Cleaning plate

A technology for cleaning discs and turntables, applied in the field of cleaning discs, can solve problems such as the inability of the bristles to respond elastically, the rapid wear and tear of the bristles, and the wear and tear of the bristles, and achieve the effects of easy adjustment of the elasticity, prolonging the service life, and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

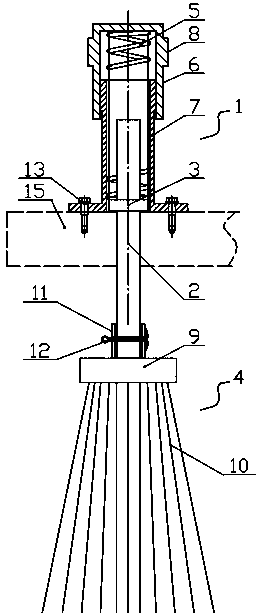

[0028] Such as figure 1 , figure 2 and image 3 As shown, the elastic broom comprises a cylinder body 1, a piston rod 2, a piston 3, a hair brush 4 and a stage clip 5, and the cylinder body 1 is arranged in an upside-down manner, that is, the opening of the cylinder body faces downward; The cylinder body is composed of an upper cylinder body 6 and a lower cylinder body 7 which are screwed together. Specifically, the upper cylinder body 6 is buckled on the upper part of the lower cylinder body 7, and the middle and lower inner wall of the upper cylinder body 6 is provided with an inner thread, the upper outer wall of the lower cylinder body 7 is provided with an external thread, and the internal thread and the external thread are screwed together. It should be specially noted that, relative to the position of the screw connection of the inner and outer threads, the lower port of the upper cylinder body 6 extends downward for a section, so as to protect the inner and outer th...

Embodiment 2

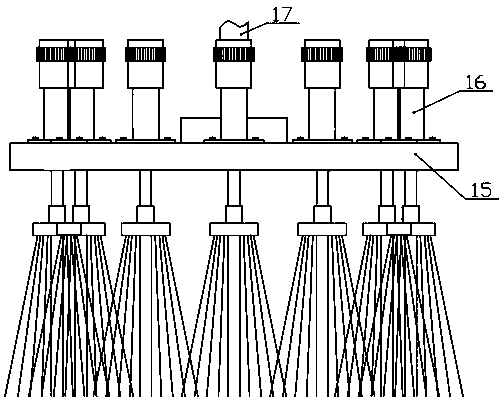

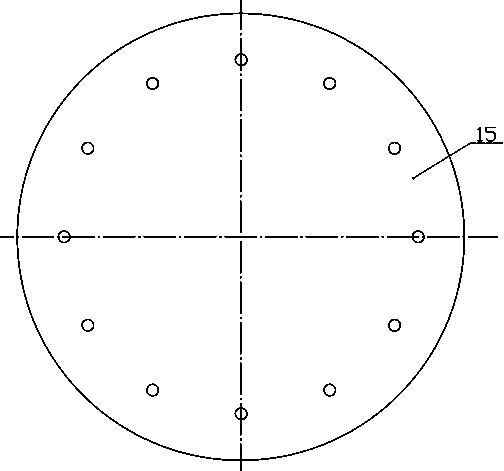

[0034] Such as Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9As shown, the elastic broom comprises a cylinder body 1, a piston rod 2, a piston 3, a hair brush 4 and a stage clip 5, and the cylinder body 1 is arranged in an upside-down manner, that is, the opening of the cylinder body faces downward; The cylinder body is composed of an upper cylinder body 6 and a lower cylinder body 7 which are screwed together. Specifically, the upper cylinder body 6 is buckled on the upper part of the lower cylinder body 7, and the middle and lower inner wall of the upper cylinder body 6 is provided with an inner thread, the upper outer wall of the lower cylinder body 7 is provided with an external thread, and the internal thread and the external thread are screwed together. It should be specially noted that, relative to the position of the screw connection of the inner and outer threads, the lower port of the upper cylinder body 6 extends downward for a section,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com