Swivel Drive

A rotary drive and machine technology, applied in the direction of rotating bearings, anti-centrifugal force rotating parts, moving/orienting solar collectors, etc., can solve the problem of insufficient inspection and achieve the effect of reducing weight and stabilizing the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

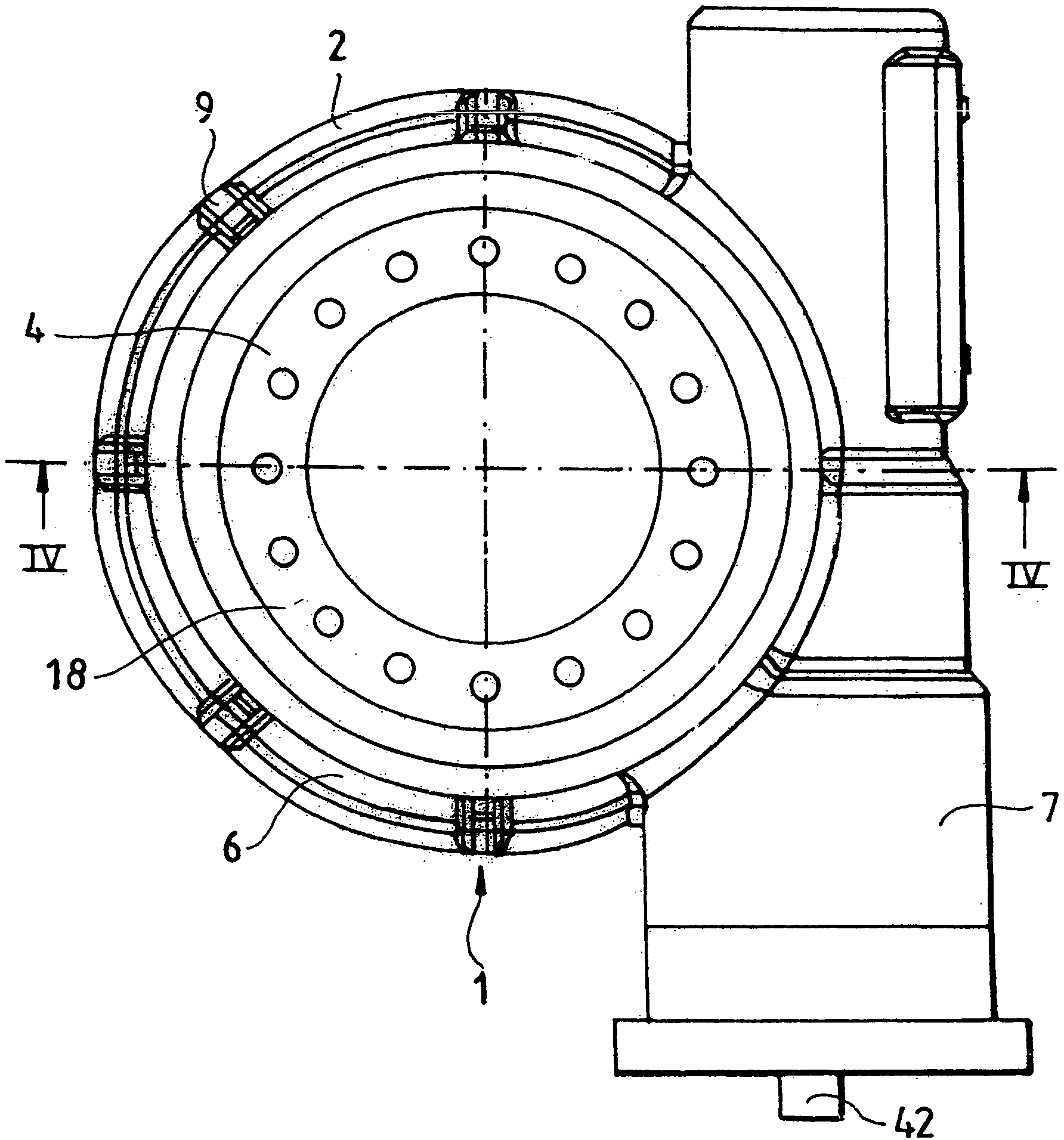

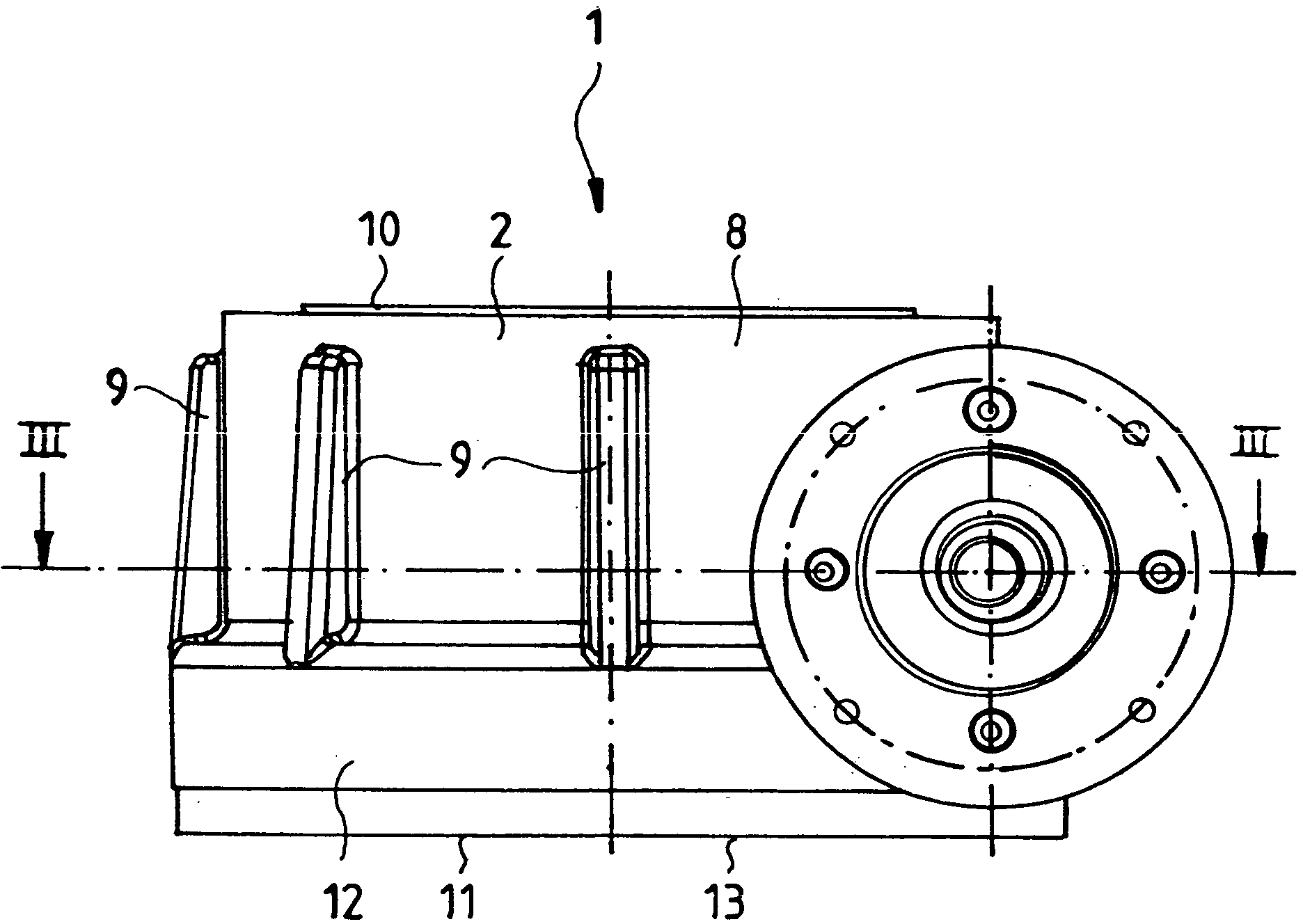

[0037] The device 1 according to the invention for driving one part of a machine or plant in rotation relative to another part of the plant or a base or chassis shows a particularly simple structure, namely a housing 2 in which a worm 3 and a turbine 4 are connected in Pivot in a rotatable way.

[0038] according to figure 1 The plan view of the housing 2 shows the two main parts of the housing 2, namely, the first annular housing part 6 which accommodates the turbine 4 concentric with the axis of revolution 5 of the rotary drive 1, and the housing part 6 for housing the worm The second straightly extending housing part 7 of 3.

