Combined grinding ball

A wear-resistant ball and alloy wear-resistant layer technology, applied in the field of wear-resistant balls, can solve the problems of not being strong enough, easy to separate, and the wear-resistant effect of the wear-resistant ball surface is not ideal, so as to achieve difficult separation, low cost, and increased grinding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

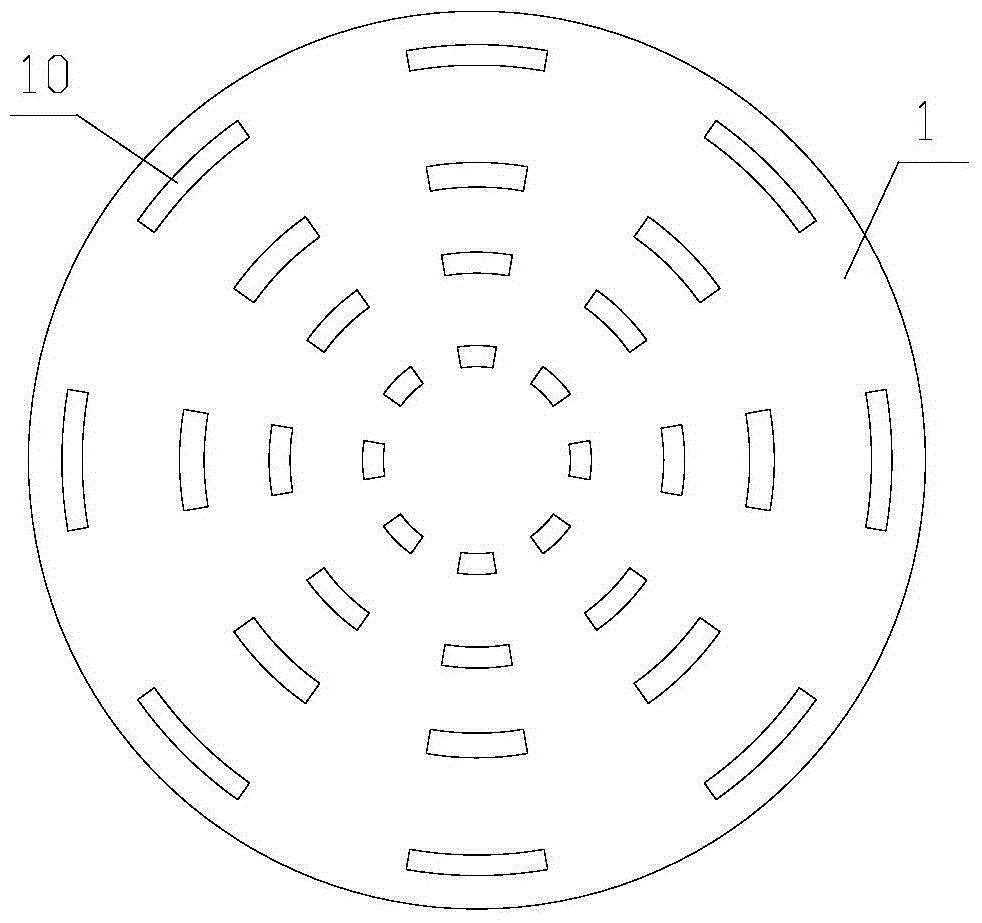

[0035] Embodiment 1, combining image 3 :

[0036] The surface of the alloy wear-resistant layer 1 is provided with several protruding units, the protruding unit includes several arc-shaped protrusions 10, and the several arc-shaped protrusions 10 in one protruding unit are distributed in a circle around the radial direction of the wear-resistant ball .

[0037] Through the design of the protrusions 10, the protrusions 10 are evenly distributed around the radial direction of the wear-resistant ball. No matter how they roll, the protrusions 10 can exert friction on the material, and the protrusions 10 in different protrusion units exert friction on the material. Forces in different directions, so that the grinding material is uniform, the grinding effect is good, the degree of wear of the protrusions 10 is consistent, and the service life is long.

Embodiment 2

[0038] Example 2, combined with Figure 4 :

[0039]The surface of the alloy wear-resistant layer 1 is provided with at least two protruding units, and the protruding units include several rectangular protuberances 12, and the extending direction of the protruding 12 in one protruding unit is different from the protruding 12 in the other The direction of extension is oblique or vertical.

[0040] Through the design of the protrusion 12, by setting at least 2 protrusion units, no matter how they roll, different protrusion units exert friction in different directions on the material, and the friction strength of different protrusion units on the material is different, so that the grinding material is uniform and the grinding The effect is good, the degree of wear of the protrusions 12 is basically the same, and the service life is long; if the extension directions of the protrusion units are consistent, the force on the material is the same, and the grinding effect is not good....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com