Pneumatic vehicle tire

一种车辆、轮胎的技术,应用在充气轮胎的增强层、重型轮胎、车辆部件等方向,能够解决不均匀磨损等问题,达到改善耐久性、长结构耐久性、磨损减少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

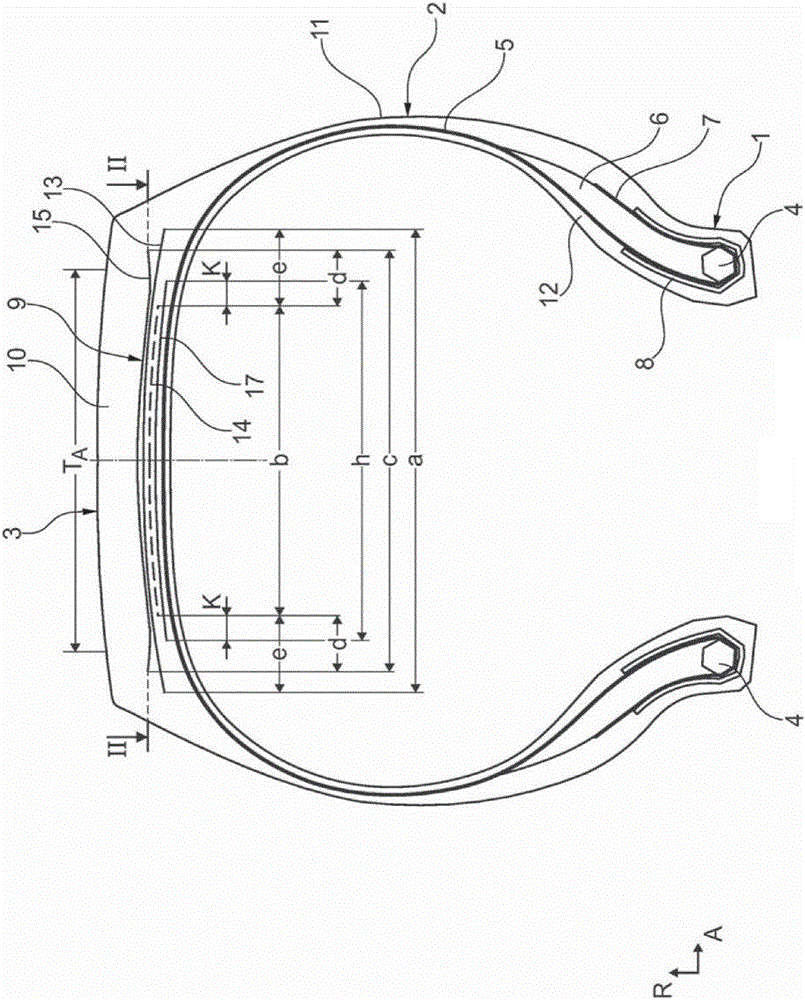

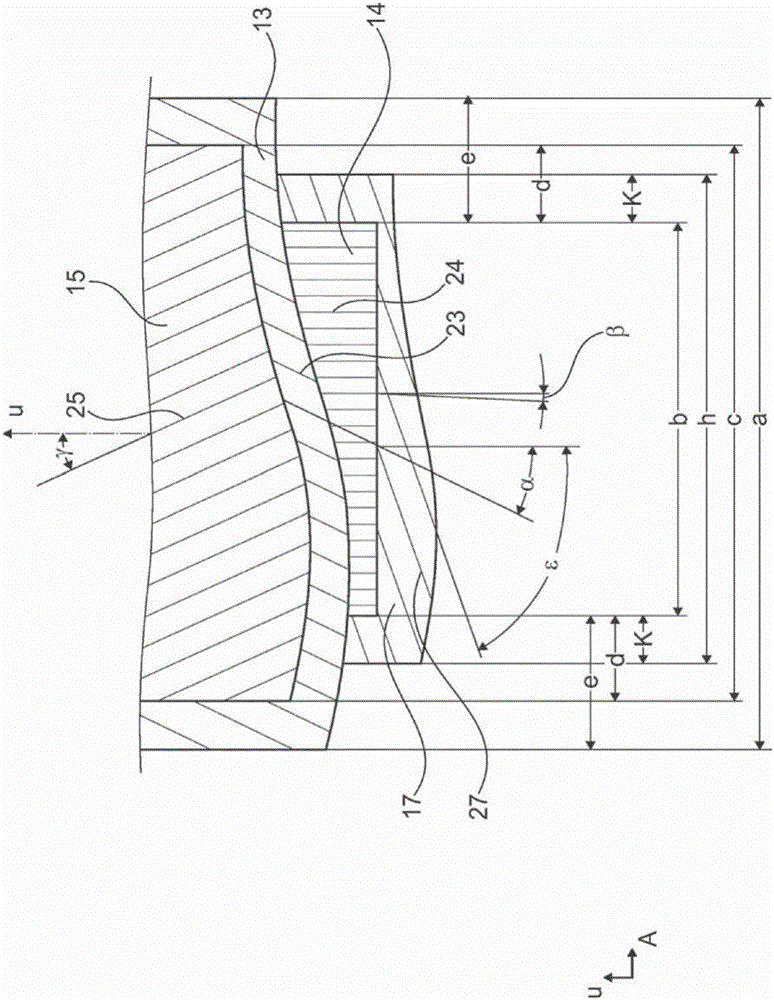

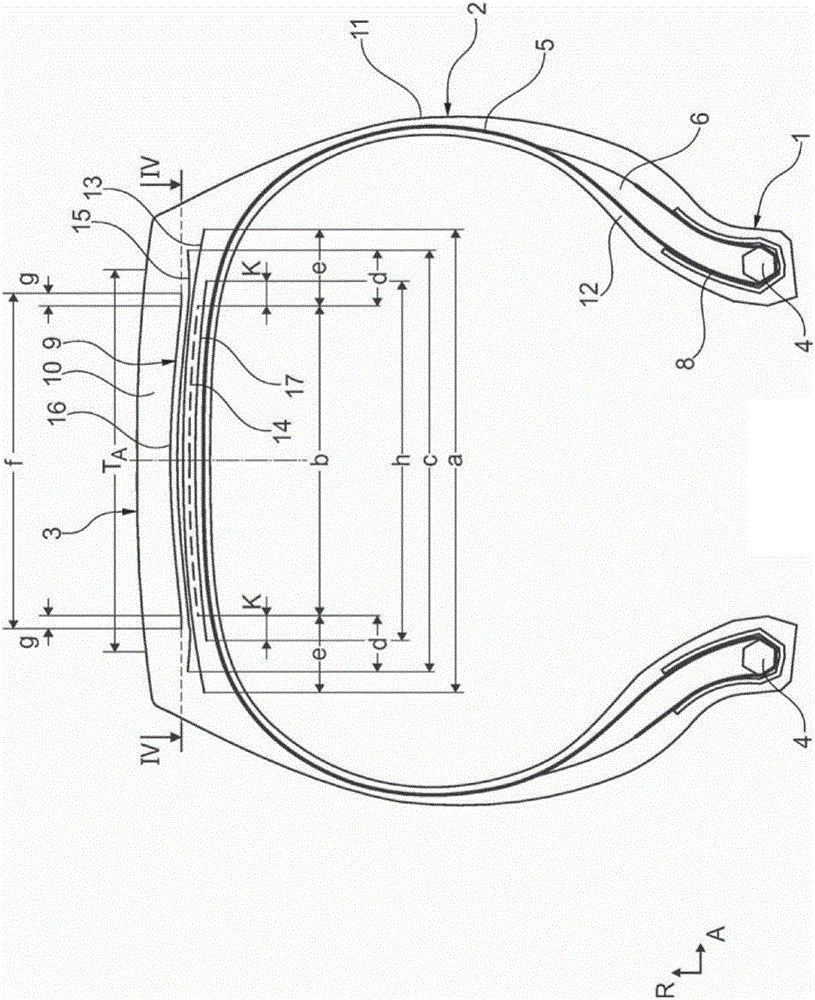

[0023] figure 1 and figure 2Shown is a pneumatic tire of radial configuration for a utility vehicle having two side walls 2 extending in the radial direction R of the vehicle tire and having axially formed between said side walls The crown area 3. These sidewalls each have, at the end of their extent directed inwards in the radial direction, a bead area 1 in which a bead core 4 of known type is formed, which in the circumferential direction U Has high tensile strength and extends circumferentially over the circumference of the tire. In a known manner, the bead core 4 is formed in a wound manner from a wire, which extends in the circumferential direction U of the pneumatic vehicle tire and is embedded in rubber. An apex (bead filler) 6 that is triangular in cross section is formed on the bead core 4 from a hard rubber material in a conventional manner. The pneumatic vehicle tire is formed with a carcass 5 extending outwardly in the radial direction R of the pneumatic vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com