Movable central positioning feeding numerical control shearing machine

A center positioning and shearing machine technology, applied in positioning devices, shearing devices, accessories of shearing machines, etc., can solve the problems of affecting accuracy, laborious movement, lack of busbar positioning, etc., to improve production efficiency, reduce inconvenience, Consistent wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

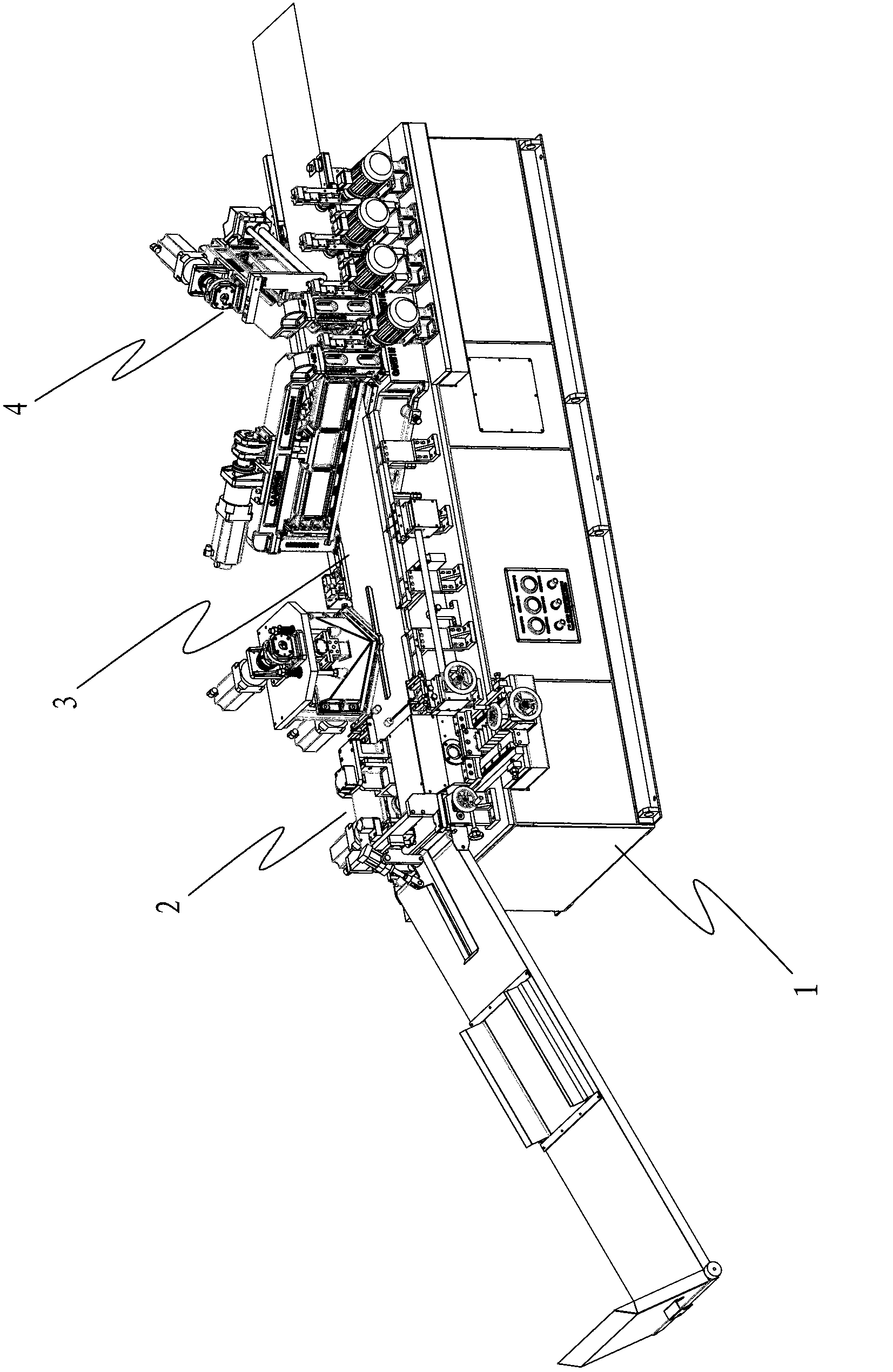

[0023] refer to figure 1 , the present invention provides a kind of numerically controlled shearing machine of movable center positioning feeding, comprising a machine base 1, a feeding mechanism 2, a conveying channel 3 and a shearing mechanism 4 are sequentially arranged on the machine base 1, and the conveying channel 3 is arranged on the feeding mechanism 2. The rear is used to convey materials. The shearing mechanism 4 is arranged above the conveying channel 3 and is used to shear the conveyed materials. According to the shape requirements of the sheared sheet, the shearing mechanism 4 can be horizontal scissors or The oblique scissors can also be used as a combination of horizontal scissors and oblique scissors.

