Patents

Literature

105 results about "Heavy goods vehicle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heavy goods vehicle (HGV), also large goods vehicle (LGV) or medium goods vehicle, is the European Union (EU) term for any truck with a gross combination mass (GCM) of over 3,500 kilograms (7,716 lb). Sub-category N2 is used for vehicles between 3,500 kilograms (7,716 lb) and 12,000 kilograms (26,455 lb) and N3 for all goods vehicles over 12,000 kilograms (26,455 lb) as defined in Directive 2001/116/EC. The term medium goods vehicle is used within parts of the UK government to refer to goods vehicles of between 3.5 and 7.5 tonnes which according to the EU are also "large goods vehicles".

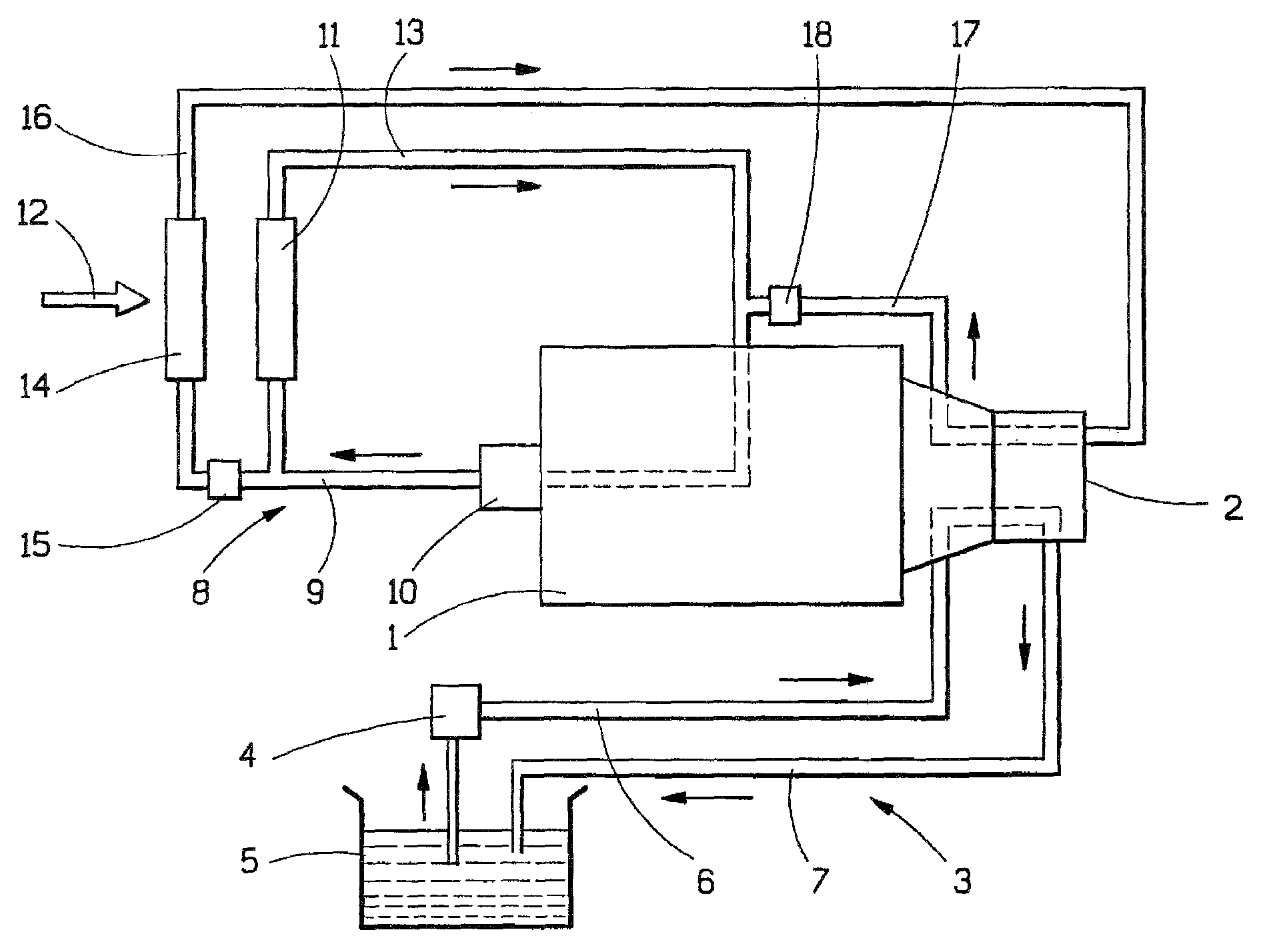

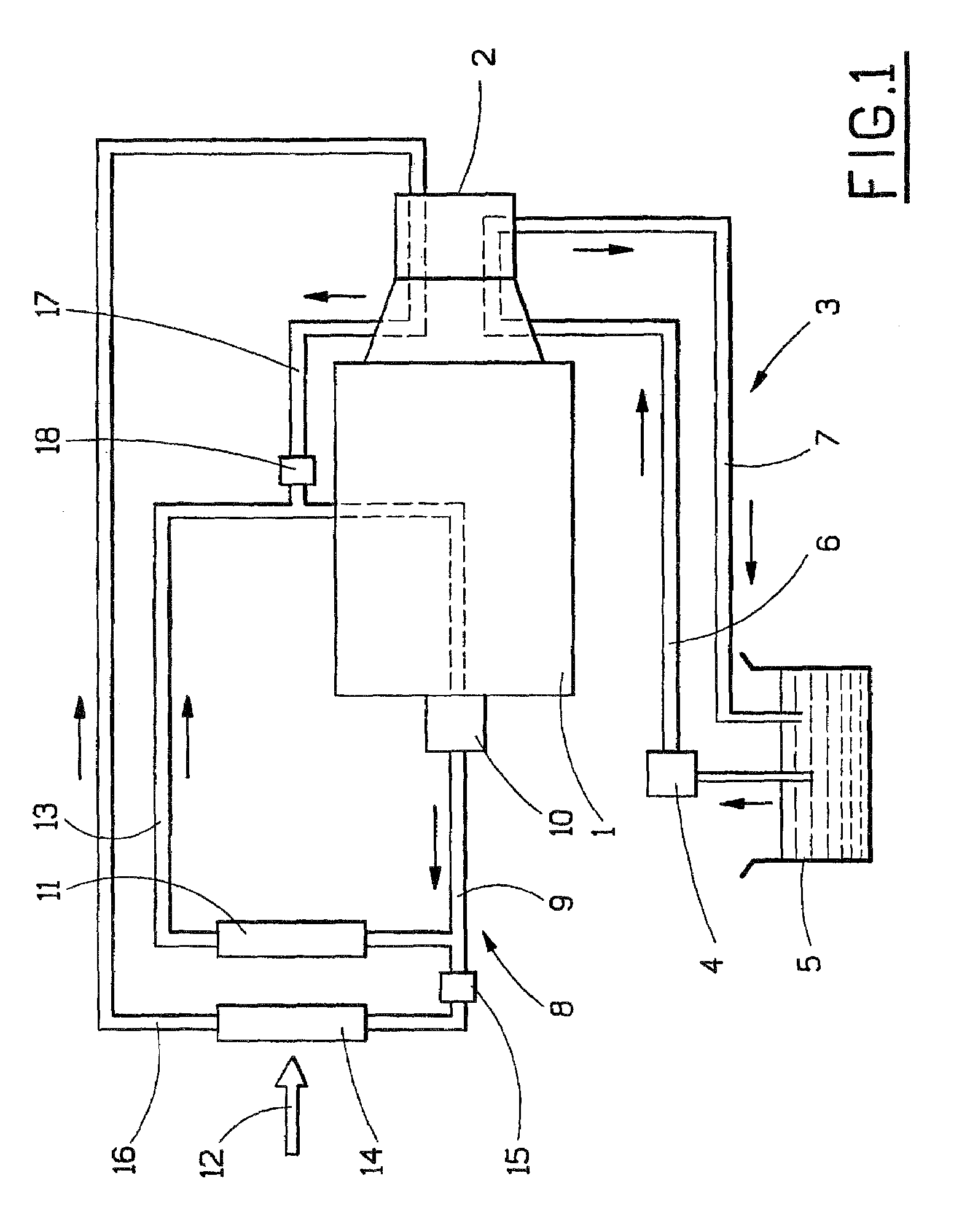

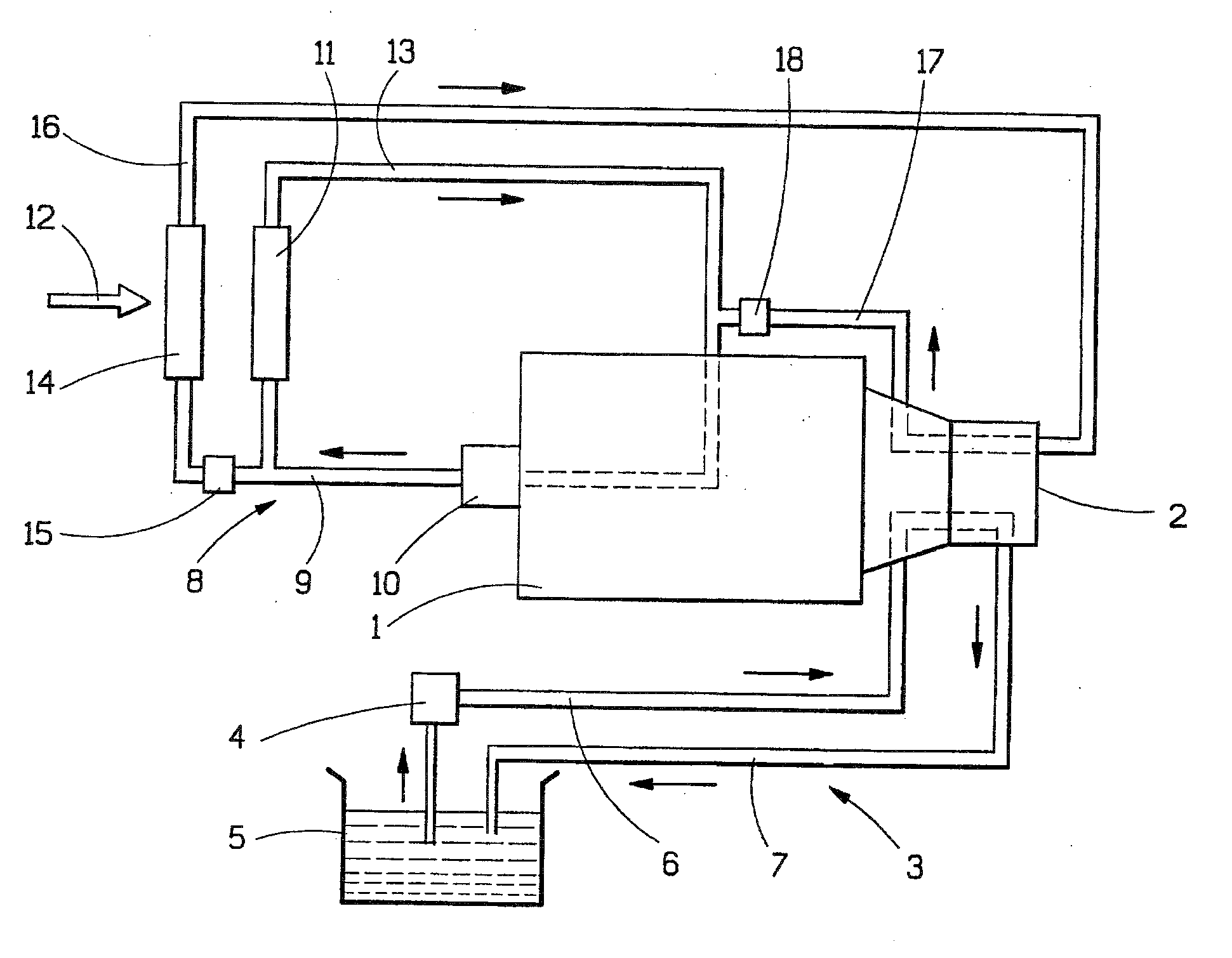

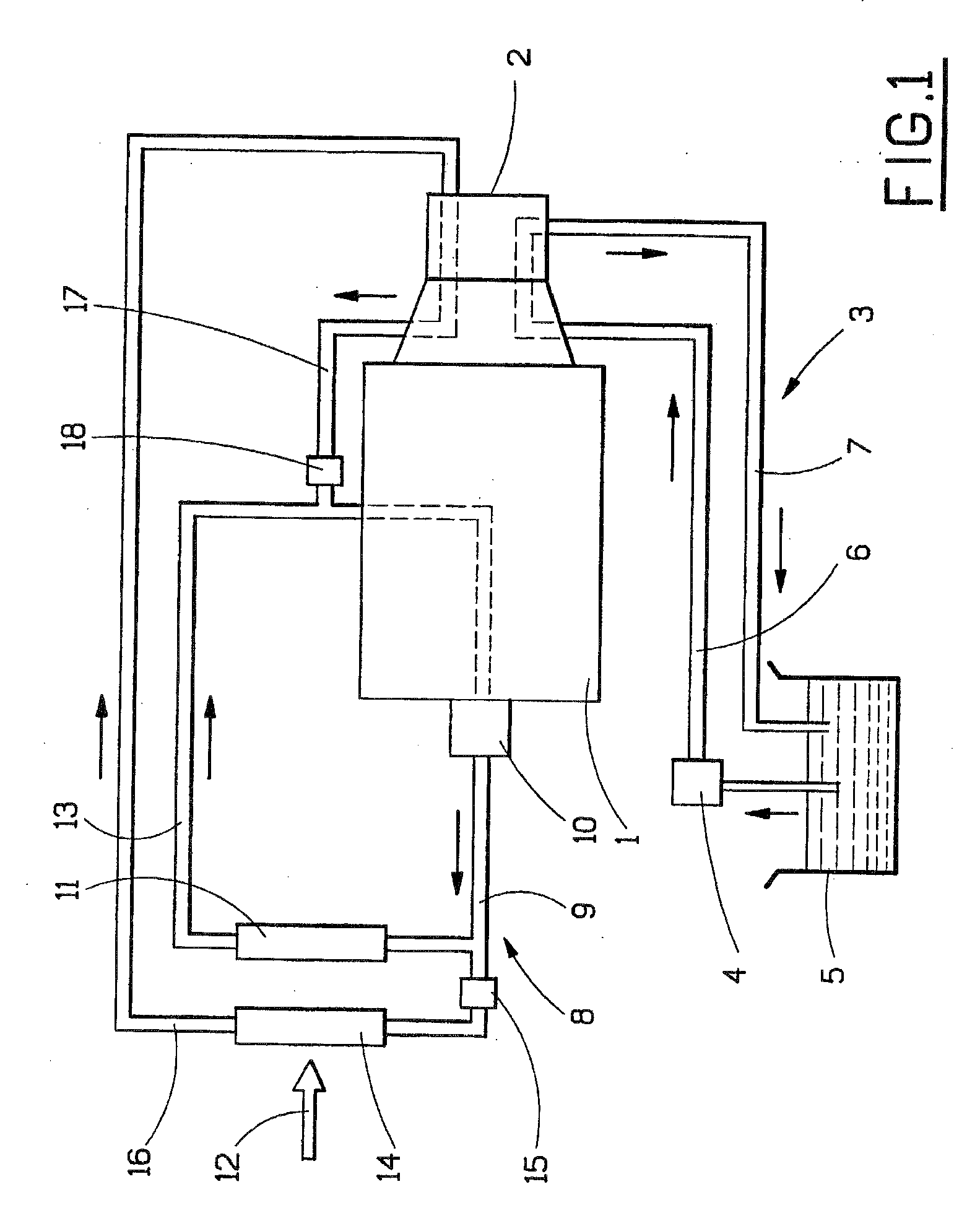

Arrangement for cooling a vehicle component

ActiveUS7210522B2Reduce the temperatureImprove cooling effectExhaust apparatusGear lubrication/coolingEngineeringControl valves

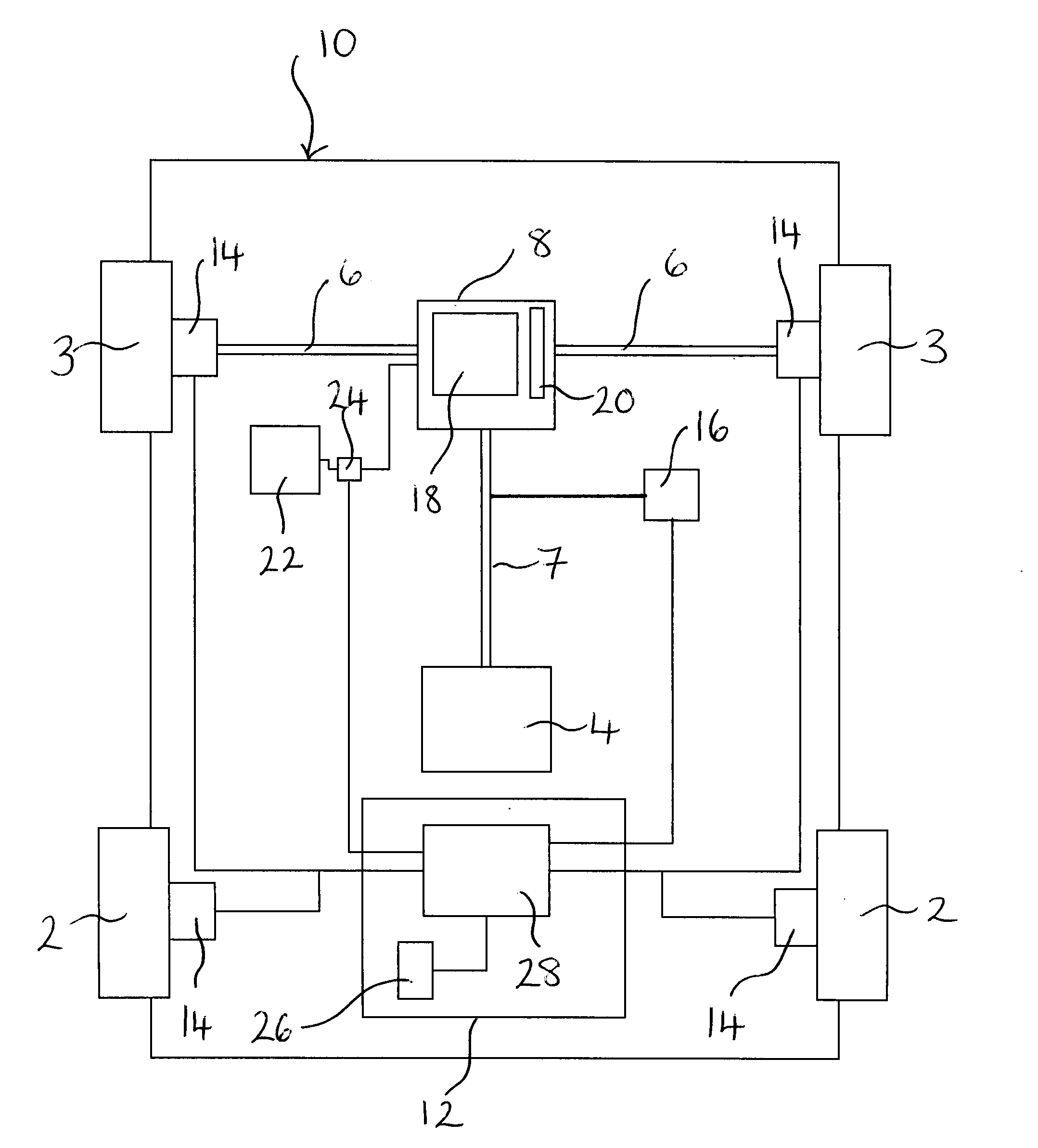

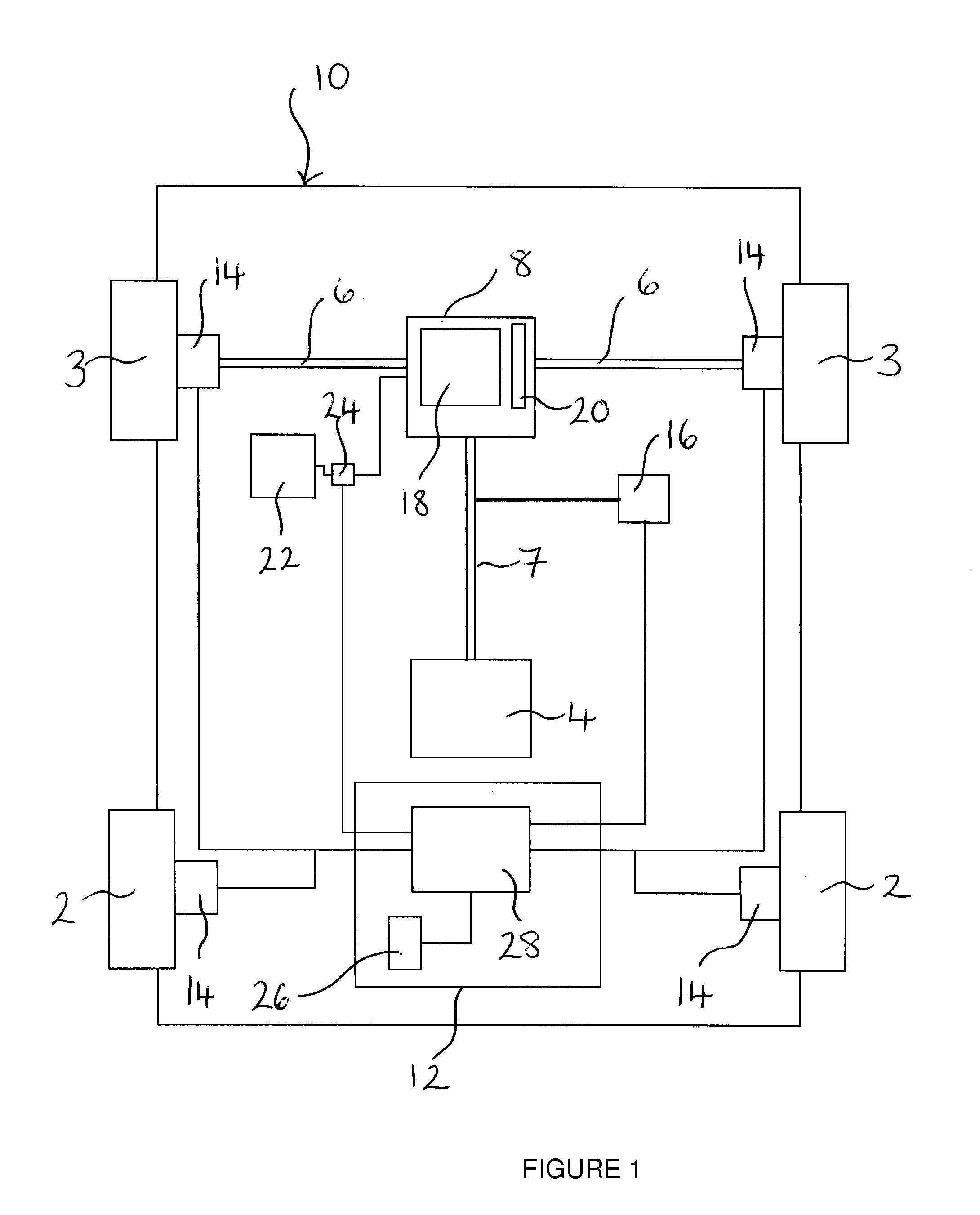

The invention constitutes an arrangement for cooling a vehicle component, for example a transmission, disposed adjacent to an engine, which arrangement includes a cooling circuit designed to feed a coolant through the transmission and including a line for coolant to the transmission and a line for coolant to the transmission. According to the invention, the cooling circuit is also designed to cool the engine and includes a further line for feeding the coolant to the engine, and the cooling circuit includes a flow control valve for controlling the coolant in the cooling circuit such that the flow of coolant to the vehicle component is lower than the flow to the engine. As a result of the invention, an improved arrangement is obtained for cooling, for example, a transmission, for example in heavy goods vehicles.

Owner:VOLVO LASTVAGNAR AB

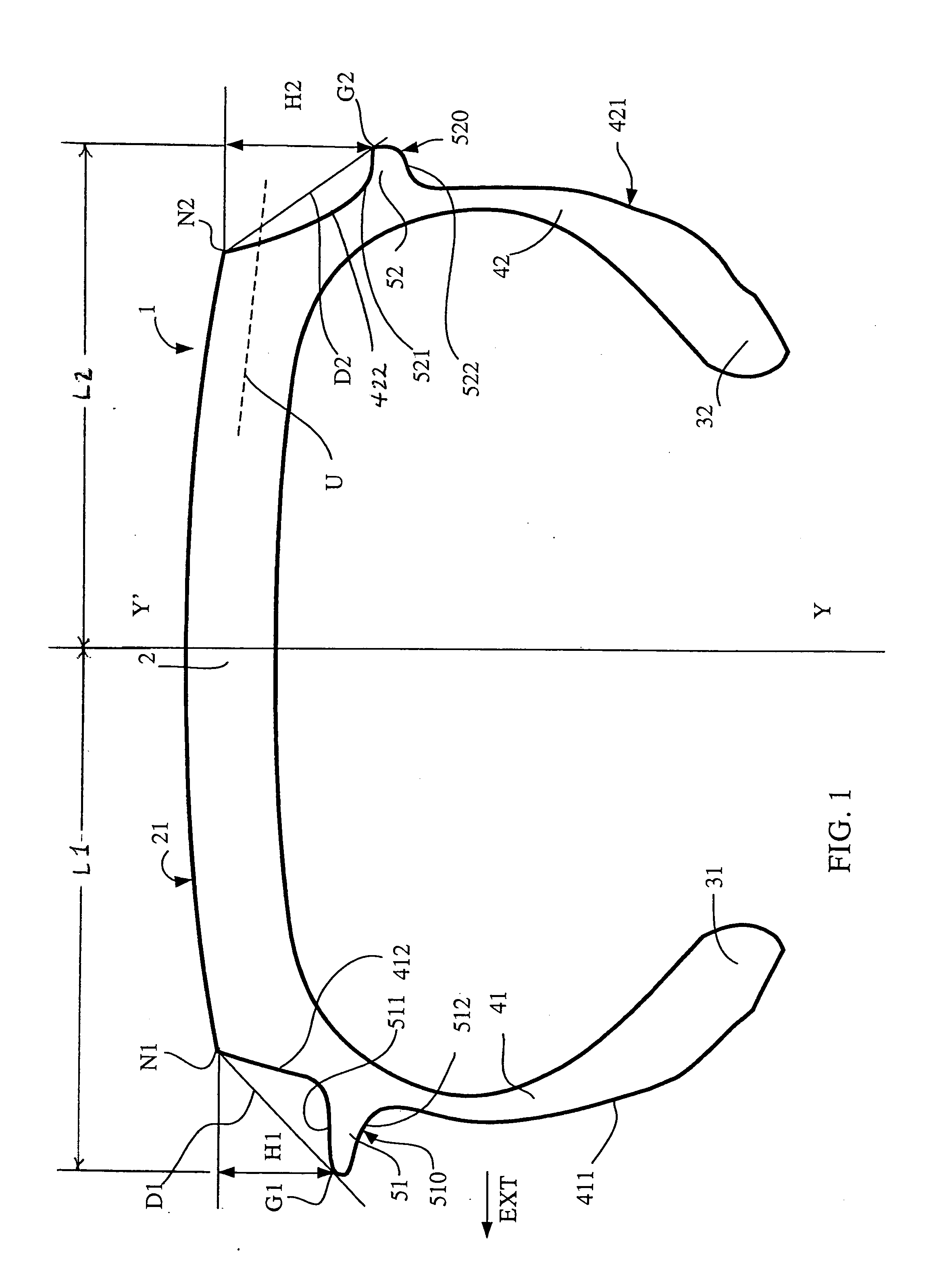

Heavy goods vehicle driven axle tire tread

ActiveUS20150059943A1Improve gripImprove wear resistanceTyre tread bands/patternsNon-skid devicesEngineeringHeavy goods vehicle

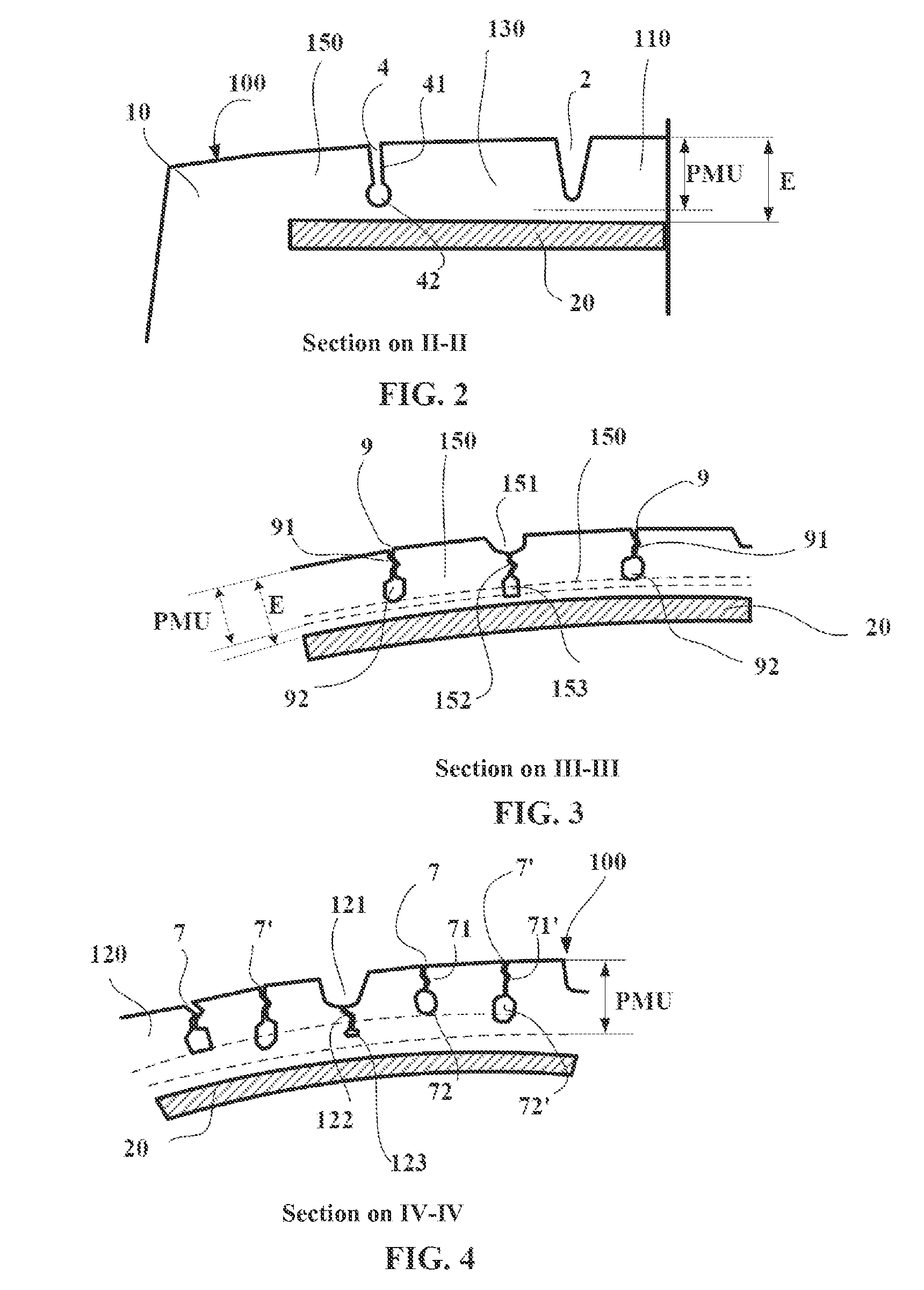

Tread having a maximum thickness PMU of material to be worn away during running, having: at least two grooves of circumferential overall orientation delimiting at least one intermediate row and two edge rows, a plurality of cuts of transverse overall orientation on each intermediate and edge row, representing, in the new state, a void of total volume Vco open onto the tread surface, at most equal to 13% of the total volume of the tread, channels or cavities extending under the tread surface in the new state, adapted to form new grooves after the tread has partially worn away, and having, in the initial state, a total volume Vcc at least equal to 30% of the total void volume Vco in the new state, intermediate rows of suffix (i) and edge rows of suffix (e) each provided with a plurality of cuts of transverse or oblique orientation distributed over each row evenly or near-evenly with a mean pitch of Pi and Pe respectively, having mean depths, Di and De respectively, which are at least equal to 20% of the thickness PMU and at most equal to thickness PMU, wherein: on the edge rows, Pe is such that 1.30<Pe / De<3.00, and on the intermediate rows, Pi satisfies 1.00<Pi / Di<1.70, and Pe is greater than Pi.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Heavy goods vehicle tyre

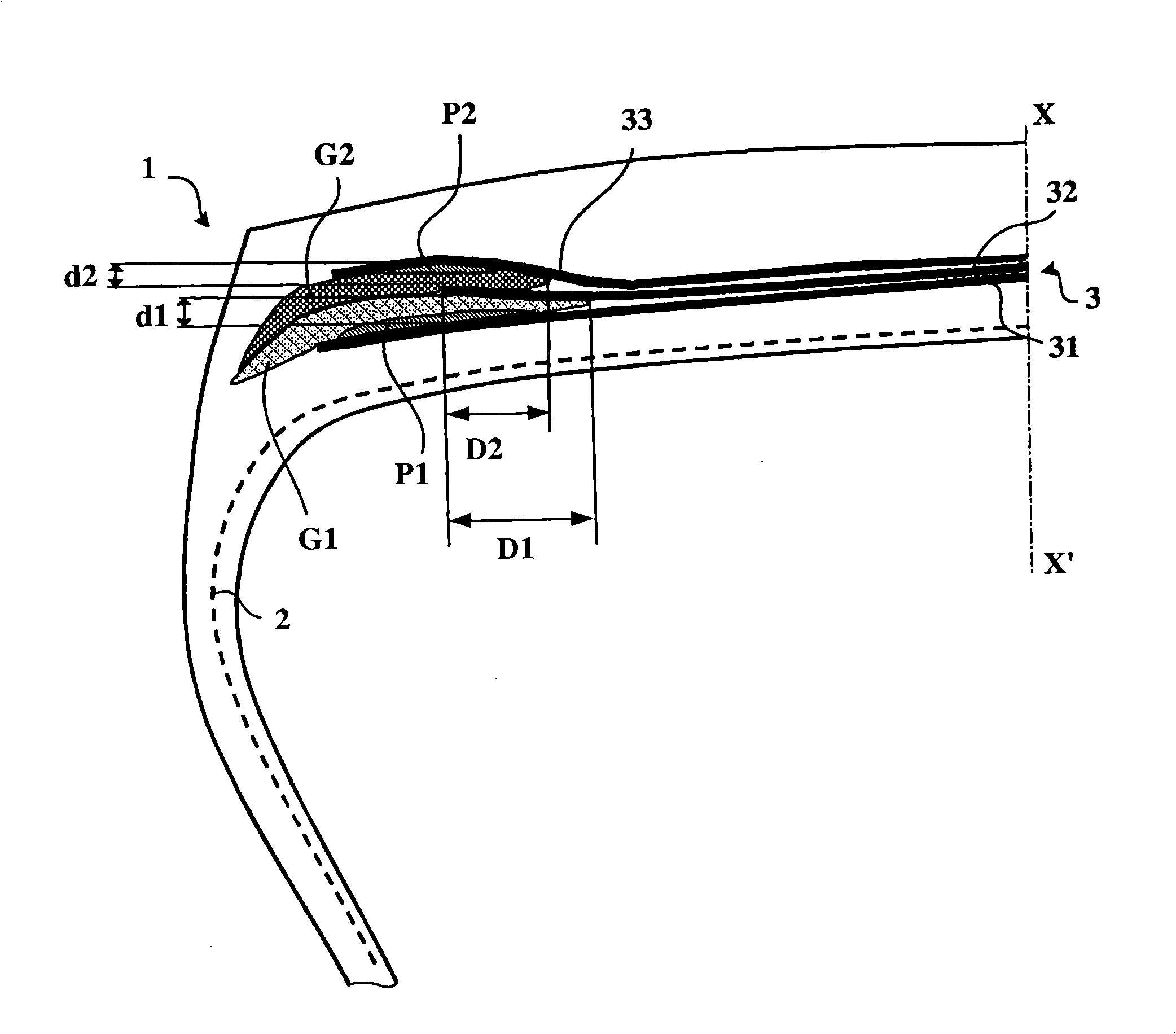

The invention relates to a tyre in which the crown reinforcement comprises at least three plies of reinforcing elements. According to the invention, there are: at least a first profile P1 the axially outer end of which lies a shorter distance from the equatorial plane of the tyre than the distance separating said plane from the end of a second ply, said profile P1 being radially separated from the radially outer calendering C1 of a first ply by a second profile made of rubber compound G1, at least one third profile P2 the axially outer end of which lies a shorter distance from the equatorial plane of the tyre than the distance separating said plane from the end of a third ply, said profile P2 being radially separated from the radially inner calendering C2 of said first ply by a fourth profile of rubber compound G2, said profiles of rubber compound P1, P2 and G1, G2 and said calendering C1, C2 having respective secant tensile elastic moduluses at 10% of elongation of MP1, MP2, MG1, MG2, MC1, MC2 such that MC1 = MG1 > MP1 and MC2 = MG2 > MP2.

