Rail weld joint grinding robot capable of achieving flexible grinding

A robot and industrial robot technology, applied in the direction of grinding machines, manipulators, abrasive belt grinders, etc., can solve the problems of incomplete welding seam grinding, damage to the track body, etc., and achieve the effect of avoiding track damage, avoiding excessive grinding, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

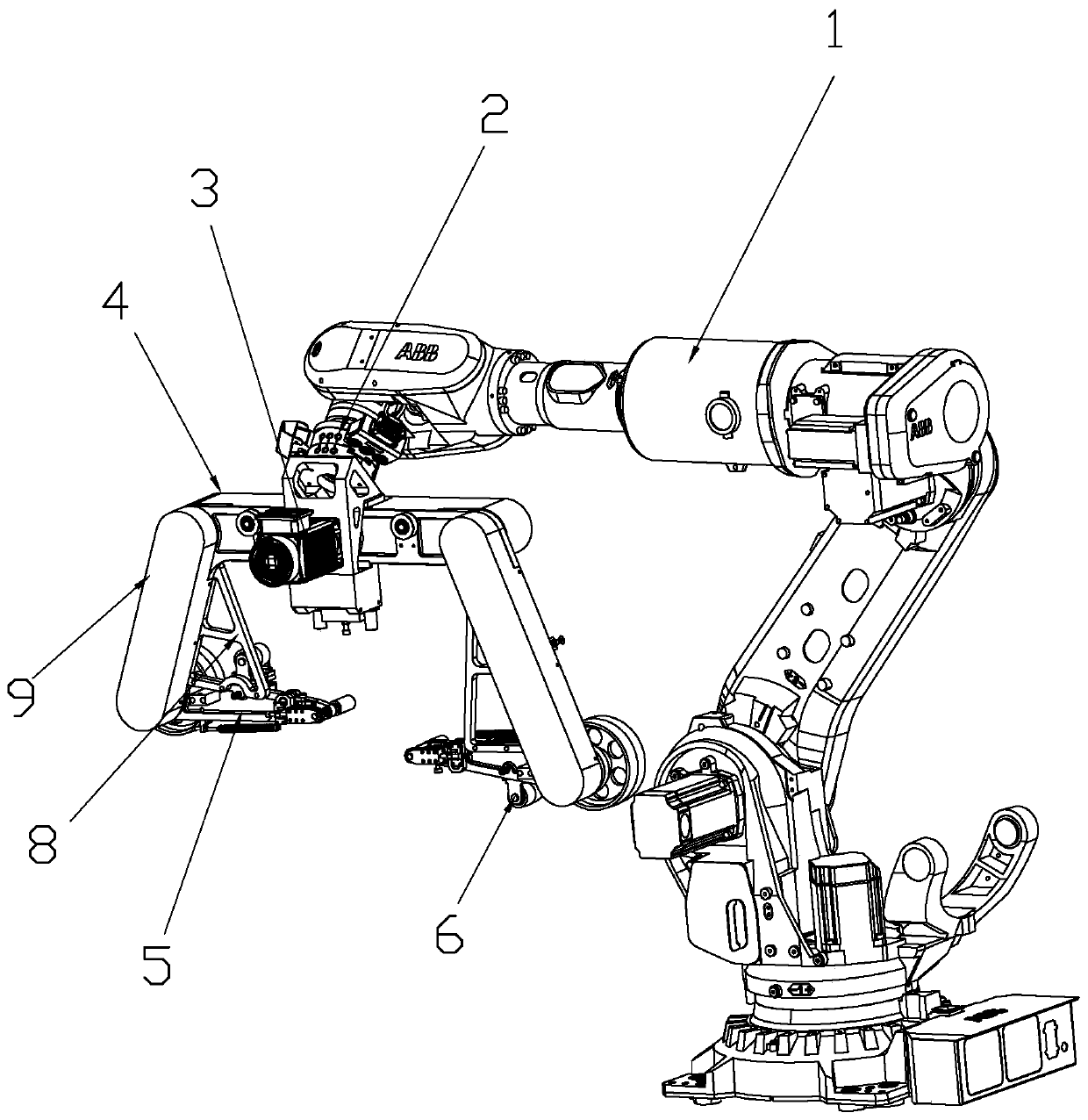

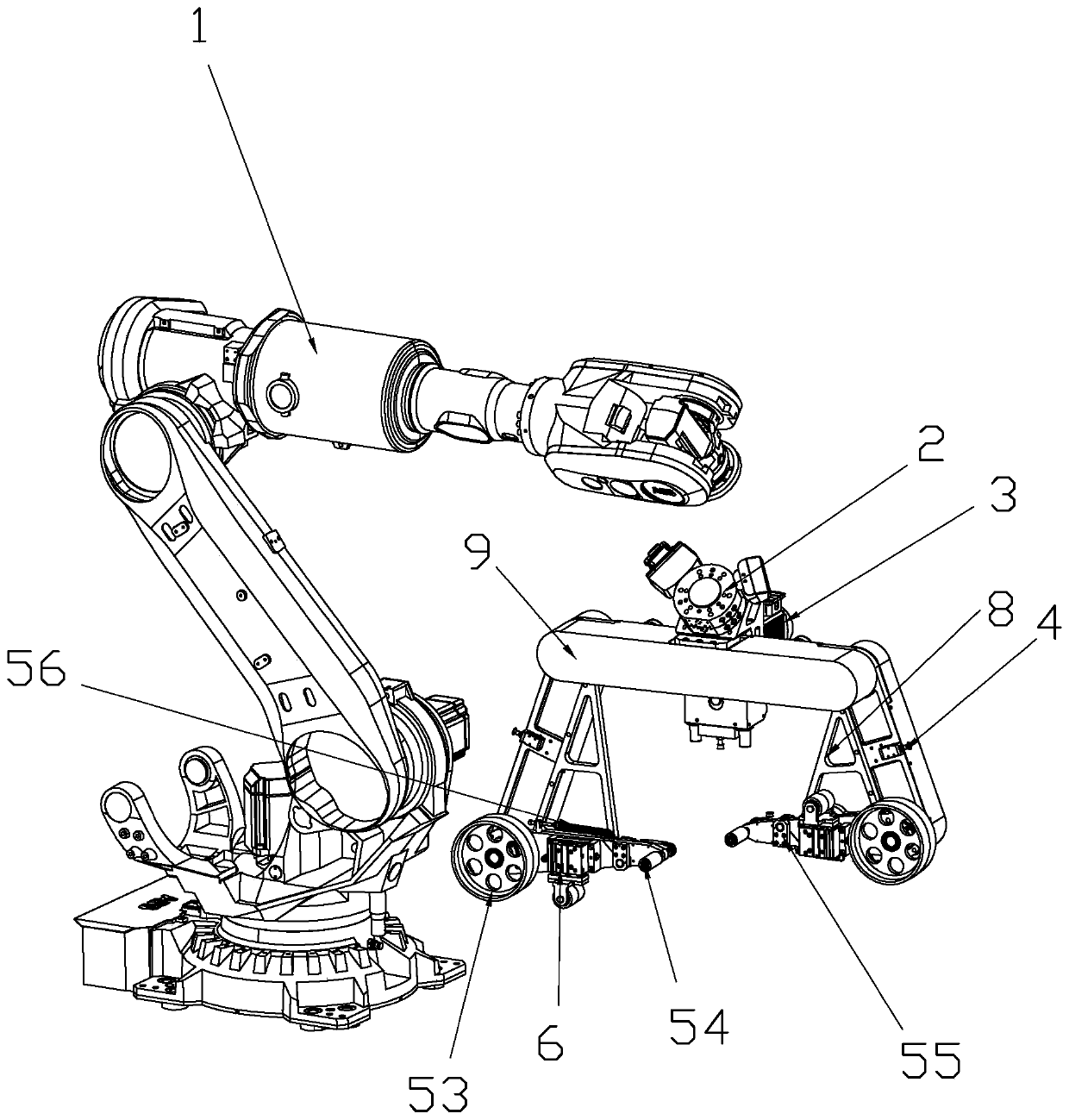

