Heat pipe

A heat pipe and pipe body technology, applied in the field of heat pipes, can solve the problems of liquid transport capacity drop, disintegration, thermal resistance increase, etc., and achieve the effect of increasing fluid transport capacity and enhancing heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

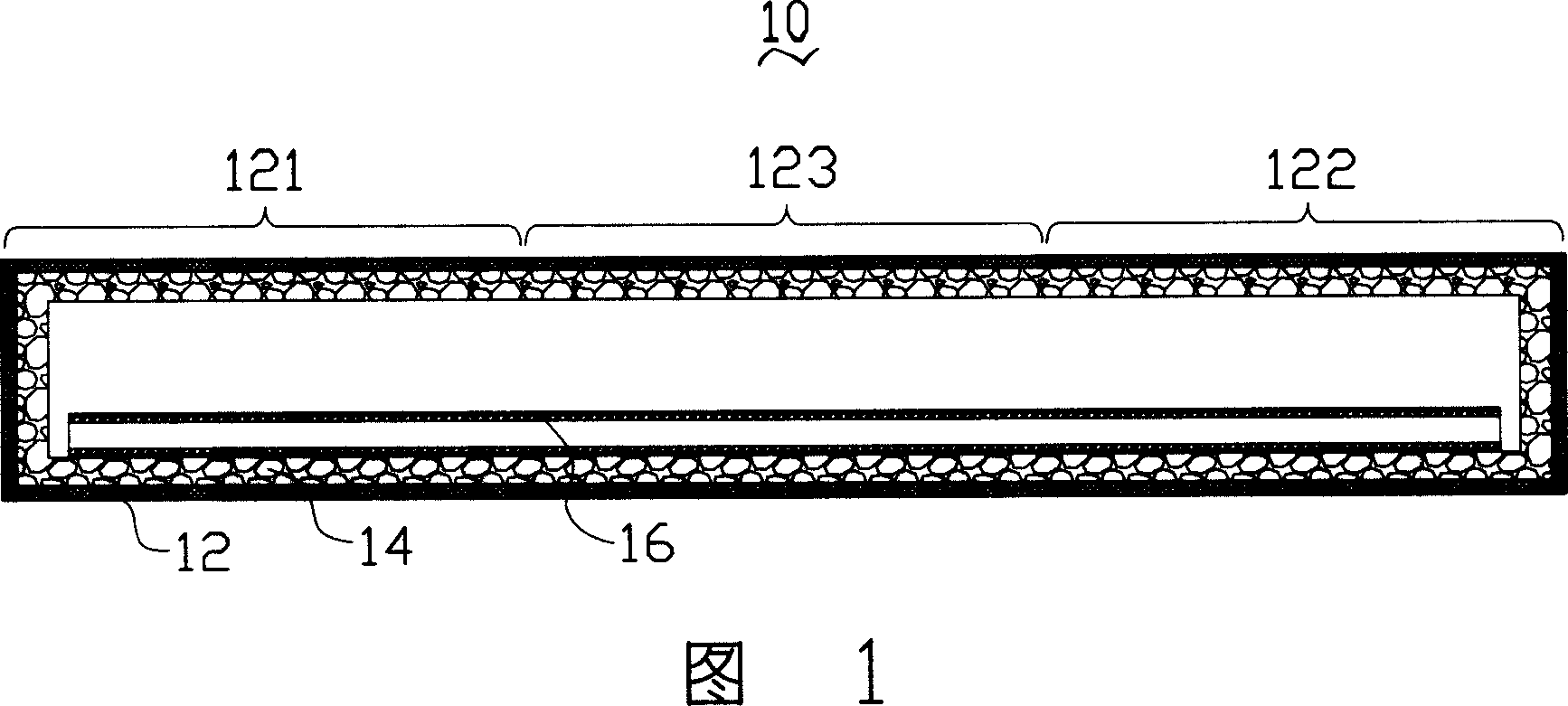

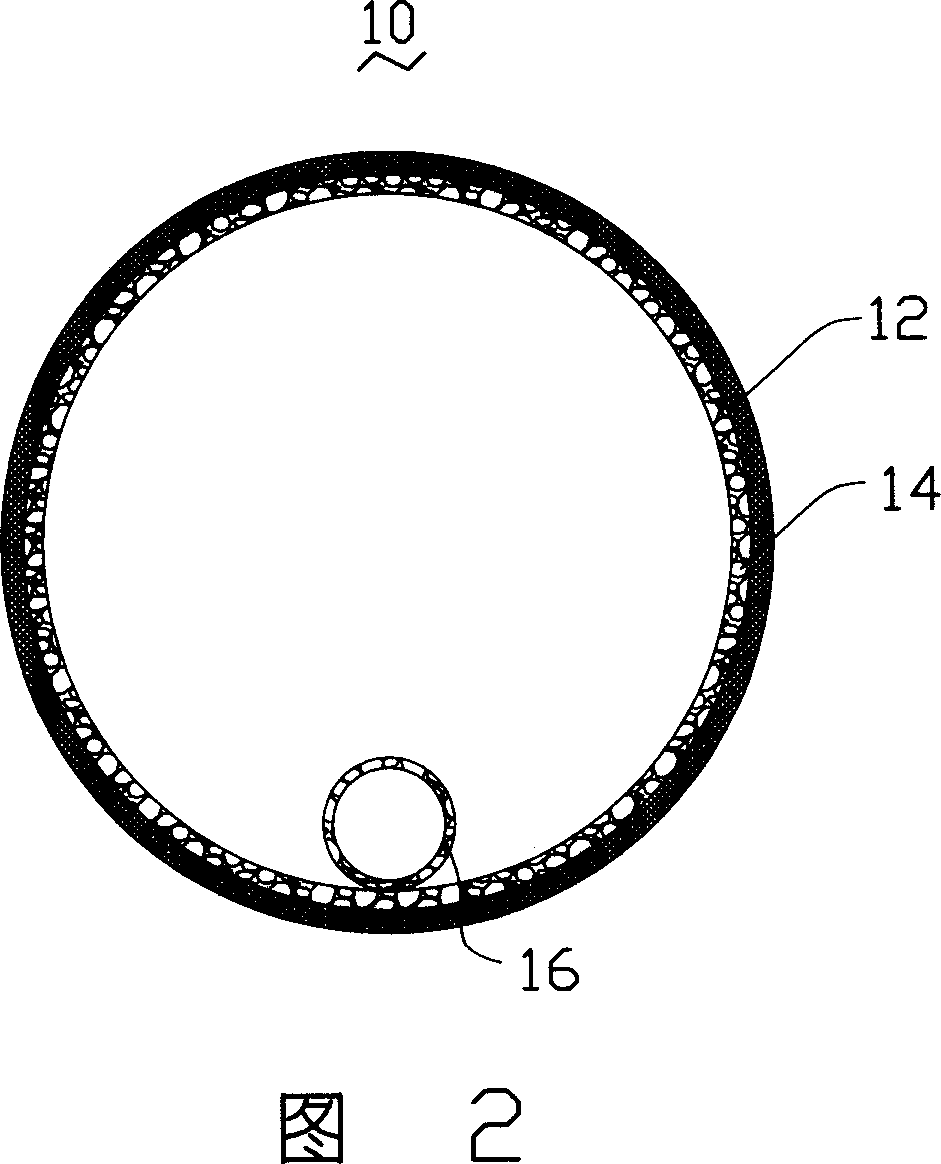

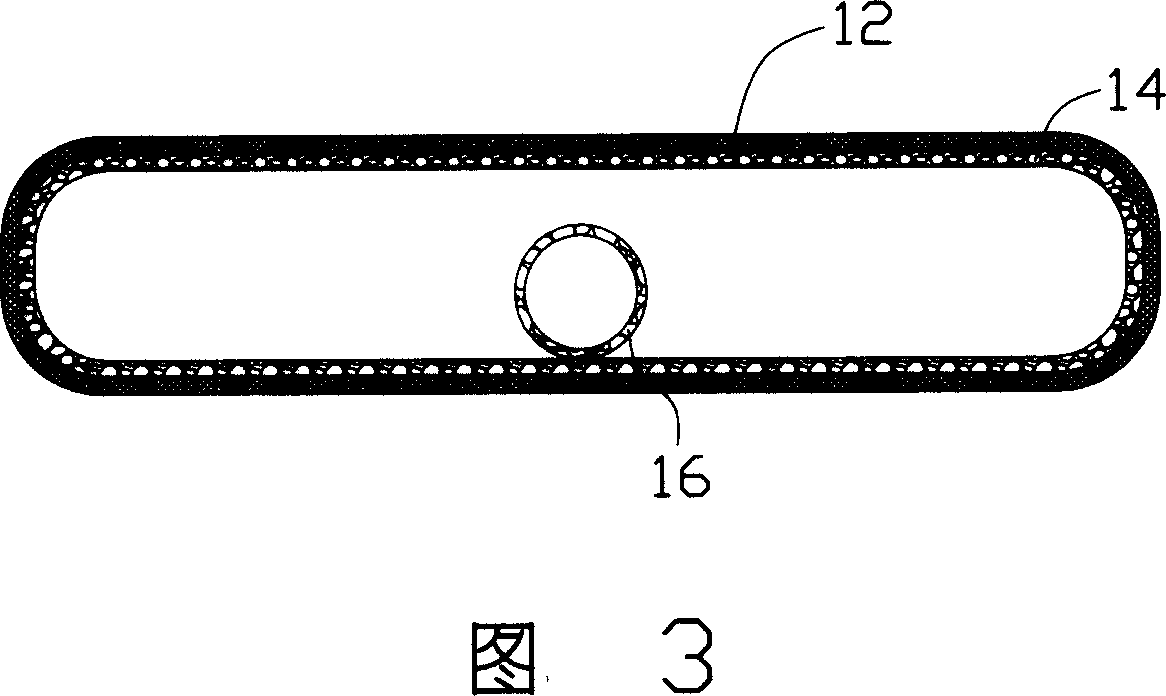

[0016] Please refer to FIG. 1 , the heat pipe 10 includes a tube body 12 , a main capillary structure 14 , an auxiliary capillary structure 16 and a working medium.

[0017] The tube body 12 is made of a material with good thermal conductivity such as copper, which can transfer the heat generated by a heating element to the inside of the tube body 12. The heat insulating part 123 of the evaporating part 121 and the condensing part 122 .

[0018] The working medium is filled in the tube body 12 and is water, wax, alcohol, methanol and other substances with a relatively low boiling point. The working medium absorbs heat and evaporates from the evaporation part 121 of the pipe body 12, moves to the condensation part 122 with heat, condenses into a liquid after releasing heat in the condensation part 122, releases the heat, and completes heat dissipation to the heating element.

[0019] The capillary structure 14 is arranged on the inner wall of the tube body 12, and can be in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com