Owner:OCIETE DE TECH MICHELIN

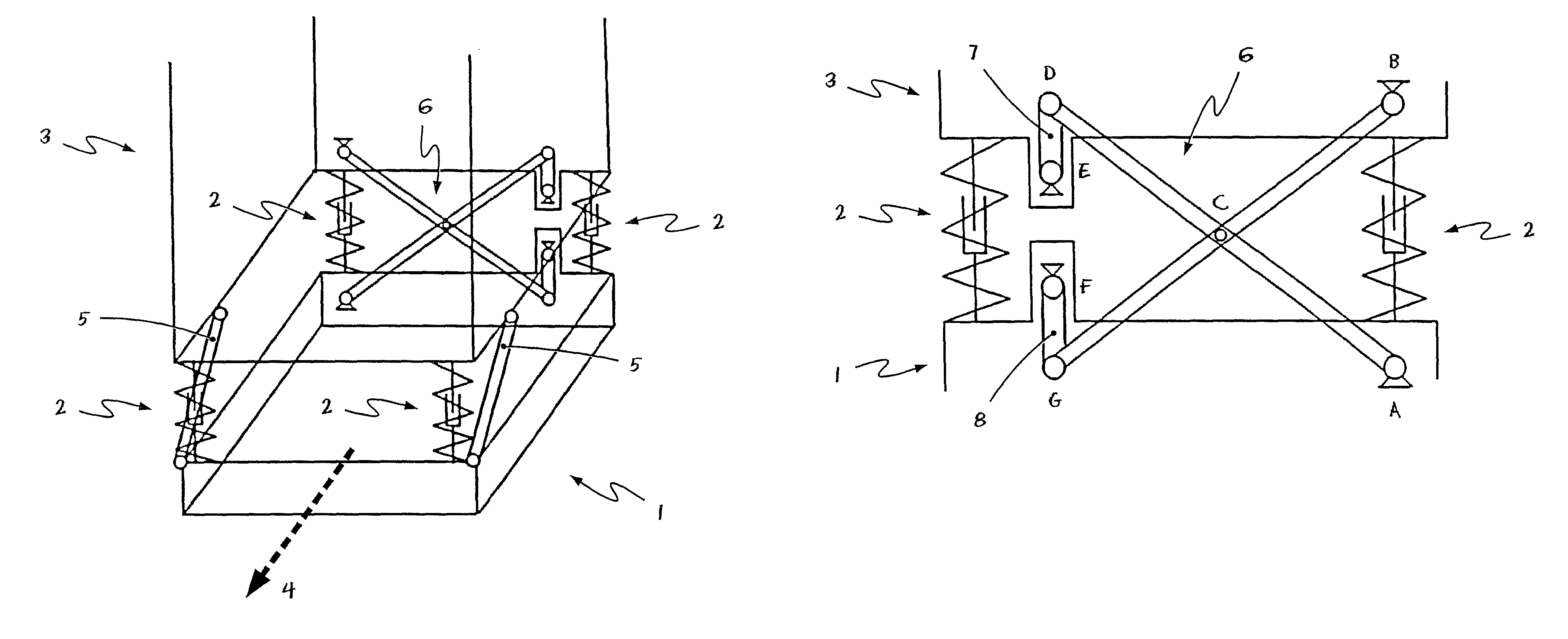

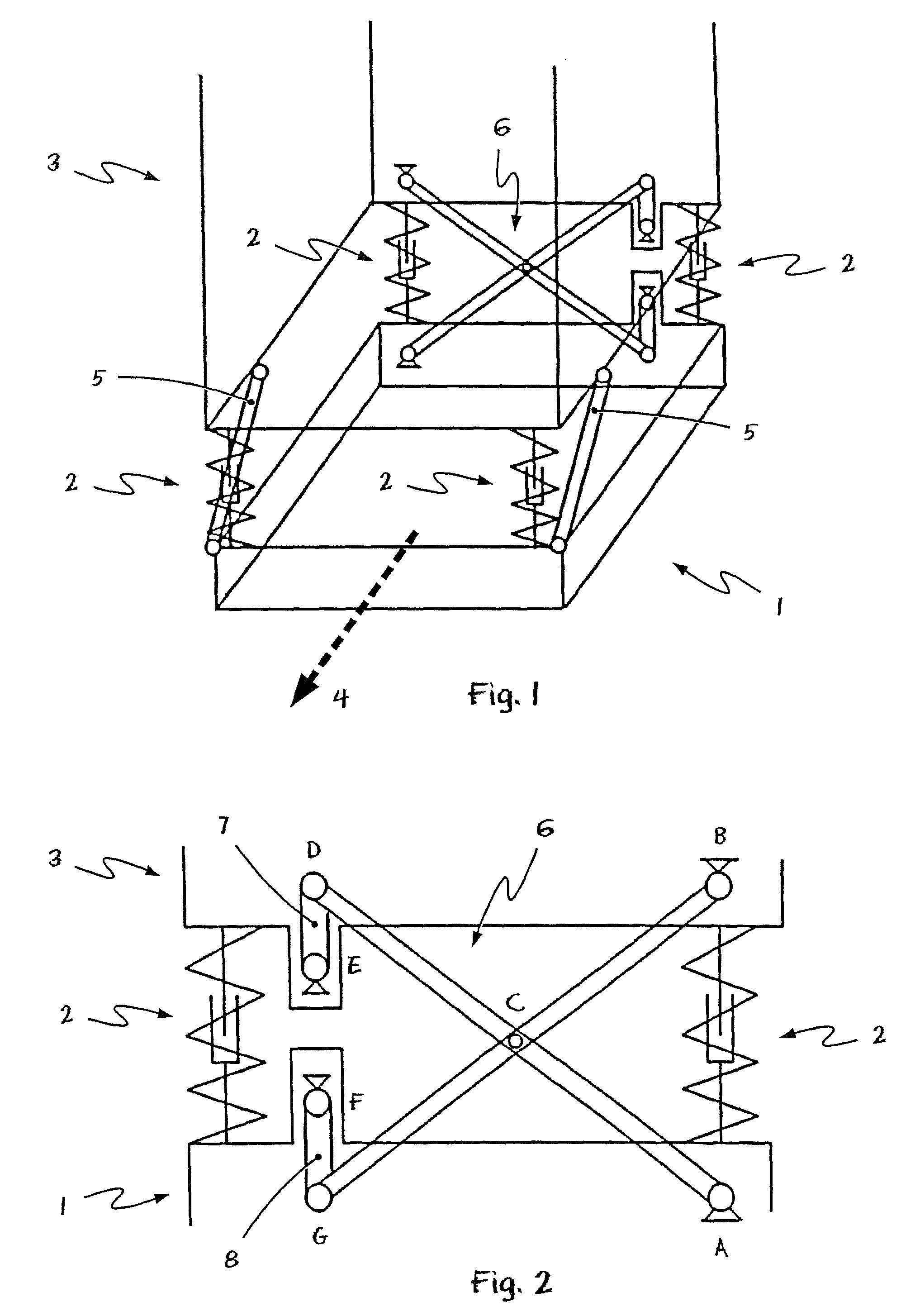

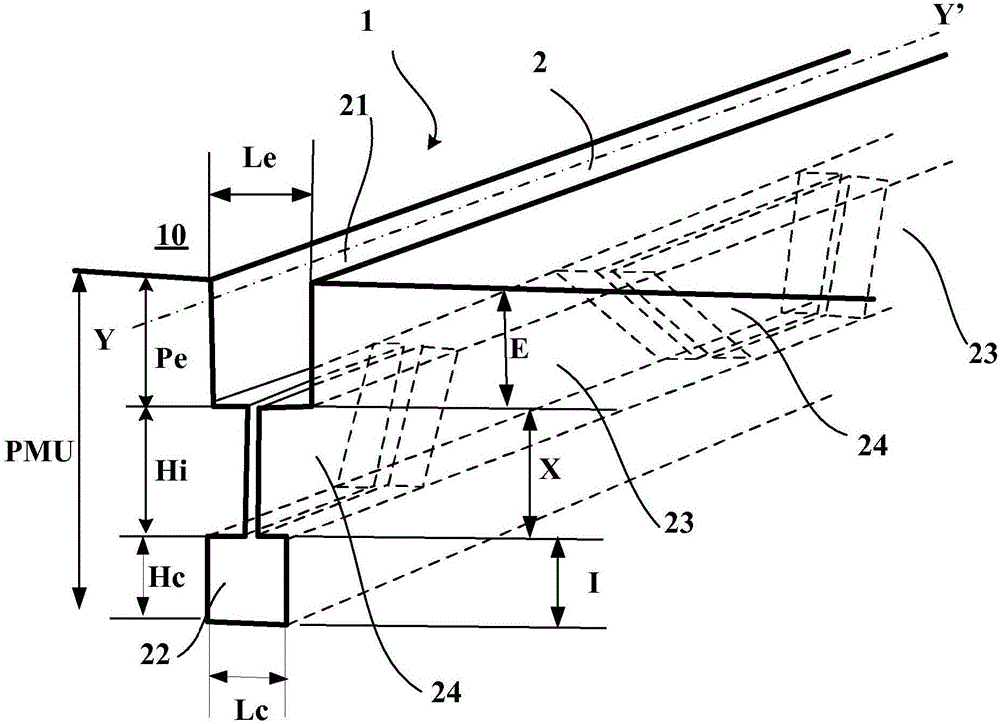

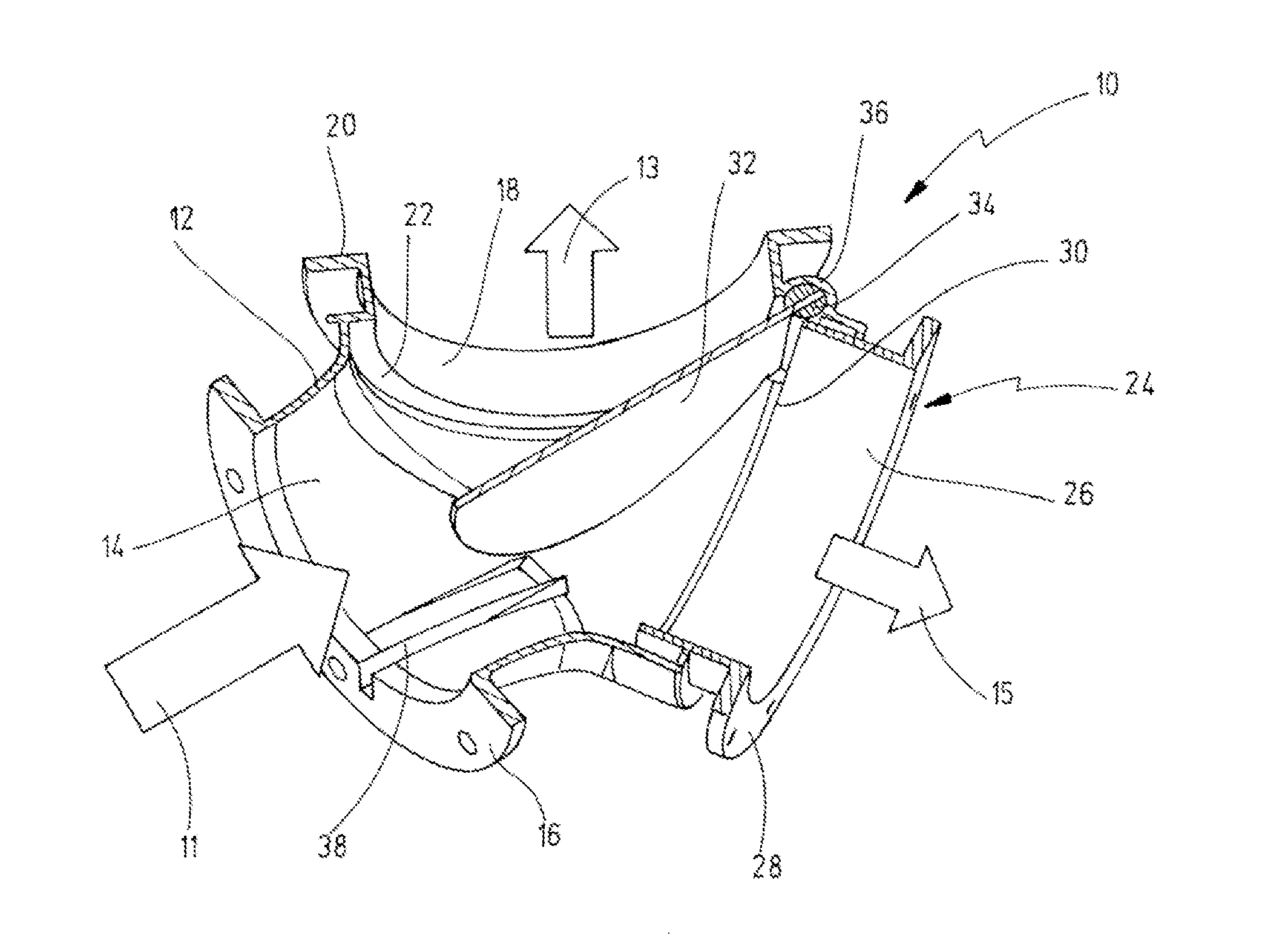

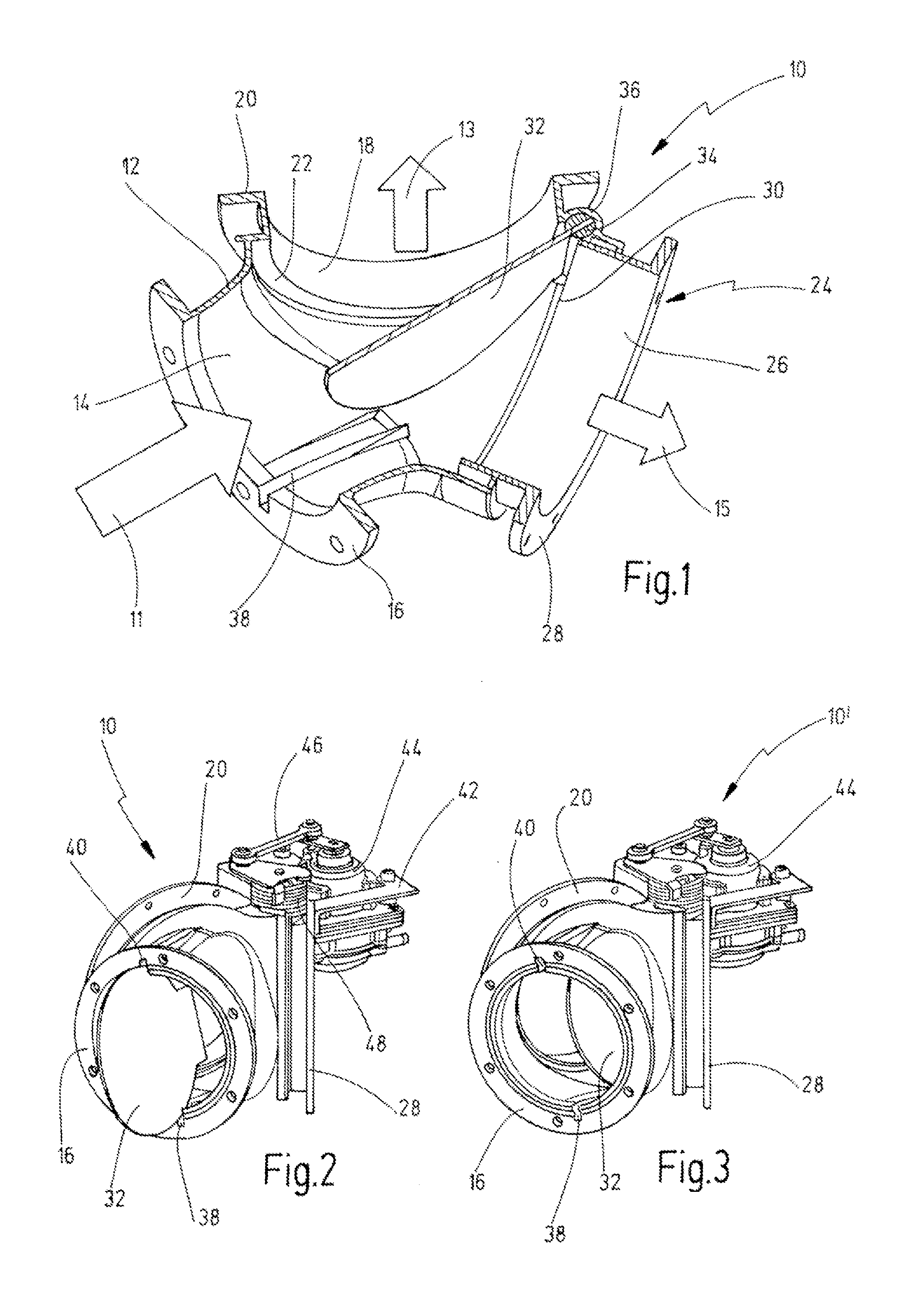

Suspension means with scissor pantograph

InactiveUS7950727B2Reliable settingsEffectively absorb and suppressVehicle seatsStands/trestlesEngineeringSpatial direction

A suspension arrangement for spring suspending a mass body (3) in relation to a substructure (1), for example, a driver's cabin (3) of a heavy goods vehicle in relation to the vehicle chassis (1) thereof. The suspension arrangement comprises a spring / damper arrangement (2) which is arranged between the mass body (3) and the substructure (1) and which is used to dampen thrusts and / or oscillations. The suspension arrangement in characterized in that it comprises at least one pantograph (6) which is used to reduce the freedom of movement of the mass body (3). The inventive suspension arrangement is constructively robust and can determine the provided freedom of movement of the mass body in a reliable manner and can dampen and / or prevent undesired movements in other spatial directions. The invention enables an economical and a reliable spring suspension, in particular, for a driver's cabin of heavy good vehicles, to be produced.

