Heavy goods vehicle tyre

A technology for tires and tire crowns, applied to wheels, vehicle parts, tire parts, etc., can solve problems such as tire damage, delay the appearance and/or spread of cracks, and improve resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

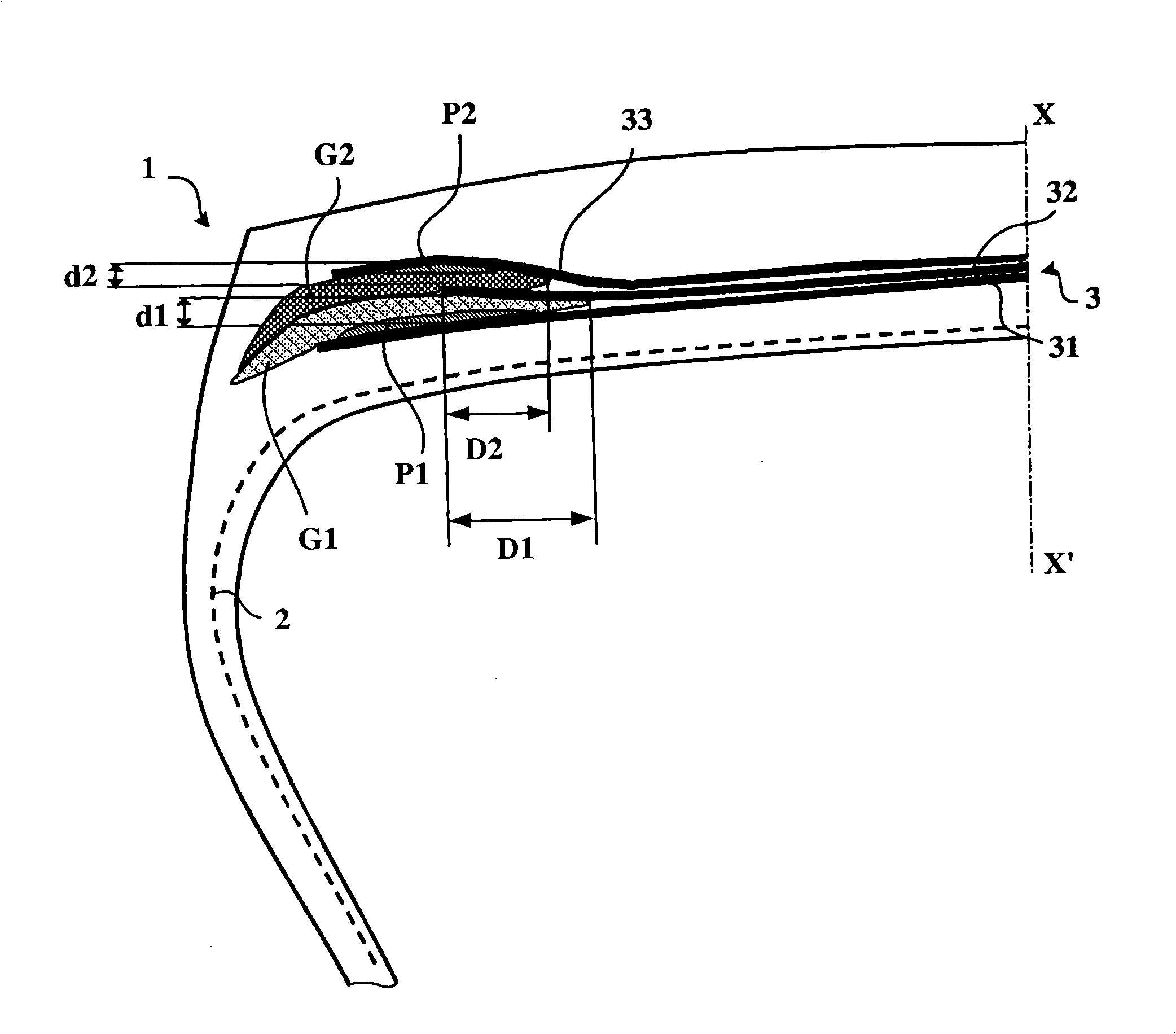

[0049] figure 1 A partial schematic view in meridian section of a tire 1 of size 40.00R57 is shown.

[0050] The tire 1 comprises a radial carcass reinforcement 2 fixed in each bead; said beads are not shown in the figures. This radial carcass reinforcement is covered radially outwards on top of it with a crown reinforcement 3 comprising, radially from the inside to the outside:

[0051] - a first working crown ply 31 formed by inextensible metal cords made of steel forming an angle α1 equal to 18° with the circumferential direction;

[0052] - a layer of rubber compound P1 radially outside and in contact with the first working crown ply 31 ;

[0053] - a layer of rubber compound G1 radially outside and in contact with the layer of rubber compound P1;

[0054] - radially outside the layer of rubber compound G1, a second working crown ply 32 formed of the same metal cords as those of the first working crown ply 31 forming an angle with the circumferential direction α1 oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com