Adaptive multi-plate sequencing large-torque friction clutch device with one-way transmission function

A technology of one-way transmission and friction clutch, which is applied in the direction of one-way clutches, clutches, mechanical equipment, etc., can solve the problem of reducing the wear resistance of multi-plate friction clutches, which cannot be used as high-torque power transmission devices, and cannot be used by multi-plate friction clutches. Bearing and other problems, to achieve the effect of shortening the corresponding time, novel structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

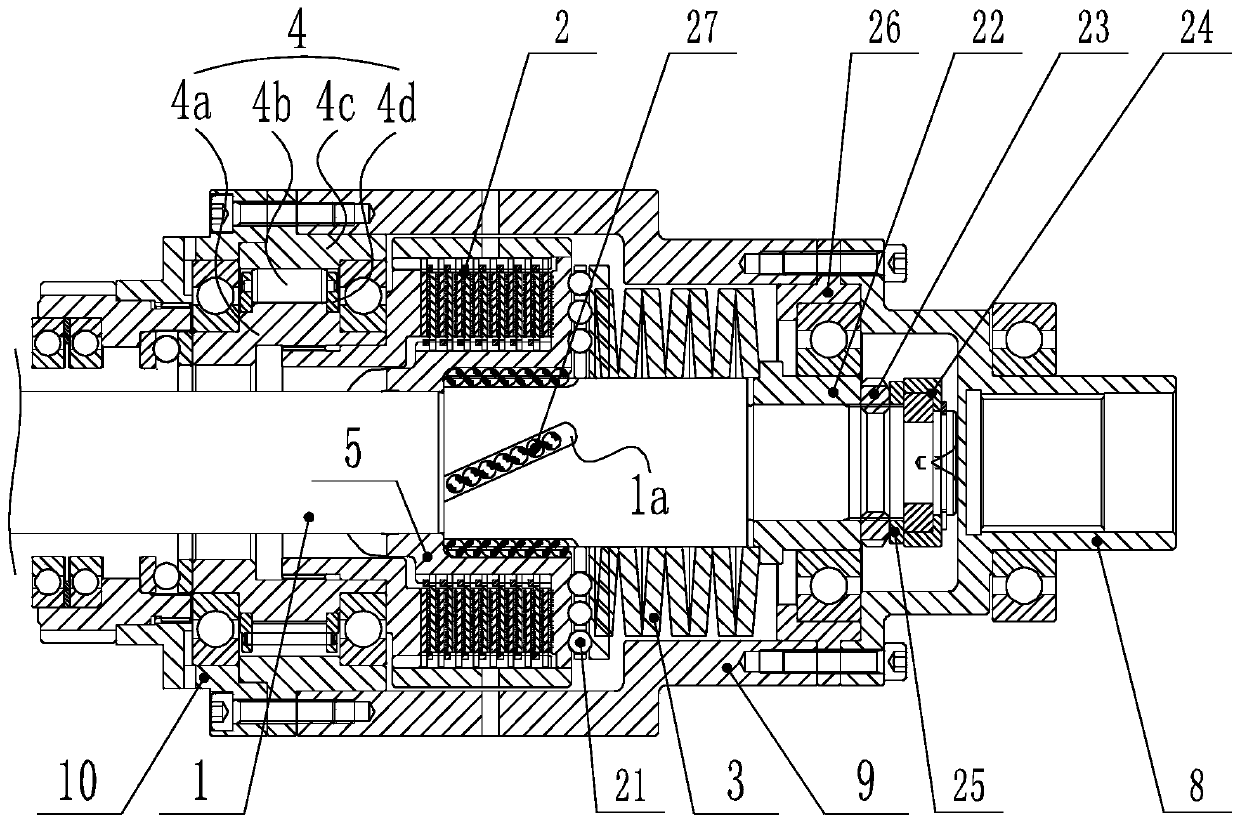

[0037] Such as figure 1 As shown, an adaptive multi-disc sorting high-torque friction clutch device with one-way transmission function mainly includes a power input mechanism, a main shaft 1, a first overrunning clutch 4, an inner spiral raceway sleeve 5, a friction clutch 2 and The elastic element group 3, wherein the power input mechanism is used for inputting power, and the main shaft 1 is used for outputting power.