Owner:ZF FRIEDRICHSHAFEN AG

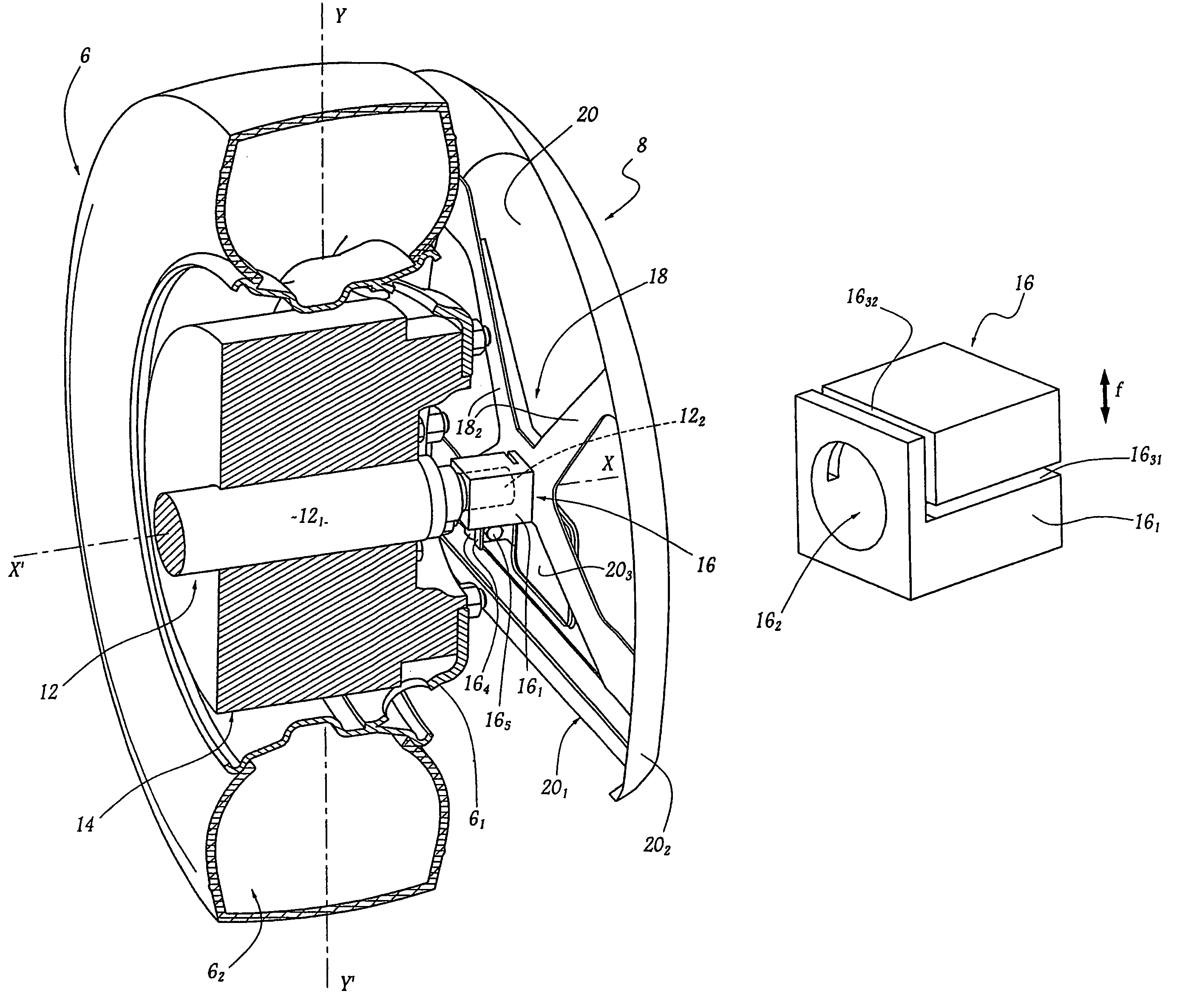

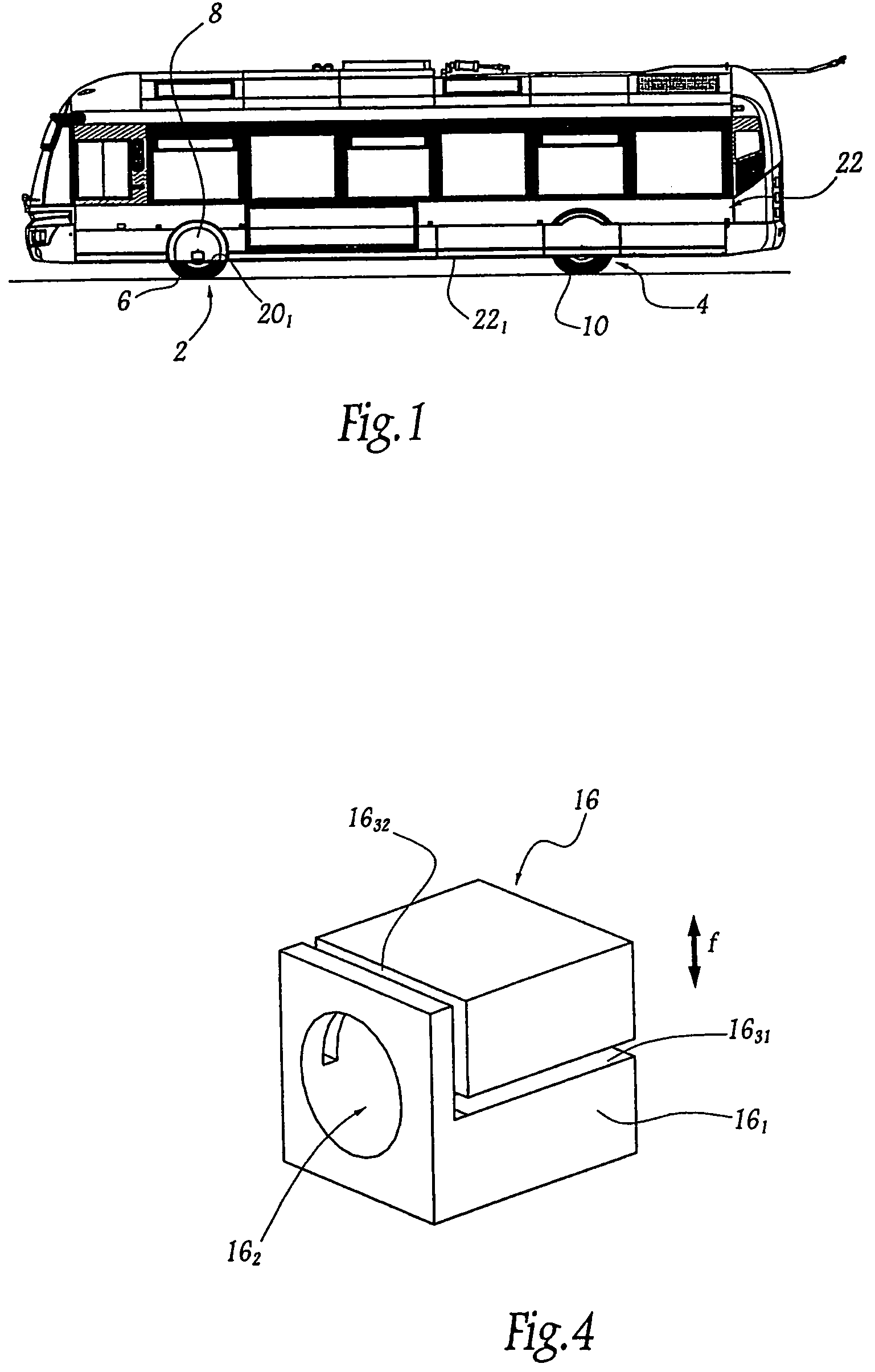

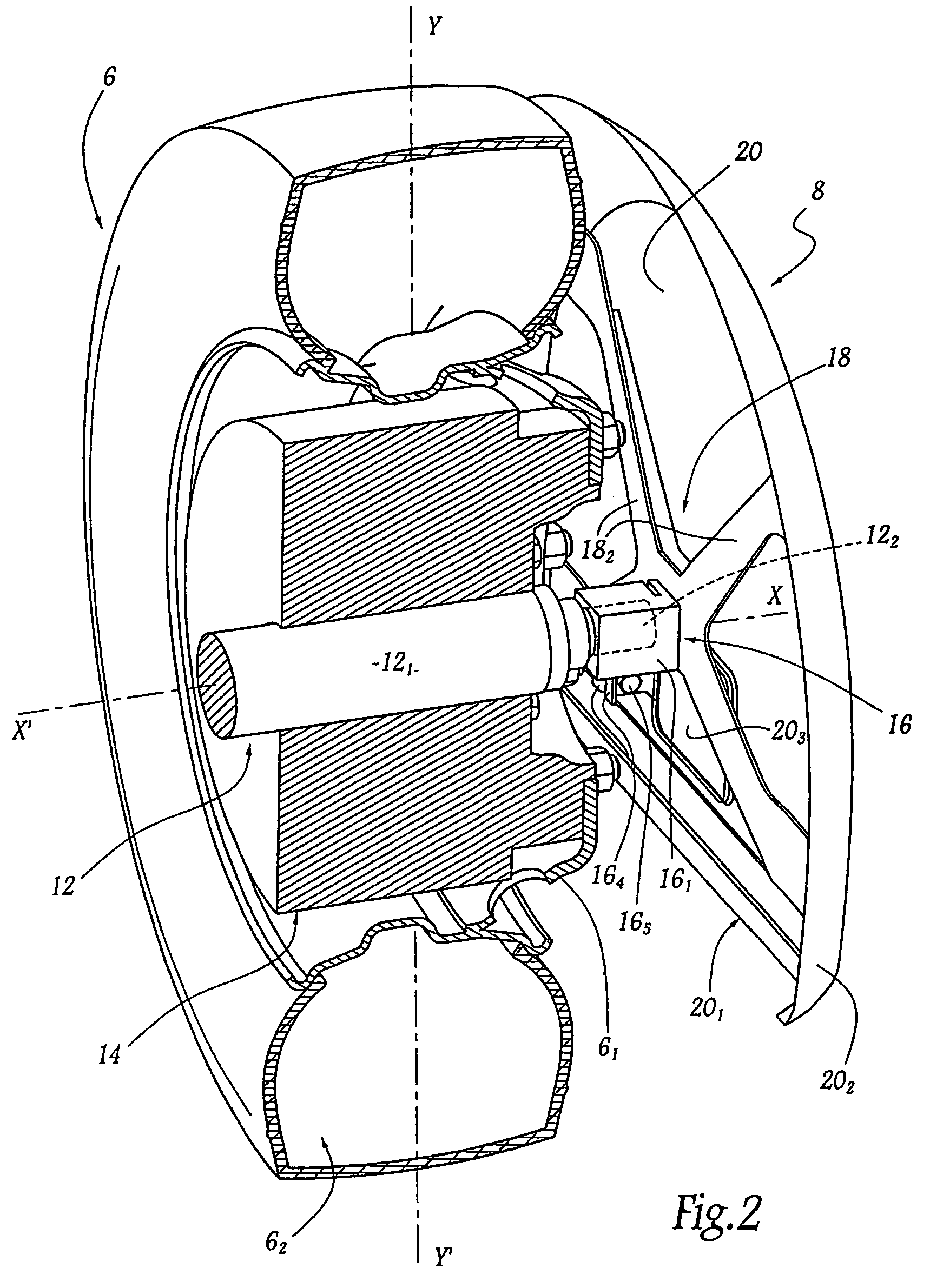

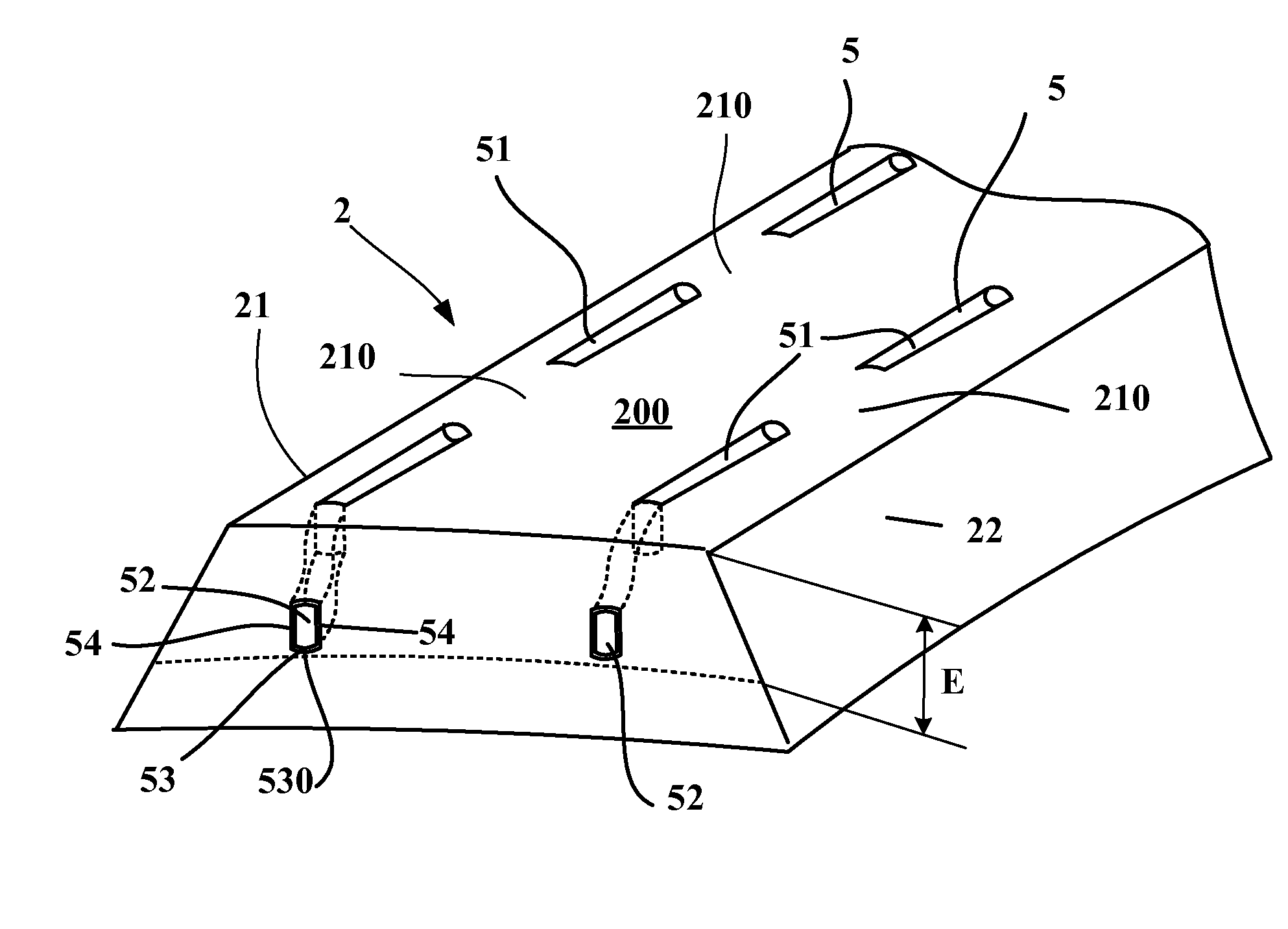

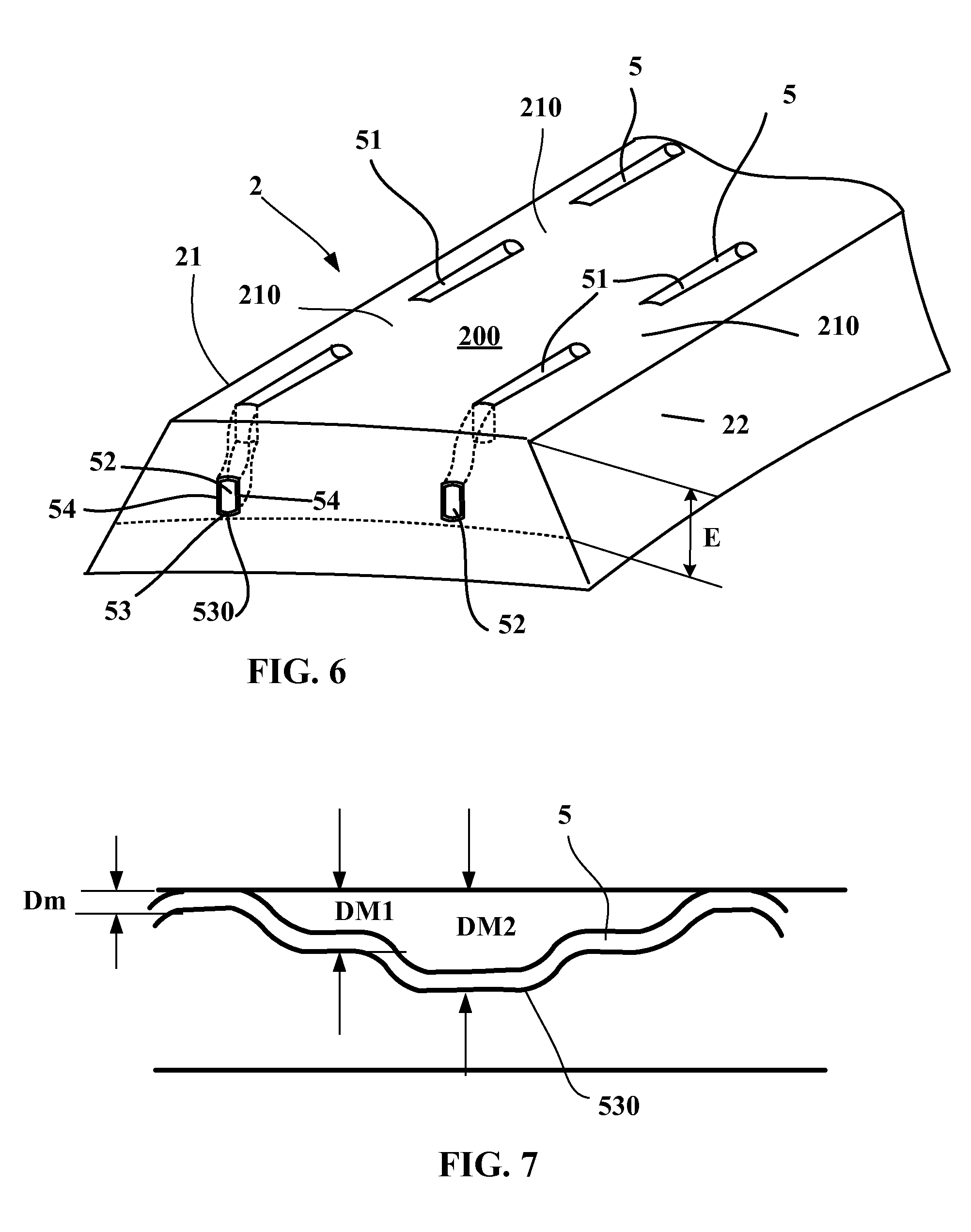

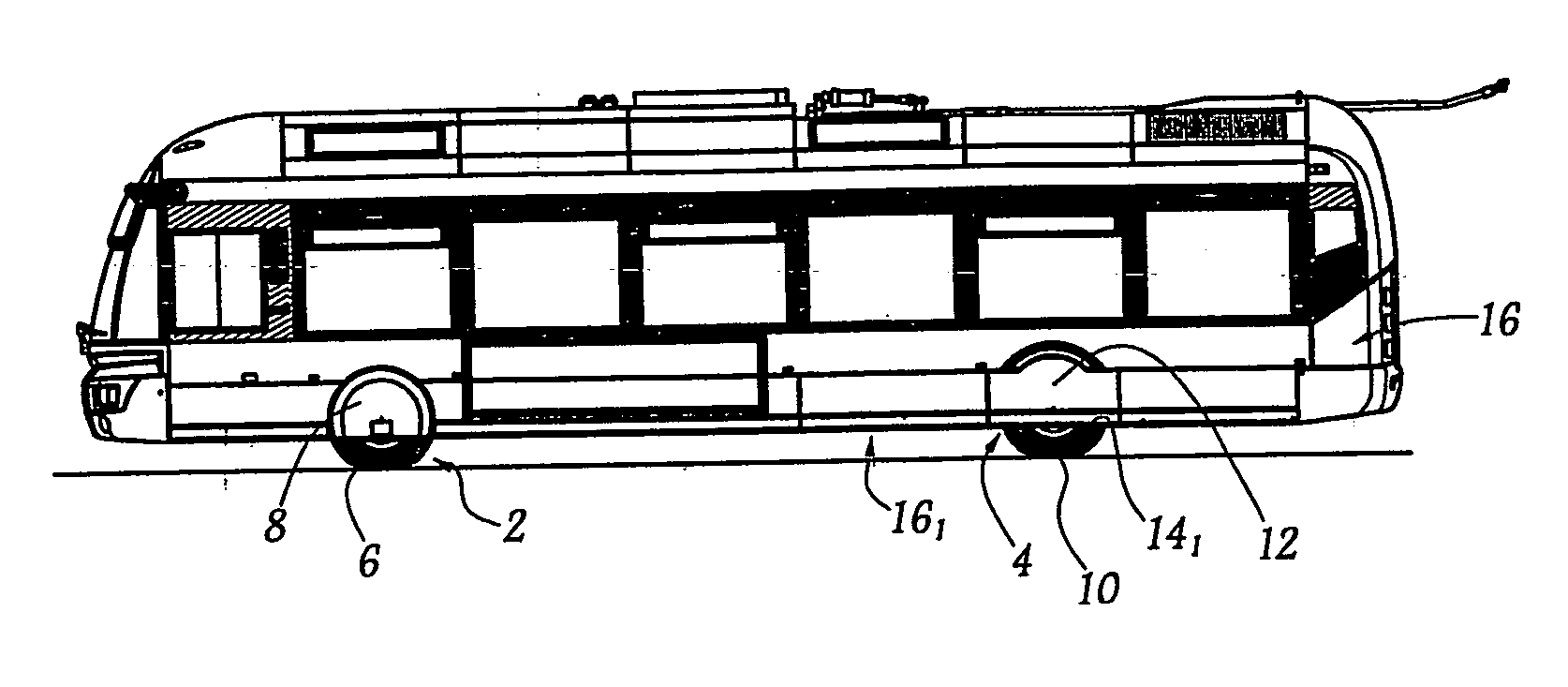

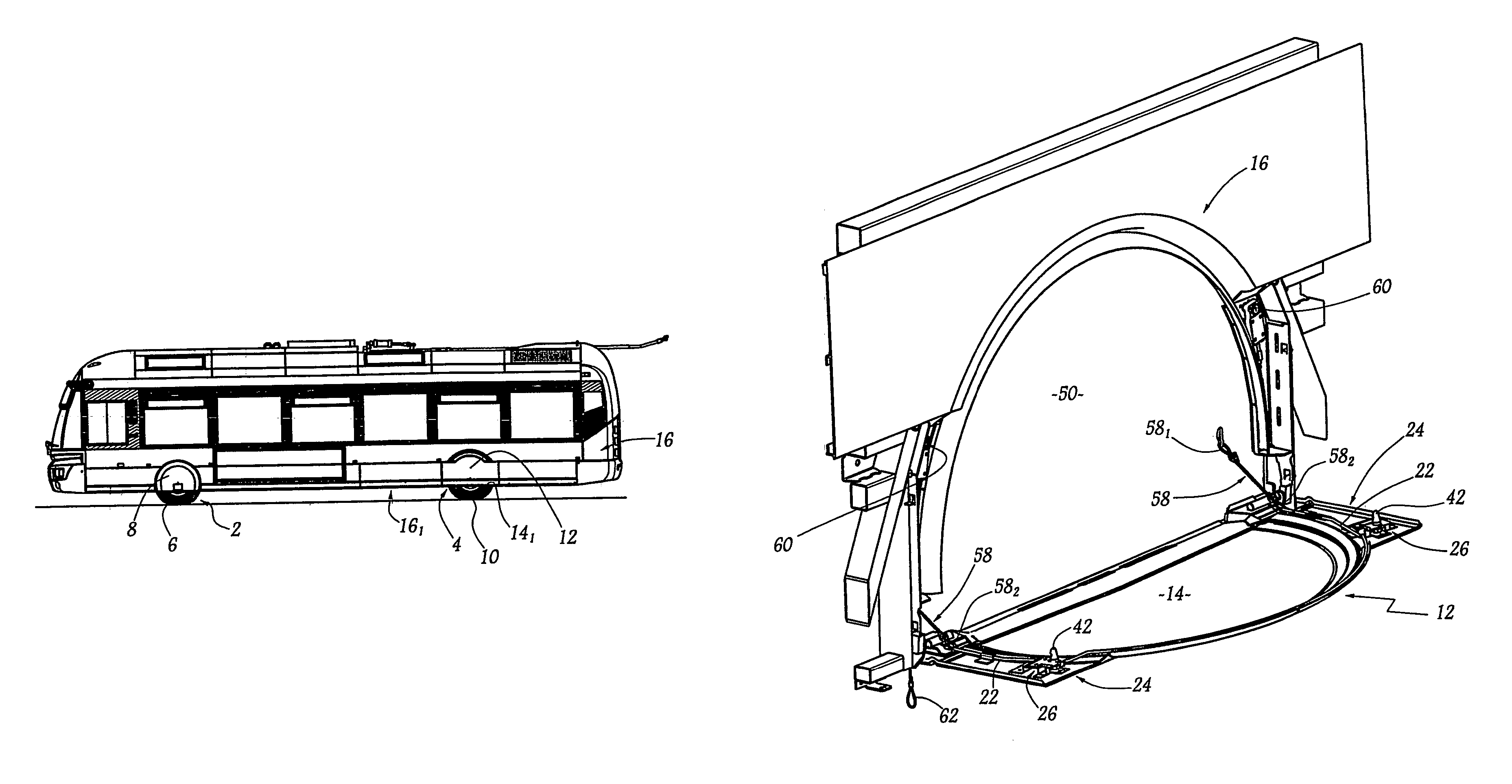

Assembly comprising at least one drive wheel and a fairing for a heavy goods vehicle, and the corresponding heavy goods vehicle

InactiveUS7651108B2Compact dimensionsProcess safetySuperstructure subunitsWheel protectionDrive wheelHeavy goods vehicle

Owner:IRISBUS FRANCE

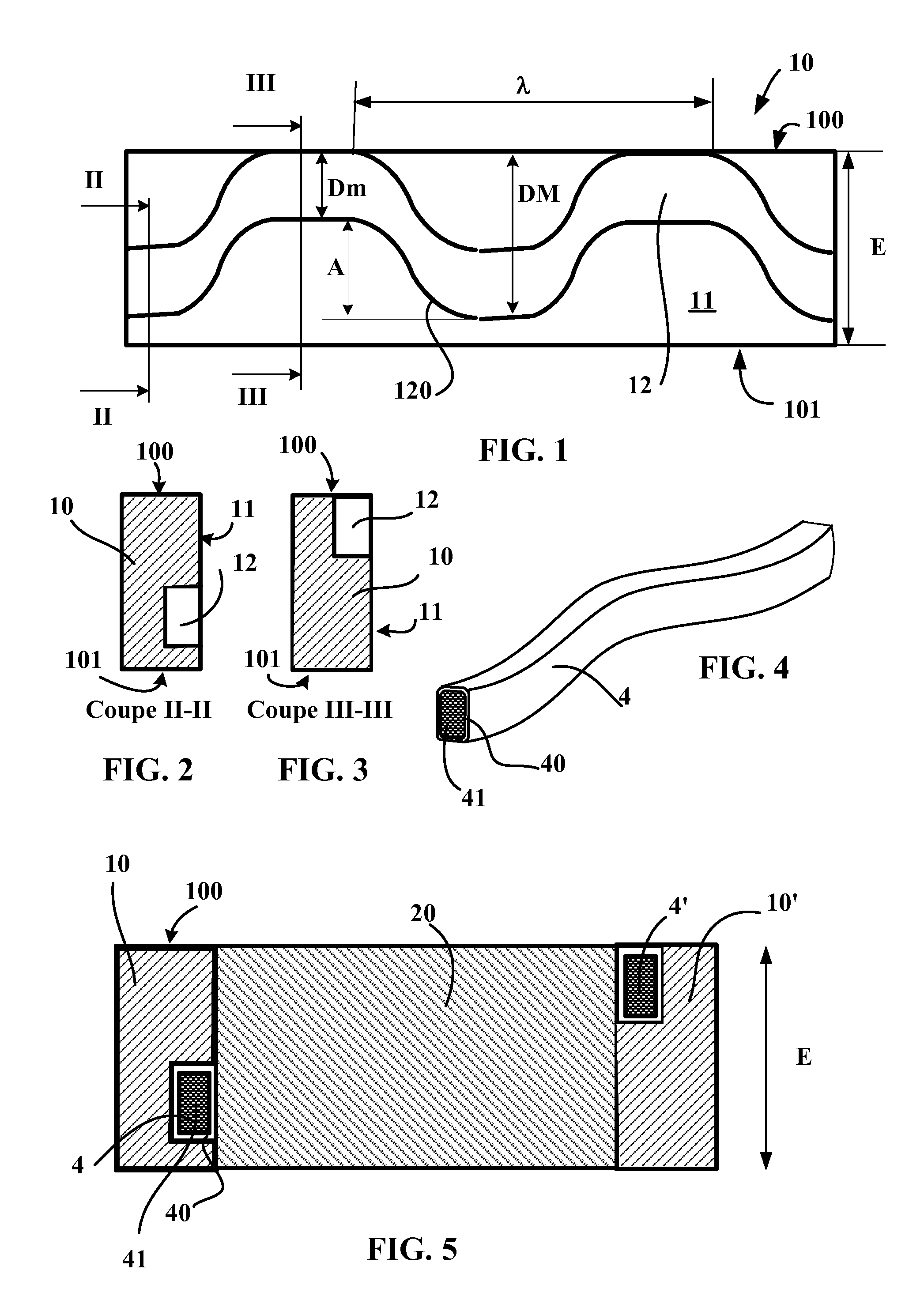

Tread including at least one wavy groove, and method for producing same

Tire for a heavy goods vehicle comprising a tread of total thickness E and total volume V, having a tread surface intended to come into contact with a roadway, at least one cavity or groove that is continuous in a main direction, and delimited by side walls connected by a bottom, a cross section, the points furthest towards the inside of the bottom of each cavity defining a bottom line, wherein each cavity or groove comprises a plurality of open sections open onto the tread surface in the new state and a plurality of closed sections, connected to the open sections being arranged in alternation, each closed section being spaced away from the tread surface by a bridge of rubber, wherein the points on the bottom line of said cavity or groove lie at distances between a minimum distance Dm and a maximum distance DM with respect to the tread surface, the bottom lineof each cavity or groove following a wavy geometry of positive amplitude equal to the difference (DM−Dm).

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Heavy goods vehicle tire comprising a tread based on a modified polyisoprene, process for preparing same

ActiveUS20150322183A1Improve propertiesReduce rolling resistanceTyresSpecial tyresRolling resistanceSilenes

A heavy-duty vehicle tire comprising a tread consisting of a crosslinked rubber composition comprising a reinforcing filler of siliceous type and a synthetic polyisoprene modified by grafting with a compound comprising at least one group Q, and at least one group A, which are joined to one another by at least one and preferably one “spacer” group Sp, in which:Q comprises a dipole containing at least one and preferably one nitrogen atom,A comprises an associative group comprising at least one nitrogen atom,Sp is an atom or group of atoms forming a bond between Q and A.The heavy-duty vehicle tire according to the invention has a satisfactorily improved rolling resistance / wear resistance compromise.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

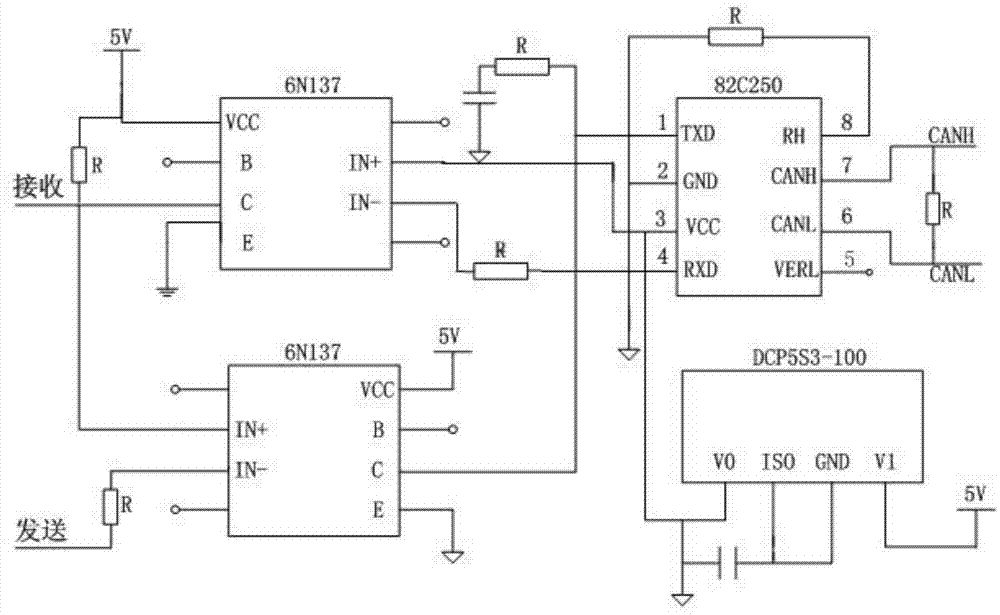

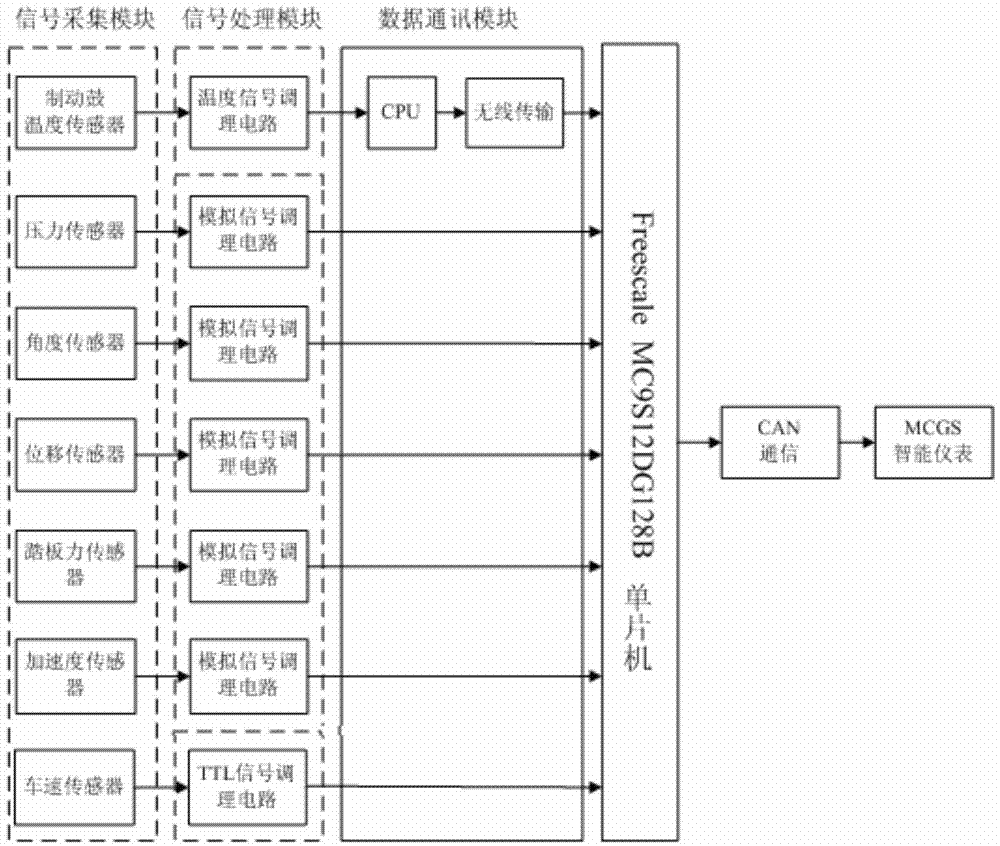

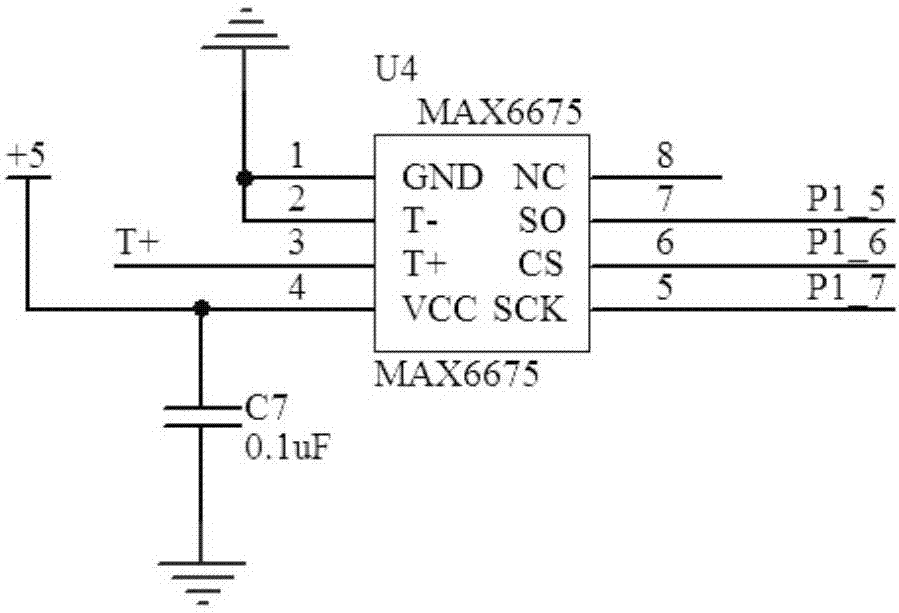

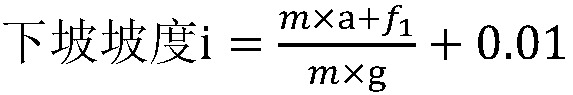

Heavy goods vehicle ramp running safety monitoring system

InactiveCN104210445AImprove stabilityImprove accuracyElectric/fluid circuitMicrocontrollerArea network

The invention discloses a heavy goods vehicle ramp running safety monitoring system which comprises a signal acquisition module, a signal processing module, a data communication module, a singlechip microcomputer and a man-machine interaction intelligent instrument, wherein the signal acquisition module is used for converting an acquired signal into a standard voltage signal or TTL (Time To Live) pulse signal which can be recognized by the singlechip microcomputer and is connected with the singlechip microcomputer by virtue of the signal processing module and the data communication module; the singlechip microcomputer is used for transferring the signal processed by the singlechip microcomputer to the man-machine interaction intelligent instrument by virtue of a CAN (Controller Area Network) communication module; the man-machine interaction intelligent instrument is used for displaying the monitoring data and an alarm signal to a driver. The heavy goods vehicle ramp running safety monitoring system can be used for effectively monitoring the safety parameters and alarming in real time in a running process, realizing intelligentization and visualization of a heavy goods vehicle running process, meeting the requirements on the running safety and stability and effectively improving the heavy goods vehicle ramp running safety.

Owner:CHANGAN UNIV

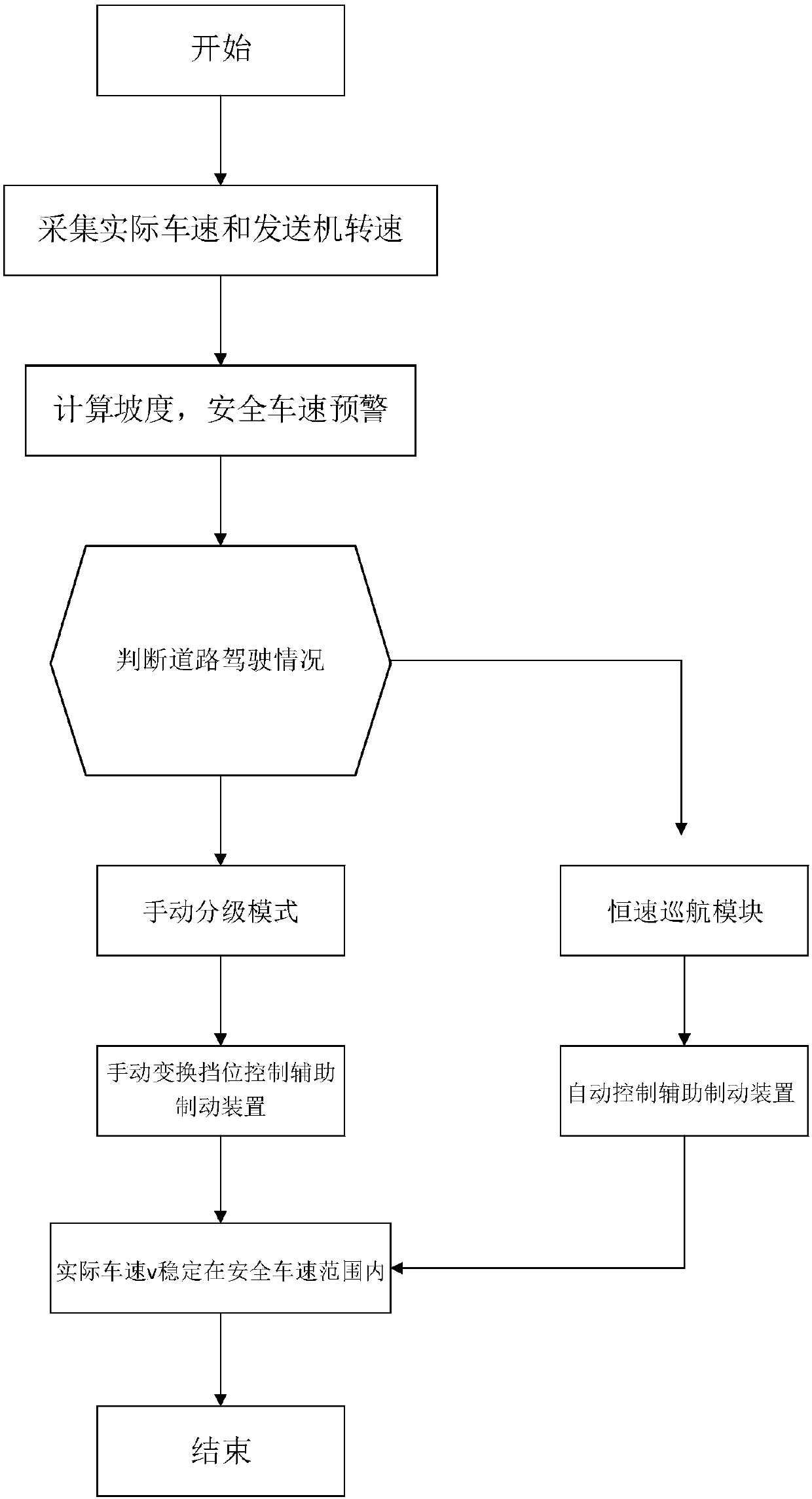

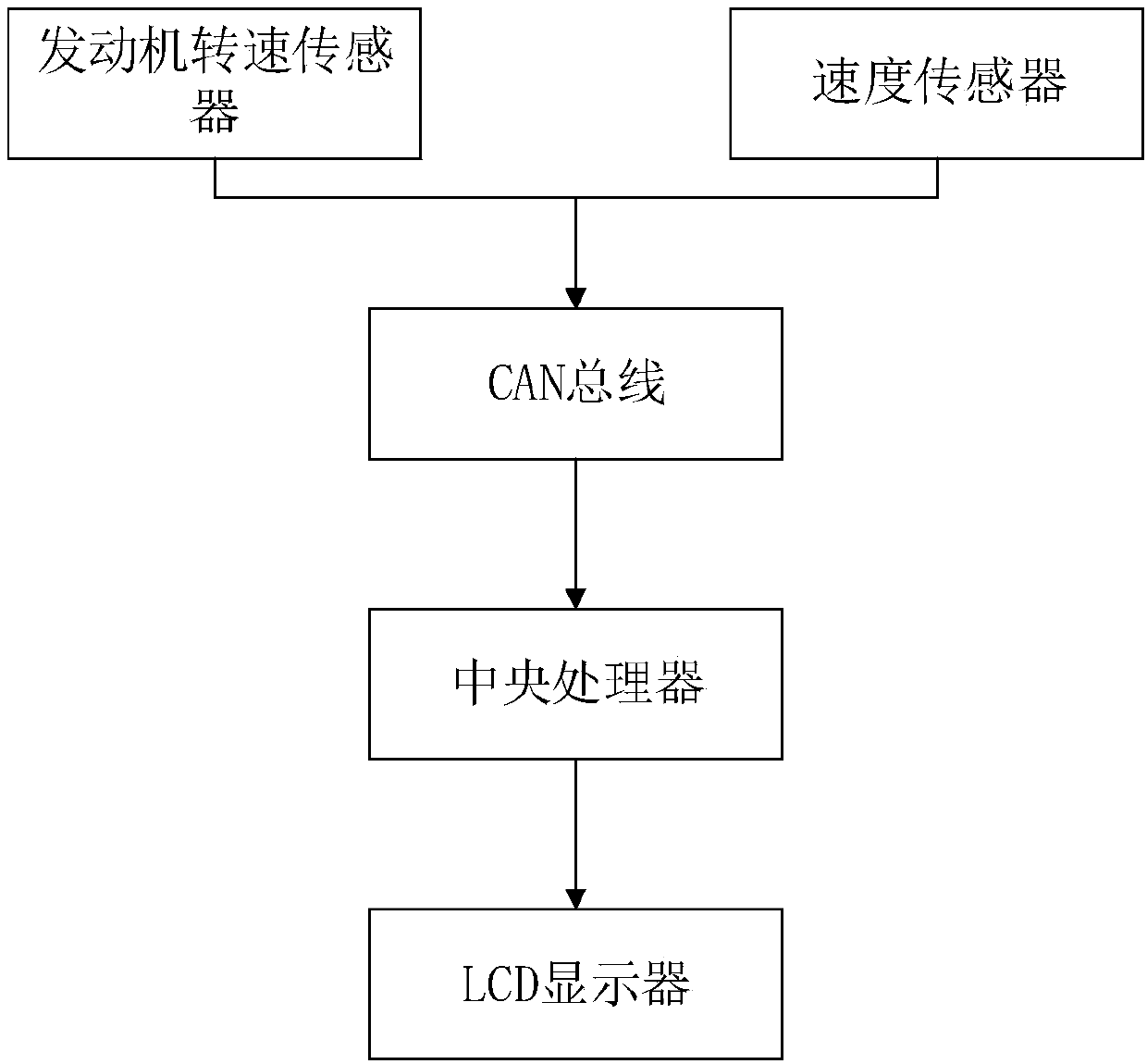

Safety control method for driving heavy truck on long downhill

PendingCN107738579AImprove the problem of overheating failureStrong continuous braking functionVehicle fittingsAutomatic initiationsContinuous useTraffic crash

The invention discloses a safety control method for driving a heavy truck on a long downhill. The method includes then steps of measuring the truck speed and the rotate speed of an engine by using a sensor to collect truck traveling information, and then by using a central processing unit to calculate and obtain gradients, giving a safety truck speed warning prompt according to different gradientconditions and safety speed technology requirements; when the actual speed of the truck exceeds a safety truck speed warning, reminding to enable auxiliary braking equipment. According to the method,an engine brake and a hydrodynamic retarder are used synthetically, a strong continuous braking function within a wide range of the truck speed is achieved, and the needs of the long big downhill segments of different roads can be met, so that the status that continuous use of a wheel brake of the heavy truck during long downhill driving leads to overheating and failure of the brake is greatly improved, and the probability of traffic accident involvement is decreased; moreover, through the common control of manual selection and the central processing unit, the possibility of misoperation is reduced, and the safety of driving is improved.

