Rail polishing processing line

An assembly line and rail technology, applied in the direction of grinding workpiece supports, metal processing equipment, grinding machines, etc., can solve the problems of time-consuming and laborious, damage to the rail body, incomplete welding seam grinding, etc., to protect worker safety, intelligent worker safety, Improve the effect of factory environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

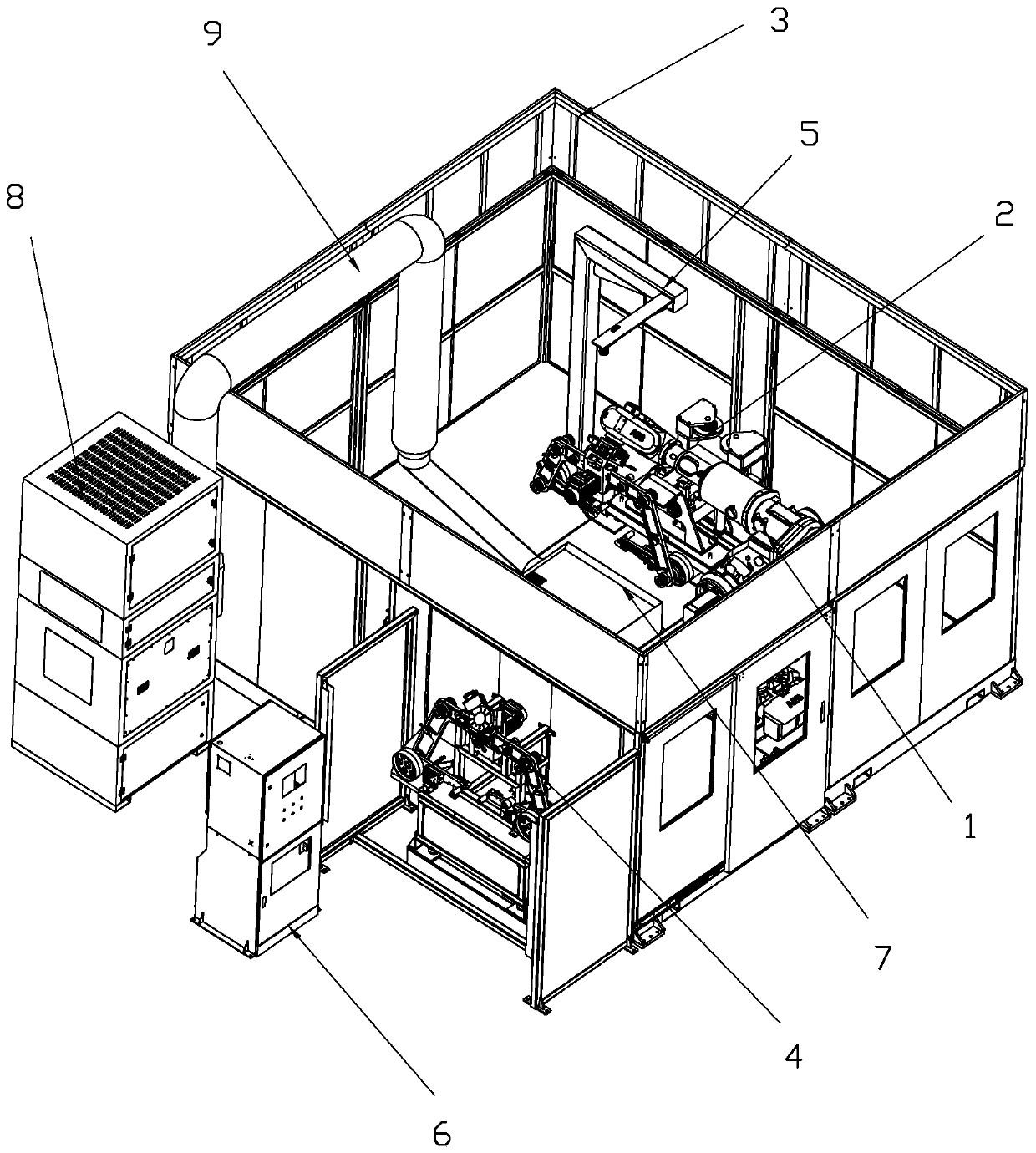

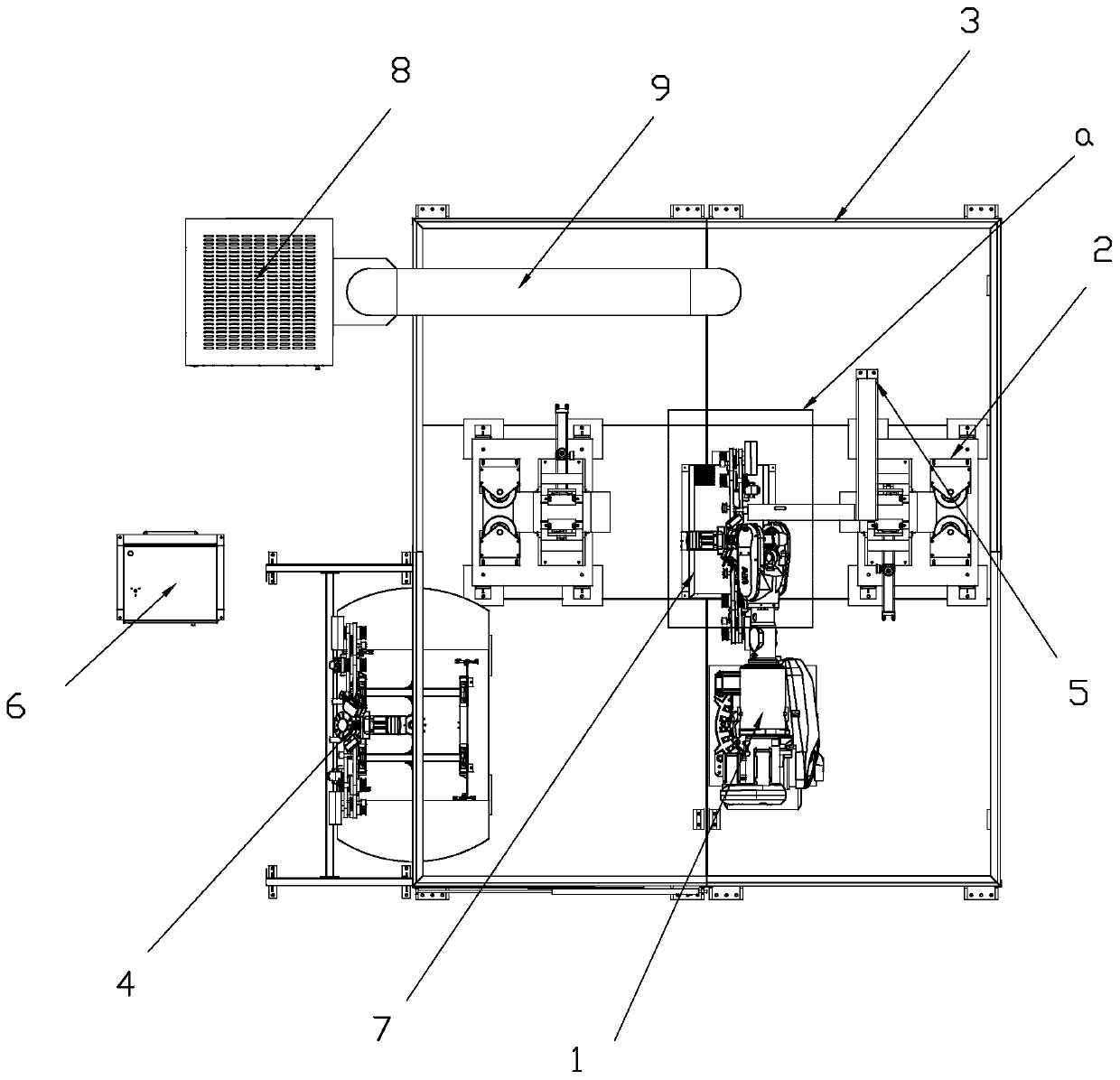

