Combined pneumatic dry-type friction clutch brake for forging machine

A friction clutch and combined technology, which is applied in the direction of brake type, brake parts, coupling and brake combination, etc., can solve the problems of asynchronous movement, inconsistent wear, cylinder wear, etc., and achieve good impact resistance and reduce Cost of production input, consistent effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

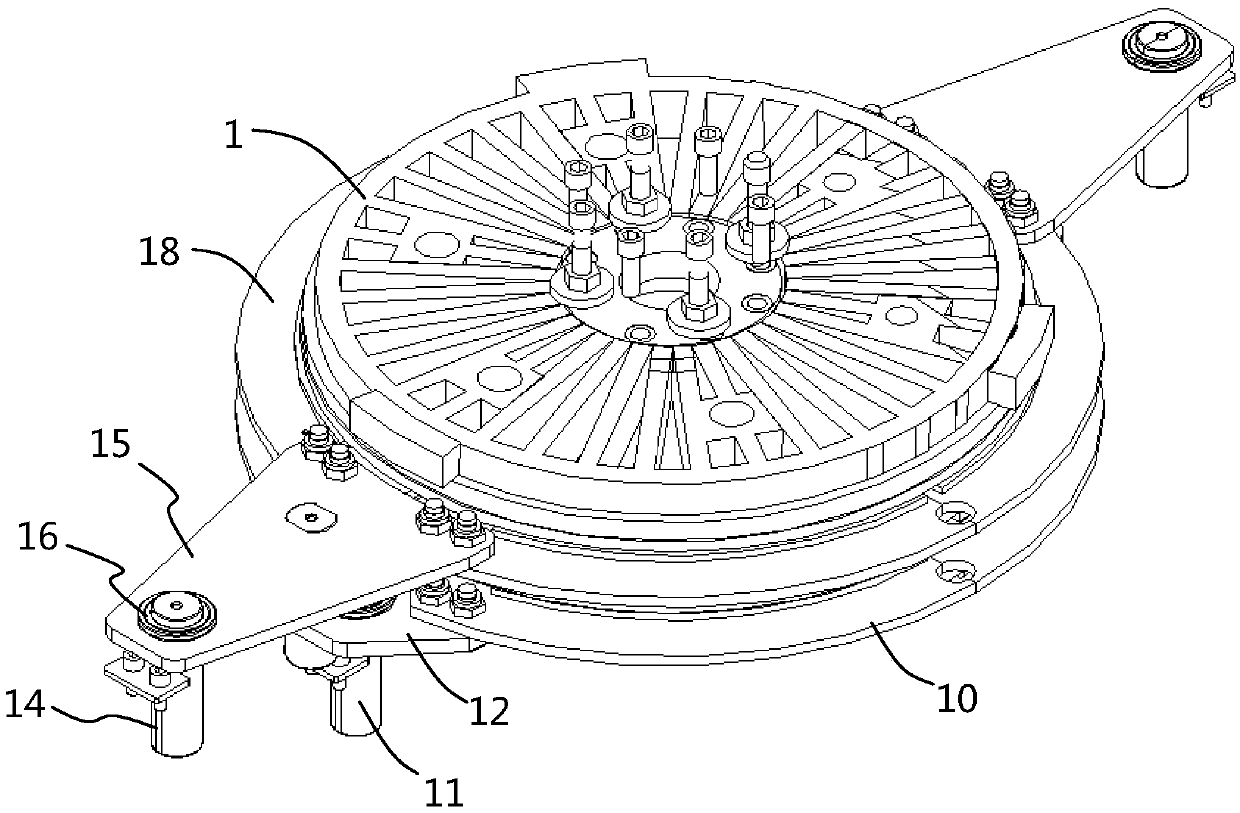

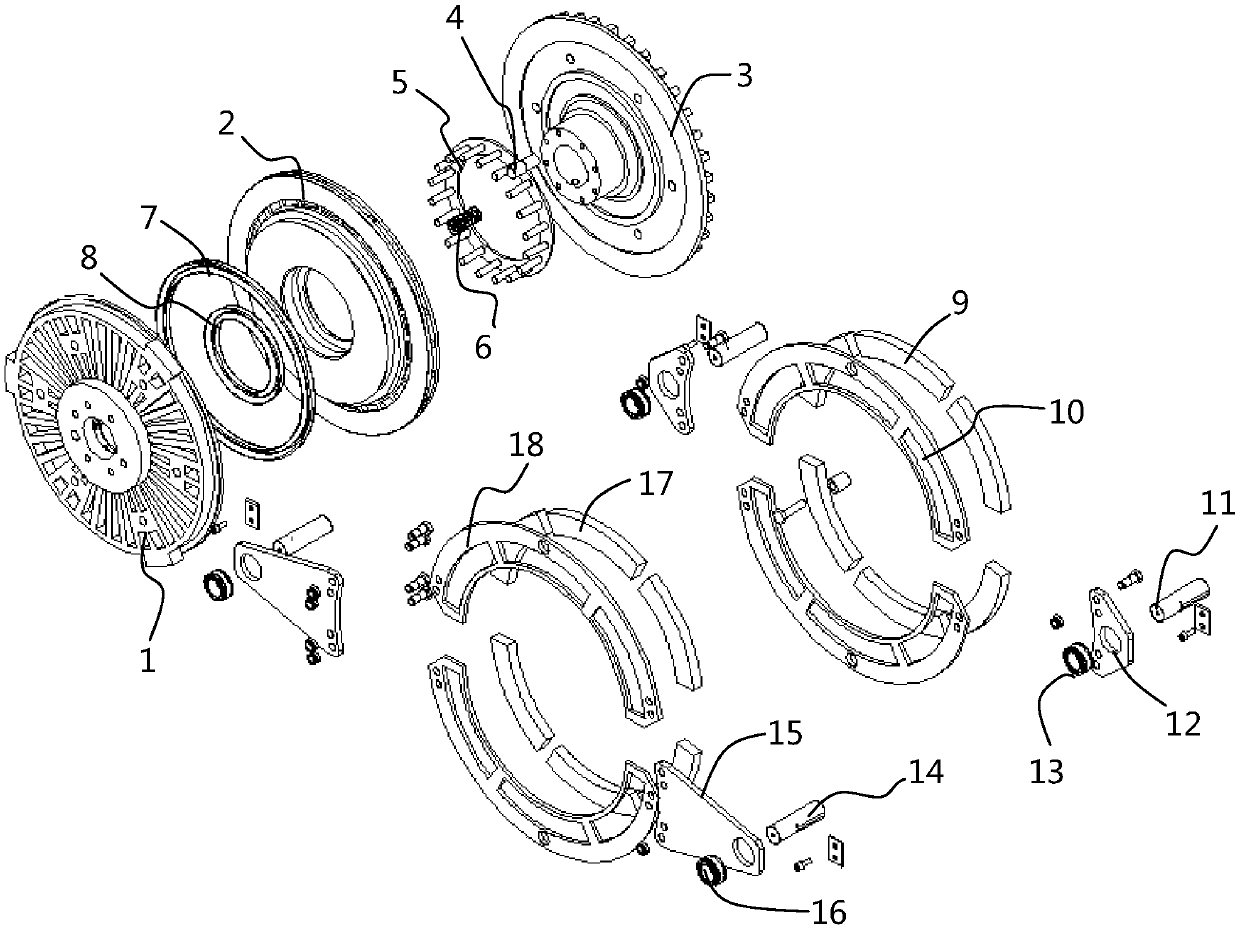

[0038] Please refer to Figure 1 to Figure 6 , the combined pneumatic dry friction clutch brake for forging machinery of this embodiment includes a clutch disc 10, a first friction block 9 and a brake disc 18 arranged on the clutch disc 10, and a second friction block arranged on the brake disc 18. The friction block 17, wherein the disc surface of the clutch disc 10 is provided with a plurality of strip-shaped through holes along the circumferential direction, and the first fixed magnetic pole pieces 101 are arranged around the strip-shaped through holes. The first fixed magnetic pole pieces 101 include N poles and S poles. A first movable magnetic pole piece 91 is provided around a friction block 9, and the first movable magnetic pole piece 91 includes N poles and S poles opposite to the N pole and S pole positions of the first fixed magnetic pole piece 101, and the gap between the first friction block 9 is Cooperately placed in the strip-shaped through-holes; the disc surfa...

Embodiment 2

[0043] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as figure 2 , Figure 4 with Image 6 As shown, the structural shapes of the clutch disc 10 and the brake disc 18 are consistent. For the convenience of installation, they are composed of two semi-circular plates. The connecting part of the brake disc 18 is fixed by the other connecting part of the machine tool through the brake pin 14, the brake ear plate 15 and the brake joint bearing 16.

[0044] The material of the clutch disc 10 and the brake disc 18 is cast iron, and the cast iron is Q235 cast iron, Q400 cast iron or Q450 cast iron. Cast iron has good heat transfer function. In addition, cast iron has good toughness and good impact resistance. 10 or on the circumference of the brake disc 18, three equidistant bar-shaped through holes are evenly distributed.