Owner:CHANGAN UNIV

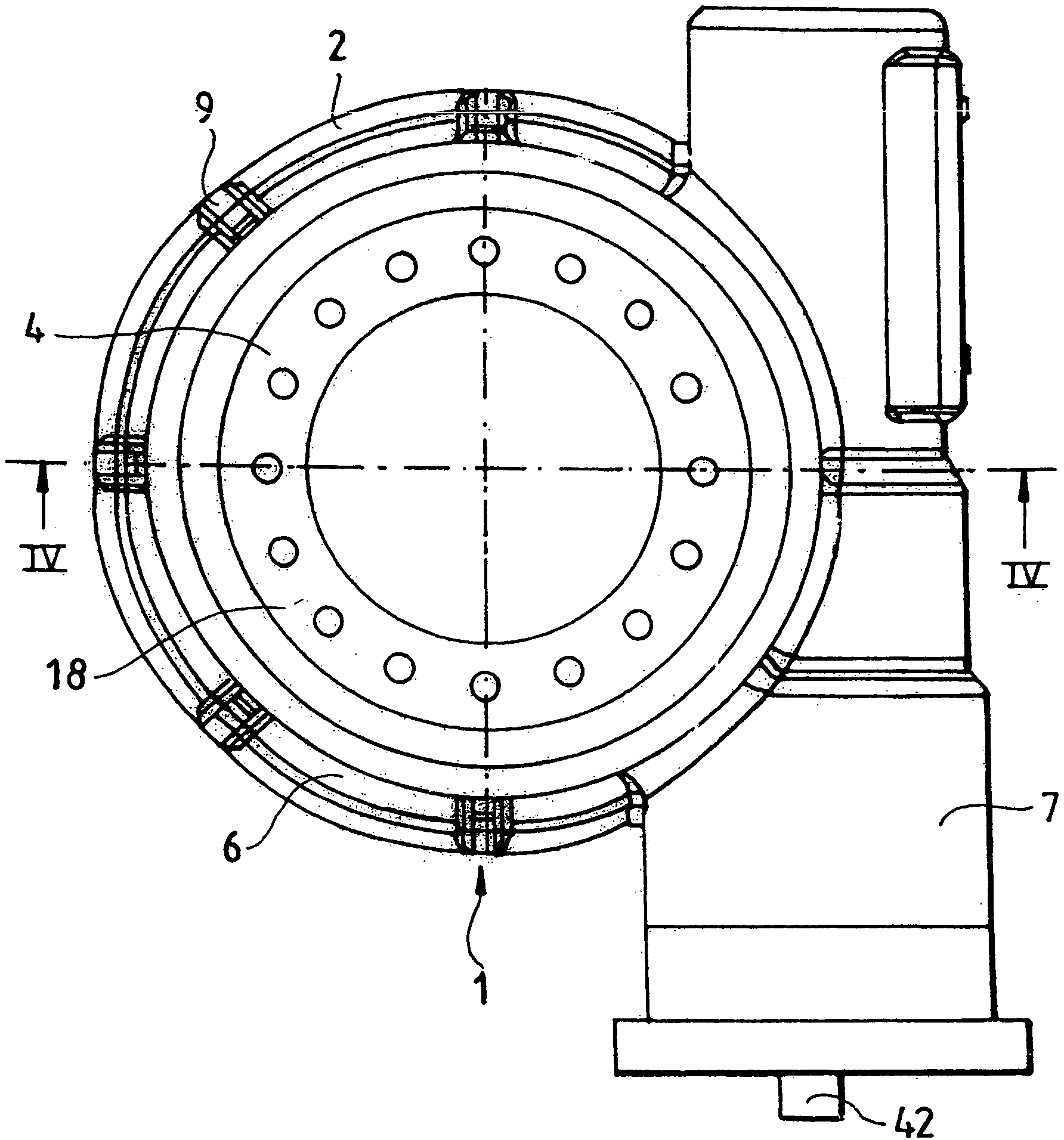

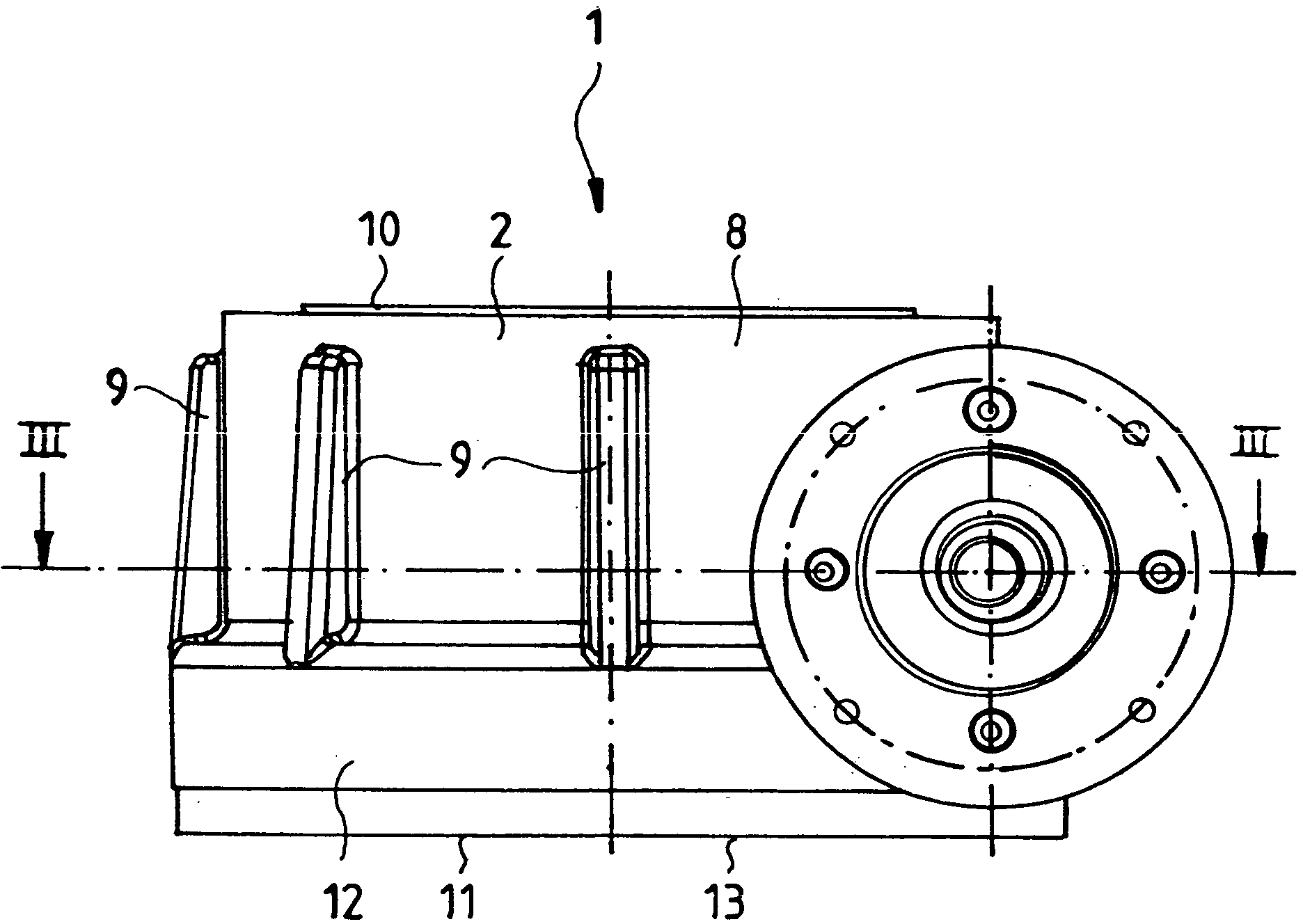

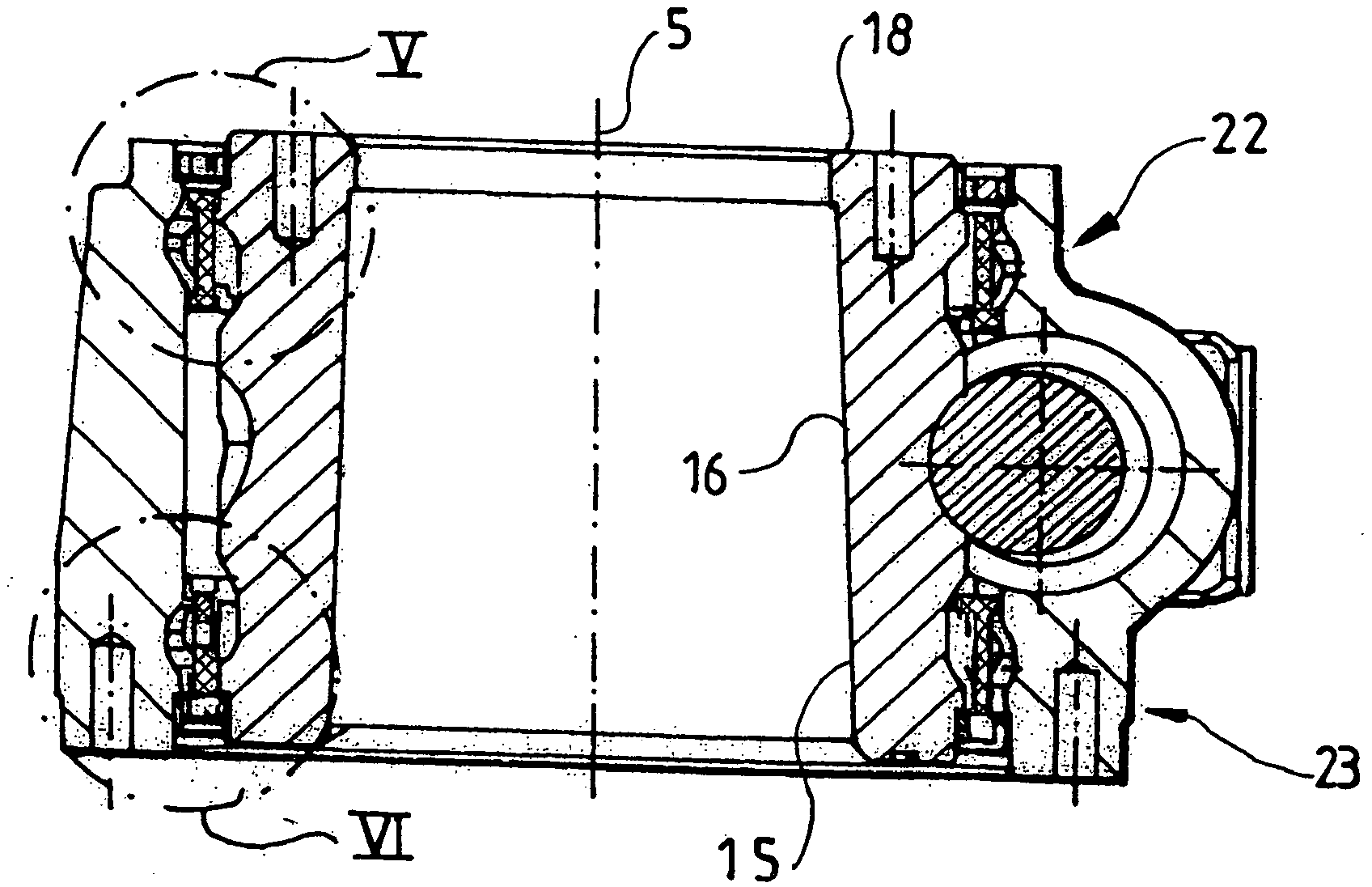

Swivel Drive

InactiveCN103038542ALight in massReduce weightSolar heating energySolar heat devicesHeliostatDrive motor

The invention relates to a device (1) for the rotary drive of part of a machine or piece of equipment, for example a crane, an elevating working platform, a tracking photovoltaic assembly or heliostat or the like equipment for tracking mirrors within the context of a solar thermal power station, etc., on a foundation or on a chassis, for example of a heavy goods vehicle, or another part of a machine or piece of equipment, comprising a worm gear mechanism having a housing (2) which has a connecting surface for connecting to a part of the machine or piece of equipment, to a chassis or to a foundation, having a worm which can be caused to rotate manually or by means of a drive motor, and having a worm gear (4) which is rotatably mounted in the housing, in that, on both sides of the toothing of the worm gear provided to engage with the worm (3), at least one rolling contact bearing is provided in each case, and which has a connecting surface for connecting to a part of a machine or piece of equipment, to a chassis or to a foundation; according to the invention, the housing (2) and the worm gear (4) are each formed in one piece, wherein the smallest internal diameter of the housing (2) is larger than the largest external diameter of the worm gear (4).

Owner:IMO HOLDING GMBH

Braking apparatus for a vehicle and vehicle comprising said braking apparatus

ActiveUS20120111691A1Minimize damageReduce wearBraking element arrangementsCurtain accessoriesReduction driveLubrication

A braking apparatus for a vehicle, in particular a heavy goods vehicle, includes a drive axle having a transmission gear, such as a differential, around which an amount of oil for lubrication is variable. The brake apparatus further includes at least one friction brake and at least one retarder that is capable of operating to slow the vehicle through the transmission gear. The braking apparatus comprises a brake operating device for operating the at least one friction brake and the least one retarder, and a determining feature to determine an oil level around the transmission gear. The brake operating device, on operation by a user, is arranged to apply the retarder when the oil level around the transmission gear is above a threshold level, and, if the oil level is below the threshold level, the brake operating device is arranged to initiate an increase in the oil level around the transmission gear.