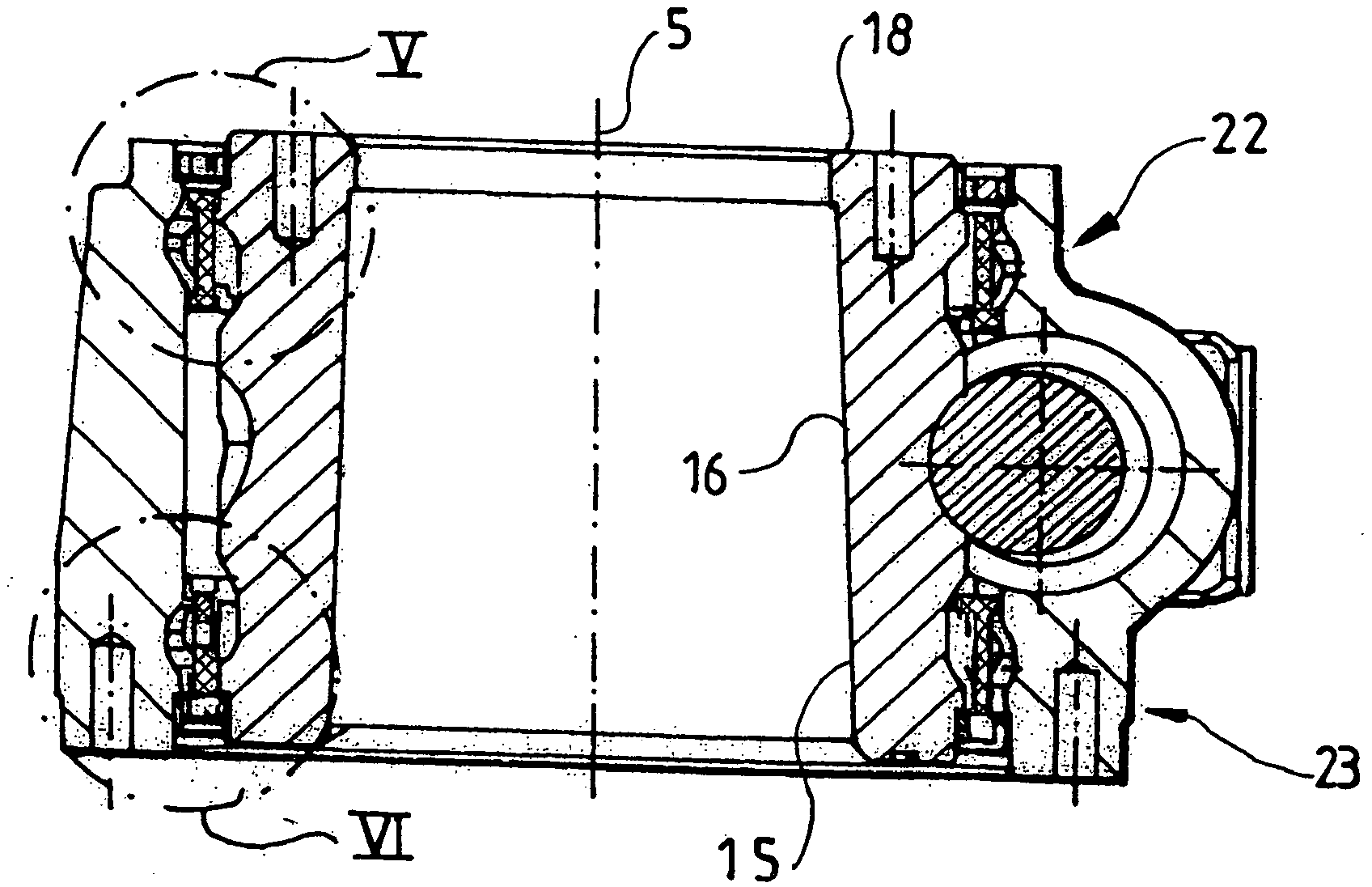

[0039] Figure 4 The cross-sectional view in FIG. 2 indicates the structure of the annular housing part 6 : said annular housing part 6 has a sleeve-like geometry substantially without a base or closure plate at its underside and without a cover at its upper side. As a distortion of the purely cylindrical geometry, some stiffening ribs 9 parallel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com