Novel multi-wire sawing machine

A wire saw machine, a new type of technology, is applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., which can solve the problems of unstable machining accuracy gear train system, increase the diameter of the driving wheel, and difficulty in ensuring system stability, etc., and achieve reduction Equipment use and maintenance costs, increased synchronization stability, and shortened time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the drawings, and the following embodiments can enable those skilled in the art to better understand the present invention, but do not limit the present invention in any form.

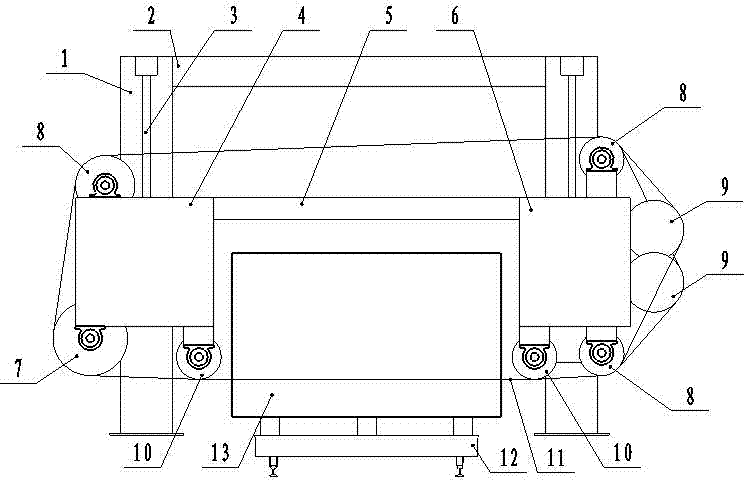

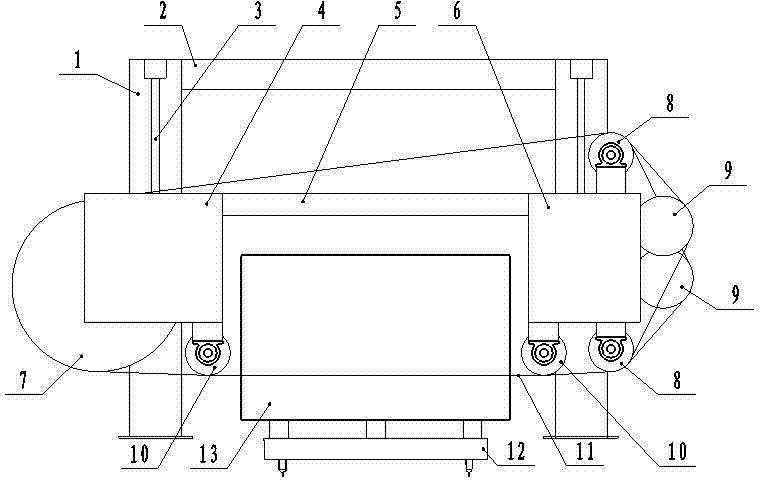

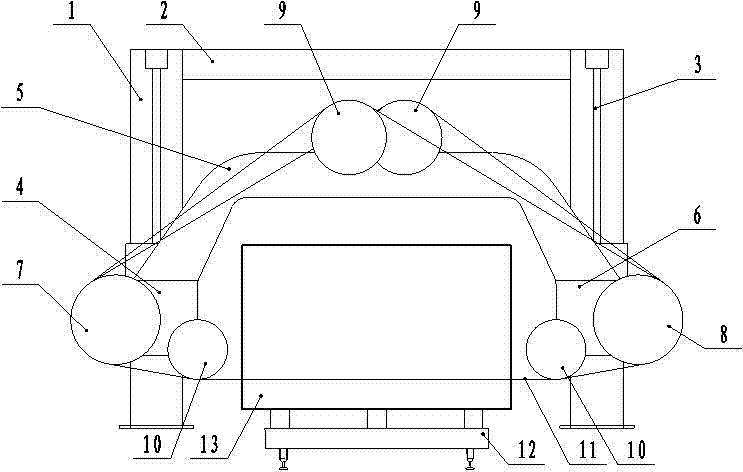

[0031] A new type of multi-wire saw machine is improved on the basis of the existing multi-wire saw machine. Its fixed frame is similar to the prior art, and consists of a column 1, a main beam 2, a vertical lifting device 3, and a driving end frame 4 , frame beam 5, tensioning end frame 6, also has drive wheel 7, guide wheel 8, tension wheel 9, positioning wheel 10, diamond beaded rope 11, block car 12, stone 13 is fixed on the block car 12, the main changes are: the tensioning wheel 9 is fixed on the top of the frame beam 5, and is located between the columns 1 on both sides (not necessarily the middle part), the driving wheel 7 and the guide wheel 8 are fixed on the side of the column 1 on both sides, and the two sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com