Owner:MERITOR TECH

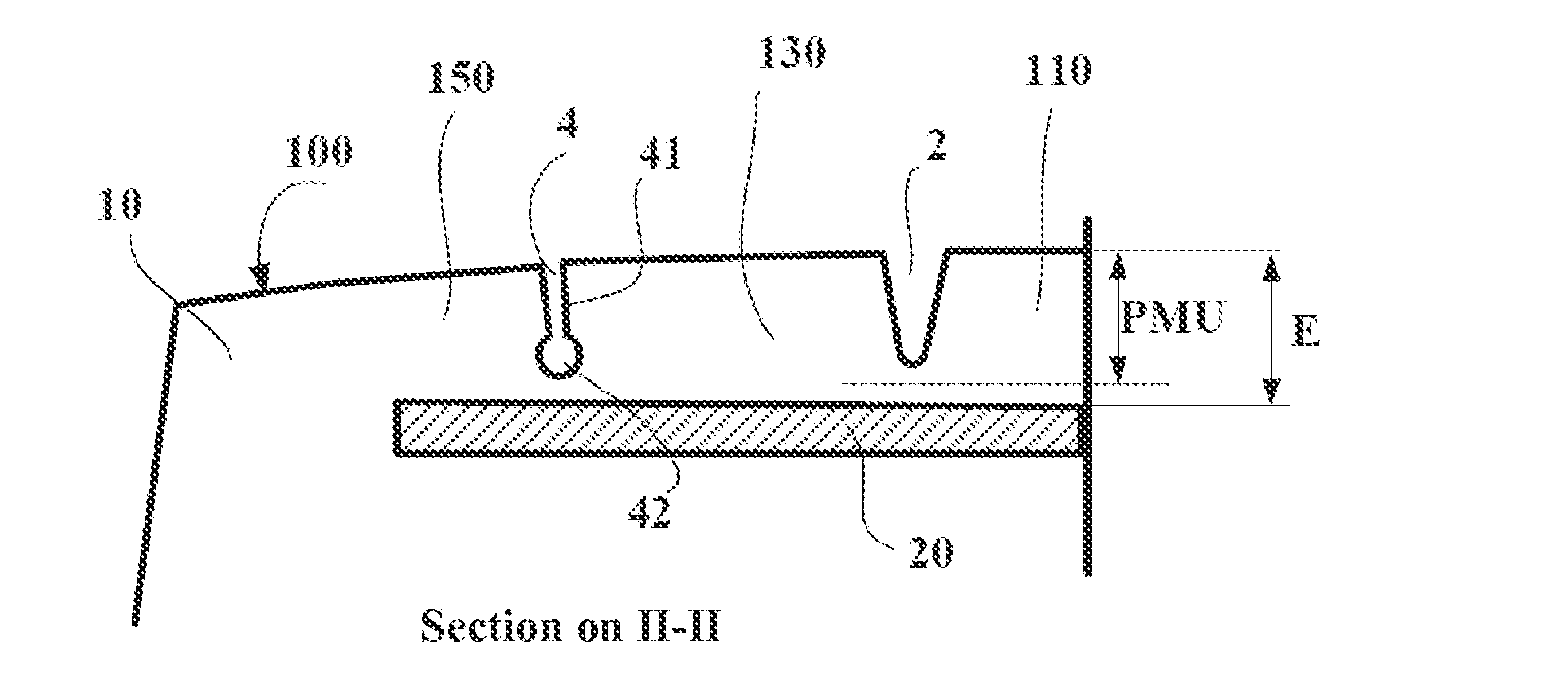

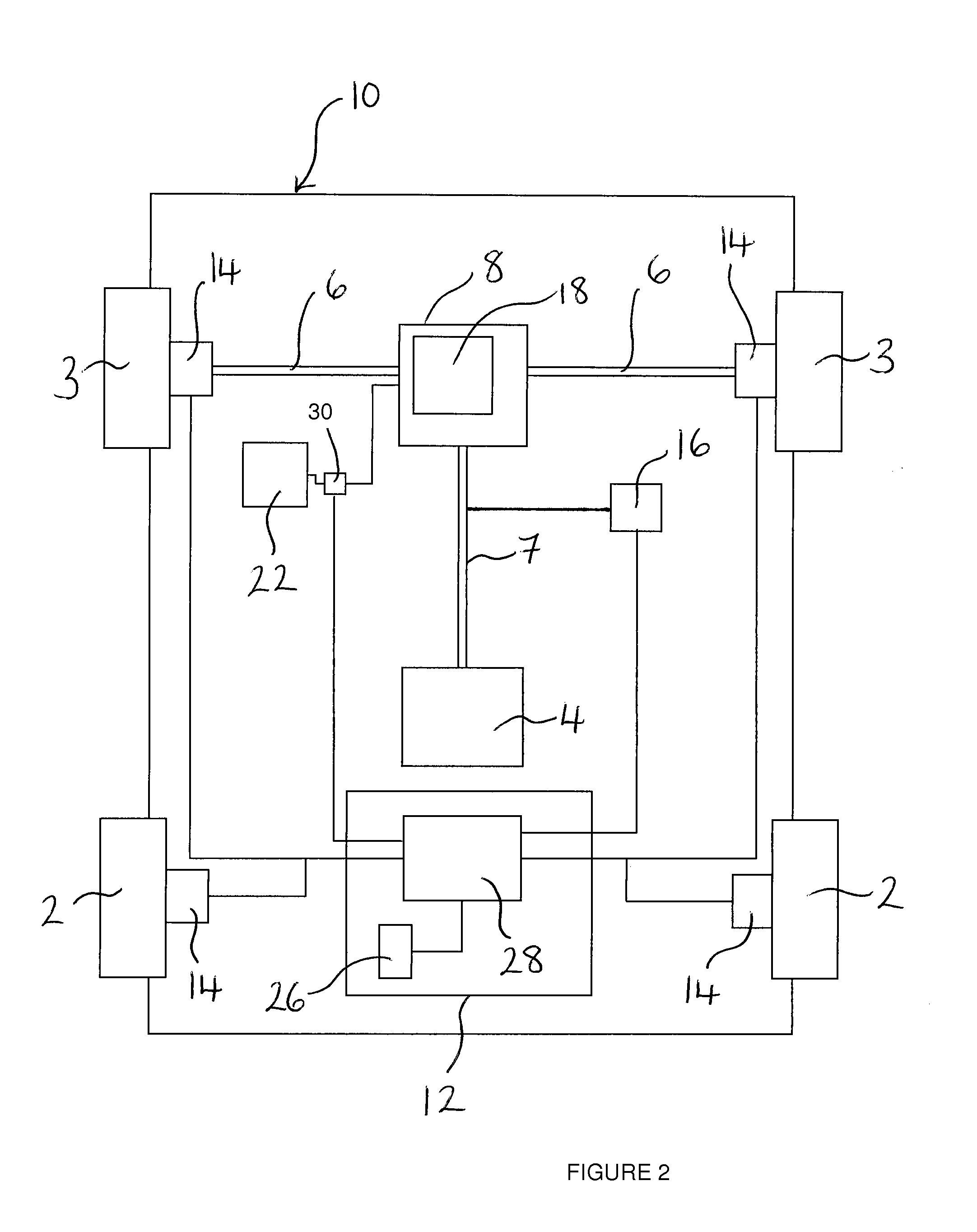

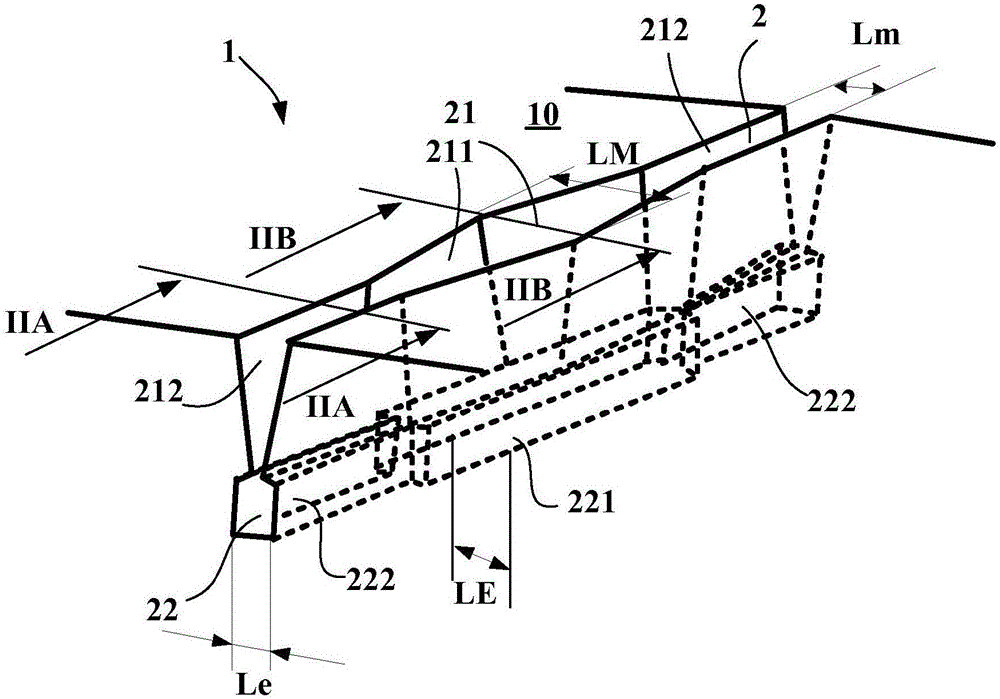

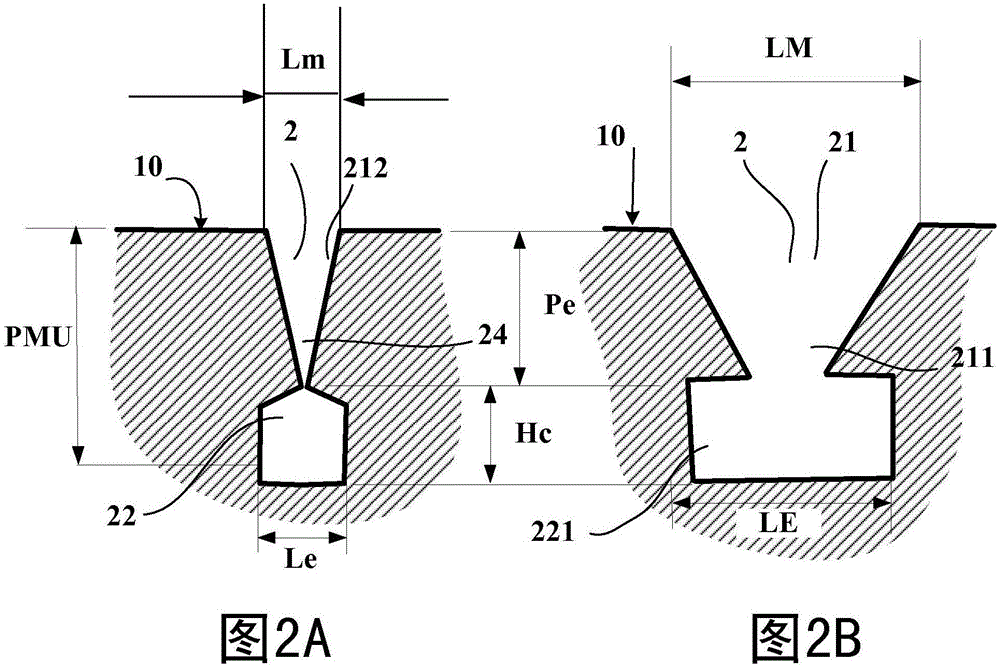

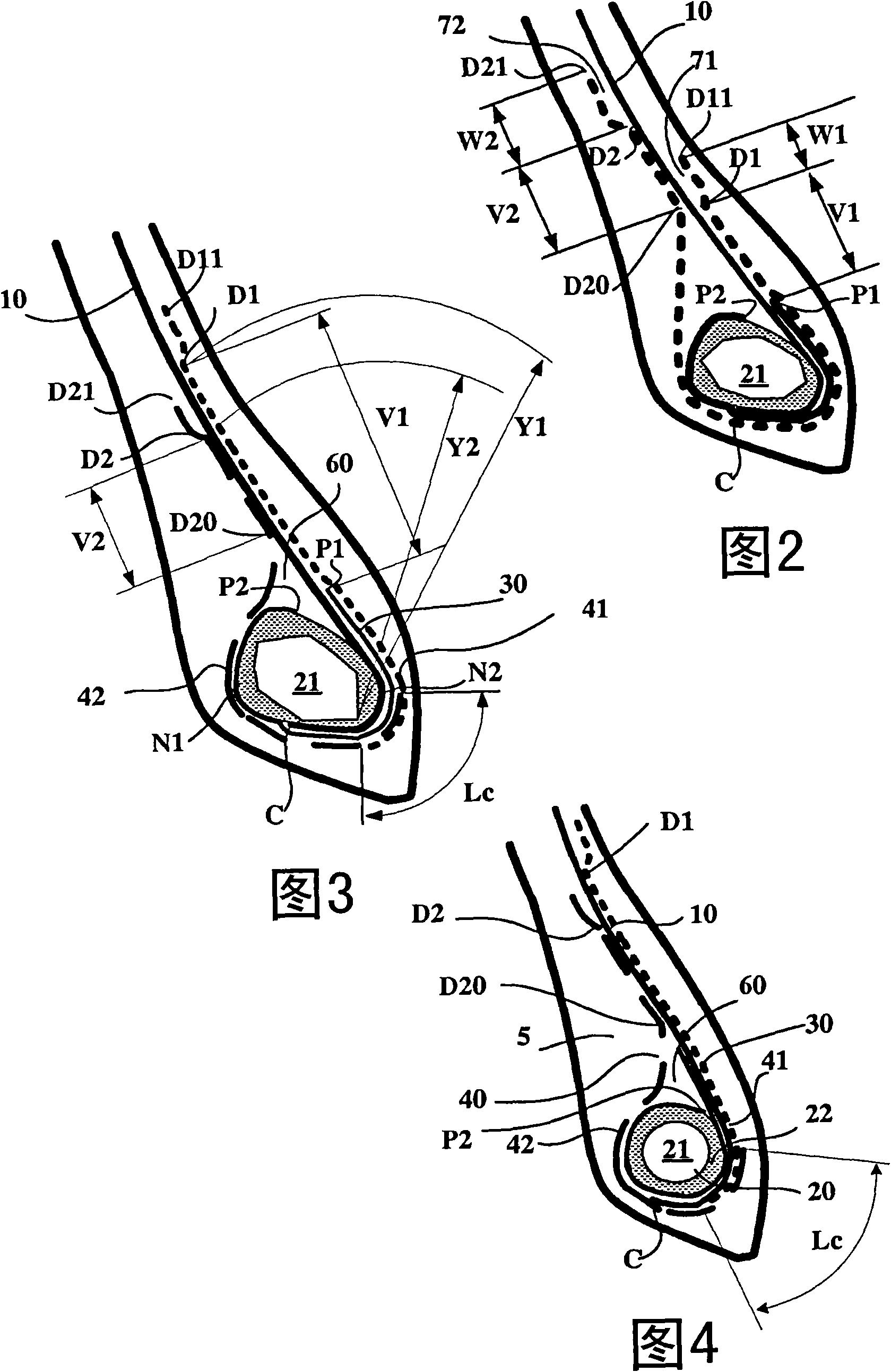

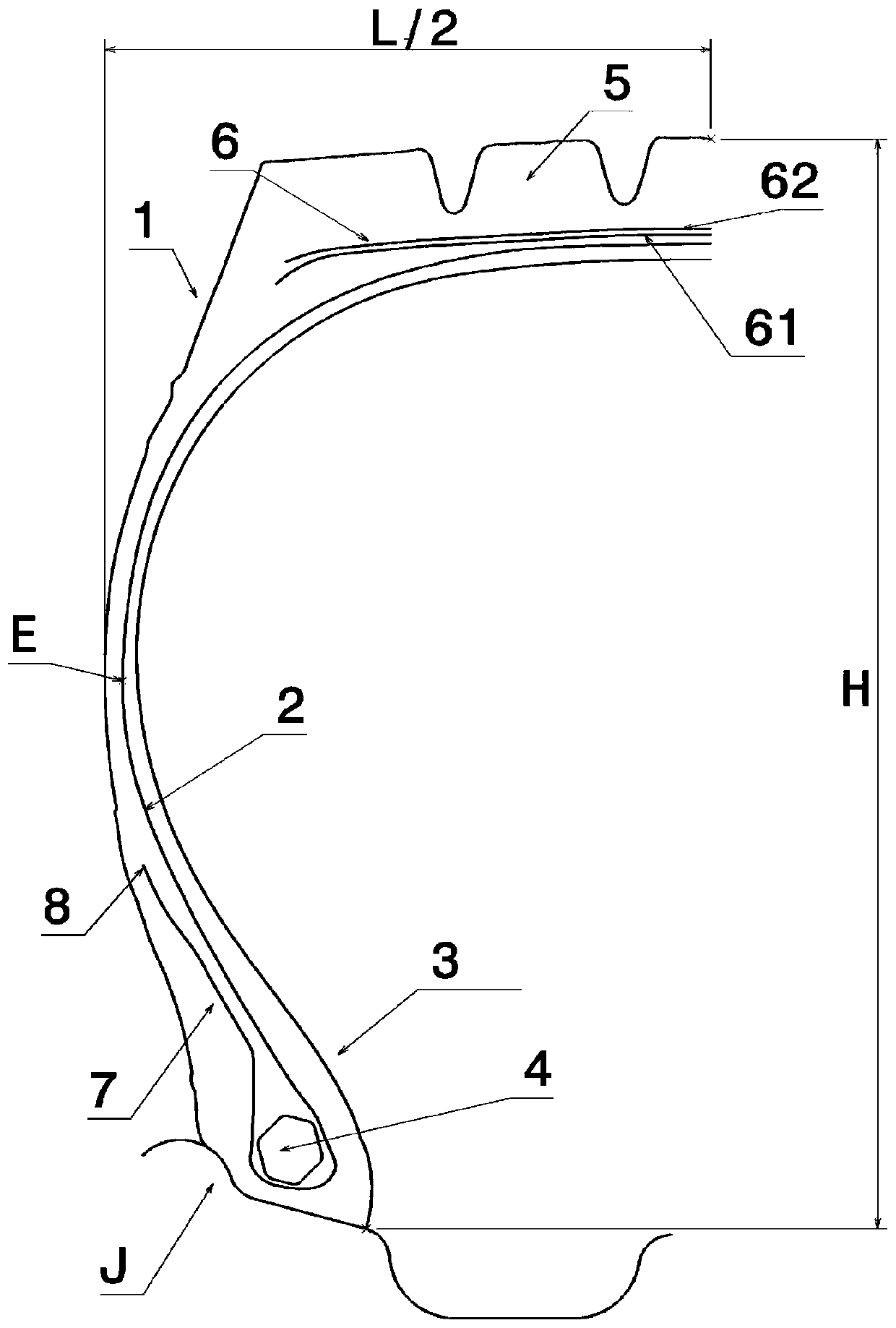

Evolving tread for a tyre

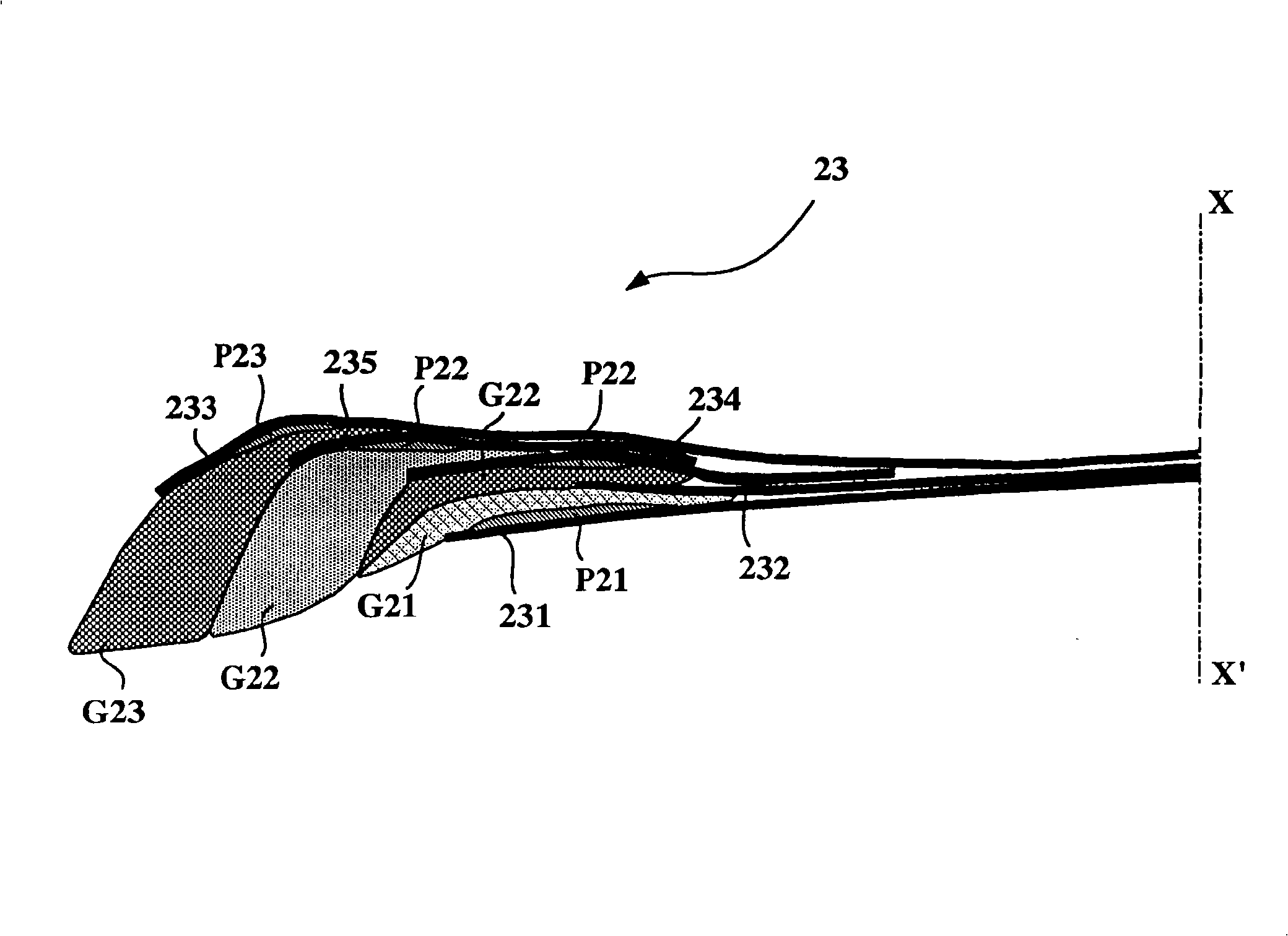

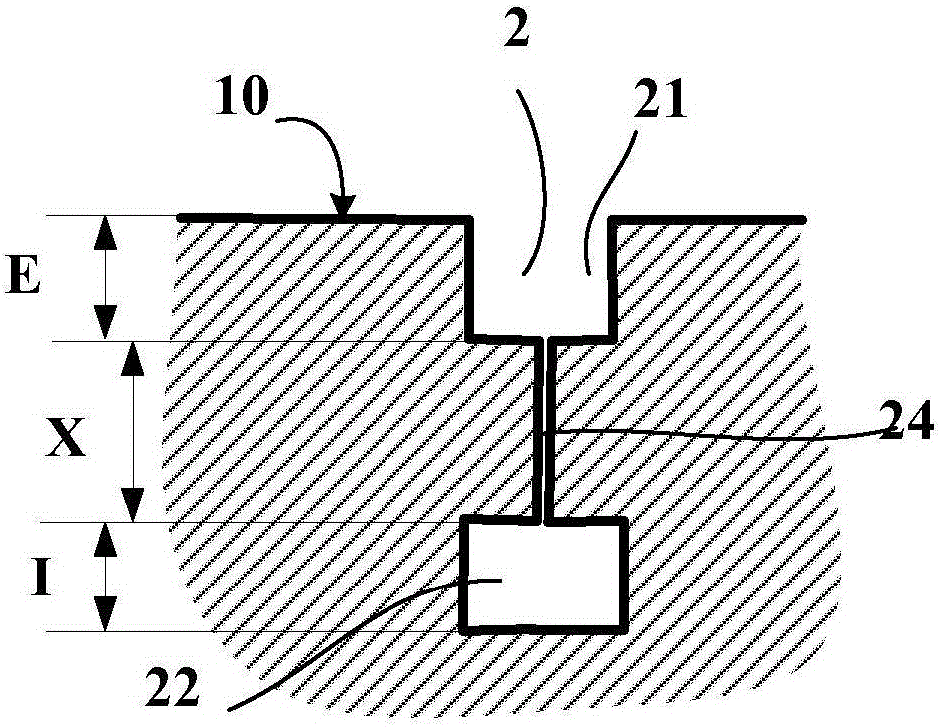

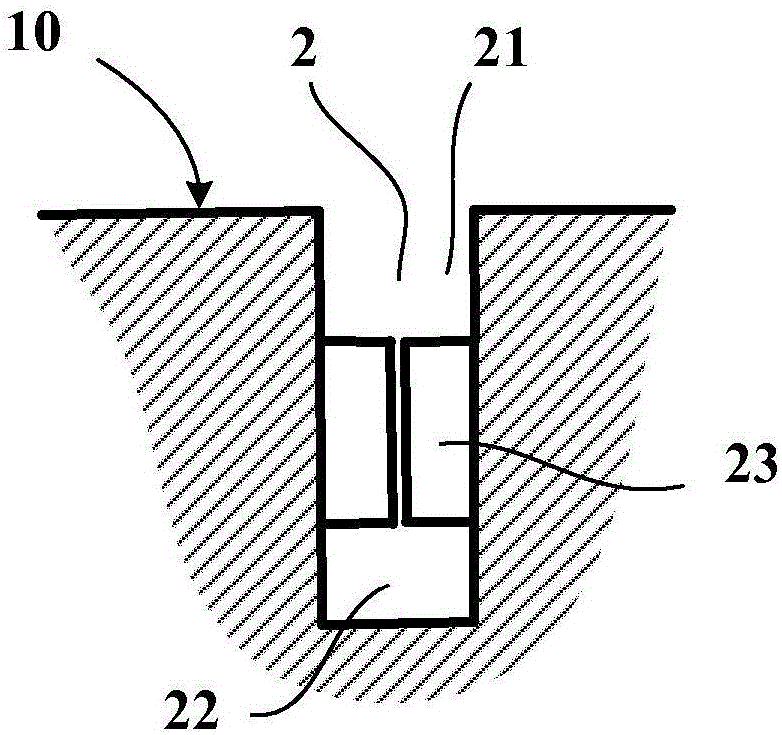

Heavy goods vehicle tyre tread (1) of total thickness PMU, this tread in the new state having a tread surface (10) and comprising at least one cut (2) opening in the initial state onto the tread surface (10), this cut (2) being such that it comprises an external part (E) in the form of a groove (21) in a main direction, this groove (21) being of mean depth Pe less than 80% of the thickness PMU, an internal part (I) forming the end of the cut, this internal part having the form of a canal (22) of mean width Le and of mean height Hc, this canal being intended to form a new continuous groove after the tread has suffered partial wear at most equal to 80% of the thickness PMU; an intermediate part (X) making the connection between the internal part (I) and the external part (E), this intermediate part (X) comprising in alternation - in the main direction of the groove that forms the external part - a succession of wide parts (23) and of narrow parts (24), the wide parts (23) being suited to not closing up as they enter the contact patch and the narrow parts (24) being suited to closing up as they enter the contact patch thus limiting the reduction in stiffness of the tread which reduction is associated with the presence of this cut (2).

Owner:OCIETE DE TECH MICHELIN

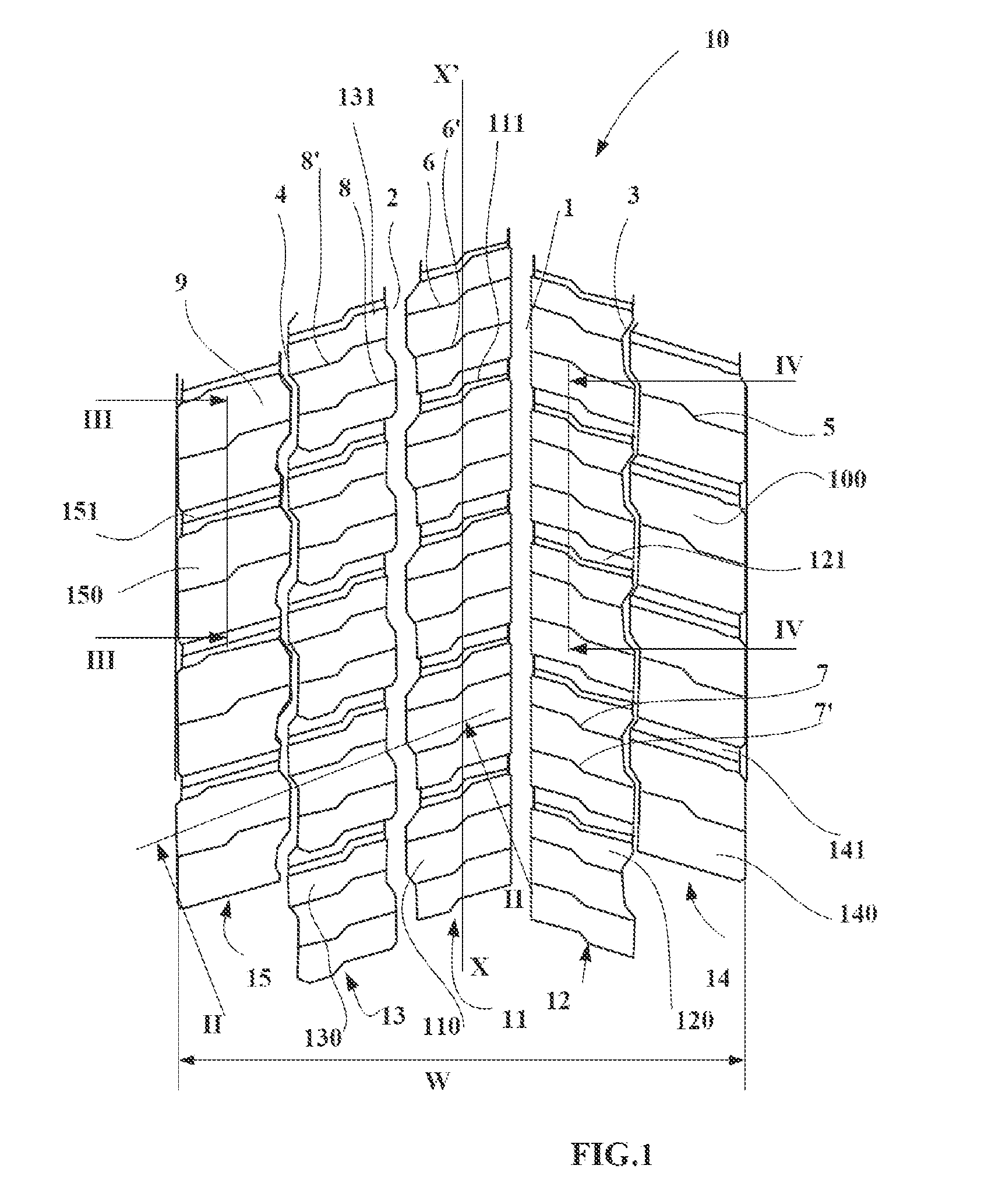

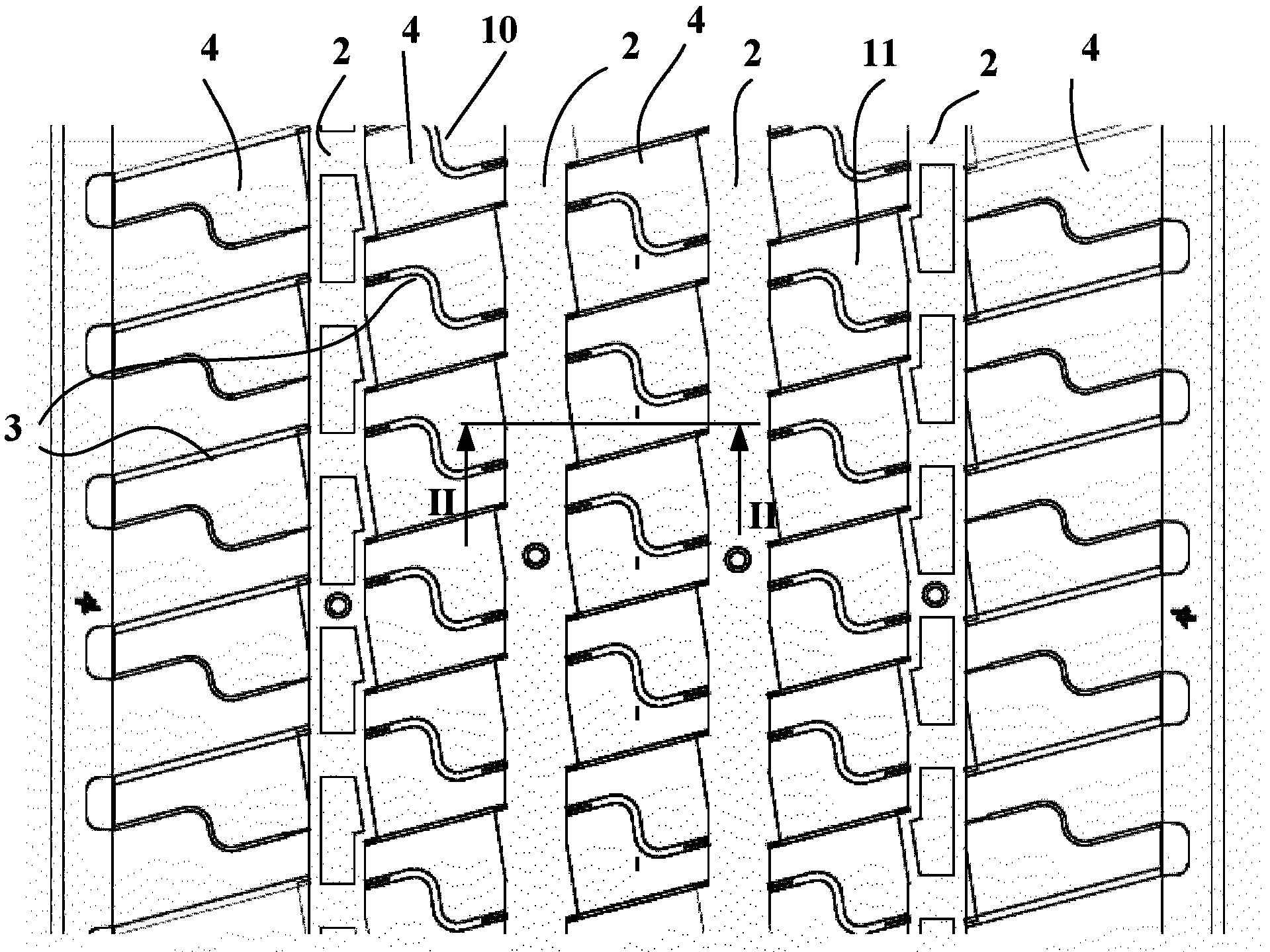

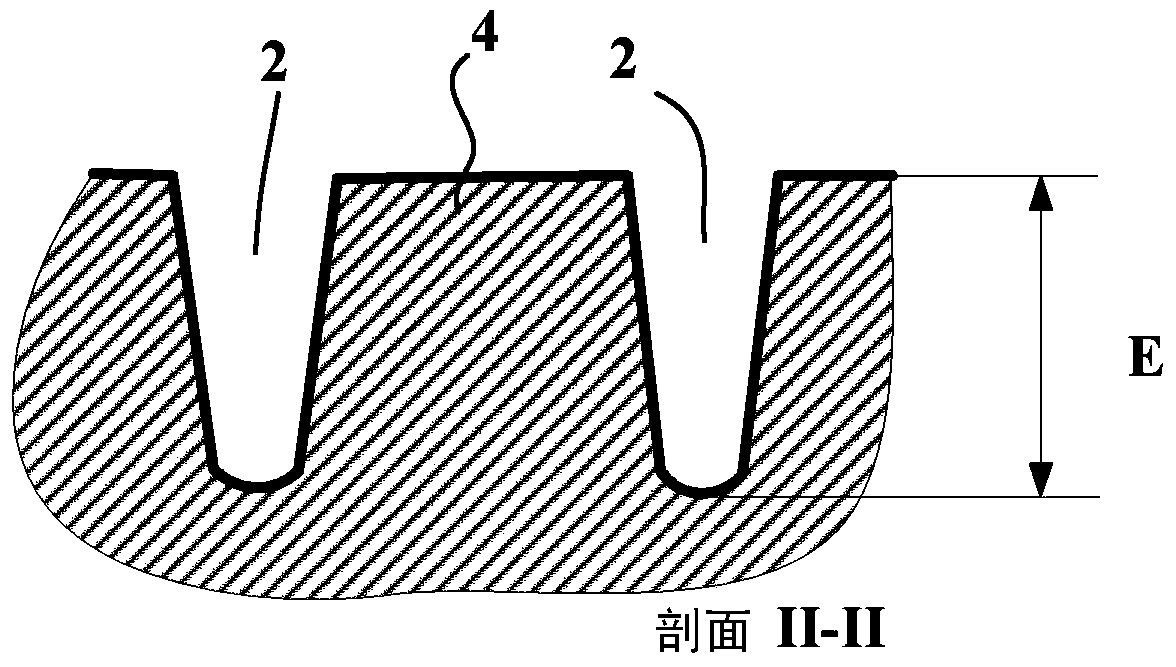

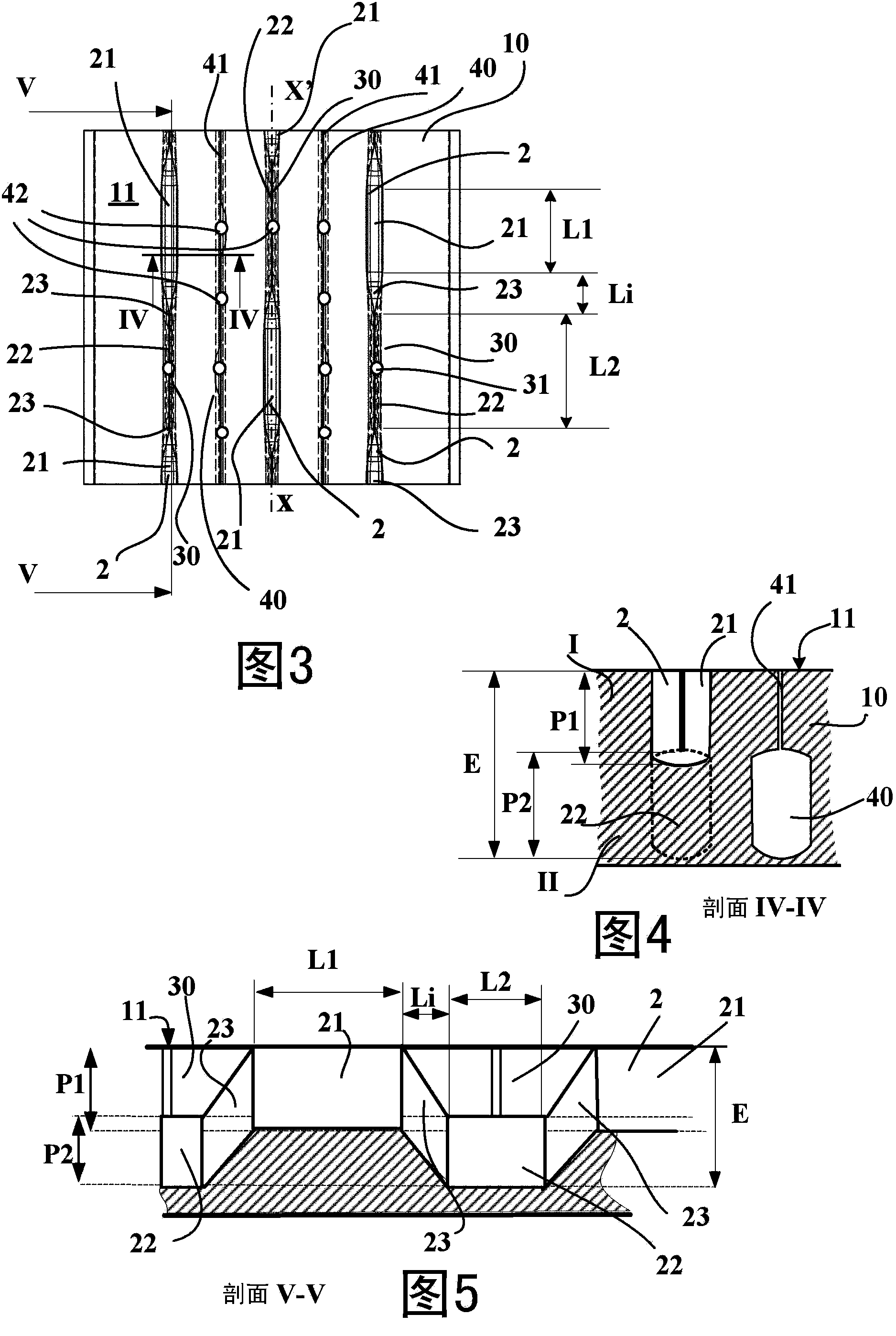

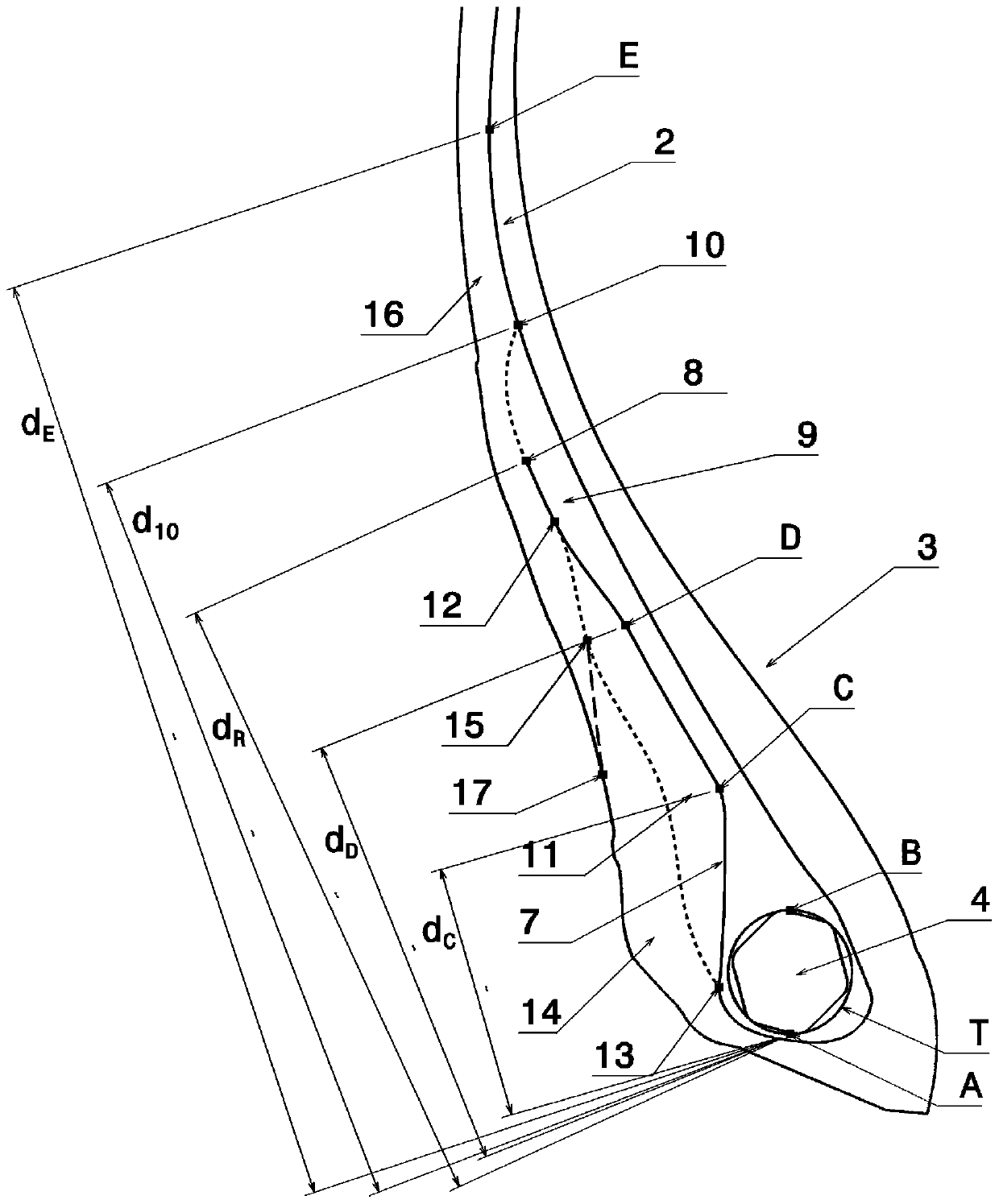

Improved tread for heavy goods vehicle tyre

Tread for heavy goods vehicle tyre is provided with a total thickness E and a total volume V, the tread is provided with at least one continuous groove (2) and comprises at least two wear layers I, II in the thickness of the tread, wherein each layer has a thickness at most equal to 75% of the total thickness E of the tread; and a plurality of external cavities (21) and a plurality of internal cavities (22) positioned radially and wholly inside the tread surface (11) in the as-new condition, wherein each internal cavity is connected to one external cavity by a connecting duct. The tread has a total groove volume Vc at least equal to 7% and at most equal to 12% of a volume equal to the sum of the total volume V and of the total groove volume, the tread also has an effective groove volume Ve for each wearing layer that is less than the total groove volume Vc, the effective groove volume satisfies the following relationship: 0.4 St < Ve < 0.8 St, in which 0.4 and 0.8 are heights expressed in millimetres and St is the surface area bounded by the external contour of a contact patch of the tread measured under static conditions with customary pressure and loading, and furthermore thd tread is designed in the way that at least the first wearing layer I consists of a rubber compound based on at least one material having a dynamic Tg measured in accordance with standard ASTM D 5992-96, higher than -40 DEG C and containing a predominant proportion of SBR copolymer with a Tg > -65 DEG C.

Owner:SOCIETE DE TECH MICHELIN

Evolving tyre tread

Heavy goods vehicle tyre tread (1) having a total thickness PMU corresponding to the thickness of material that can be worn away during driving, this tread having a tread surface (10) and comprising at least one cut (2) opening in the initial state onto the tread surface (10) in the new state, this cut (2) comprising: an external part forming a groove (21) having a mean depth Pe at most equal to 90% of the thickness PMU, and a minimum width Lm measured on the tread surface in the new state; an internal part forming the end of the cut (2) and having the form of a canal (22) of mean height Hc, the canal (22) comprising at least one narrow part (222) of maximum width Le and at least one widened part (221) of maximum width LE, each widened part (221) of the canal (22) extending into the groove (21) of the external part of the cut (2) via a widening (211) of the groove (21), this widening (211) having a maximum width LM, measured on the tread surface in the new state, at least equal to the maximum width LE of the widened part (221) of the canal.

Owner:OCIETE DE TECH MICHELIN

Flexible semicrystalline polyamides

ActiveCN101072833AHigh operating temperatureImprove heat agingSynthetic resin layered productsFlexible pipesPlasticizerPolyamide

Composition comprising, by weight, the total being 100 %: 50 to 100 % of at least one polyamide A1 of formula X.Y / Z or 6.Y2 / Z in which: X denotes the residues of an aliphatic diamine having from 6 to 10 carbon atoms, Y denotes the residues of an aliphatic dicarboxylic acid having from 10 to 14 carbon atoms, Y2 denotes the residues of an aliphatic dicarboxylic acid having from 15 to 20 carbon atoms and Z denotes at least one unit chosen from the residues of a lactam, the residues of an a,-aminocarboxylic acid, the unit X1, Y1 in which X1 denotes the residues of an aliphatic diamine and Y1 denotes the residues of an aliphatic dicarboxylic acid, the weight ratios Z / (X+Y+Z) and Z / (6+Y2+Z) being between 0 and 15 %; 0 to 40 % of a plasticizer; 0 to 50 % of an impact modifier; and 0 to 50 % of a polyamide A2. The invention also relates to structures comprising a layer consisting of the above composition. This structure is useful for making devices for storing or transferring fluids, in particular in motor vehicles and heavy goods vehicles. The fluids may for example be petrol, diesel, hydraulic brake fluid, compressed air for the brake circuits of heavy goods vehicles, and hydraulic clutch fluid. The invention also relates to these devices. Such devices may be tanks, hoses, pipes or containers. These structures may include other layers consisting of other materials.

Owner:ARKEMA FRANCE SA

Arrangement for cooling a vehicle component

ActiveUS20060180103A1Improve cooling effectReduce trafficExhaust apparatusCombustion enginesEngineeringControl valves

The invention constitutes an arrangement for cooling a vehicle component, for example a transmission, disposed adjacent to an engine, which arrangement includes a cooling circuit designed to feed a coolant through the transmission and including a line for coolant to the transmission and a line for coolant to the transmission. According to the invention, the cooling circuit is also designed to cool the engine and includes a further line for feeding the coolant to the engine, and the cooling circuit includes a flow control valve for controlling the coolant in the cooling circuit such that the flow of coolant to the vehicle component is lower than the flow to the engine. As a result of the invention, an improved arrangement is obtained for cooling, for example, a transmission, for example in heavy goods vehicles.

