Evolving tread for a tyre

A tread and tire technology, applied to tire tread/tread pattern, tire parts, vehicle parts, etc., can solve the problems of increased wear speed, reduced tread wear performance, increased deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the drawings easier to understand, the same reference numerals have been used to describe alternative forms of the invention, wherein these reference numerals designate elements of the same kind, either structurally or functionally.

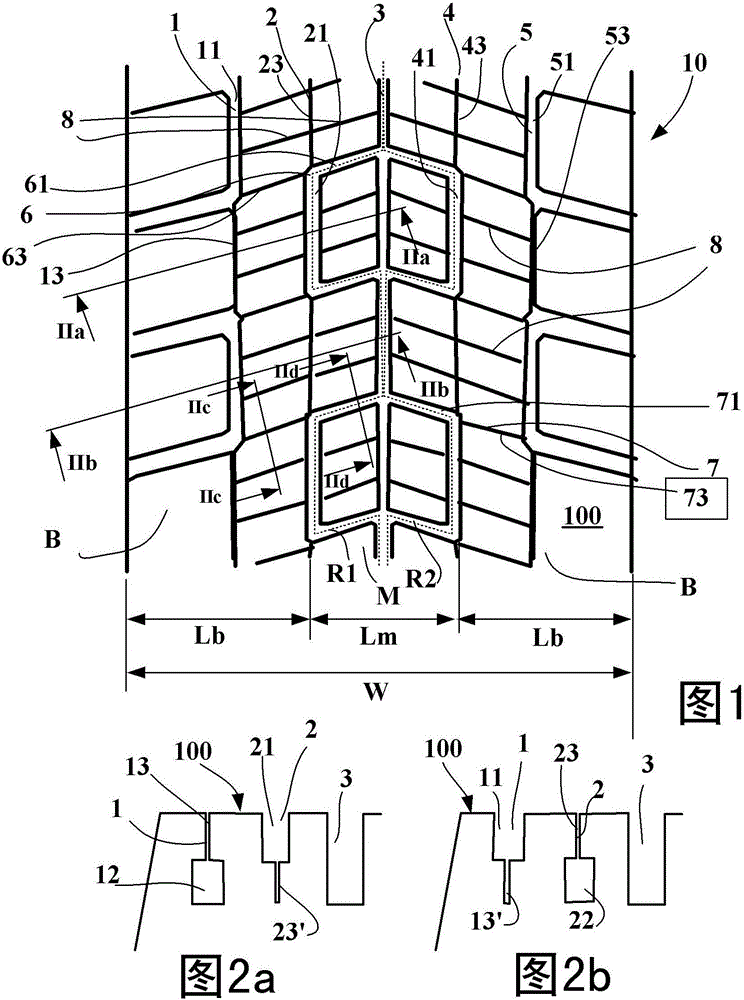

[0036] figure 1 is a partial view of the tread surface of a tire tread according to the invention when new.

[0037] Should figure 1 A portion of the tread 10 when new is shown intended to equip a heavy vehicle tire of size 315 / 70R22.5.

[0038] This tread 10 has a tread surface 100 intended to contact the road during running over a width W equal to 290 mm.

[0039] The tread is provided with five grooves 1 , 2, 3, 4, 5 generally circumferentially oriented. A central circumferential groove 3 is located on the midplane of the tread; this central groove 3 has an average width equal to 6 mm. On both sides of this middle groove 3, there are two wave-shaped grooves 2, 4 which have undulations in the thickness of the tread a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com