Lightweight tyre

A technology for tires and carcass, which is applied to heavy tires, tire parts, tire edges, etc. It can solve the problems of changing tire performance and increasing production costs, achieving light crown and bead areas, reducing curing time, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

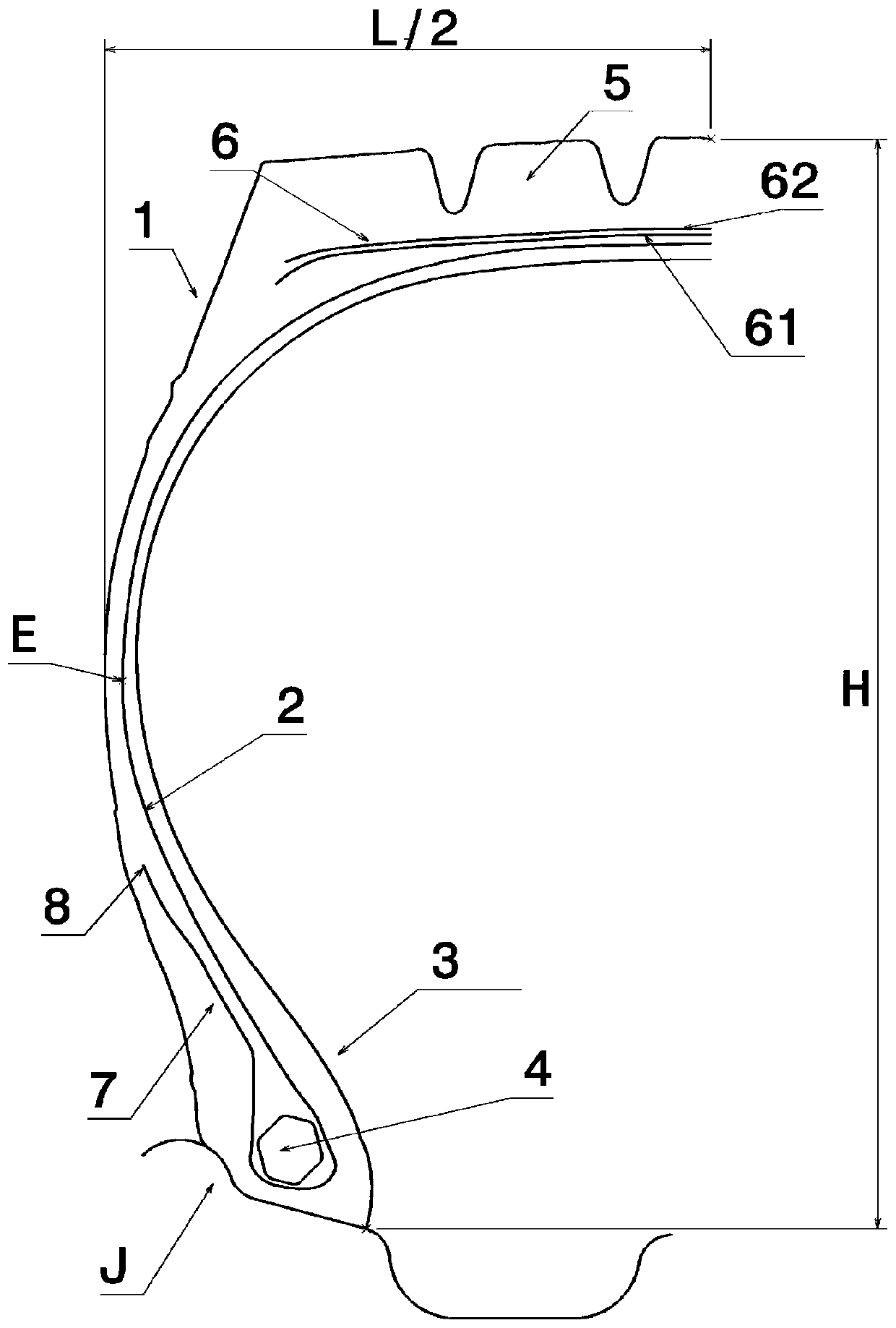

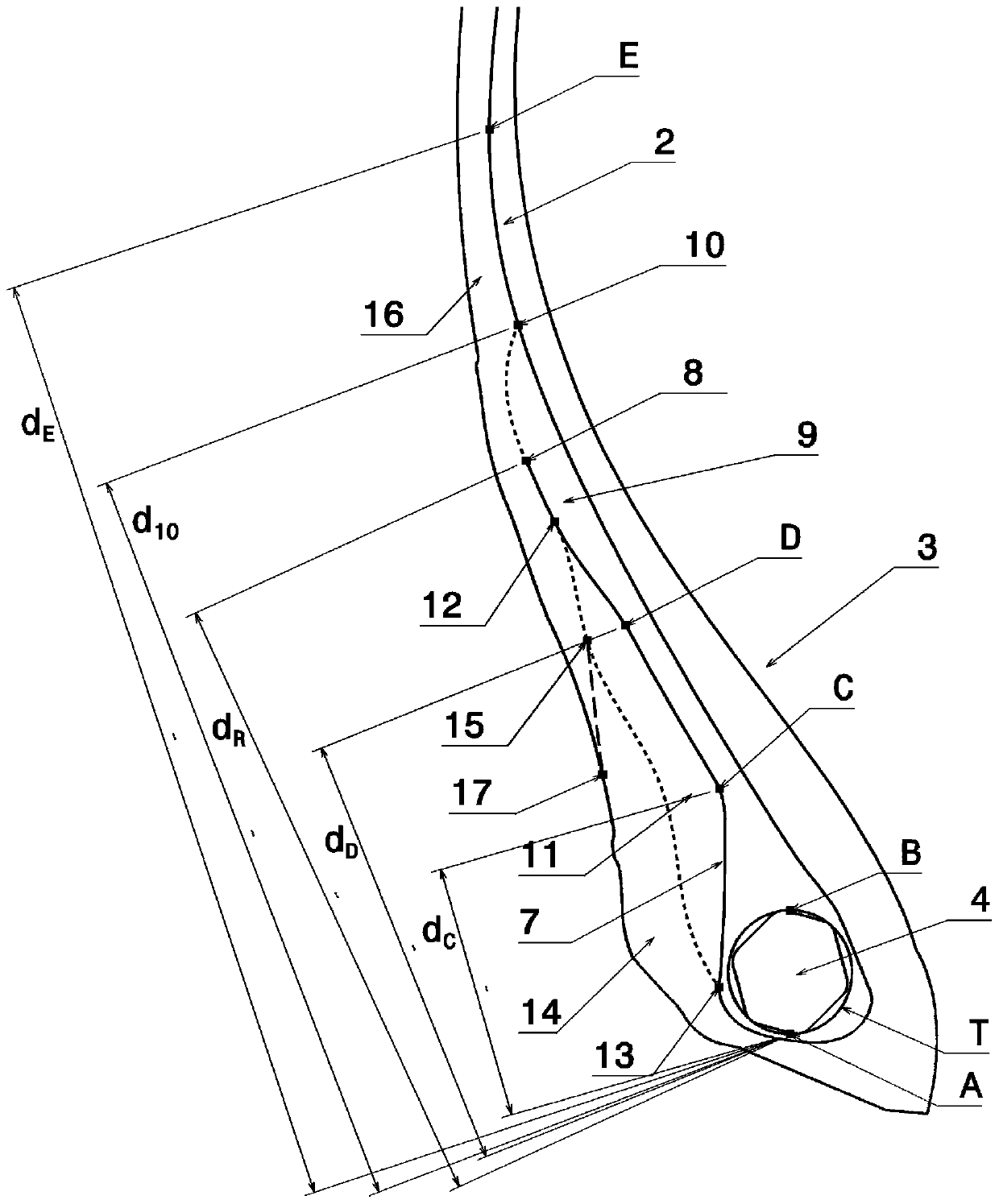

[0125] In order to make them easier to understand, the figures are not shown to scale.

[0126] figure 1 Only a half-view of a tire is shown, which extends symmetrically with respect to an axis XX' representing its circumferential mid-plane or equatorial plane.

[0127] figure 1 A tire 1 of size 12R 22.5 is shown. Said tire 1 comprises a radial carcass reinforcement 2 anchored in two beads. A carcass reinforcement 2 formed of a single layer of metal cords is wound around a bead wire 4 in each bead 3 and a turn-up 7 of the carcass reinforcement having an end 8 is formed in each bead 3 . The tire also has a tread 5 .

[0128] exist figure 1 , the carcass reinforcement 2 is hooped according to the invention by a crown reinforcement 6 formed radially from the inside to the outside by:

[0129] - a first working layer 61 formed by metal cords oriented at an angle equal to 16°,

[0130] - a second working layer 62 formed of metal cords oriented at an angle equal to 30° and cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com