Owner:VOLVO LASTVAGNAR AB

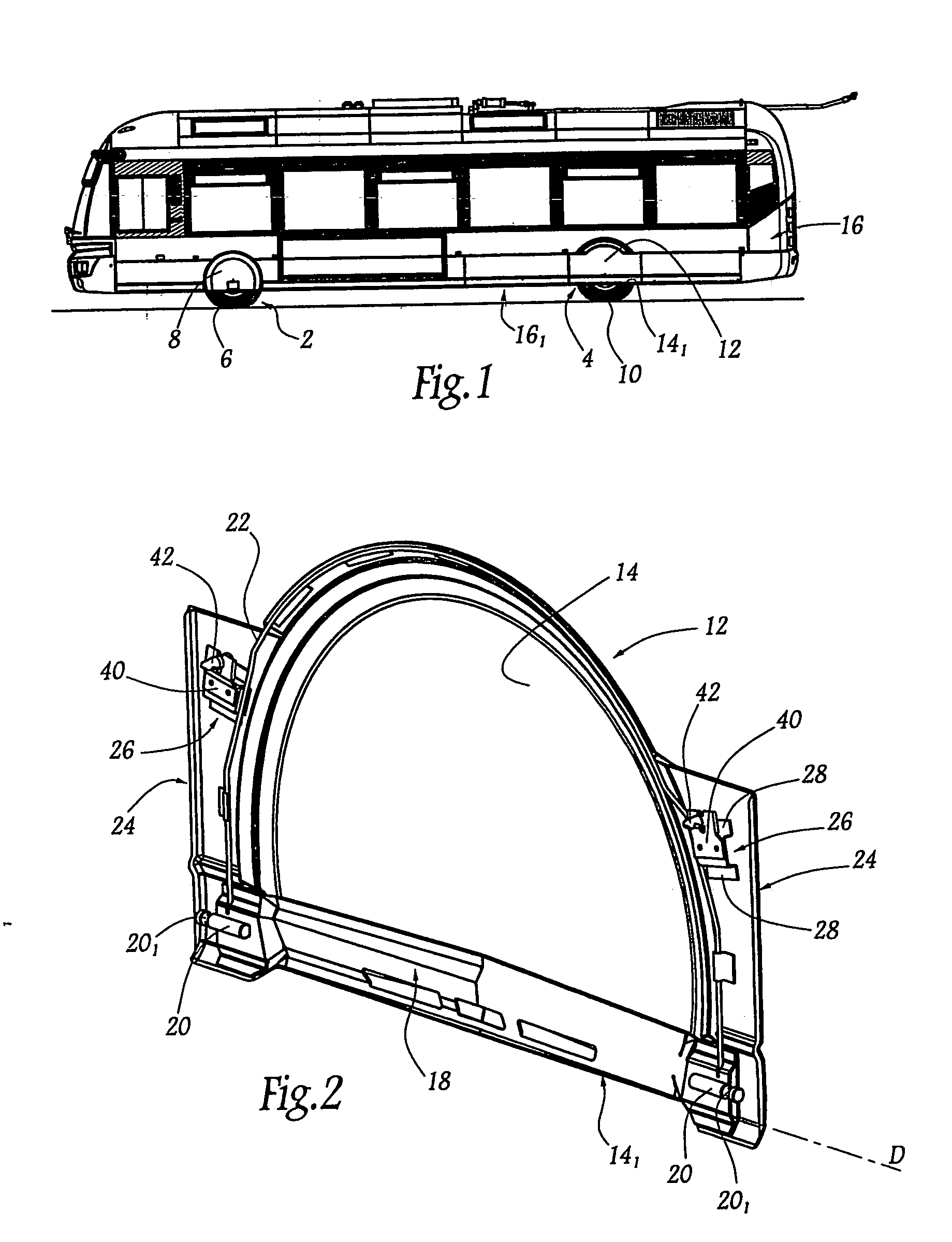

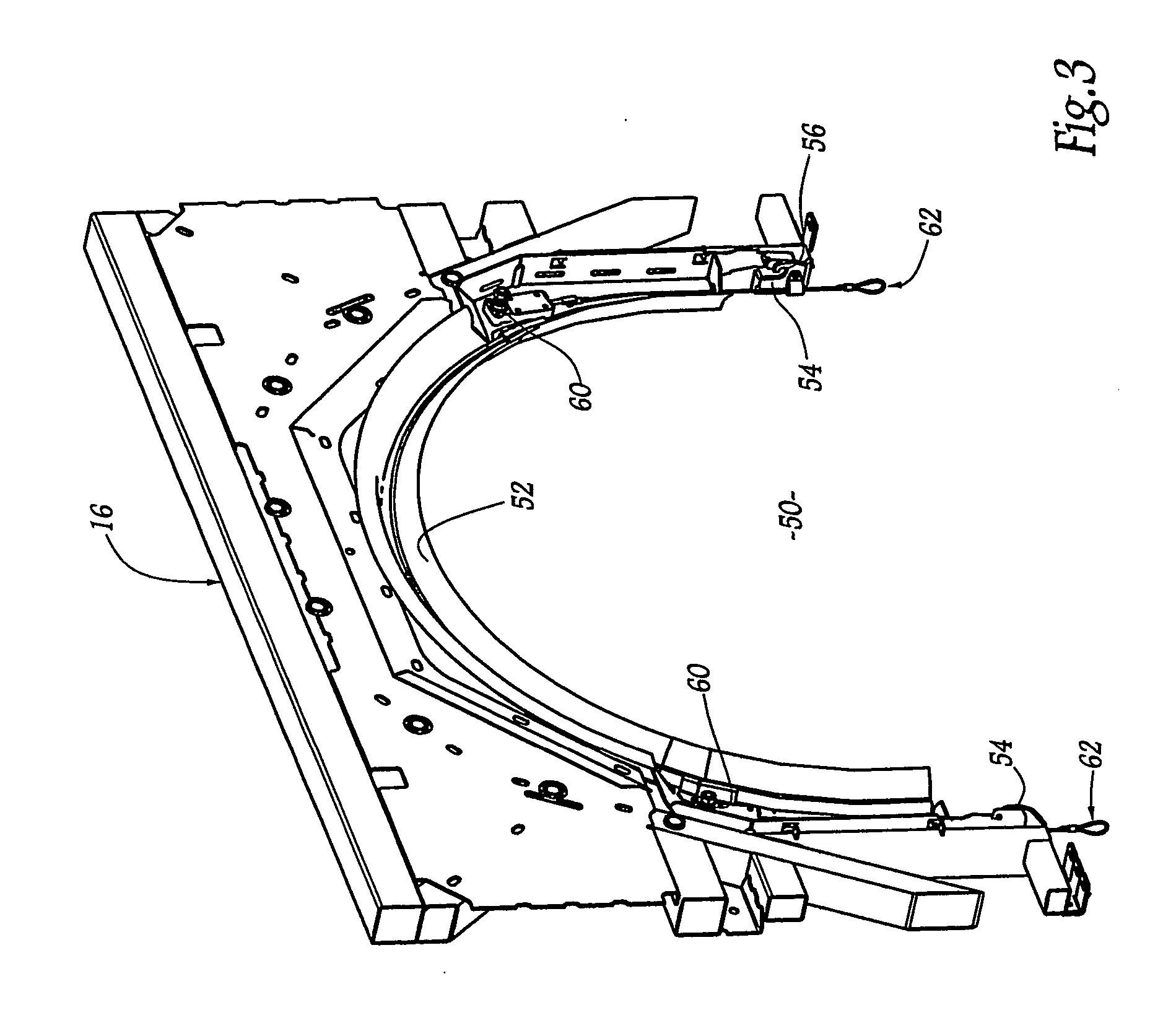

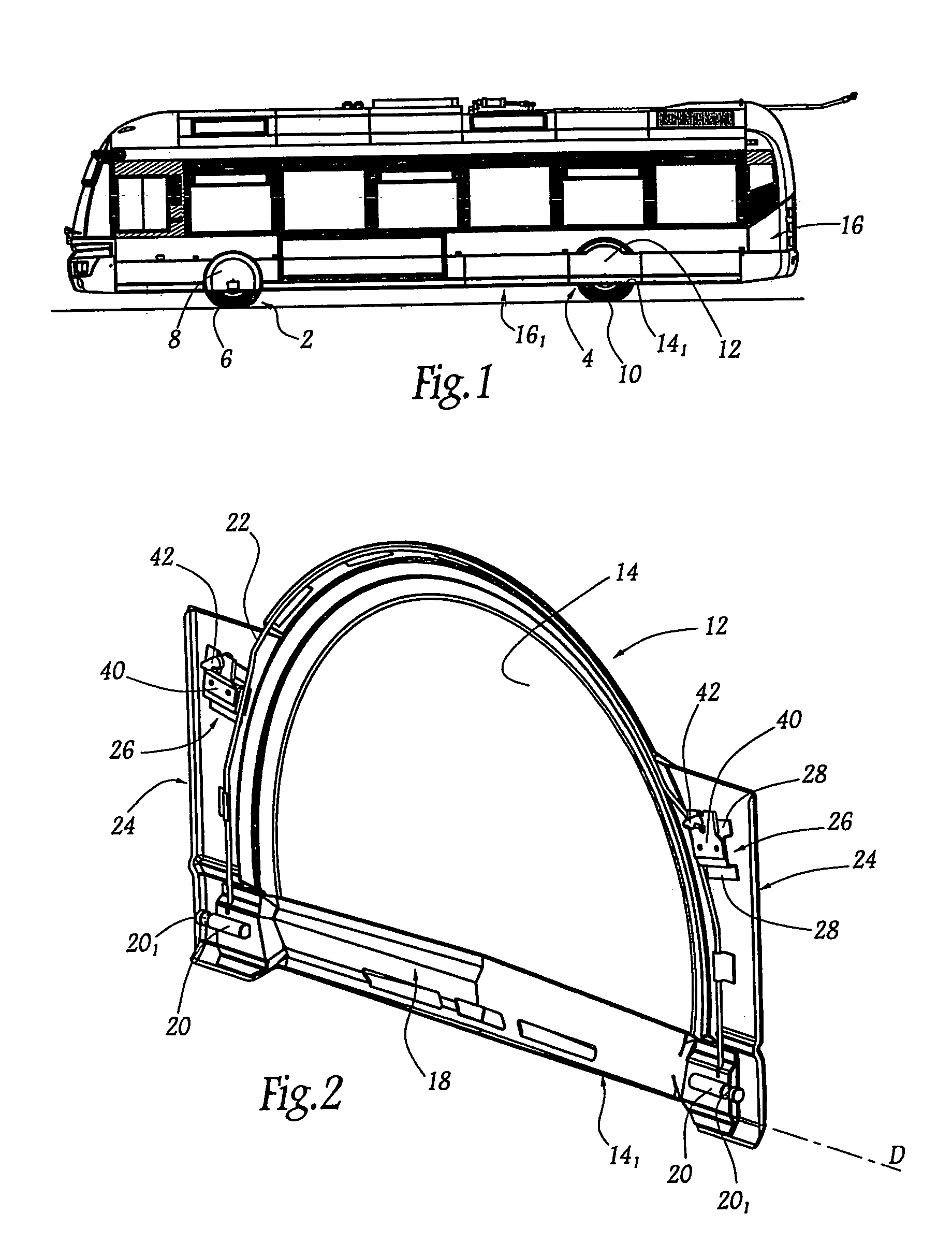

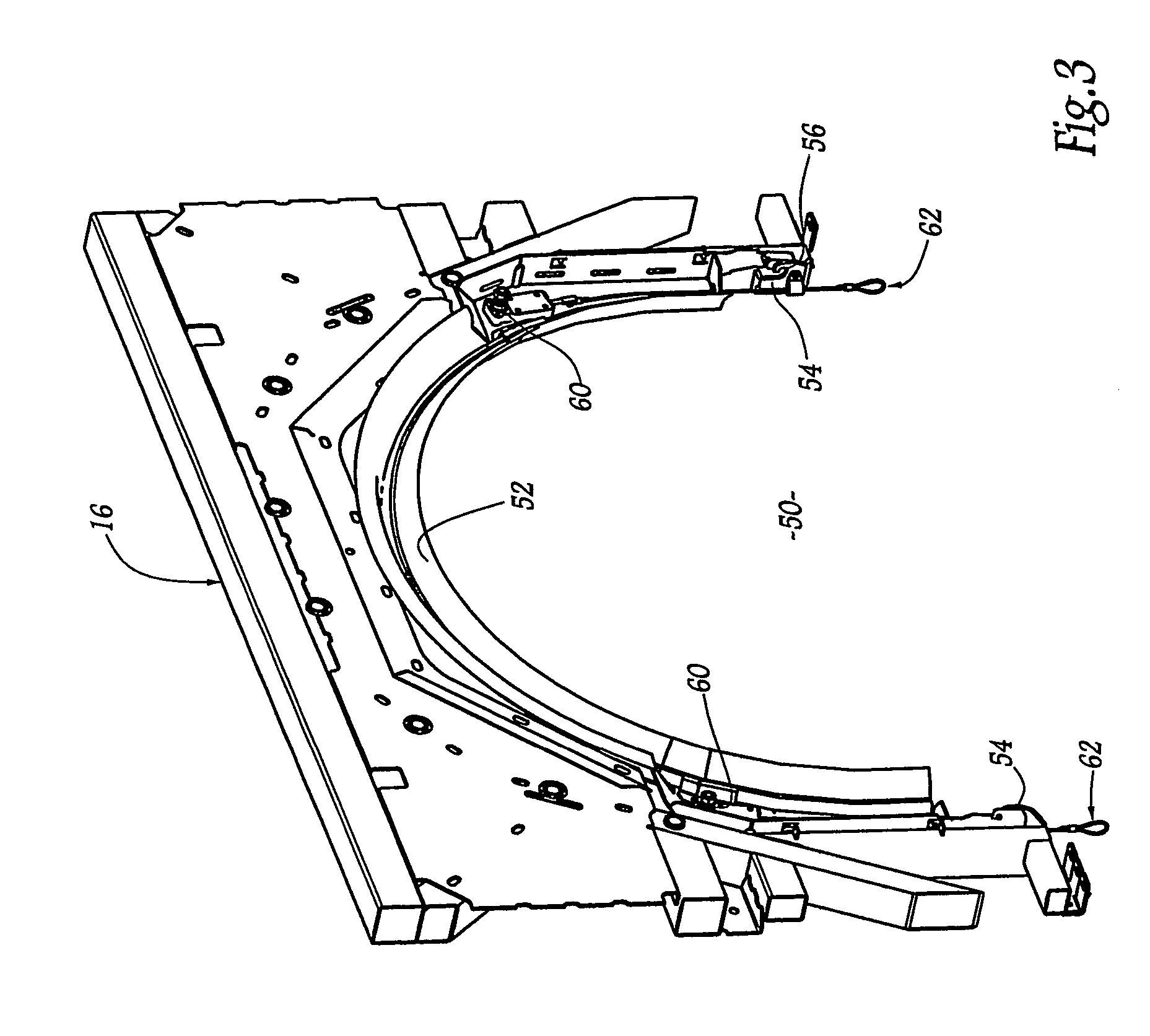

Fairing for wheel of heavy goods vehicle, and the corresponding heavy goods vehicle

ActiveUS20060157952A1Avoid premature separationVehicle seatsSuperstructure subunitsHeavy goods vehicleProjectile

This fairing comprises a cowl (14) and means (26, 42) for connecting said fairing to the vehicle body (16),said connecting means are designed to allow the release of the fairing from the vehicle body, according to a release movement, when said fairing is subjected to a force exceeding a preset value, in particular when the tyre of said wheel bursts, and said fairing also includes means that enable it to be retained to vehicle body (16) during said release movement, to prevent said fairing from forming projectile material.

Owner:IVECO FRANCE S AS

Fairing for wheel of heavy goods vehicle, and the corresponding heavy goods vehicle

ActiveUS7458595B2Avoid premature separationVehicle seatsSuperstructure subunitsEngineeringHeavy goods vehicle

This fairing comprises a cowl (14) and means (26, 42) for connecting said fairing to the vehicle body (16),said connecting means are designed to allow the release of the fairing from the vehicle body, according to a release movement, when said fairing is subjected to a force exceeding a preset value, in particular when the tyre of said wheel bursts, and said fairing also includes means that enable it to be retained to vehicle body (16) during said release movement, to prevent said fairing from forming projectile material.

Owner:IVECO FRANCE S AS

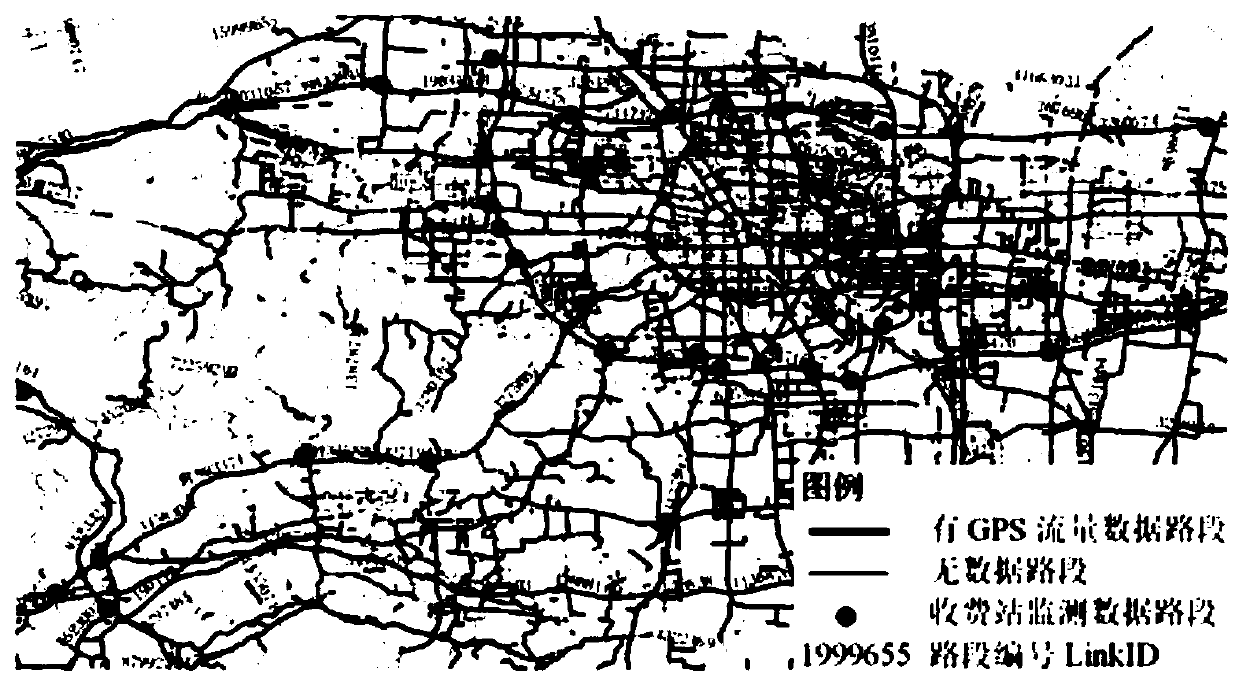

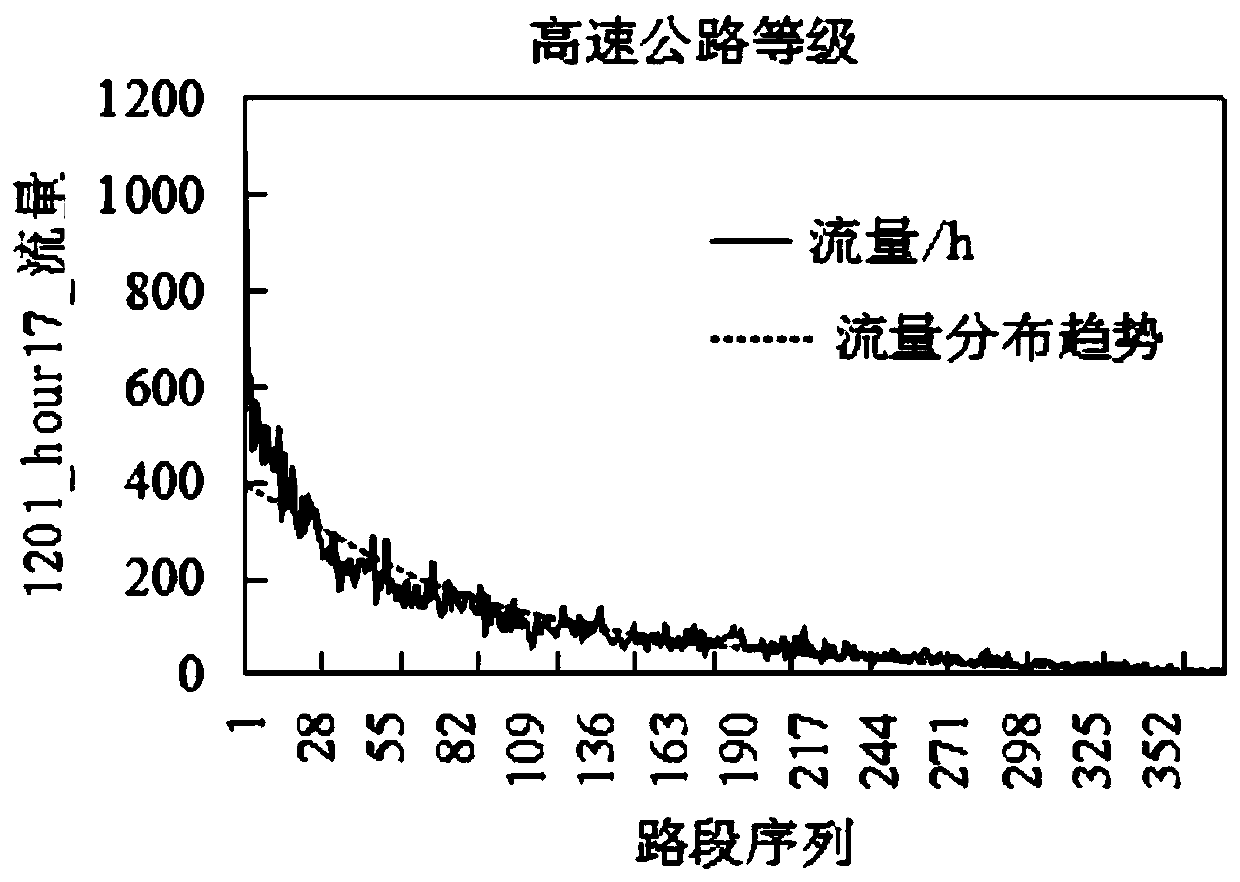

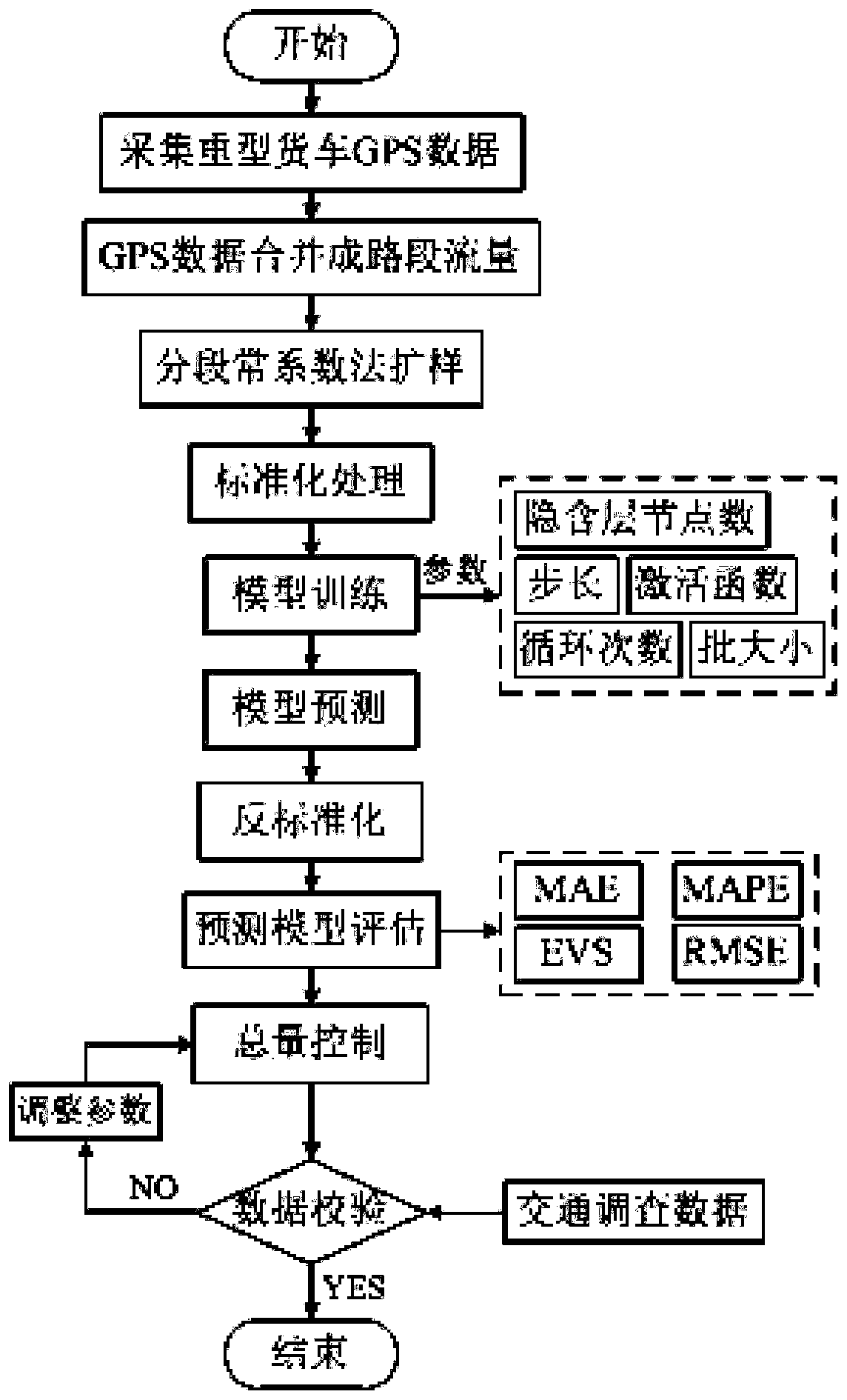

Road network heavy truck traffic flow prediction method based on data quality control

InactiveCN111583628AEase traffic congestionImprove operating conditionsDetection of traffic movementNeural architecturesData OriginTraffic prediction

The invention relates to a road network heavy truck traffic flow prediction method based on data quality control, which is characterized in that two data sources of GPS flow data and toll station monitoring data are divided into three types of data road sections, and different prediction methods are respectively adopted. For a road section with GPS flow data, due to the fact that the GPS data arenot completely obtained, a method that sample expansion is conducted through a piecewise constant coefficient method and then long-short-term recurrent neural network prediction is conducted is adopted. And for a data-free road section without GPS data, a K nearest neighbor algorithm is adopted to predict the flow. For a toll station monitoring data road section, due to comprehensive data samples,a long-short-term recurrent neural network algorithm is directly adopted for prediction. According to the method, starting from the actual engineering problem faced by flow prediction, multiple datasource characteristics are analyzed to improve the data quality, then the road network heavy truck flow measurement and calculation method is established, and finally the road network heavy truck flowbased on data quality control is formed.

Owner:BEIJING JIAOTONG UNIV

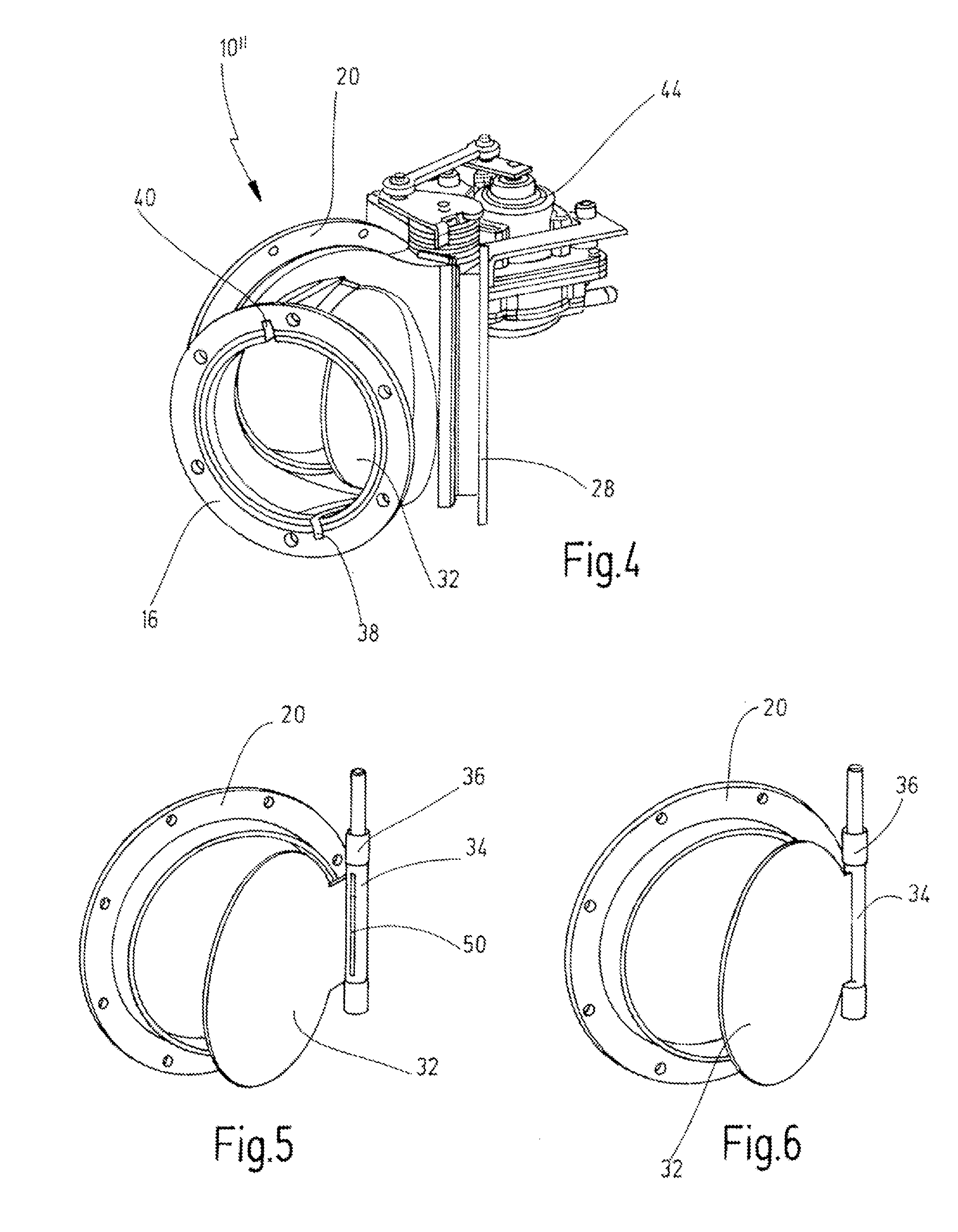

Exhaust gate

ActiveUS20150240957A1Precise bearingReduce leakageExhaust apparatusExhaust gas recirculationEngineeringHeavy goods vehicle

Owner:BORGWARNER STUTTGART GMBH

Heavy goods vehicle tire comprising a tread based on a modified polyisoprene, process for preparing same

ActiveUS10239971B2Improve propertiesReduce rolling resistanceSpecial tyresTyresRolling resistanceNitrogen

A heavy-duty vehicle tire comprising a tread consisting of a crosslinked rubber composition comprising a reinforcing filler of siliceous type and a synthetic polyisoprene modified by grafting with a compound comprising at least one group Q, and at least one group A, which are joined to one another by at least one and preferably one “spacer” group Sp, in which:Q comprises a dipole containing at least one and preferably one nitrogen atom,A comprises an associative group comprising at least one nitrogen atom,Sp is an atom or group of atoms forming a bond between Q and A.The heavy-duty vehicle tire according to the invention has a satisfactorily improved rolling resistance / wear resistance compromise.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

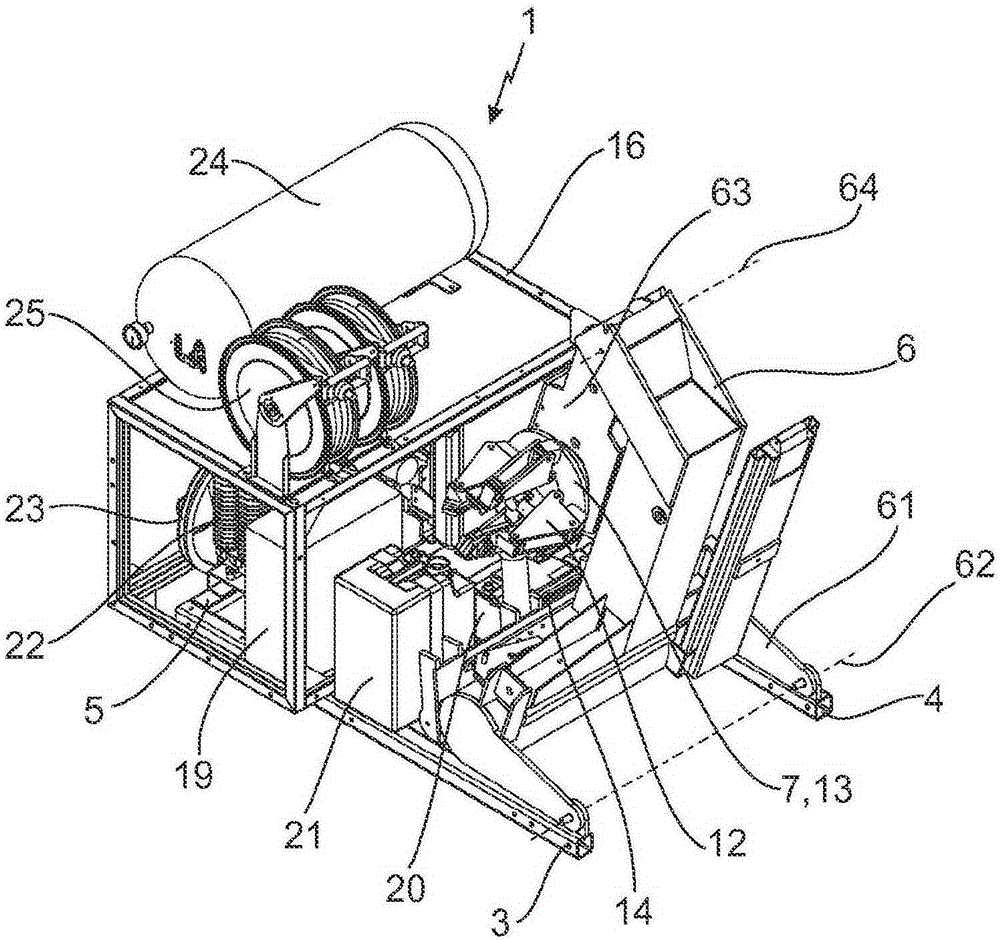

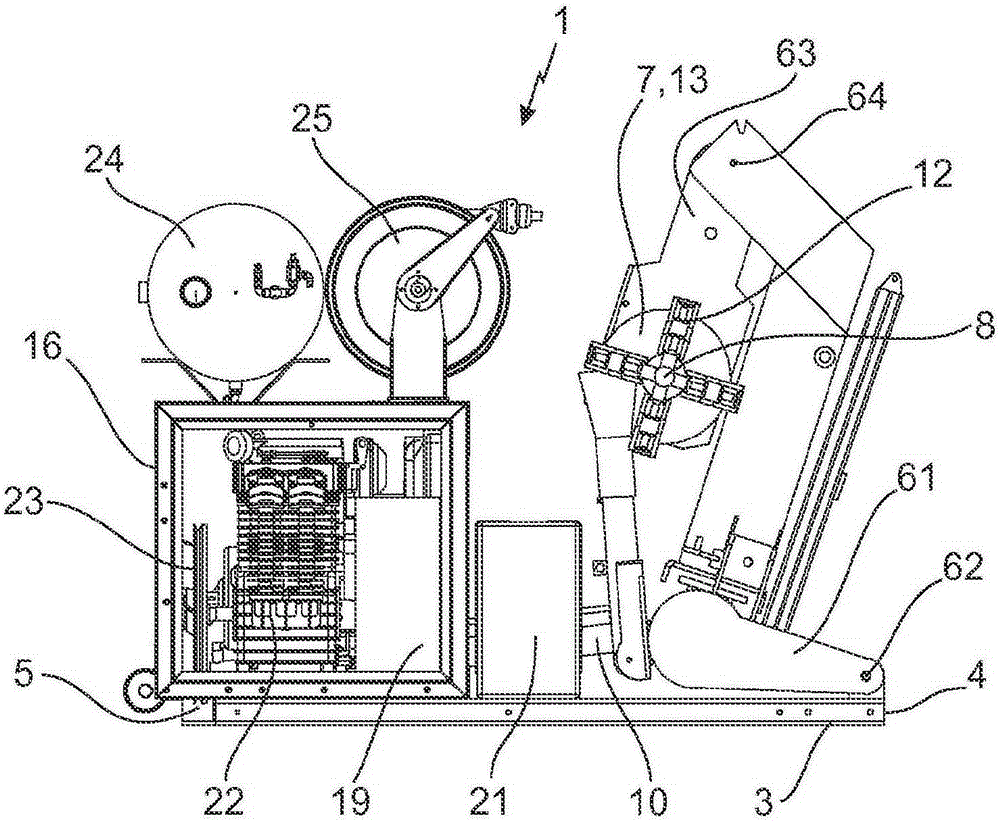

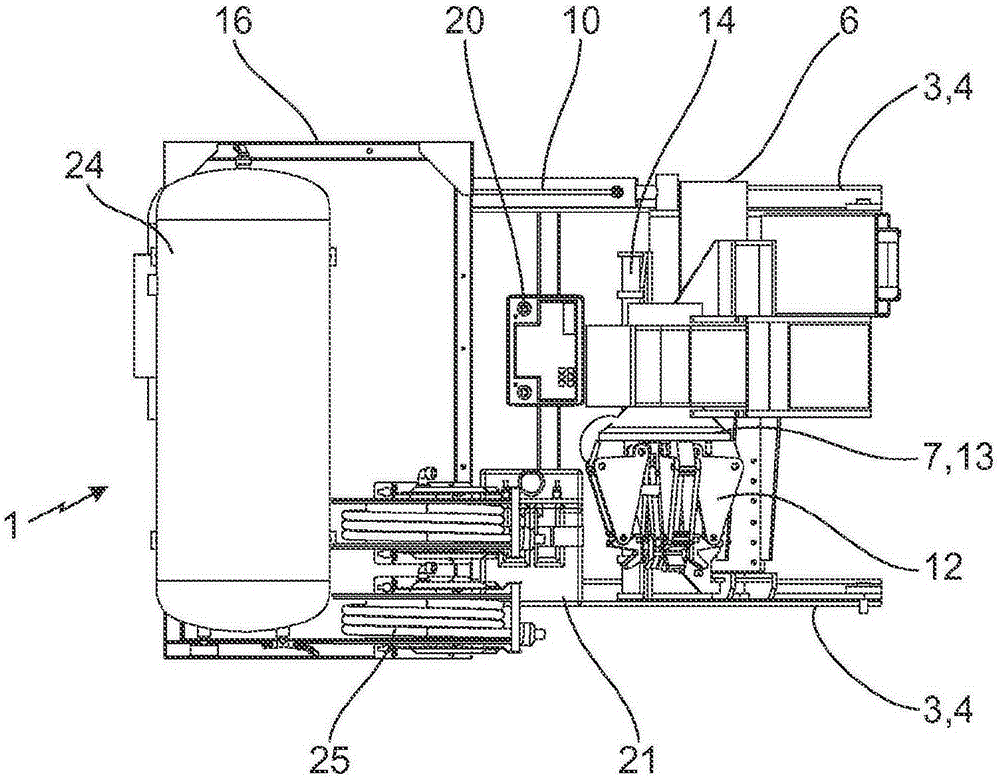

Onboard device for mounting/dismounting tyres of heavy goods vehicles

ActiveCN105209271AEasy to useEasy maintenanceItem transportation vehiclesTyre repairingOn boardHydraulic pump

The present invention concerns a device (1) for mounting / dismounting tyres installed on board a light utility vehicle, said device (1) comprising at least a first chassis (3), an arm (6) articulated to said chassis (3), a mandrel (7) rigidly connected to the free end of said arm (6) and arranged to secure a rim and rotate same about a first substantially horizontal axis of rotation, and a tool holder provided with at least one tool, said tool holder being telescopic and being capable of moving relative to said arm (6), said device (1) being characterised in that it comprises a heat engine rigidly connected to the first chassis (3) and a hydraulic pump directly coupled to said heat engine and designed to at least indirectly move the arm (6) and the tool holder in order to position the mandrel (7) and the tool in the respective work positions of same, and rotate the mandrel (7).