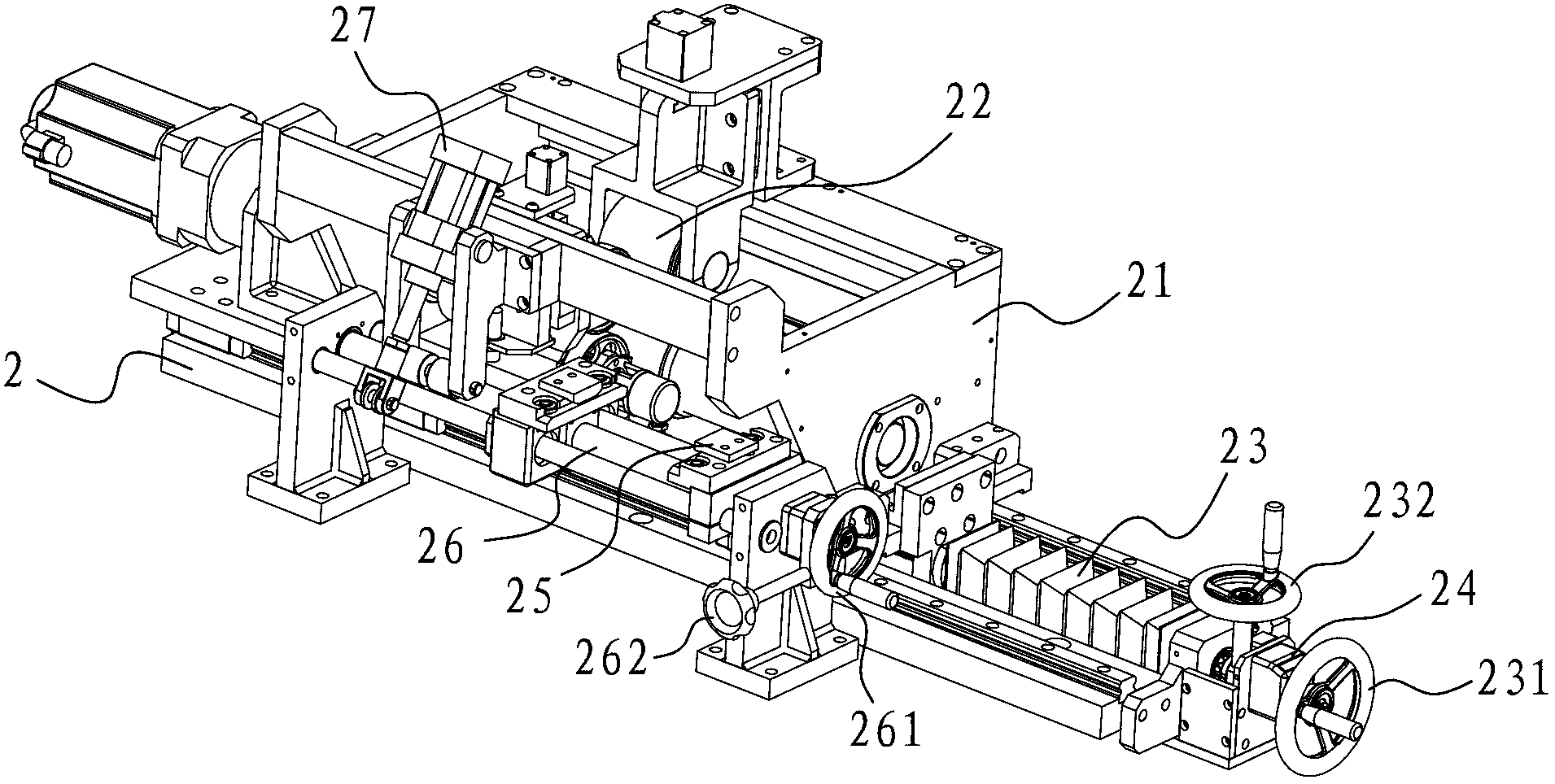

[0024] refer to figure 2 , the feeding mechanism 2 mainly includes a feeding rack 21, a motor-driven feeding wheel set 22 and a transmission screw mandrel 23, the main driving wheel of the feeding wheel set 22 in the present embodiment is made of a short feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com