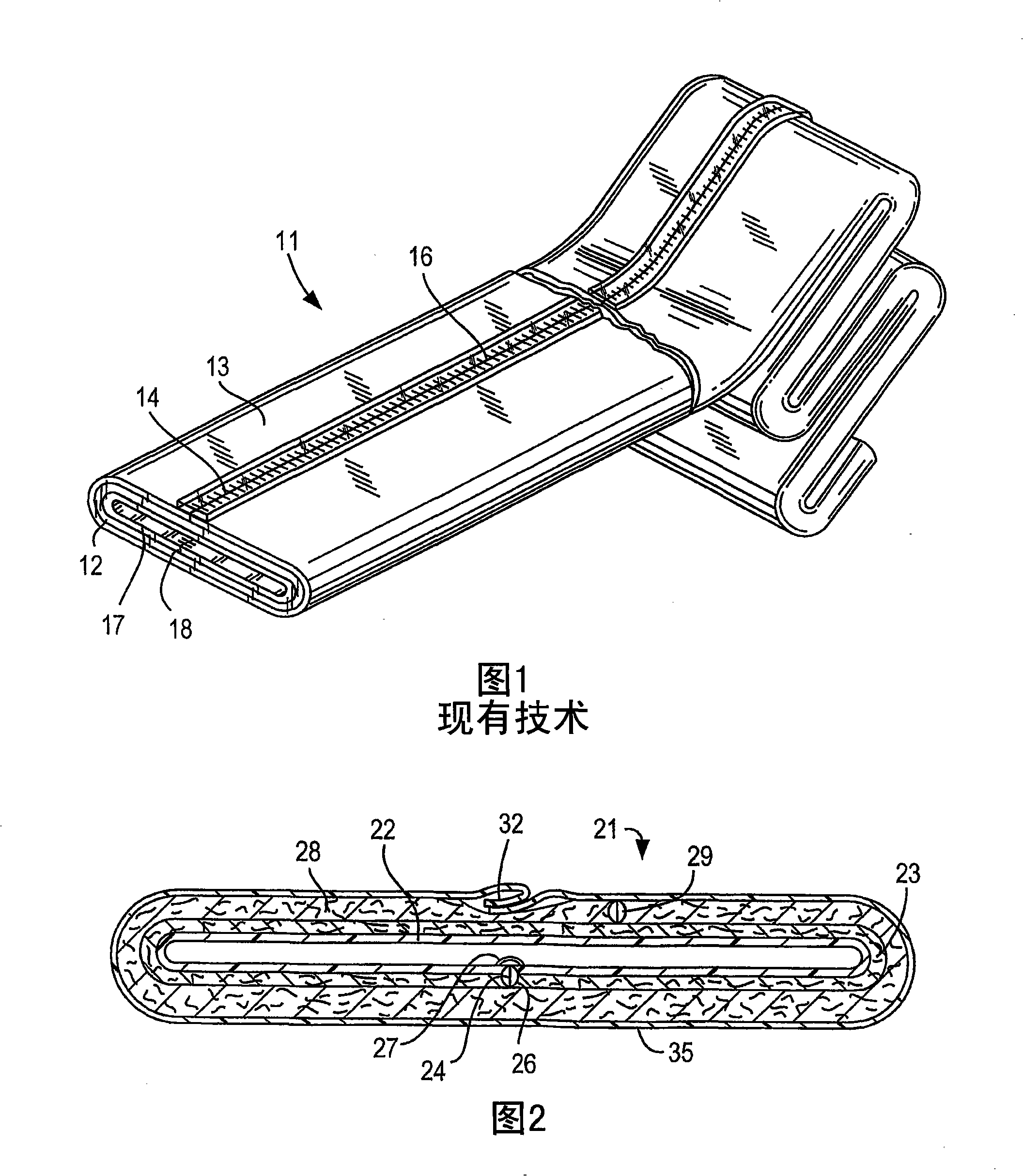

[0039] Figure 1 shows a flexible cure-in-place liner 11 known in the art and currently commonly used. The inner liner 11 is made of at least one layer of flexible resin impregnable material, for example a felt layer 12 with an outer impermeable polymeric membrane layer 13 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com