Owner:GUERNET COMPRESSEURS

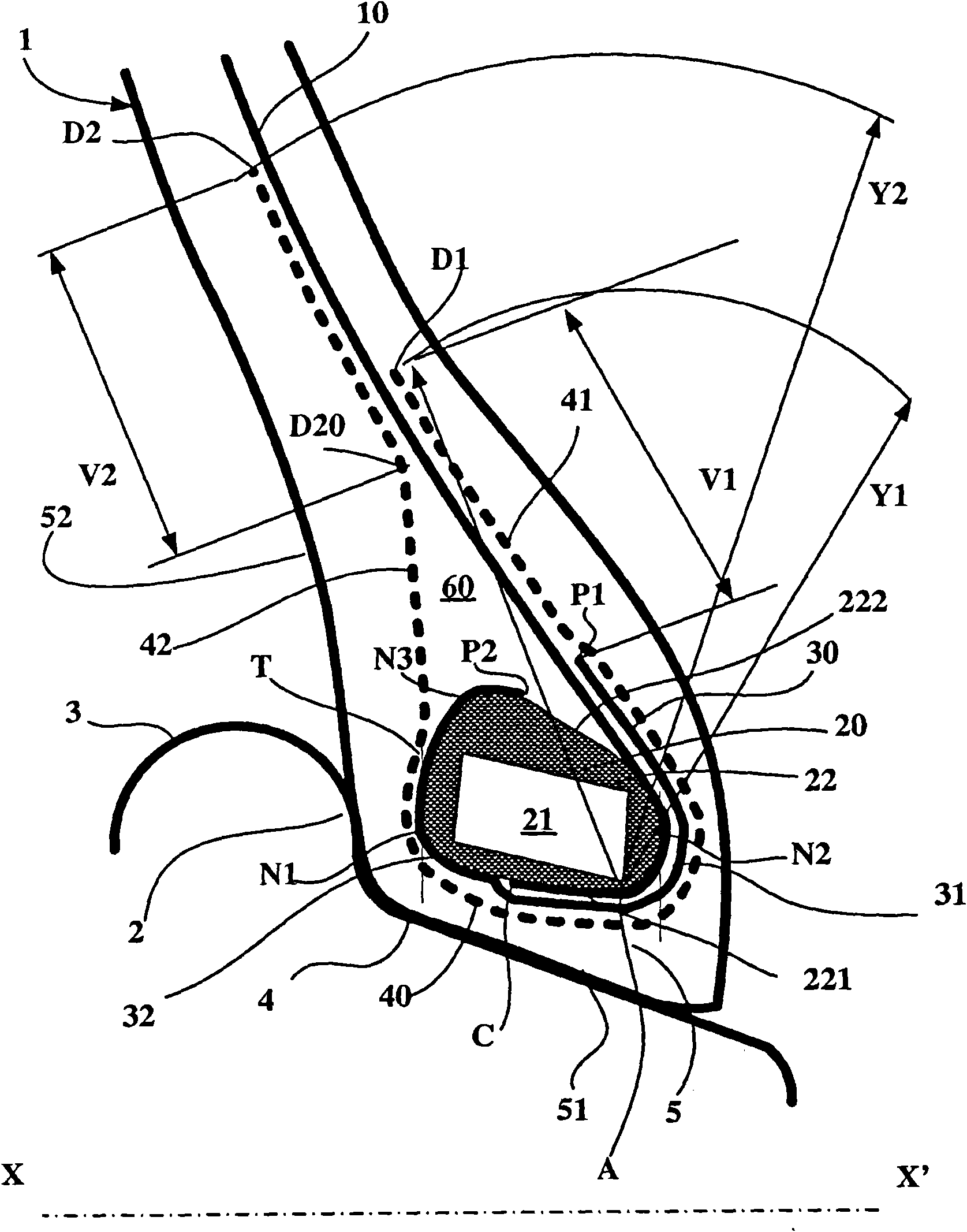

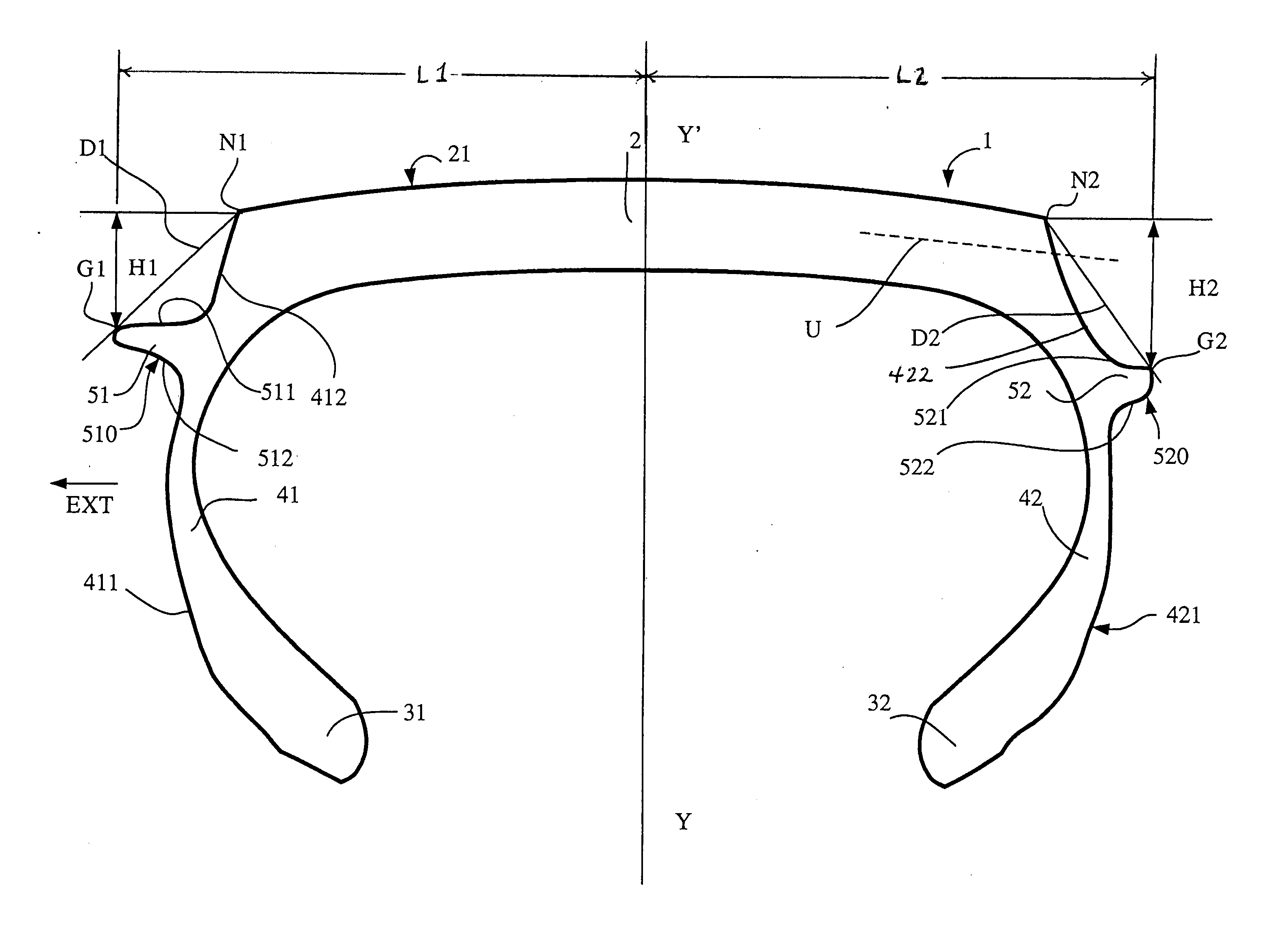

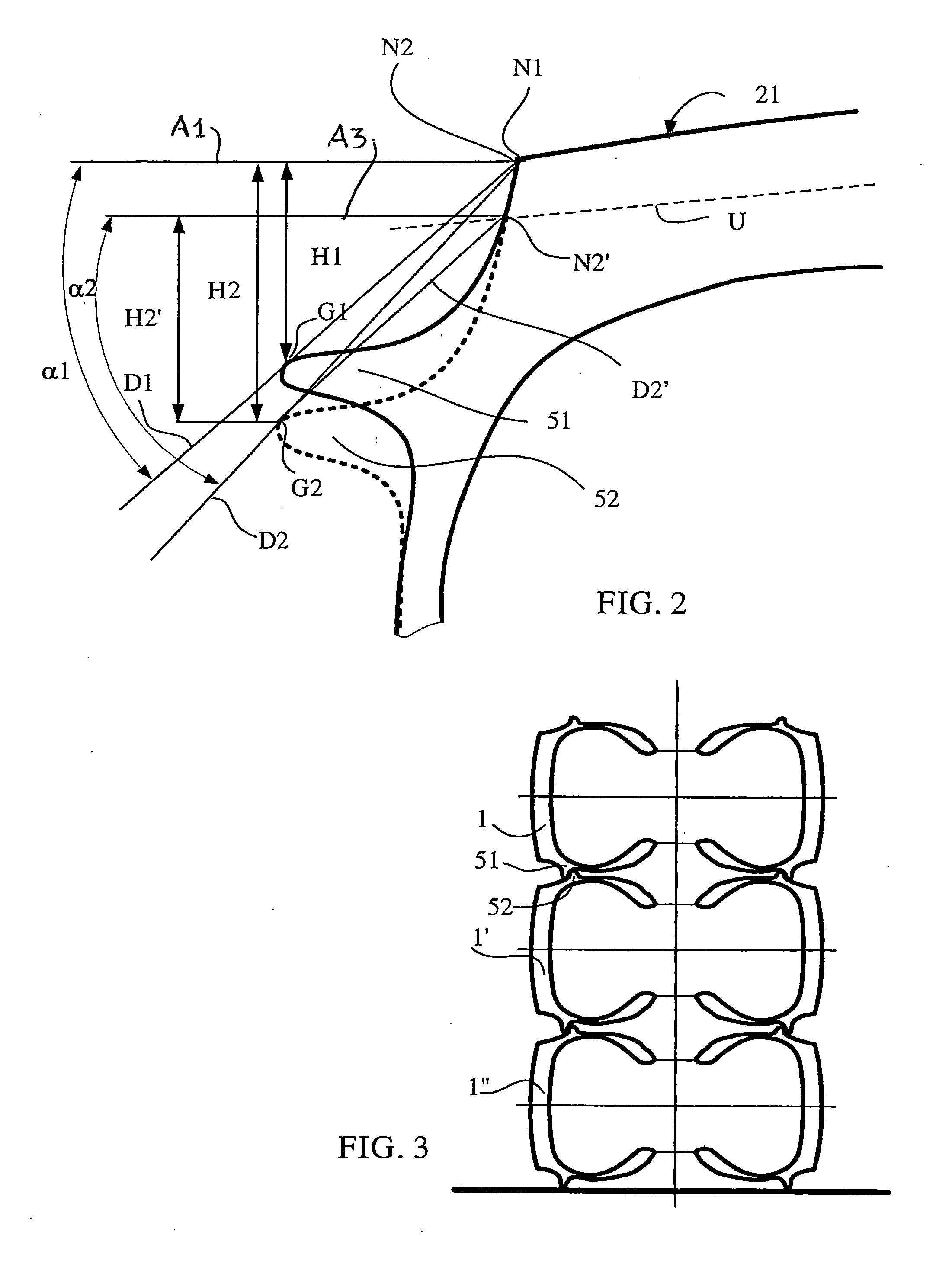

Tyre bead structure

InactiveCN101626908AAvoid risk of deteriorationRigid enoughTyre beadsWheelsEngineeringHeavy goods vehicle

Heavy goods vehicle tyre comprising: - a radial carcass reinforcement (10) anchored in each of the beads to an anchoring structure (20), this carcass reinforcement (10) being partially wrapped around an anchoring structure (20) from the inside of the tyre outwards, - a first connecting reinforcement (30) partially in contact with the carcass reinforcement (10) and wrapped around the anchoring structure (20) - a second connecting reinforcement (40) formed of a plurality of reinforcing members directed in an average direction that makes an angle of at most 50 degrees with the circumferential direction and envelopes the first connecting reinforcement (30) to form an inner strand (41) and an outer strand (42), the inner strand (41) being in contact over a length V1 with the carcass reinforcement between a first end point D1 of said first strand and the endpoint P1 of the first connecting reinforcement (30), the outer strand (42) being in contact with the carcass reinforcement from a point D20 as far as an end point D2 of the outer strand over a length V2, the points D1 and D2 being positioned radially beyond the end points P1, P2 of the first connecting reinforcement (30).

Owner:OCIETE DE TECH MICHELIN

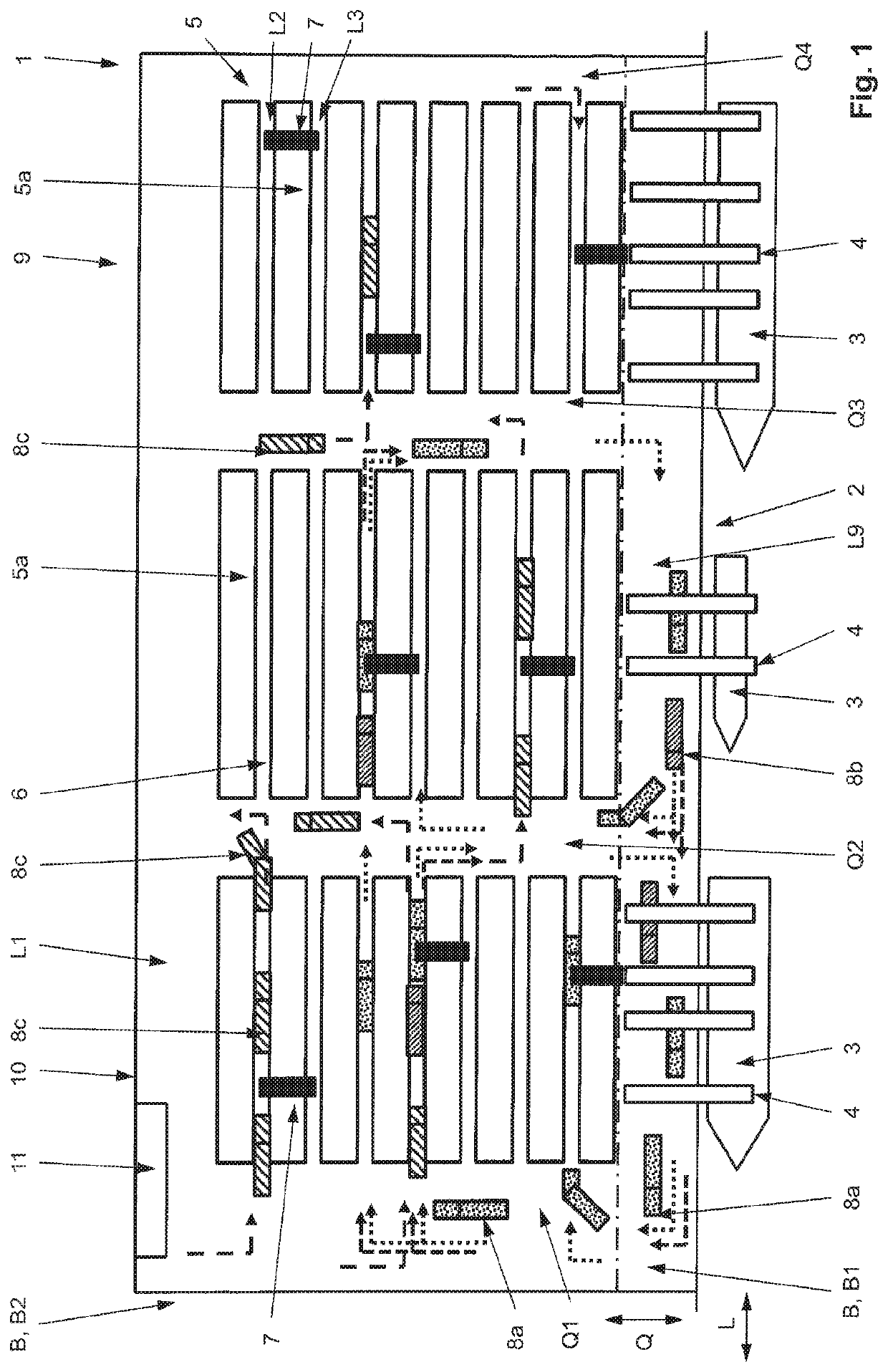

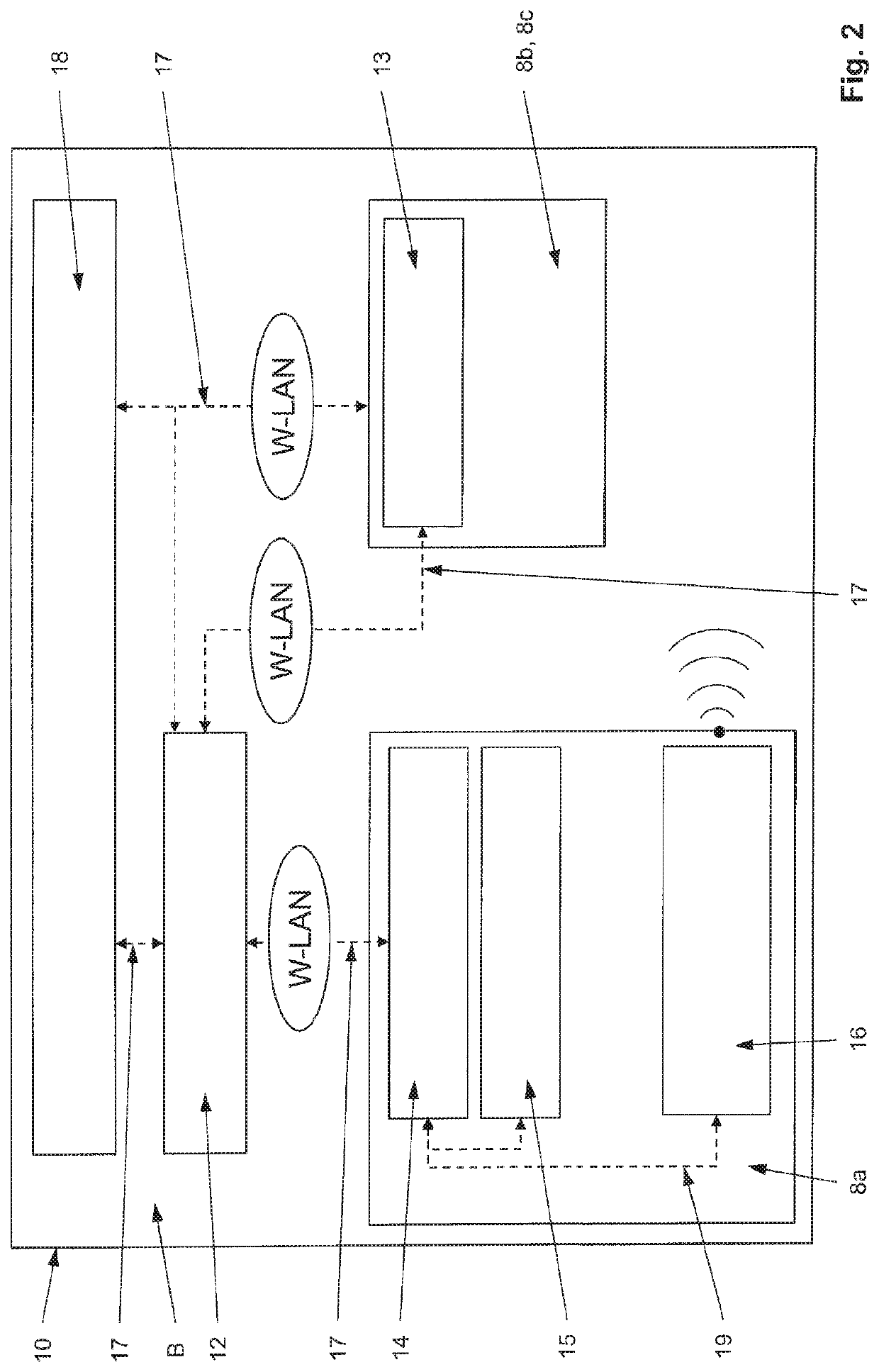

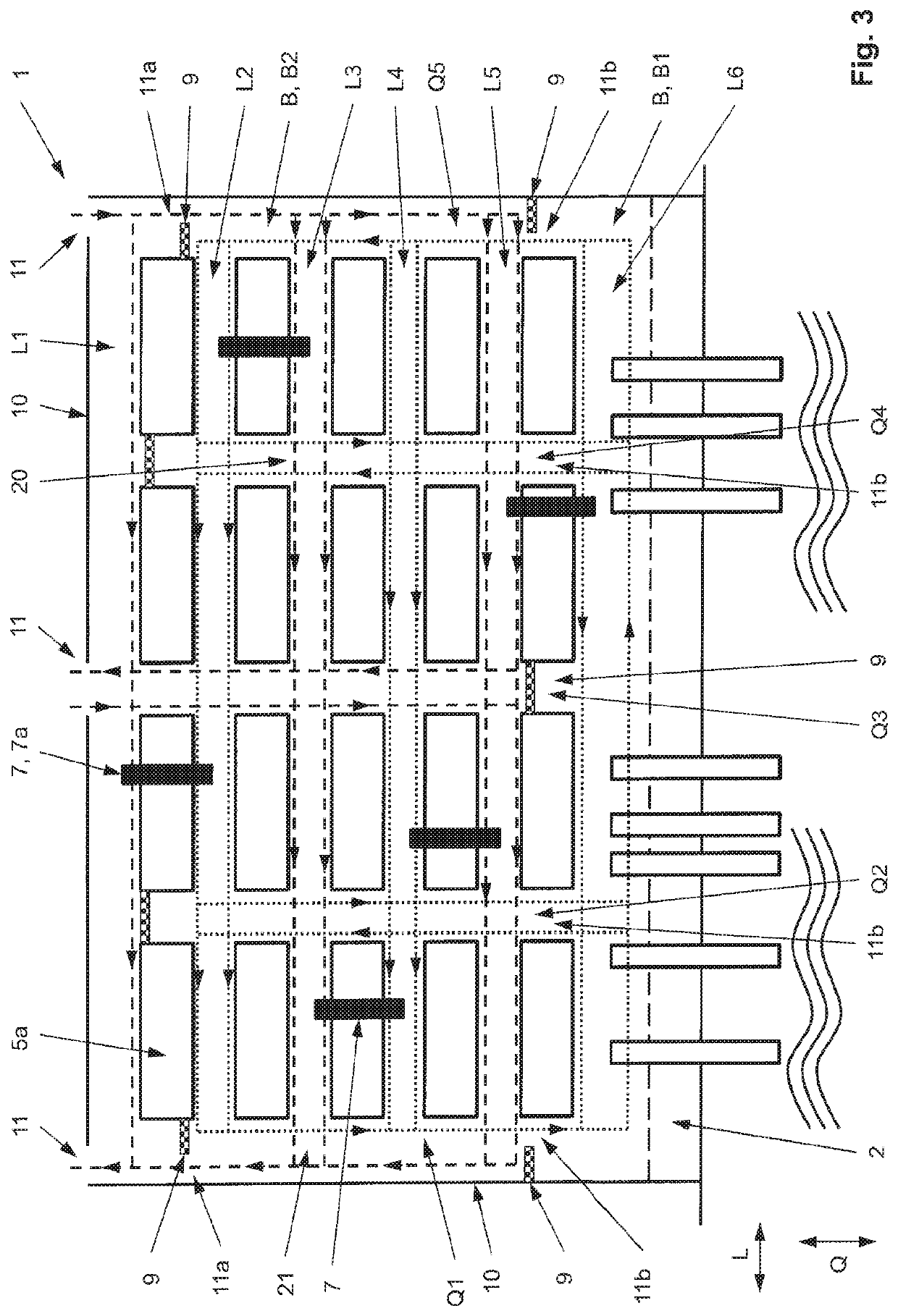

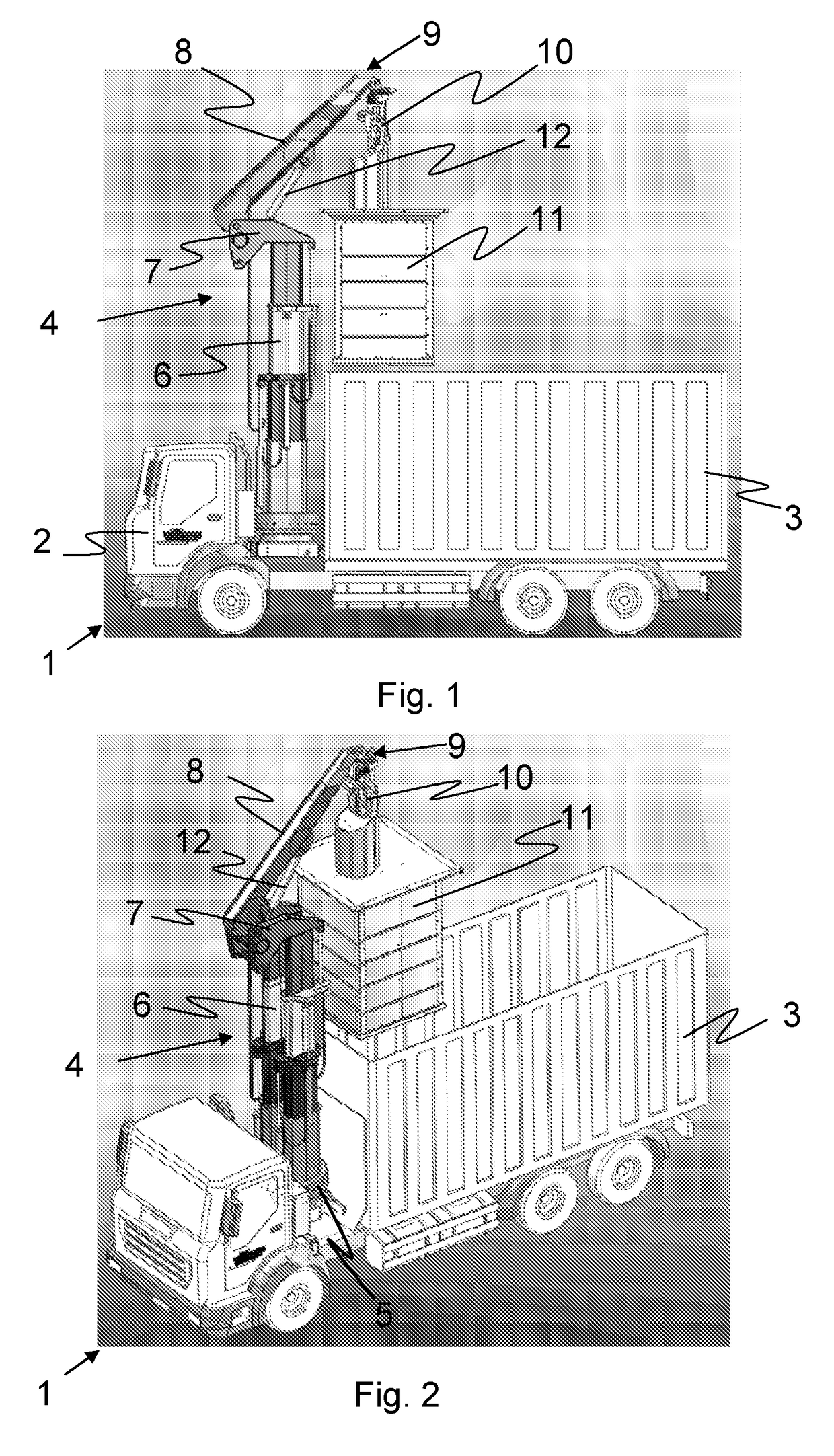

System for transporting containers, particularly iso containers, using heavy goods vehicles

ActiveUS20200307924A1Operated particularly safely and cost-effectivelySimple systemConveyorsLogisticsMechanical engineeringHeavy goods vehicle

A system for transporting containers using heavy goods vehicles having a separate operating region in which the heavy goods vehicles can be operated includes at least one first lane for at least one external heavy goods vehicle, and at least one second lane for at least one internal heavy goods vehicle are reserved in the separate operating region. The heavy goods vehicles can be operated together in a mixed traffic situation, and the first and second lanes are each guided through a transition region of a handling unit of a storage region and each arranged laterally in relation tothe storage region.

Owner:KONECRANES GLOBAL

Lightweight tyre

ActiveCN110799356AShort curing timeIncrease temperatureHeavy duty tyresHeavy duty vehicleClassical mechanicsEngineering

The invention concerns a heavy goods vehicle tyre, intended to be mounted on a hollow, 15-degree drop center rim. According to the invention, the two working crown layers alone constitute the crown reinforcement over at least 40% of the width of the tread, the absolute value of the difference between the absolute values of the angles [alpha]2 and [alpha]1 being greater than 4-degree, [alpha]2 being greater than [alpha]1 in absolute value, the mean angle [alpha] satisfying the relationship 14+131*exp(-L / 100) < [alpha] < 20+164*exp(-L / 100), and, in meridian cross-section of said tyre, the turnupof the carcass reinforcement layer and the main part of the carcass reinforcement layer are coupled and then uncoupled, and the turnup of the carcass reinforcement layer and the main part of the carcass reinforcement layer are the only layers of reinforcing elements of which the elongation at break is less than 6% present in the sidewall.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Tire Provided with Two Protuberances for Deflecting Lateral Expulsions of Water

ActiveUS20080196807A1Limit temperature riseEasy to stackTyre tread bands/patternsWheelsWater flowHeavy goods vehicle

Heavy goods vehicle tire including beads, sidewalls and a tread. To deflect the flow of water expelled laterally by this tire while running on a wet road, the tire is provided on each of its sidewalls, and near the tread, with a protuberance. One protuberance is positioned on the tire so as to be effective over a first period of use of the tire and the other protuberance is positioned on the tire so as to be effective after the tread has partially worn away, and after the worn tire has been reversed so as to place such other protuberance to the outside of the vehicle.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

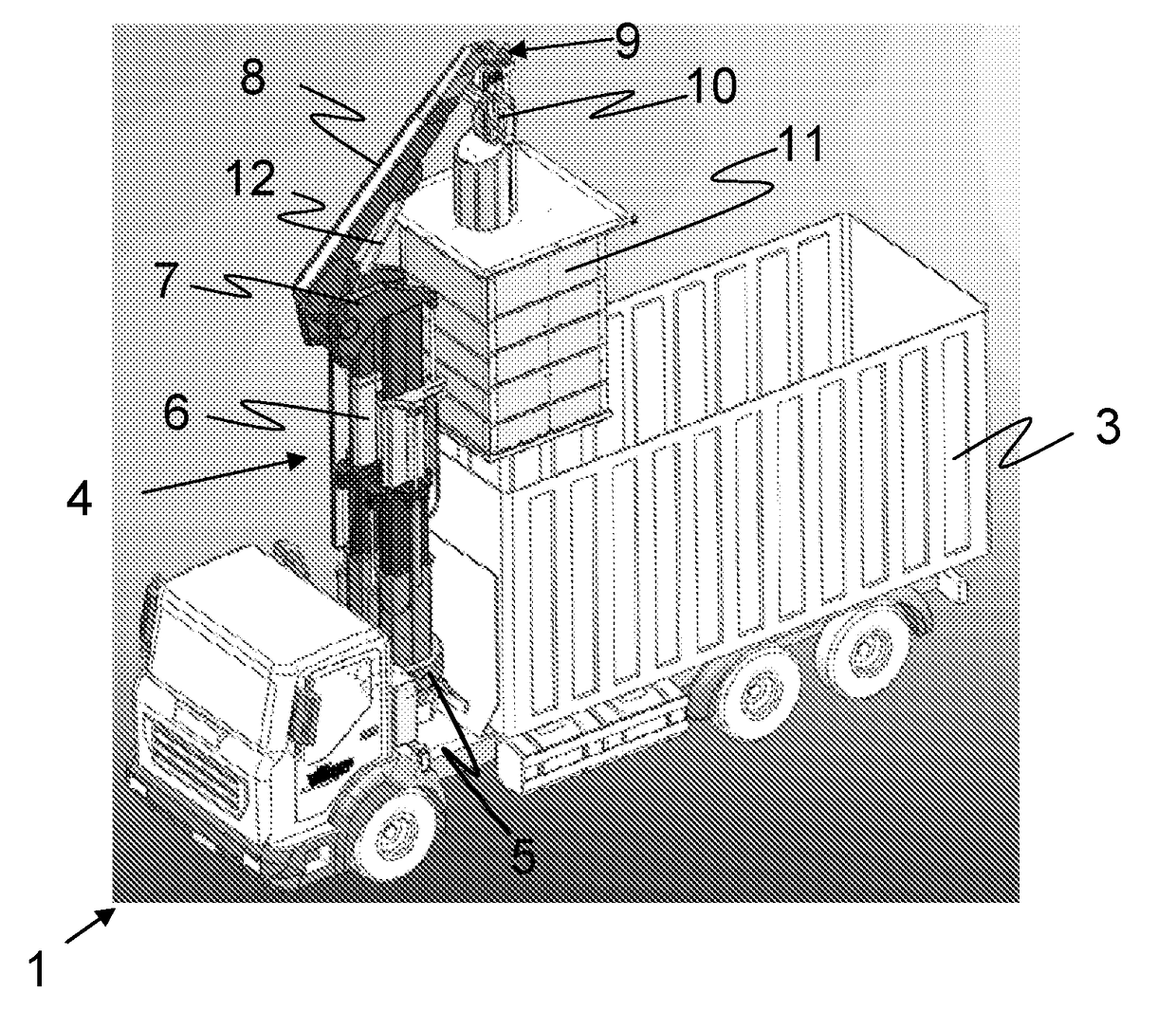

Lifting device on a lorry

ActiveUS20170183152A1Reduce riskIncreased torsional stiffnessVehicles with cranesRefuse vehiclesVertical planeWaste collection

A lifting device on a heavy goods vehicle is described, for lifting and emptying waste collection containers, having a telescopically extensible boom, which has a coupling tool for coupling to a waste collection container. An extensible support is attached on a rotating platform and has at least one interleaved, telescopically extensible profile, wherein the boom is provided at the upper end of the support with a pivot element between boom and support, so that the boom is pivotable in a vertical plane about a pivot axis. The extensible profile is designed as an internal runner having a fixed tube and runners having a polygonal footprint, and a carrier head is provided at the end of the support, which is formed as L-shaped having an overhanging carrier plate in relation to the support, which carrier plate has the pivot axis of the boom and a support for the pivot element.