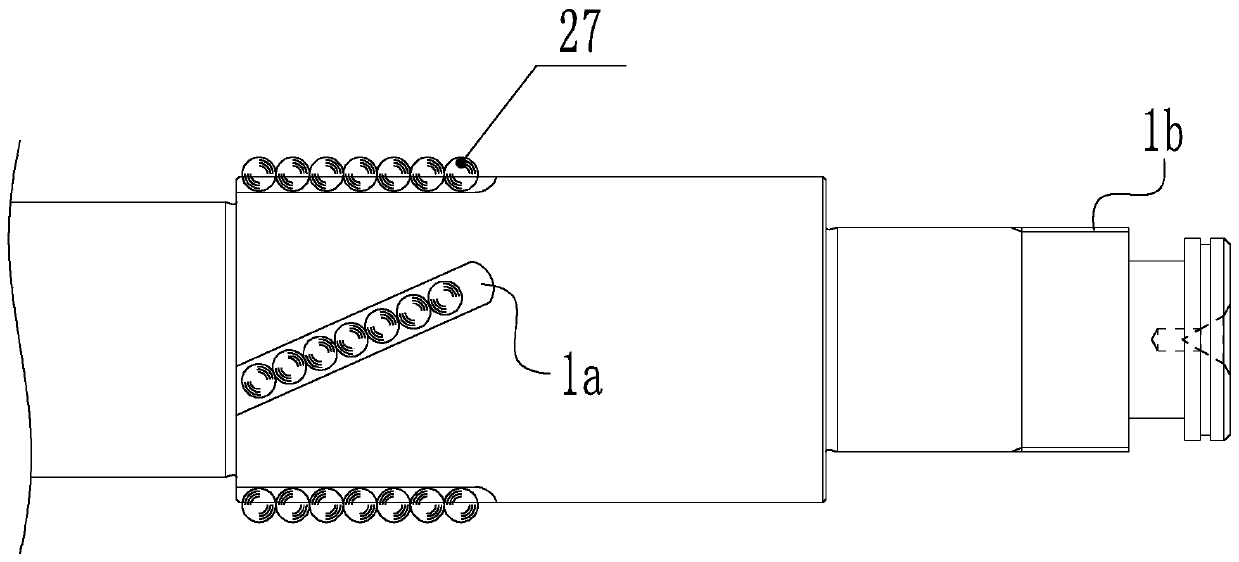

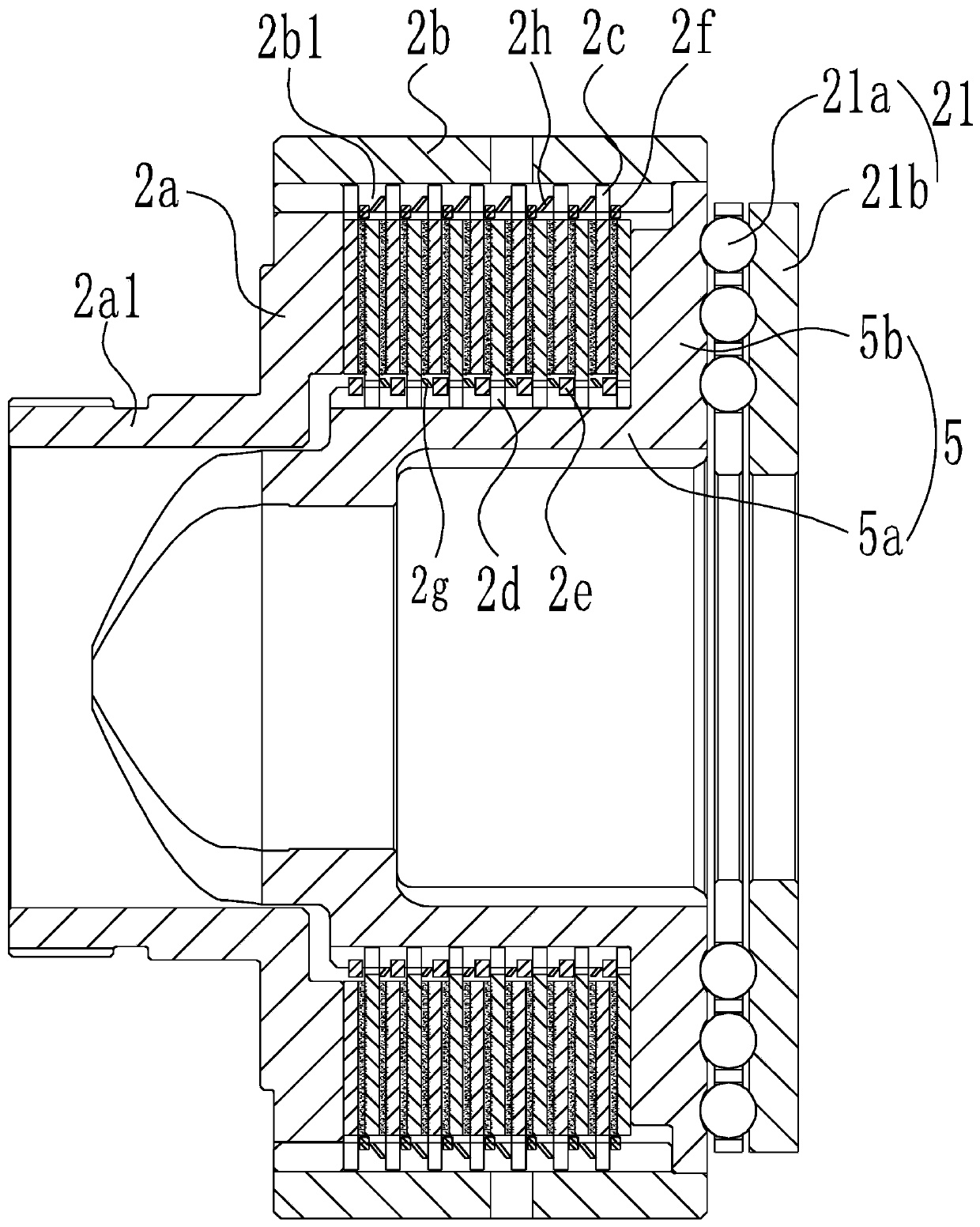

[0038] See figure 1 with image 3 , the inner spiral raceway sleeve 5 includes an integrally formed output spiral raceway barrel 5a and a friction disc pressing disc 5b, wherein the output spiral raceway barrel 5a is in a cylindrical structure, and the friction disc pressing disc 5b is in a circular shape. The disc-shaped structure, the said friction plate pressing plate 5b is vertically fixedly sleeved on the outside of one end of the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com