Lifting mechanism for small electric sweeper disc brushes

A lifting mechanism and sweeper technology, applied in road cleaning, cleaning methods, construction, etc., can solve the problem that the height and inclination angle of the disk brushes on both sides are random, the load of the disk brush is uneven, and the service life of the disk brush is reduced. and other problems, to achieve the effect of compact structure, ensuring consistency and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

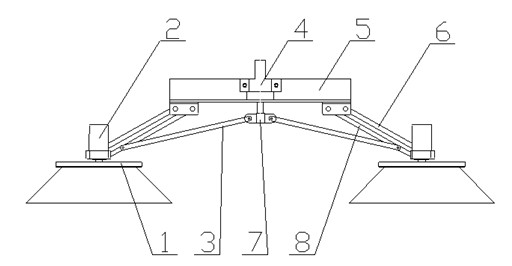

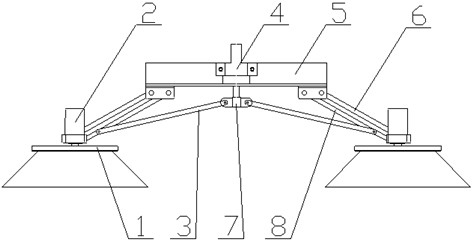

[0014] according to figure 1 As shown, the lifting mechanism of the small-sized electric cleaning vehicle disc brush of the present invention is located on the top of the disc brush 1, and the disc brush 1 is connected with a DC motor 2. The lifting mechanism includes a support 5, an electric push rod 4 and a plane six-bar mechanism 8 , said planar six-bar mechanism 8 is made up of parallelogram mechanism 6, connecting rod 3 and connector 7, said parallelogram mechanism 6 and electric push rod 4 are all fixed on the support 5, said connecting rod 3 One end is connected with the parallelogram mechanism 6 , and the other end is connected with the electric push rod 4 through the connector 7 . There are two sets of planar six-bar mechanisms 8, which are symmetrically arranged on both sides of the bracket 5, and can control the lifting of the two disc brushes synchronously.

[0015] Working process of the present invention is as follows:

[0016] An electric push rod 4 is used as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com