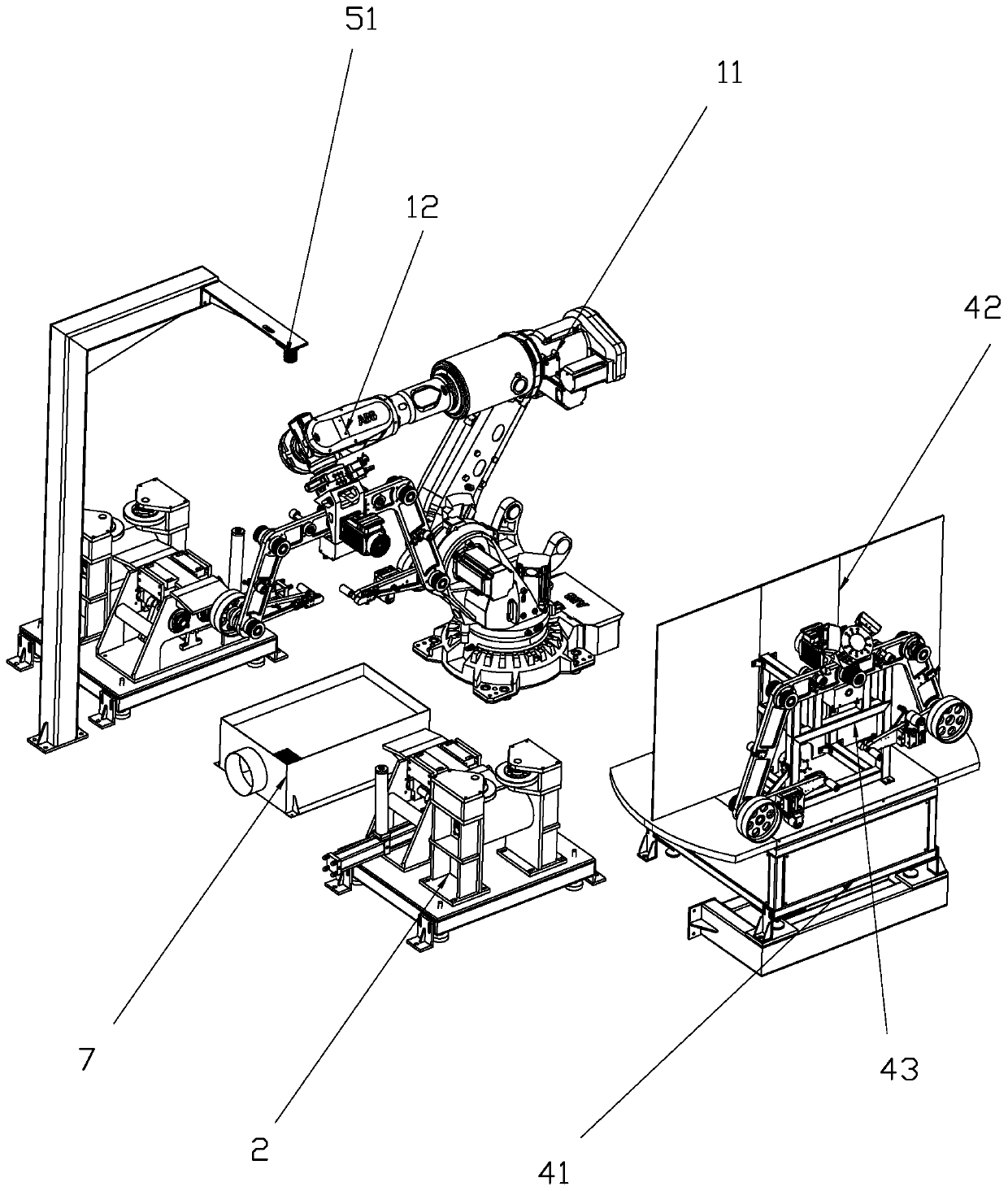

[0047] Such as Figure 1-Figure 14As shown, a track grinding processing line, the line includes a flexible grinding robot 1 for grinding track welds and track inspection fixtures 2 arranged at both ends of the flexible grinding robot 1 for transporting tracks, and also includes a grinding workshop 3, flying debris The collection and processing mechanism, the grinding device replacement mechanism 4, the grinding induction mechanism 5 and the main console 6, the track detection fixture 2 are provided with a weld detection mechanism 21 and a track clamping mechanism 22, and the flexible grinding robot 1 includes an industrial robot 11 and a The flexible grinding device 12 that is detachably connected to the industrial robot 11, the flexible grinding device 12 includes a connector 121 connected to the end of the industrial robot 11, a drive motor 122 fixed on the connector 121, a movable bracket 123 that is movably connected to the drive motor 122, Be arranged on the abrasive belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com