Embodiment 3

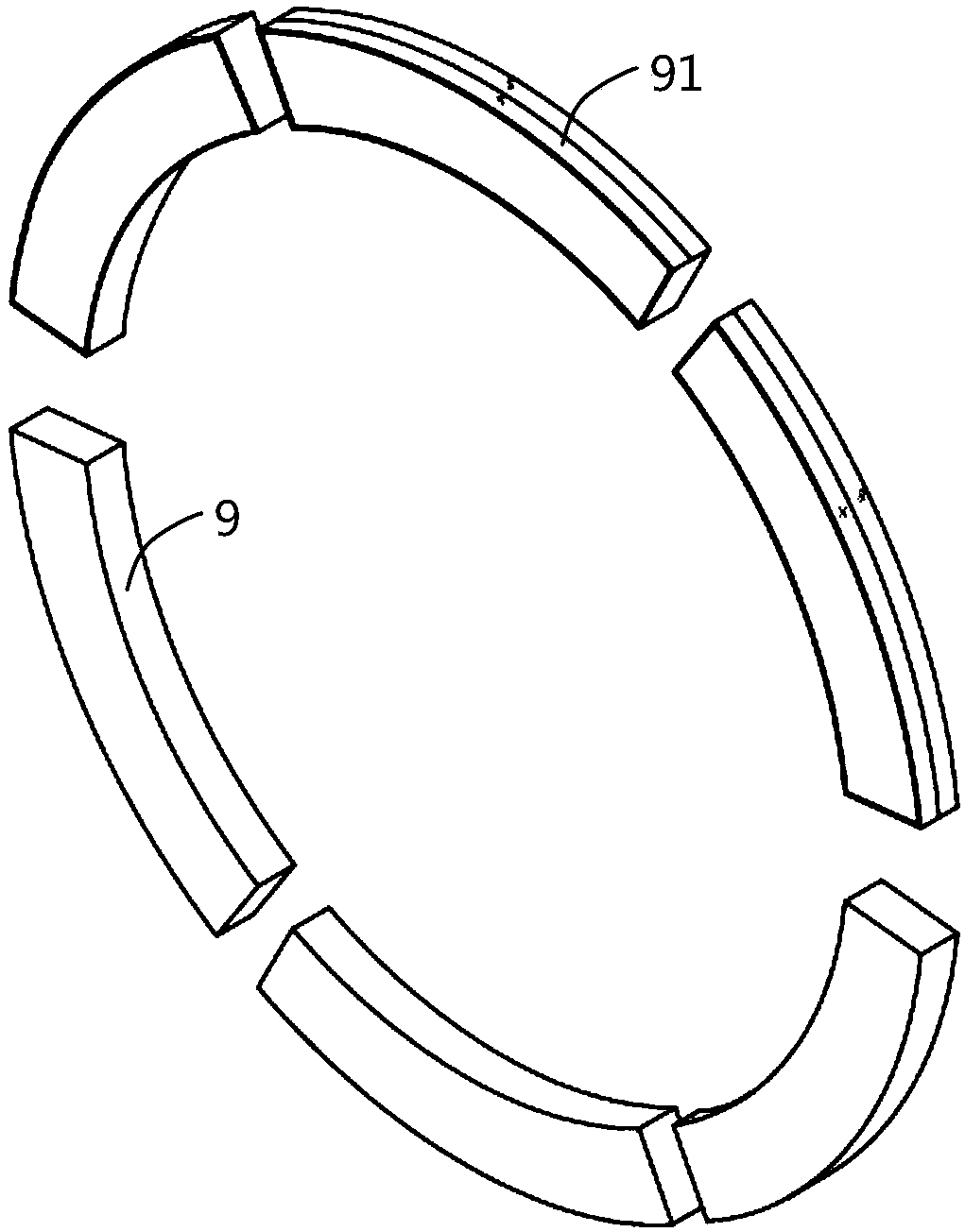

[0046] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as figure 2 , image 3 with Figure 5 As shown, the structural shapes of the first friction block 9 and the second friction block 17 are consistent, and are in the shape of an annular sheet. The first friction block 9 includes a first base body, and a first movable magnetic pole is wrapped and bonded around the first base body. The sheet 91 ; the second friction block 17 includes a second base body, and a second movable magnetic pole piece 171 is wrapped and bonded around the second base body.

[0047] In this embodiment, the thickness of the first movable magnetic pole piece 91 is consistent with the thickness of the clutch disc 10; the thickness of the second movable magnetic pole piece 171 is consistent with the thickness of the brake disc 18, and the N pole and the S pole are evenly separated, The first friction block 9 and the second friction block 17 move the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com