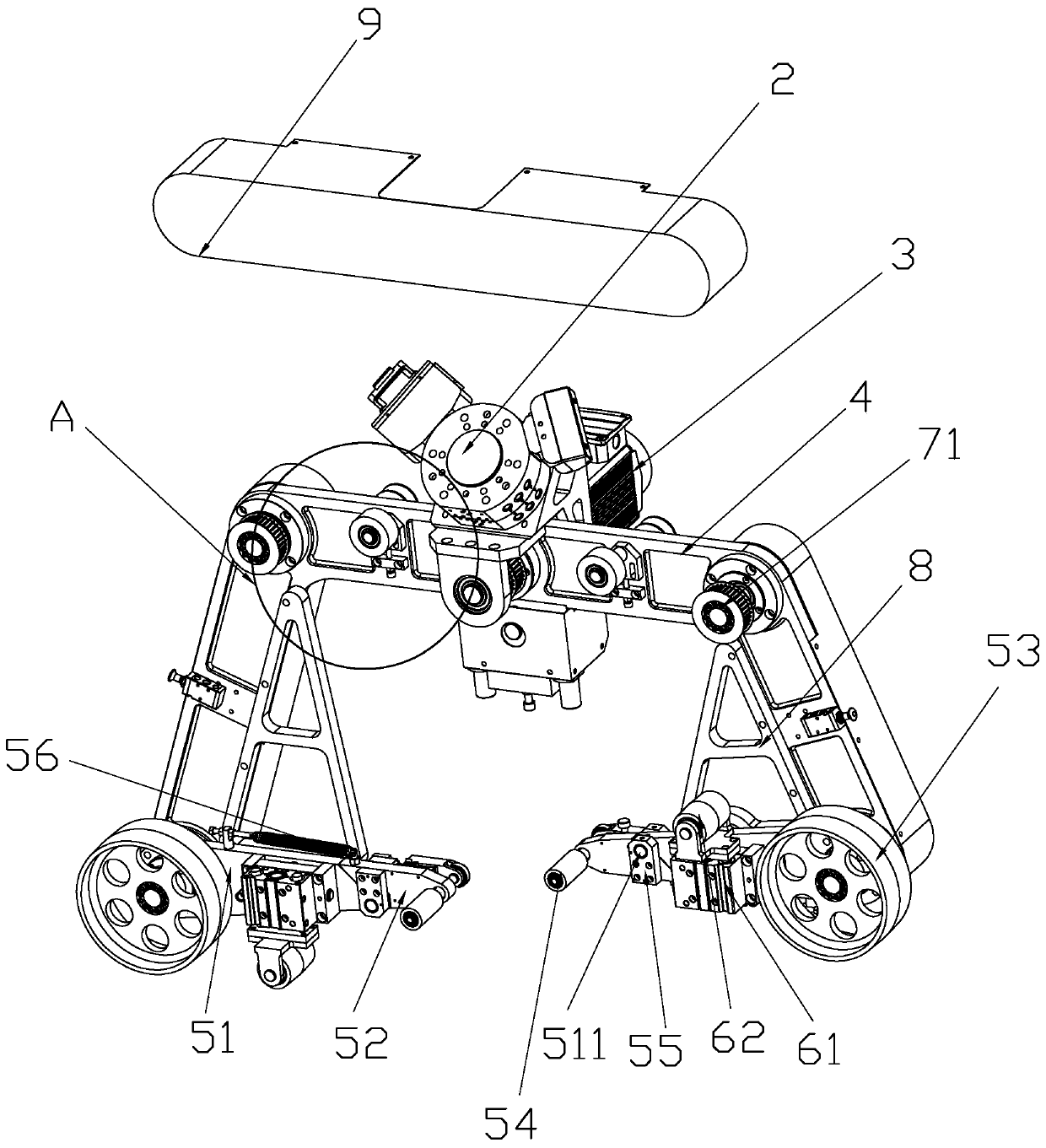

[0036] Such as Figure 1-Figure 9 As shown, a flexible grinding orbital weld grinding robot includes an industrial robot 1 and a flexible grinding device detachably connected to the industrial robot 1. The flexible grinding device includes a connector 2 connected to the end of the industrial robot 1 and fixed on the connection The driving motor 3 on the head 2, the movable support 4 movably connected with the driving motor 3, and the abrasive belt wheel assembly 5 arranged at both ends of the movable support 4 for polishing the track, the output end of the driving motor 3 is set after passing through the movable support 4 The driving wheel 31 drives the abrasive belt wheel assembly 5 to operate. The abrasive belt wheel assembly 5 includes an abrasive belt arm 51 fixedly connected to the movable support 4, and a floating arm 52 movably connected to the abrasive belt arm 51. The main wheel 53 on the arm 51 that is linked to the drive wheel 31, the fixed wheel 54 that is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com