Pantograph pan abrasion intelligent control system and method

A technology of intelligent control system and pantograph sliding plate, applied in general control system, control/regulation system, program control and other directions, can solve the problems of reducing maintenance workload, inconsistent wear of pantograph sliding plate, etc., to reduce maintenance and repair. Workload, the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the embodiment of the present invention, the rail transit vehicle includes two high-voltage units, and each high-voltage unit is equipped with two pantographs. When the two pantographs are running normally, only one pantograph is raised, and the other is used as a backup .

[0027] Based on the above technical background, in order to keep the wear states of the two pantograph slides consistent, it is necessary to intelligently control the wear of the two pantograph slides.

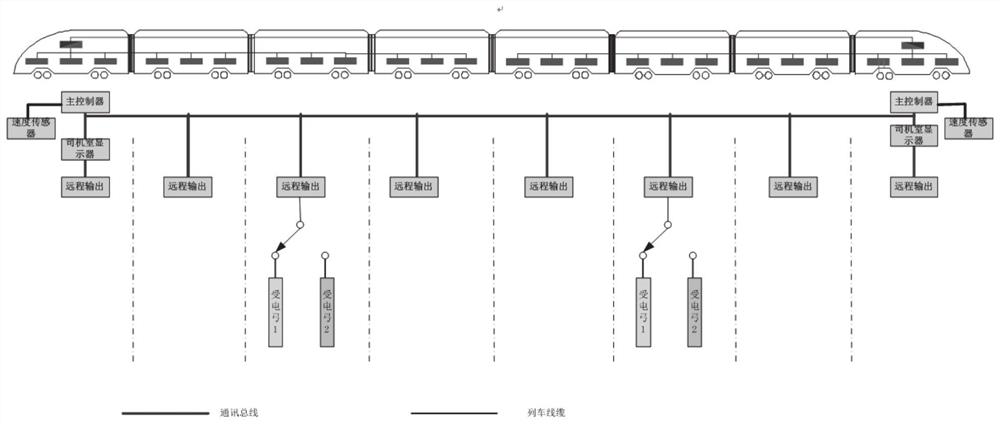

[0028] According to an embodiment of the present invention, an embodiment of an intelligent control system for pantograph slide wear is provided, refer to figure 1 ,include:

[0029] Speed sensor, each head car of the track running vehicle is equipped with a speed sensor, which is used to collect the speed information of the vehicle running and send it to the main controller;

[0030] The main controller is connected to the speed sensor through the communication bus, receives the vehicle runn...

Embodiment 2

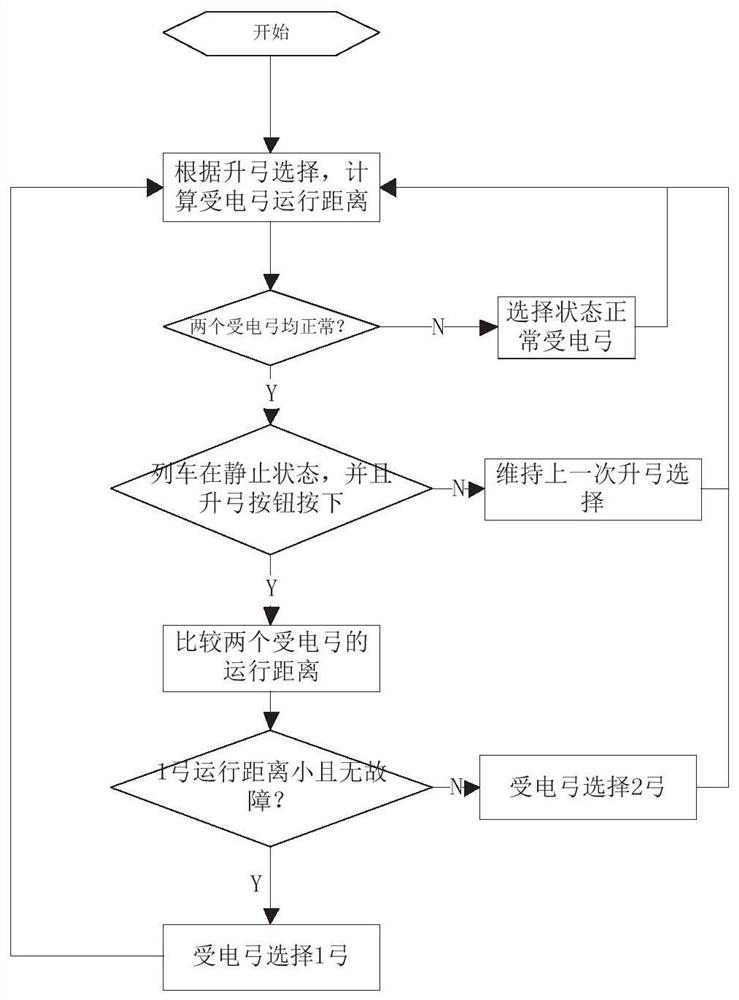

[0035] According to an embodiment of the present invention, an embodiment of an intelligent control method for pantograph slide wear is provided, refer to figure 2 , including the following steps:

[0036] Step S101, based on the running speed of the vehicle, determine the running distance of each pantograph in the high voltage unit of the vehicle;

[0037] Based on the calculation relationship between speed and distance, the cumulative running distance of each pantograph is calculated. The calculation process is simple and easy, and there is no need to consider complex judgment processes such as temperature and pressure, which facilitates the implementation of the patented technical solution.

[0038] Step S102, judging whether the pantograph selection condition is satisfied, if so, proceed to step S103, otherwise, maintain the last state of raising the bow;

[0039] Specifically, the pantograph selection condition is specifically: the vehicle is in a stationary state, and ...

Embodiment 3

[0042] According to an embodiment of the present invention, a rail vehicle is provided, including: the pantograph sliding plate wear intelligent control system disclosed in Embodiment 1 realizes the pantograph lift control of the vehicle; or, adopts the pantograph disclosed in Embodiment 2 The intelligent control method of the wear of the bow skateboard realizes the bow control of the vehicle pantograph.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com