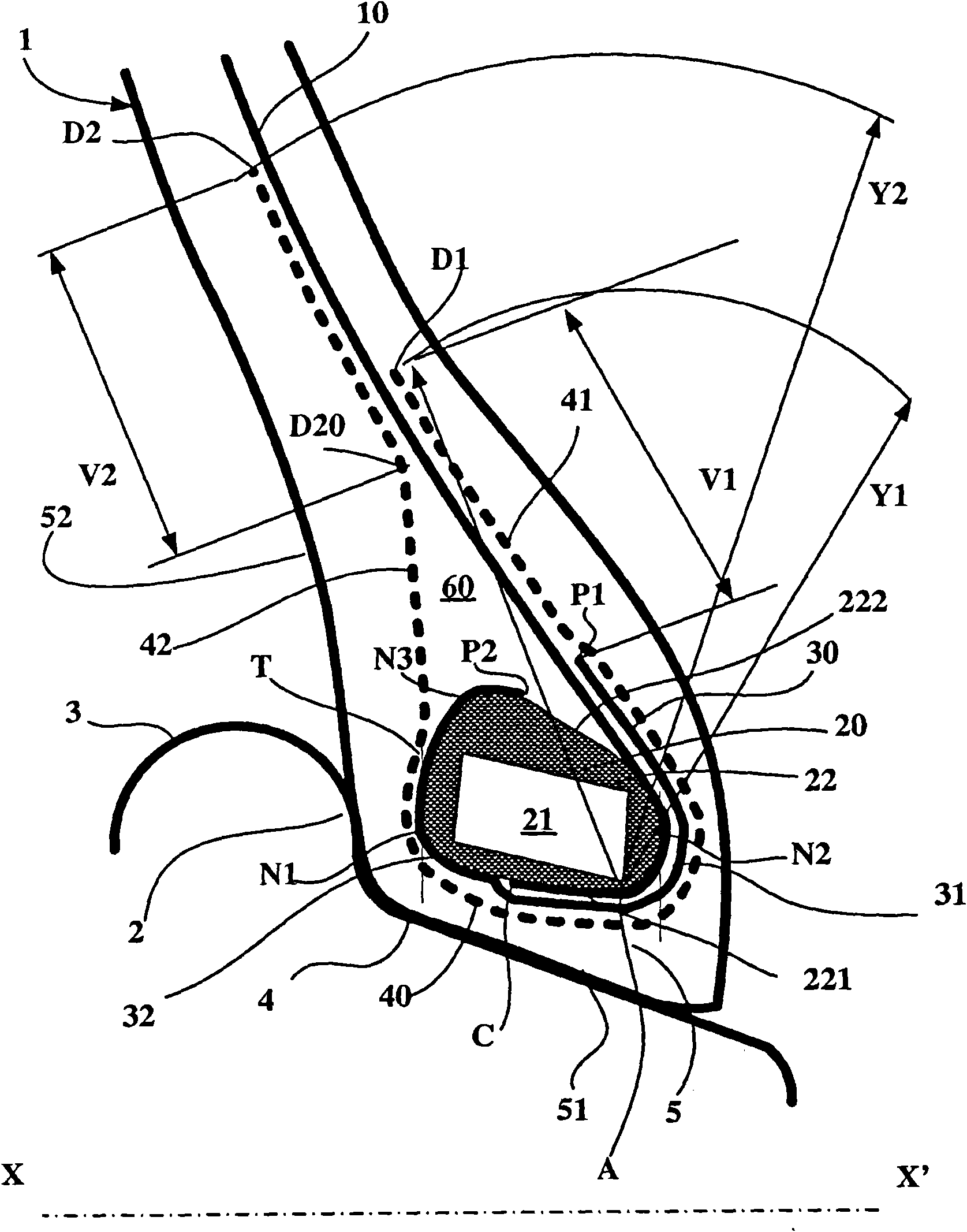

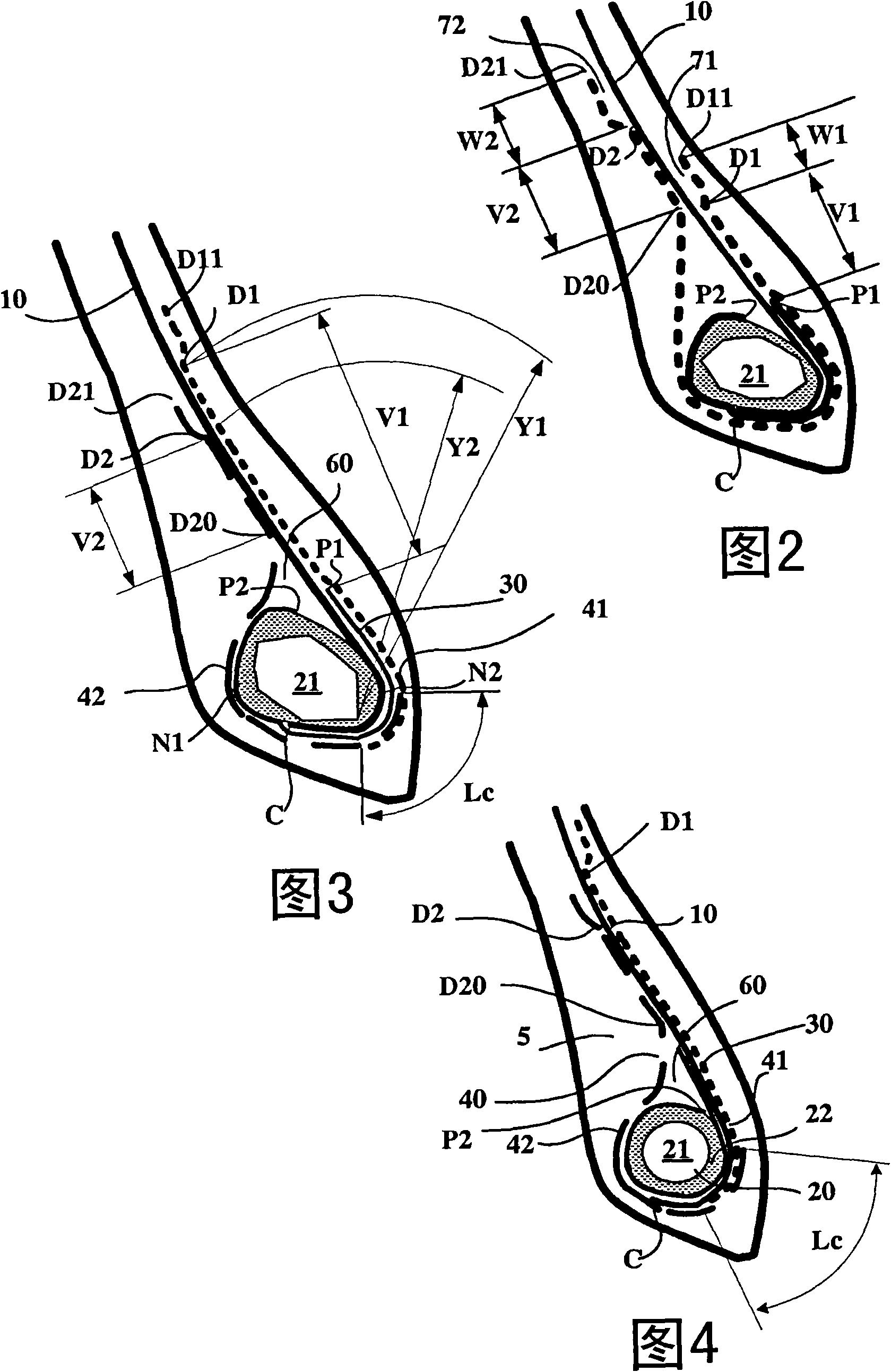

Tyre bead structure

A tire and bead technology, applied to tire parts, bead, wheels, etc., can solve expensive and difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] definition:

[0029] "Radial" refers to the direction perpendicular to the axis of rotation.

[0030] "Awarded / located on the outside in the radial direction" means a direction perpendicular to and away from the axis of rotation.

[0031] "Toward / inward in the radial direction": refers to a direction perpendicular to and approaching the axis of rotation.

[0032] "Towards / located in the axial direction": refers to the direction parallel to the axis of rotation and pointing to the inside of the chamber in which the tire inflation pressure is applied.

[0033] "Inside of the tire" means the inside of the tire chamber in which inflation pressure is applied.

[0034] "Meridian section or meridian section" corresponds to a cross section through the tire such that the section contains the axis of rotation of the tire.

[0035] When the reinforcement is mainly contained in the meridian section, it is referred to as "radial orientation". By extension, reinforcements that form an angle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com