Tyre crown for heavy goods vehicle of the civil engineering type

A technology for heavy-duty vehicles and tires, used in heavy-duty tires, tire treads/tread patterns, vehicle components, etc., to solve problems such as attacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

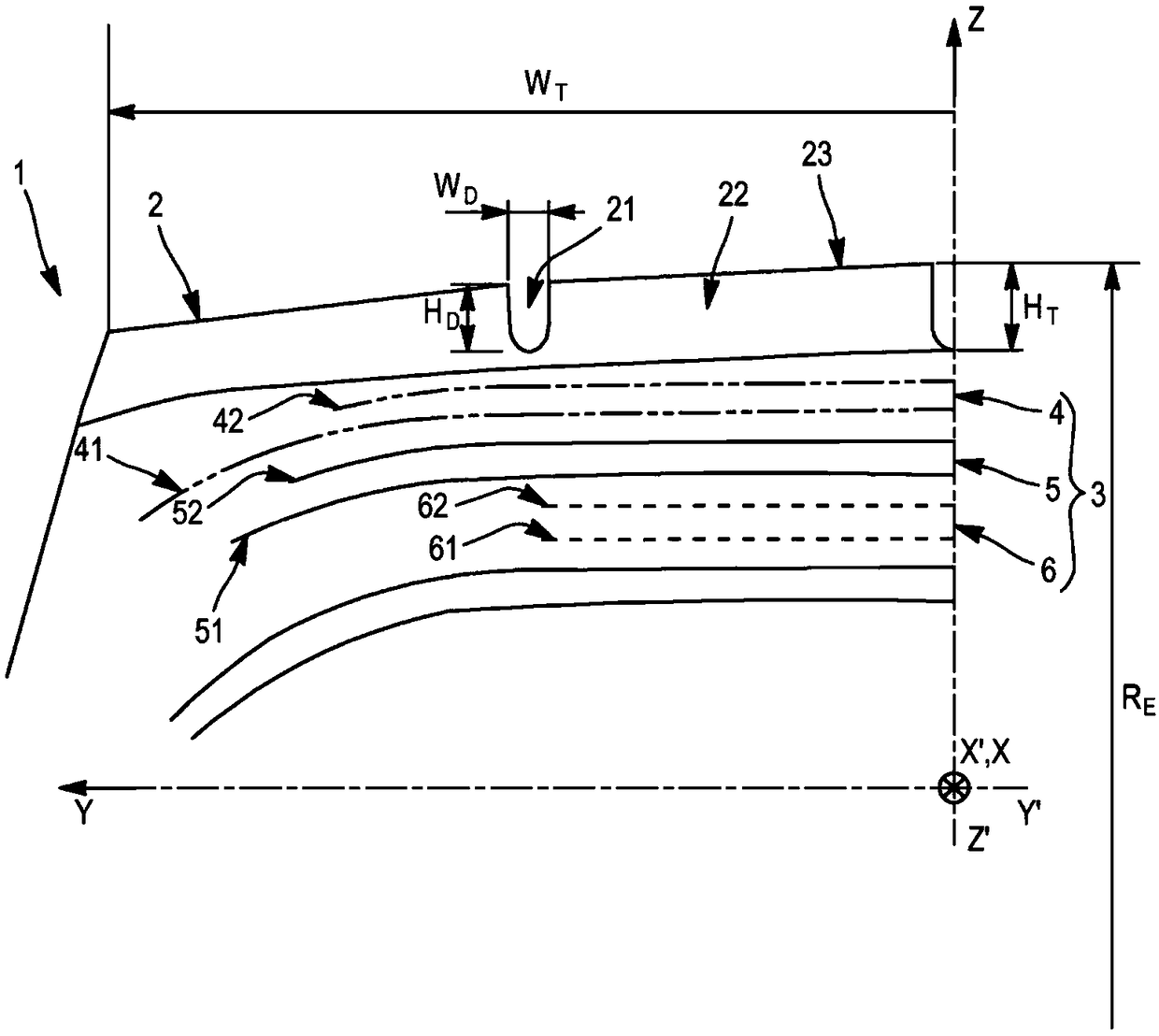

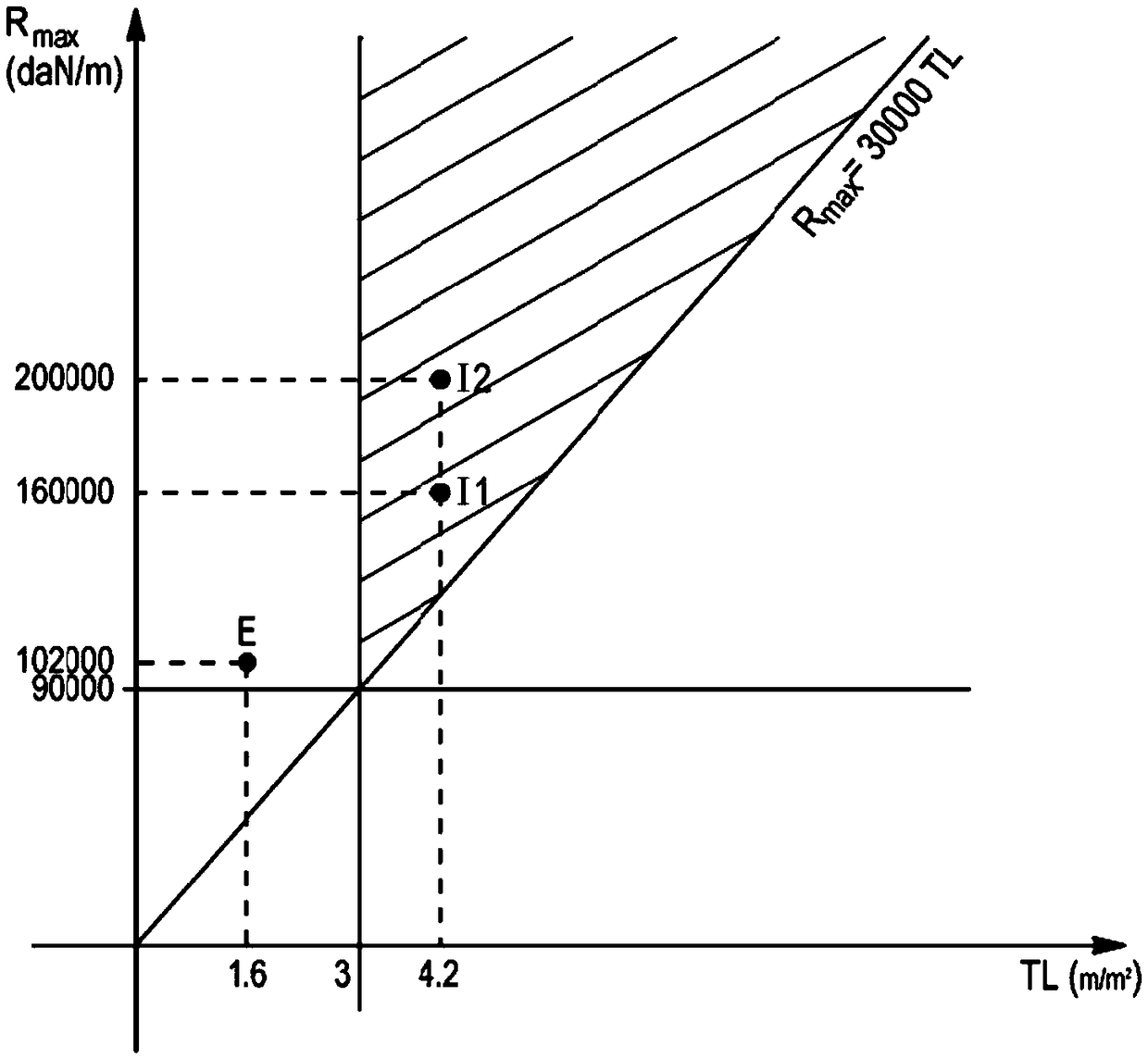

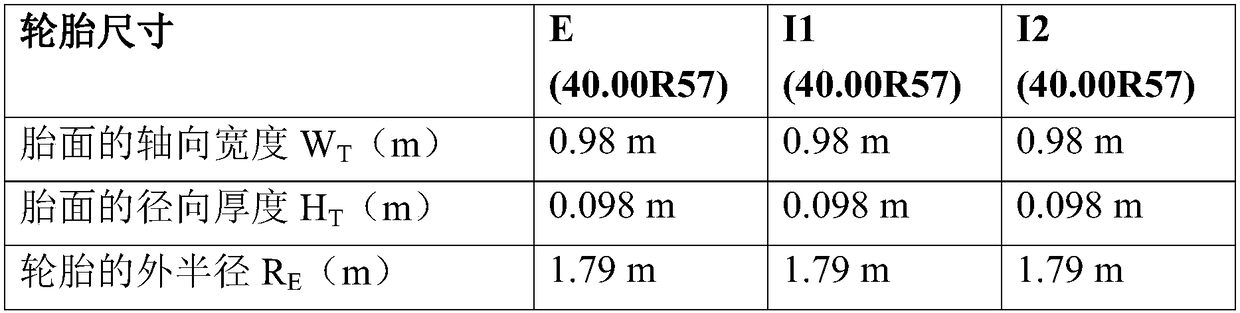

[0070] figure 1 Shows a meridian half-section of the crown of a tire 1 for a construction site type heavy vehicle comprising a tread 2 and a crown reinforcement 3 located radially inside the tread 2 , in the plane YZ. have a radial thickness H at least equal to 60 mm T The tread 2 consists of a width W D and radial depth H D The incision 21 and the relief element 22 separated by the incision 21. The width W of the notch 21 D At most equal to the radial depth H D 20% of the radial depth H D at least equal to the radial thickness H T 50% of , which is called the effective incision, and has a cumulative length L measured on the radially outer surface 23 of the tread 2 D (not shown in the figure). Tread 2 has m / m 2 Denoted surface notching TL, which is equal to the cumulative length L of the effective notch 21 D and the radially outer surface 23 of the tread is equal to 2ΠR E *W T The ratio between the area A, where R E is the outer radius of the tyre, measured in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com