Grinding device and grinder using the same

A grinding and moving device technology, applied in grinding machines, optical surface grinders, grinding/polishing equipment, etc., can solve problems such as affecting the use of grinding machines, affecting the sealing effect, and deviation of roller blinds, so as to improve processing efficiency and reduce Labyrinth gap, the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

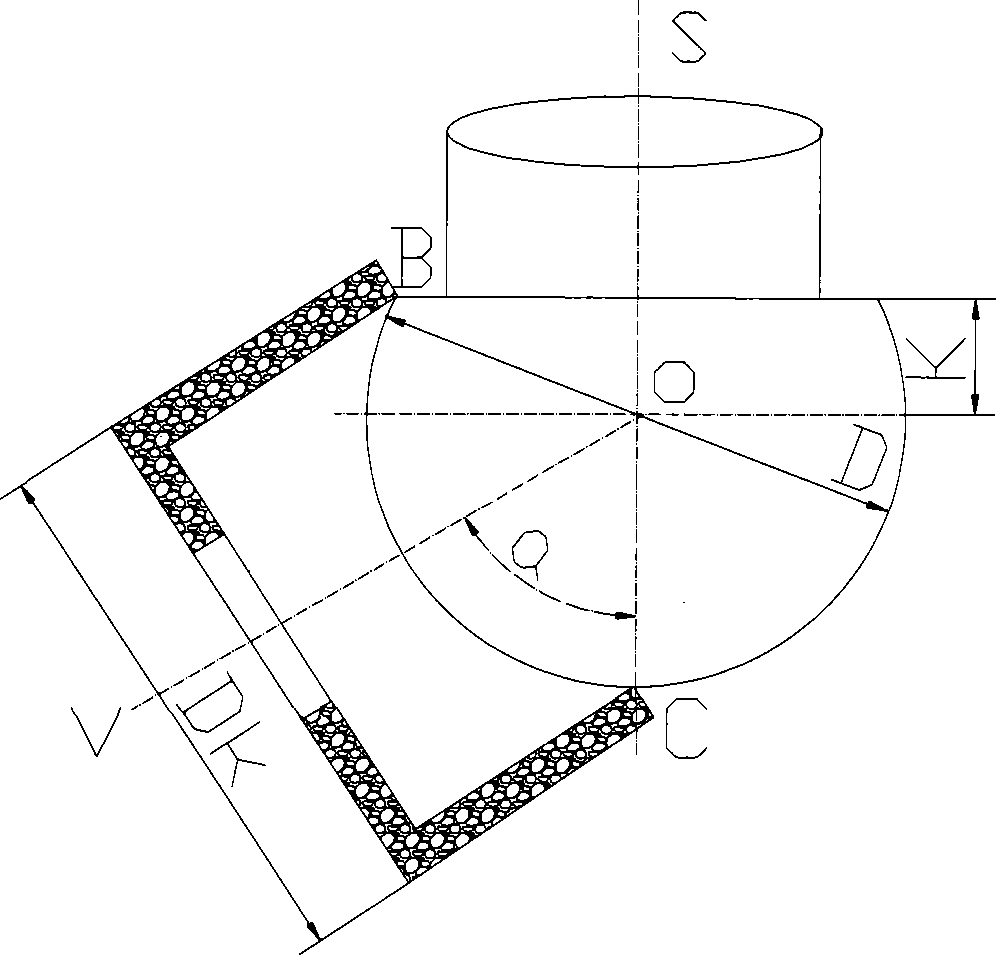

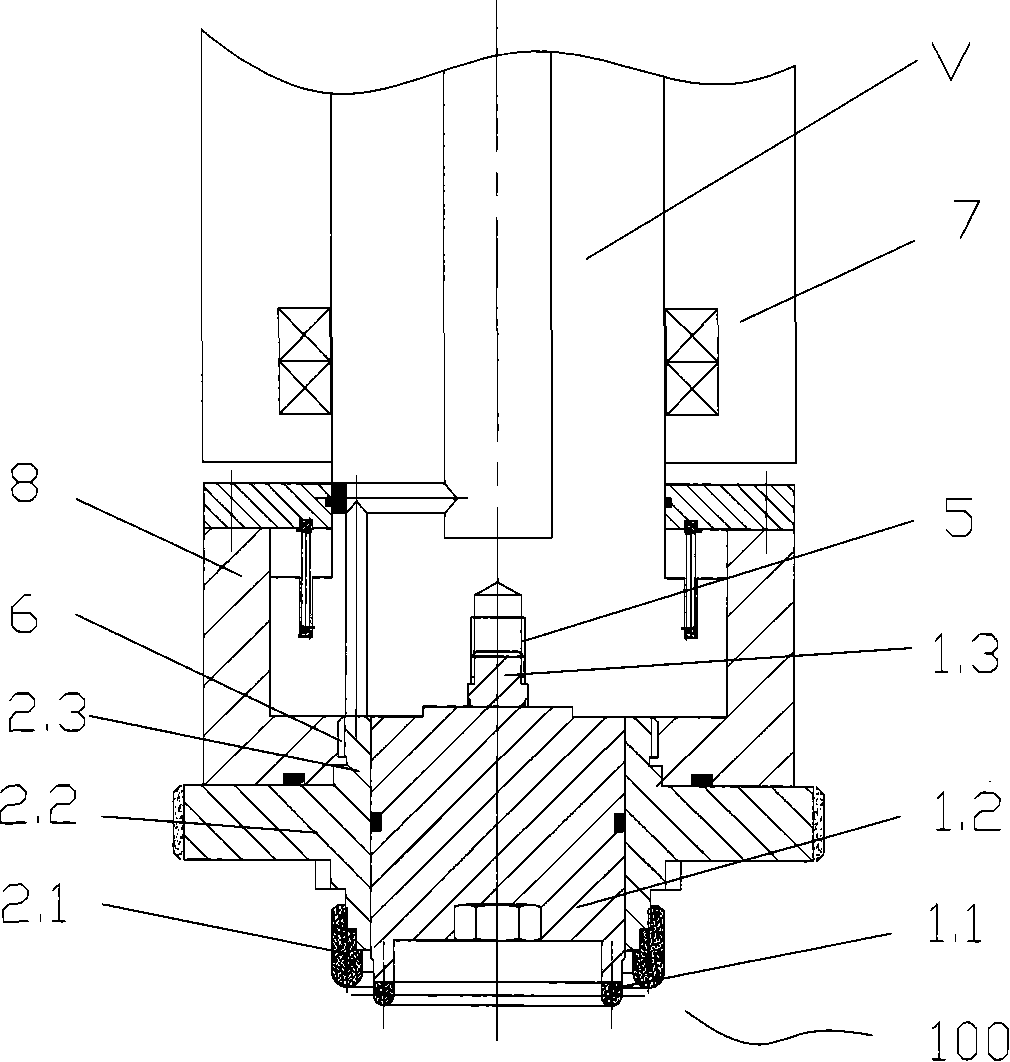

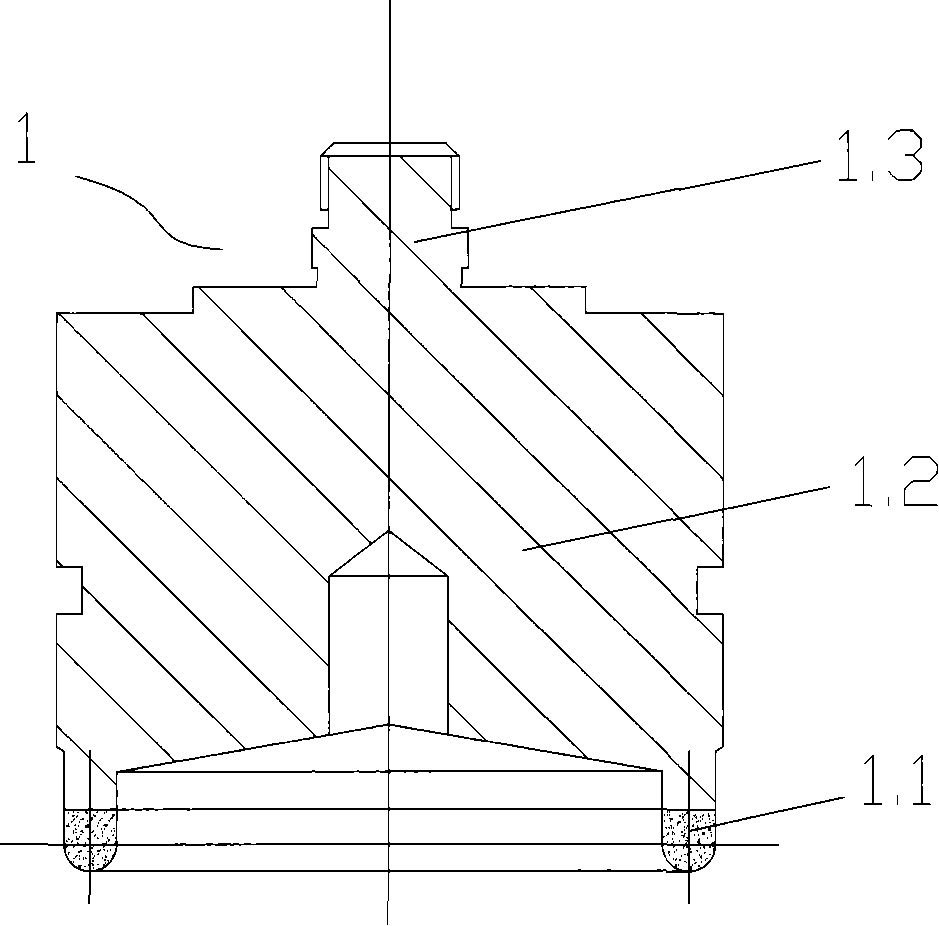

[0074] The basic idea of the present invention is: the grinding device is equipped with two mutually independent grinding wheels on the grinding wheel shaft, which are respectively an outer grinding wheel and an inner grinding wheel, wherein the inner grinding wheel is fixed on the rotating shaft of the grinding wheel shaft for fine grinding; the outer grinding wheel It can move axially along the grinding wheel shaft for coarse grinding; the grinding machine uses the above grinding device, the swing shaft is driven by a torque motor, the stator of the motor is fixed to the shell of the swing shaft, and the rotor of the motor is directly installed on the shaft of the swing shaft , and the swing shaft is directly connected with the grinding wheel shaft; further, the protective cover adopts a labyrinth protective structure, and its movable parts are made of corrosion-resistant materials through cutting.

[0075] The specific implementation manners of the present invention will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com