Owner:VILLIGER PUBLIC SYST

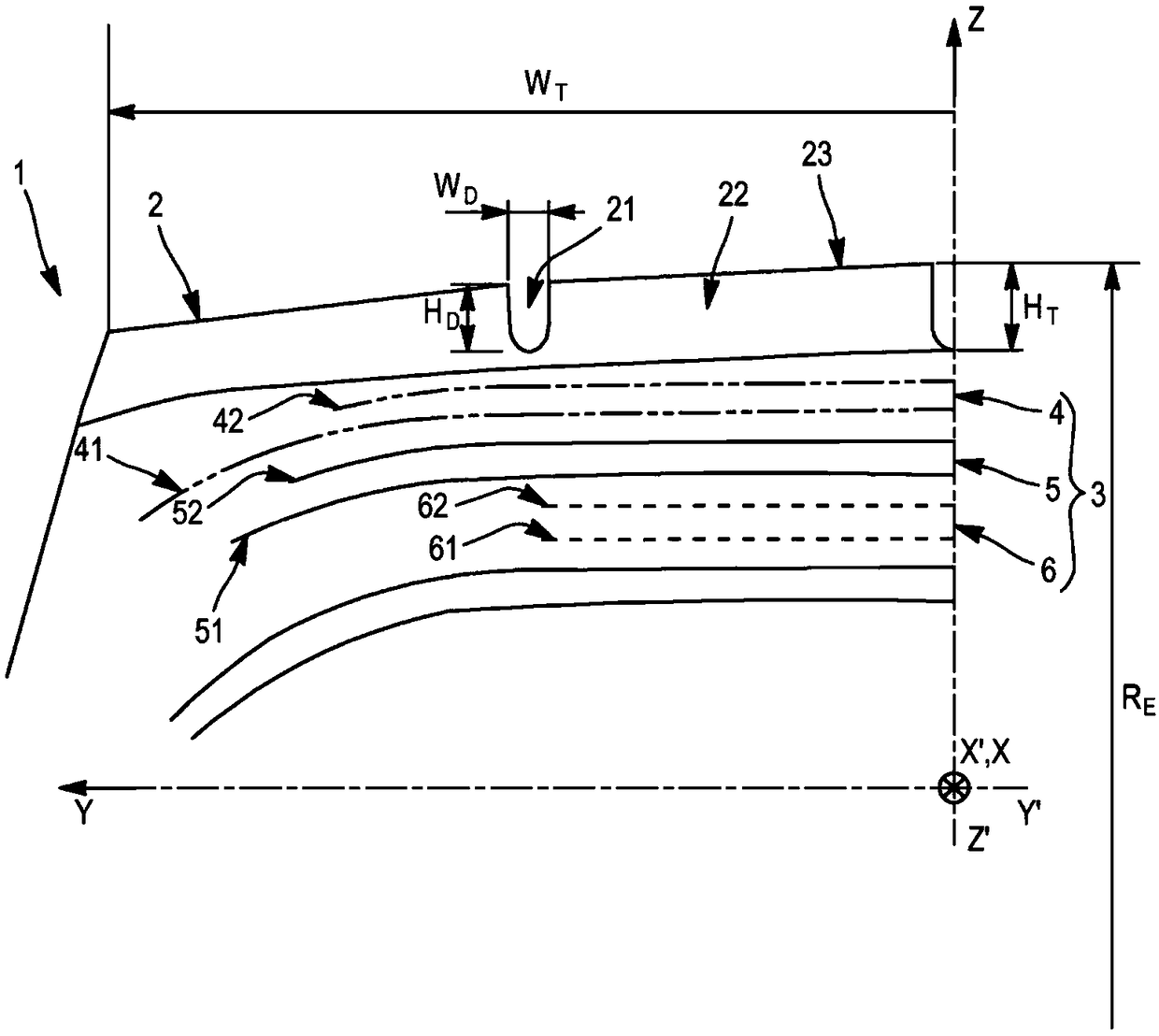

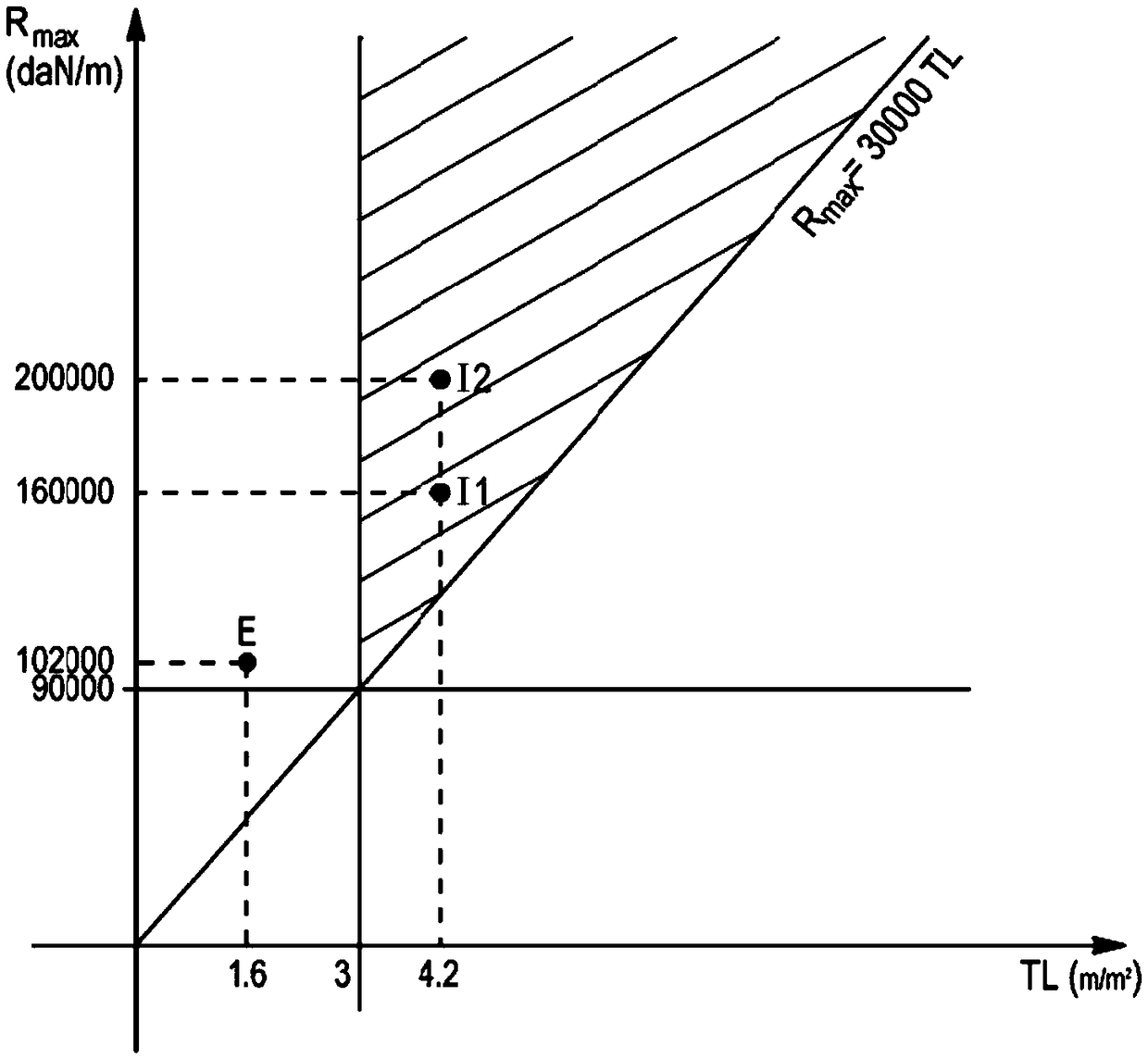

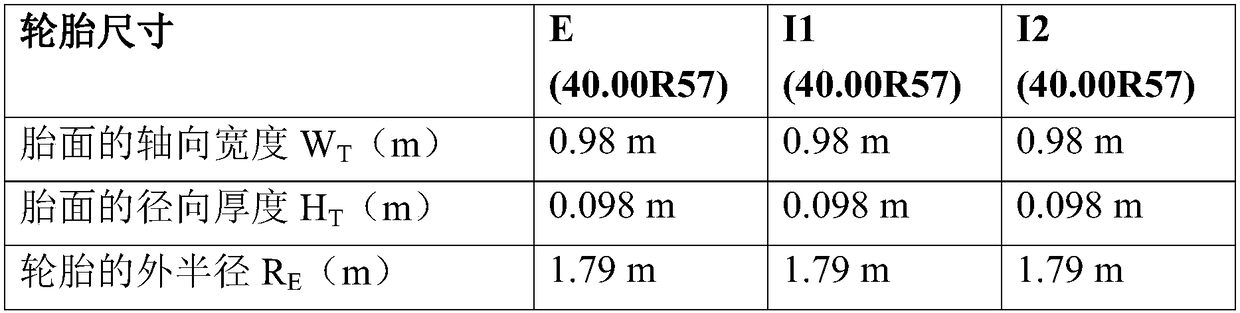

Tyre crown for heavy goods vehicle of the civil engineering type

ActiveCN108698449AHeavy duty tyresPneumatic tyre reinforcementsCoupling ratioUltimate tensile strength

The invention relates to the crown of a tyre for a heavy goods vehicle for civil engineering. The aim of the invention is to desensitise said crown to stress. To this end, the tyre (1) comprises a tread (2) having a surface siping rate TL, expressed in m / m 2, which is equal to the ratio of the cumulated length L D of the cuts (21) to the area A of the radially outer surface (23) of the tread (2),and a protective reinforcement (4) comprising at least two protective layers (41, 42) consisting of elastic metal reinforcing elements and having a maximum tensile strength R max, expressed in daN / m,such that the surface siping rate TL of the tread (2) is at least equal to 3 m / m 2, and a coupling ratio C, equal to the ratio of the maximum tensile strength R max to the surface siping rate, is at least equal to 30000 daN.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

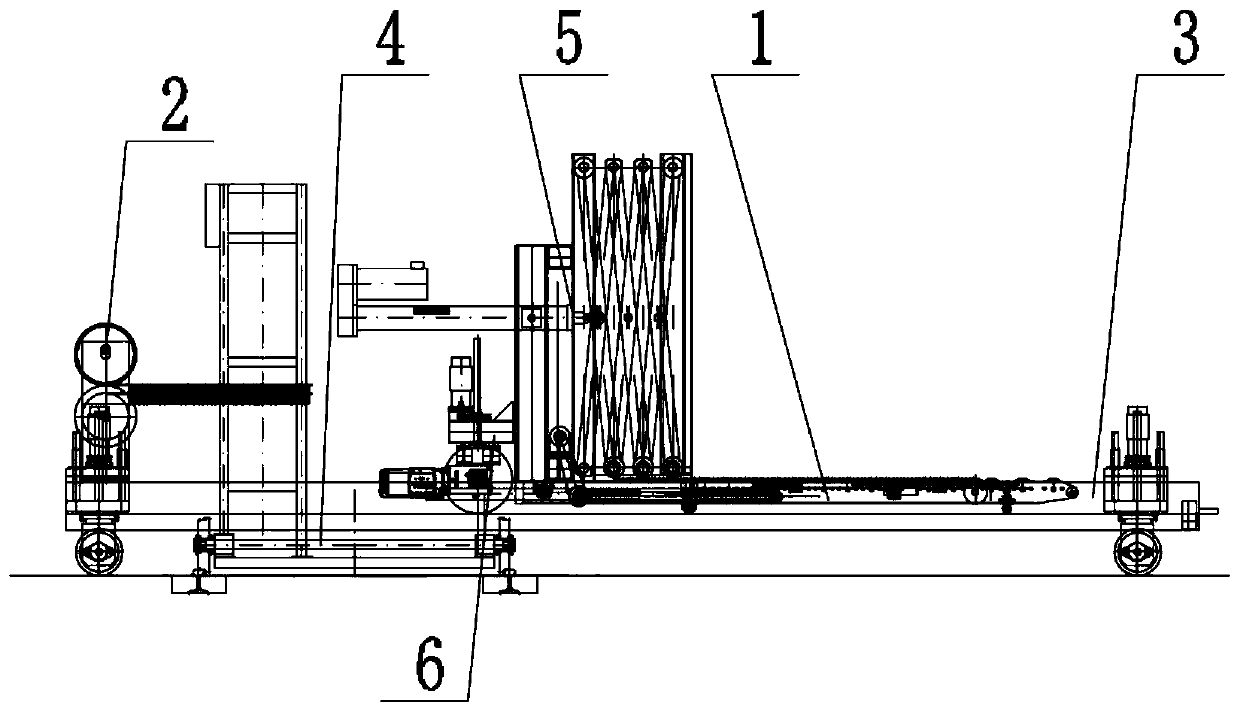

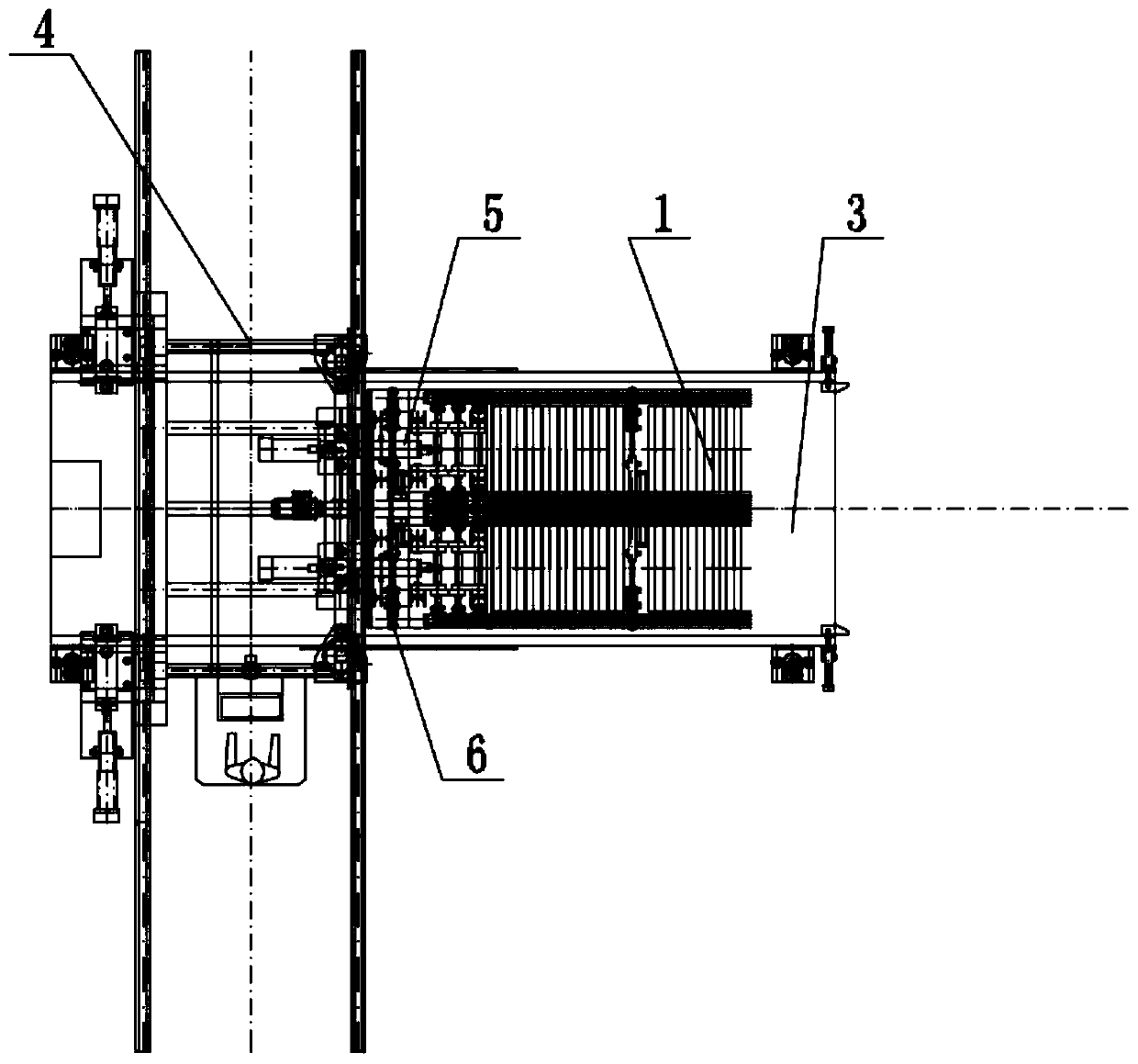

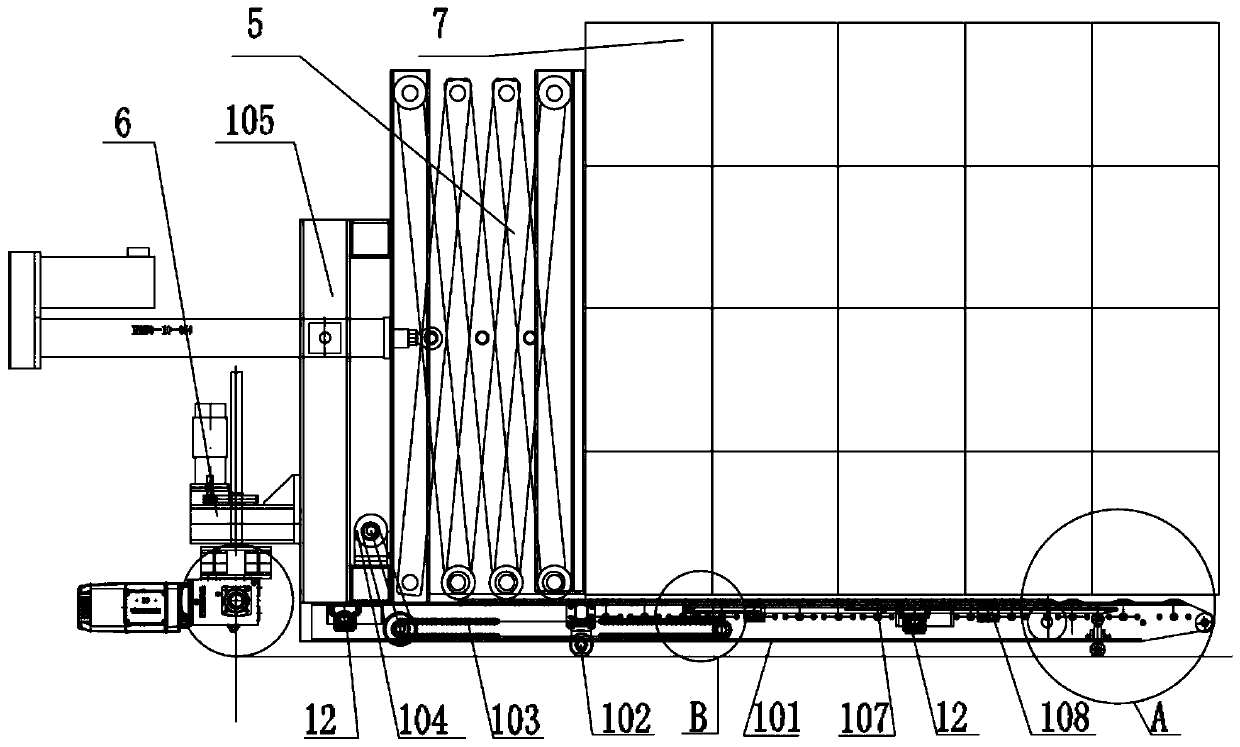

Large-scale truck tray-free automatic loader

PendingCN110155754AImprove automated shipment efficiencyRealize unmanned operationLoading/unloadingMechanical conveyorsMoving floorButt joint

The invention relates to a large-scale truck tray-free automatic loader which comprises a rail car, wherein a movable floor perpendicular to the moving direction of the rail car is connected onto therail car through a driving device; a flat car moving along the movable floor is mounted on the movable floor; a push plate mechanism moving in the horizontal and vertical directions is mounted on oneside of the flat car; an automatic height adjusting mechanism driving the flat car to go up and down integrally is connected onto the flat car; and a back-pulling mechanism mounted on the movable floor and driving the flat car to move is in butt joint with one side of the push plate mechanism. The large-scale truck tray-free automatic loader enables the carriage to be fully loaded automatically, does not need to mount a tray, doubles the efficiency or above compared with manual operation, and is high in control precision to solve the problem that the final loading stacking process has difficulty in realizing automation.

Owner:无锡宏盛智能装载技术有限公司

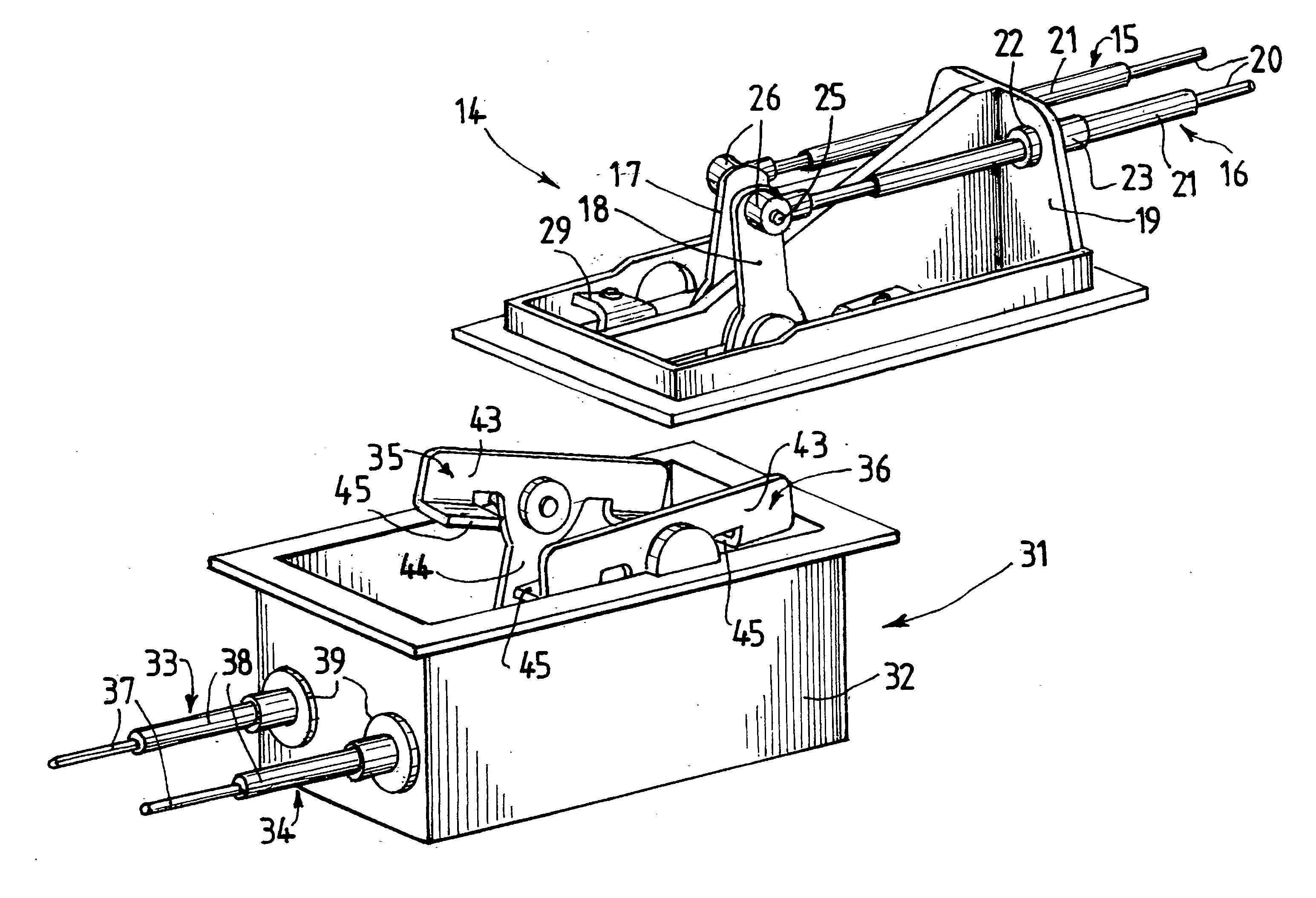

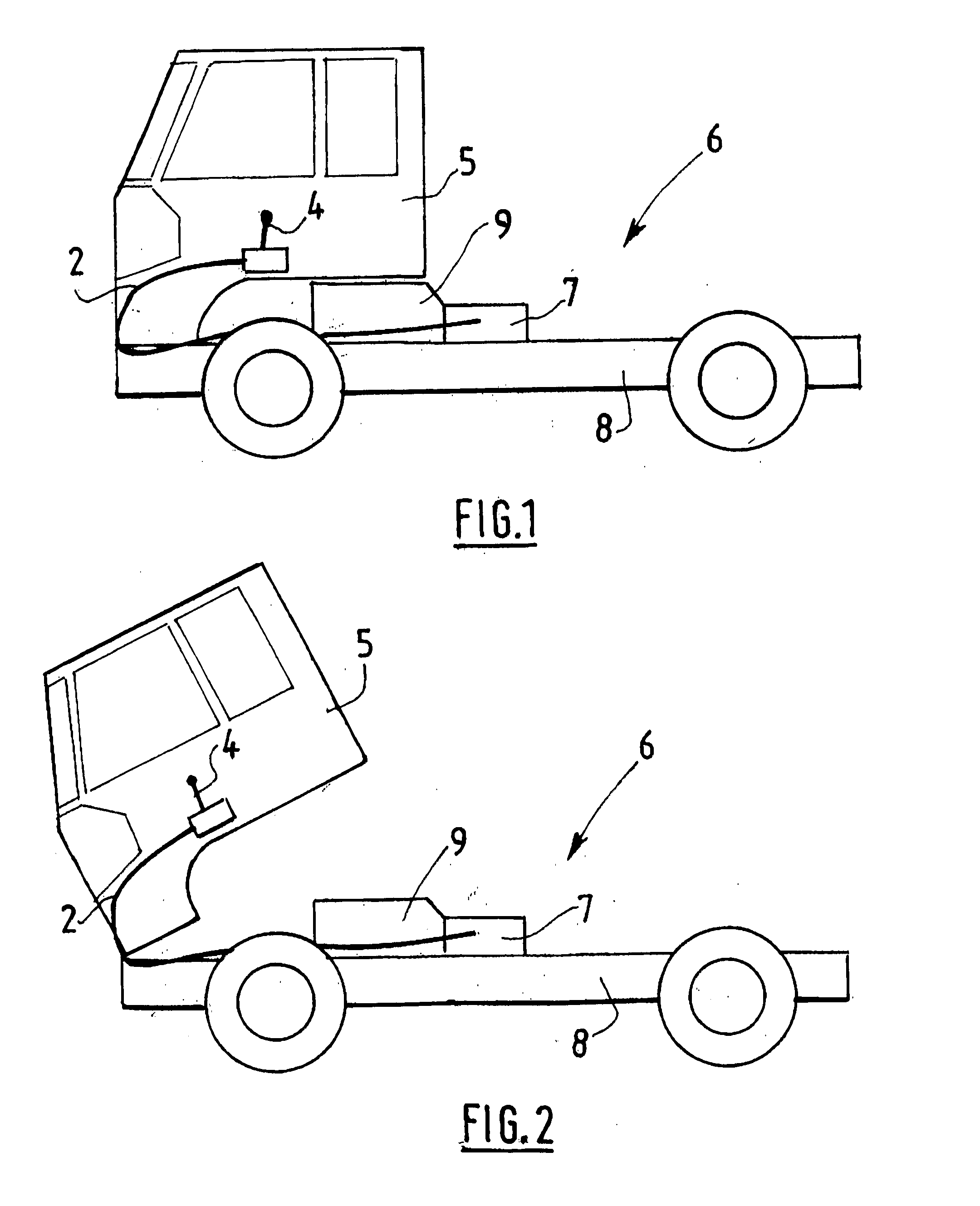

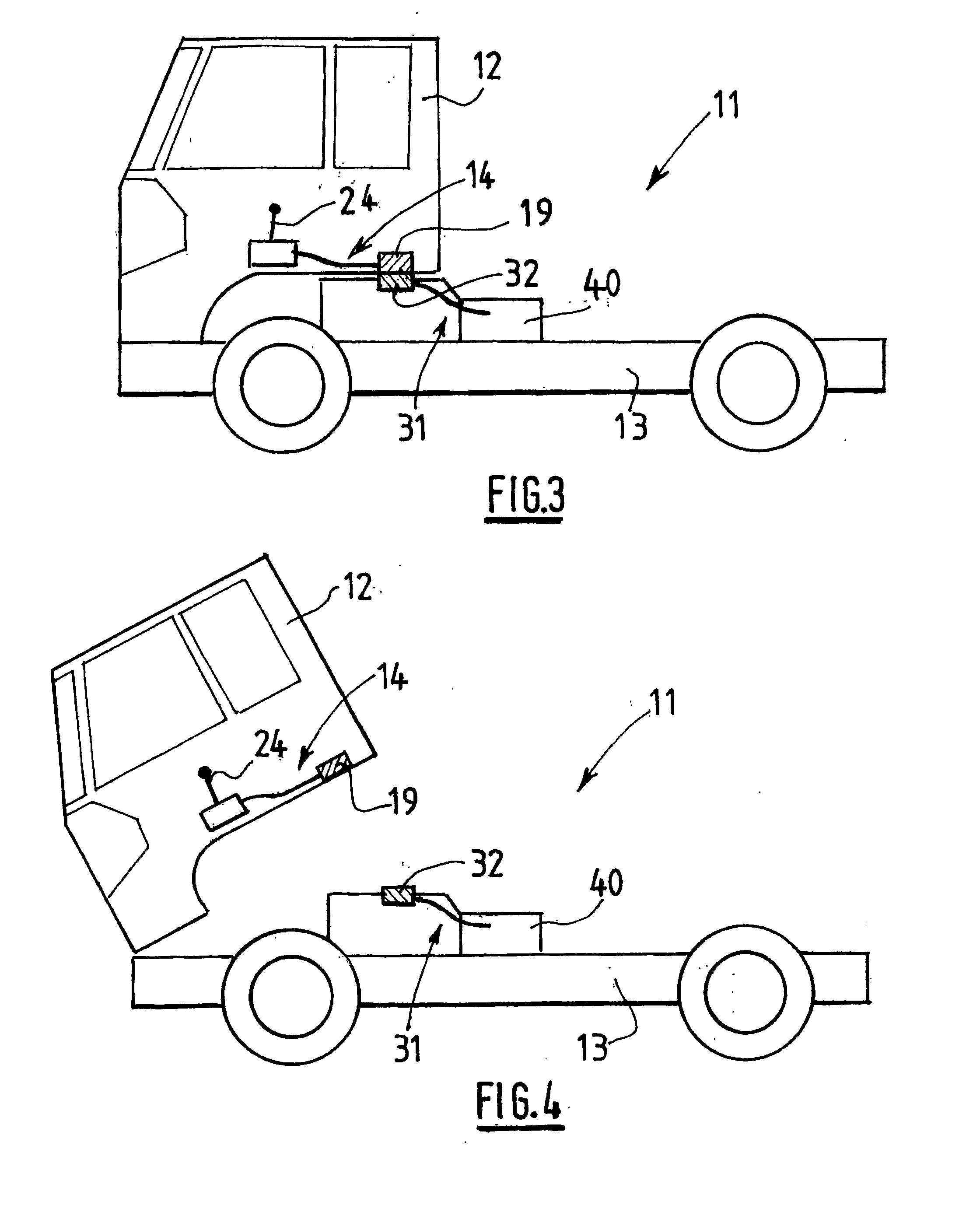

Cable and/or rod control system for a gearbox on a heavy goods vehicle with tilting cab

InactiveUS20110265596A1Simple structureEasy to installManual control with multiple controlled membersGearing controlNacelleControl system

The invention relates to a control system, comprising—a first assembly (14), fitted to the cabin (12) of the heavy goods vehicle (11) with at least one control cable, one end of which is designed to be fitted to a gear lever (24) of the heavy goods vehicle, the other end being connected to a operating means such as to move the operating means between first and second positions on a movement of the gear lever (24) by a user, a second assembly (31) mounted on the chassis (13) of the heavy goods vehicle (11) and comprising at least one control cable, one end of which is connected to an operating means and the other end of which is designed to be connected to a gearbox (40) of the heavy goods vehicle such as to bring about a change of gear ratio on a movement of the operating means between the first and second positions, the two operating means cooperating with each other in the operating position of the cabin such that a movement of the operating means of the first assembly (14) brings about a movement of the operating means of the second assembly (31).

Owner:SOC EURO DE FAB IND SEFI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com