Guide sleeve broacher

A technology of reaming machine and guide sleeve, which is applied in the direction of reaming device, reaming device, metal processing machinery parts, etc. It can solve the problems of irregular shape, inaccurate center hole size, and inability to ensure coincidence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

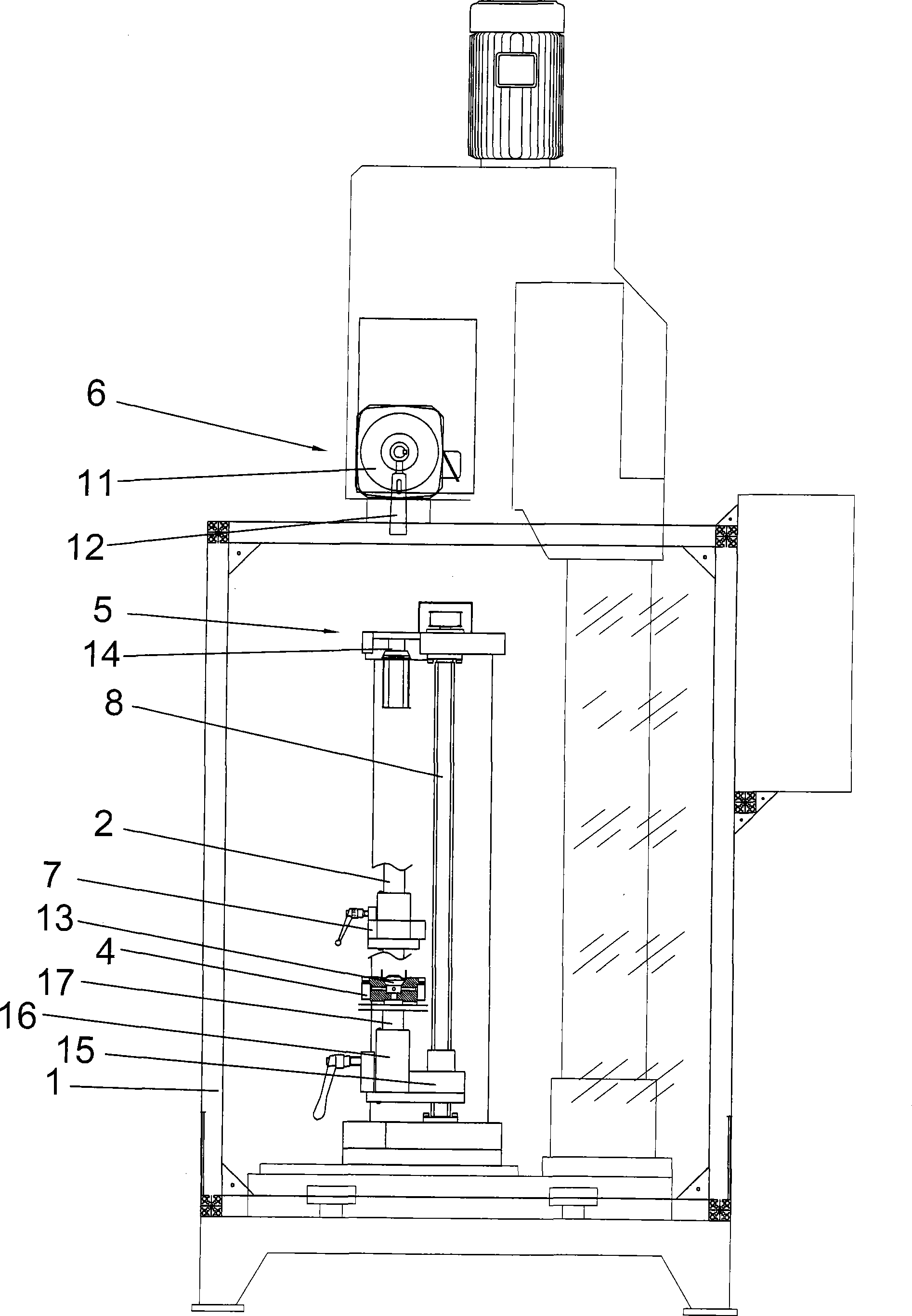

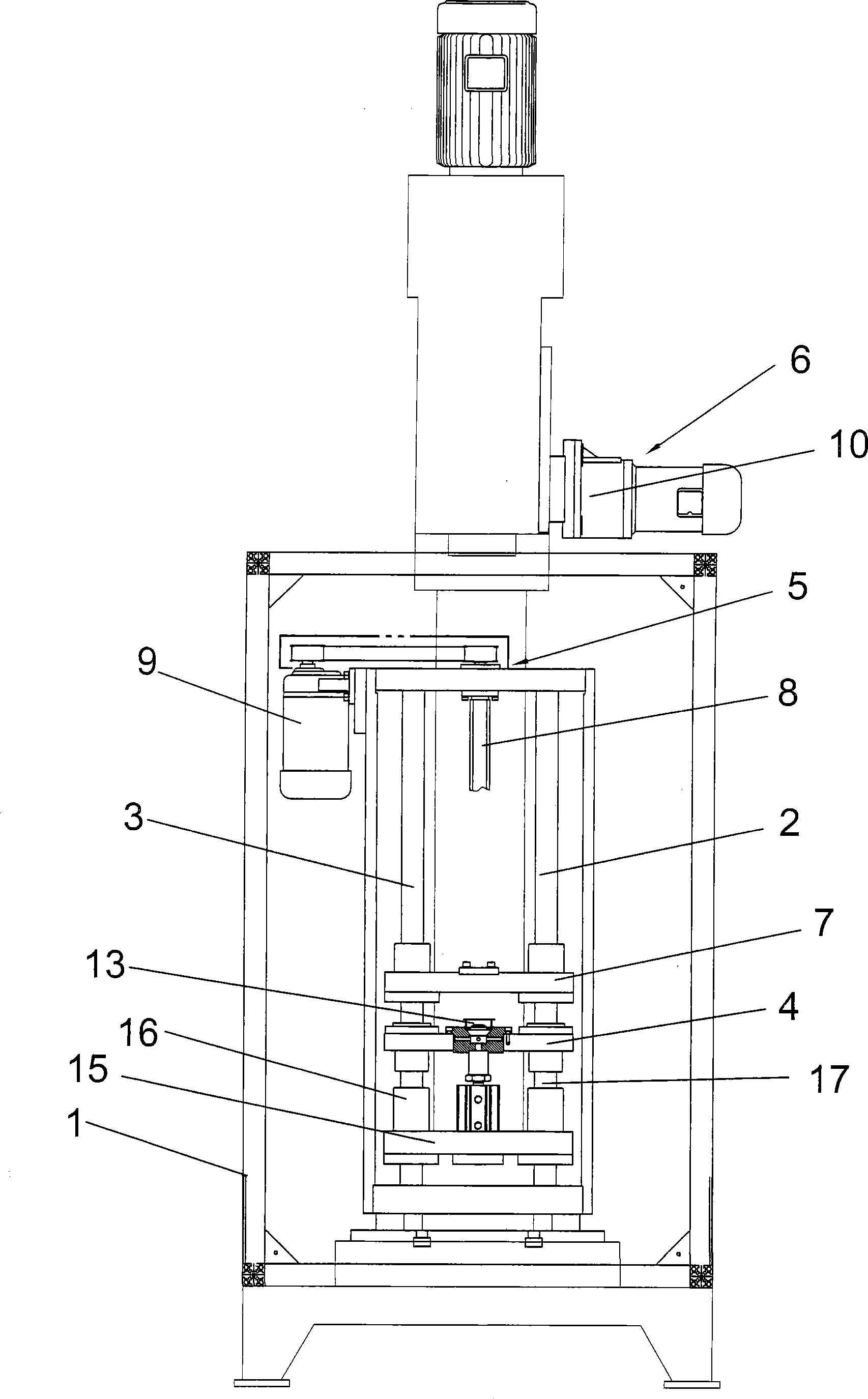

[0012] as attached figure 1 And attached figure 2 Shown, a kind of guide sleeve reaming machine, it comprises base body 1 and the reamer mechanism 6 that is arranged on described base body 1, described reamer mechanism 6 comprises motor 10 and is fixedly connected on this motor 10 The tool fixing seat 11 on the rotor, the tool fixing seat 11 is fixedly provided with a reamer 12 whose axis line is perpendicular to the horizontal plane, and the seat body 1 is fixedly equipped with a pair of guides whose axis line is perpendicular to the horizontal plane Columns 2, 3, the pair of guide columns 2, 3 are slidably sleeved with a positioning die 4, and the positioning die 4 is provided with a tapered first positioning hole 13. The top of the guide pillars 2, 3 is fixedly provided with an upper mold 5, and the upper mold 5 is provided with a tapered second positioning hole 14. When processing the guide sleeve, the guide sleeve to be processed is fixedly placed in the first positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com