Semicircular belt conveyor with deep groove and big dig

A belt conveyor, semicircular technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of endangering the production safety of the system, difficult maintenance, limited conveying inclination, etc., to reduce equipment investment and Maintenance costs, overcoming high transportation costs, and simplifying design calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

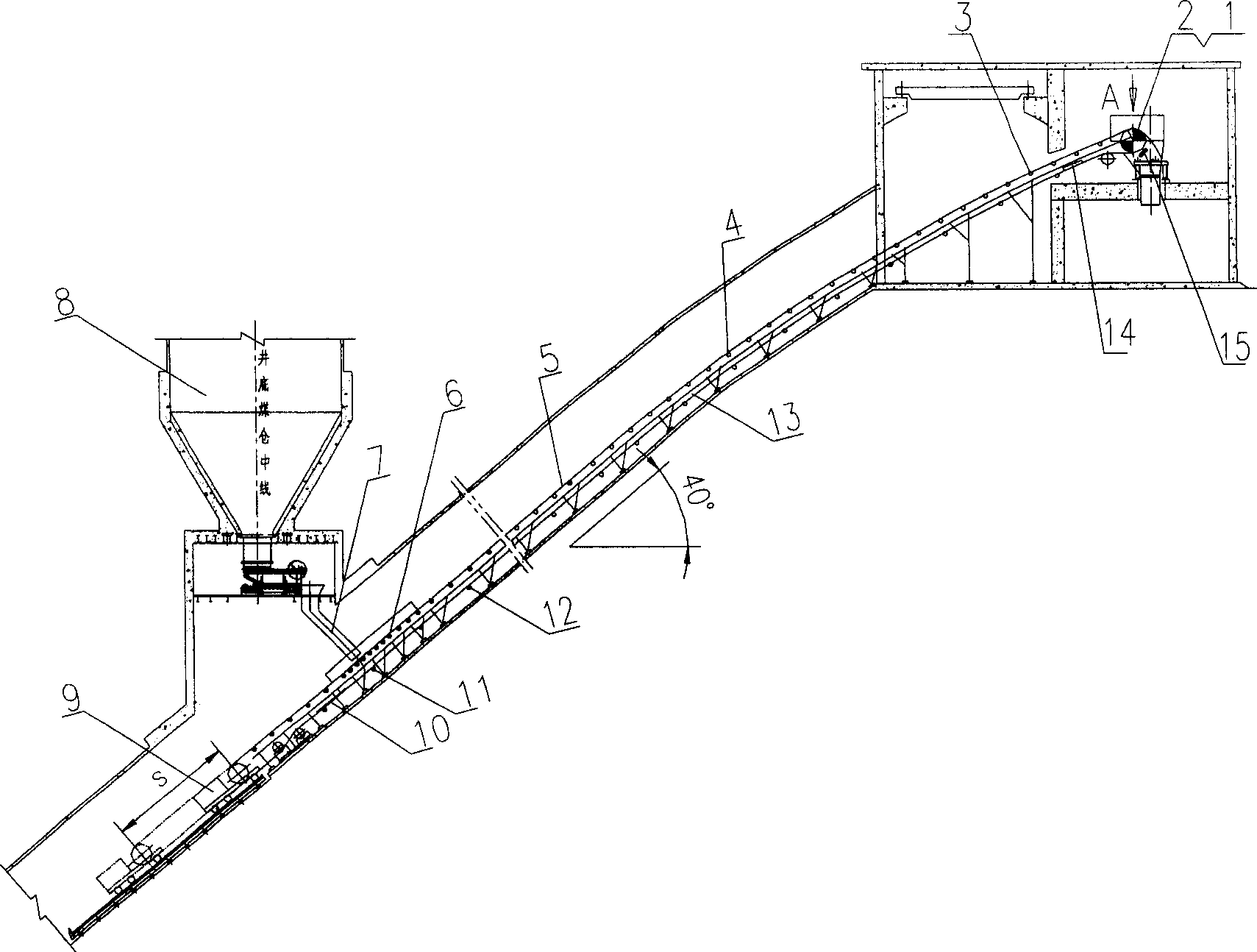

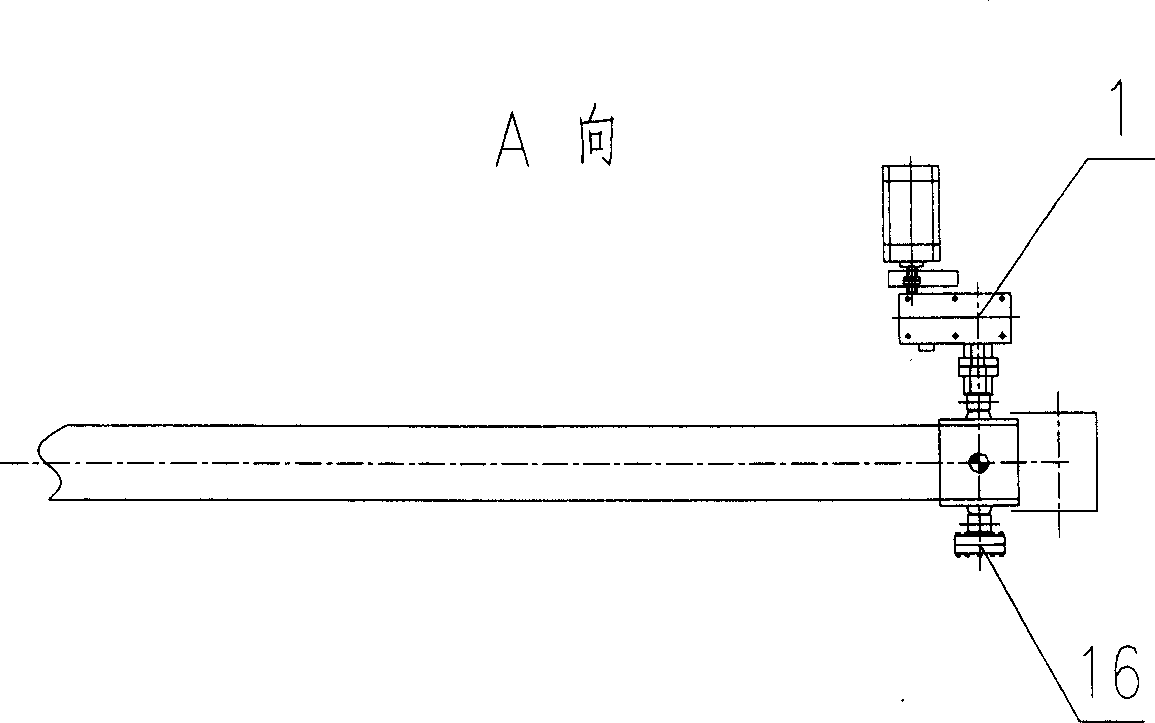

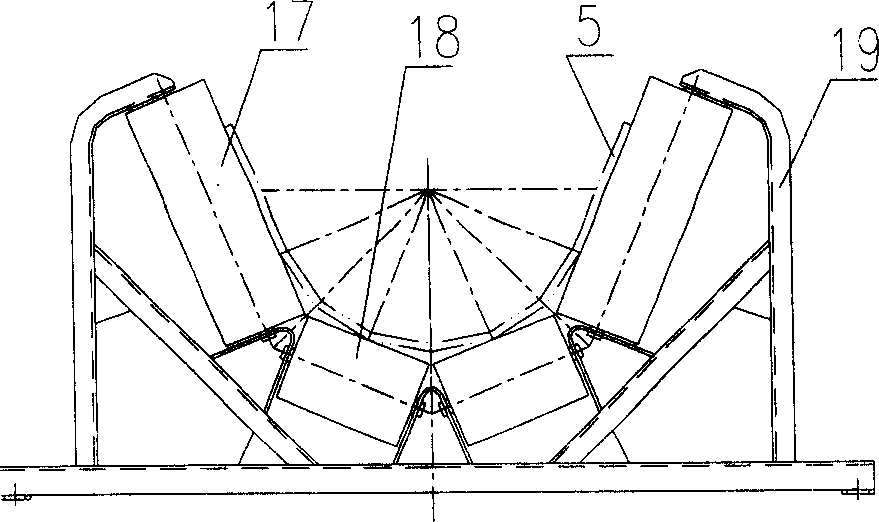

[0022] according to Figure 1-9The specific structure and working process of the present invention will be described in detail. The machine includes a frame 13 and a driving device 1 assembled on it, a driving drum 2, a tensioning drum 23, a load idler set, a transition idler set 3, a lower idler set, a conveyor belt, a car-type tensioning device and a cleaning machine. device. Among them, the specifications and shapes of the frame 13, the driving device 1, the driving roller 2, the tension roller 23, the transition roller group 3, the parallel lower roller group 11, and the V-shaped lower roller group 12 should be selected according to the actual use requirements. There is a structure of common parts for belt conveyors. Frame 13 is used to install various idler groups and support conveyor belts, and is the skeleton of the machine to ensure that materials run smoothly on the conveyor belt. The driving device 1 transmits power by the frictional force between the drive drum 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com