Rocker shaft bore-deburring machine

A rocker shaft and deburring machine technology, which is applied to reaming devices, reaming devices, metal processing machinery parts, etc., can solve the problems of increased cost and low deburring efficiency, and achieve low labor intensity, simple operation and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

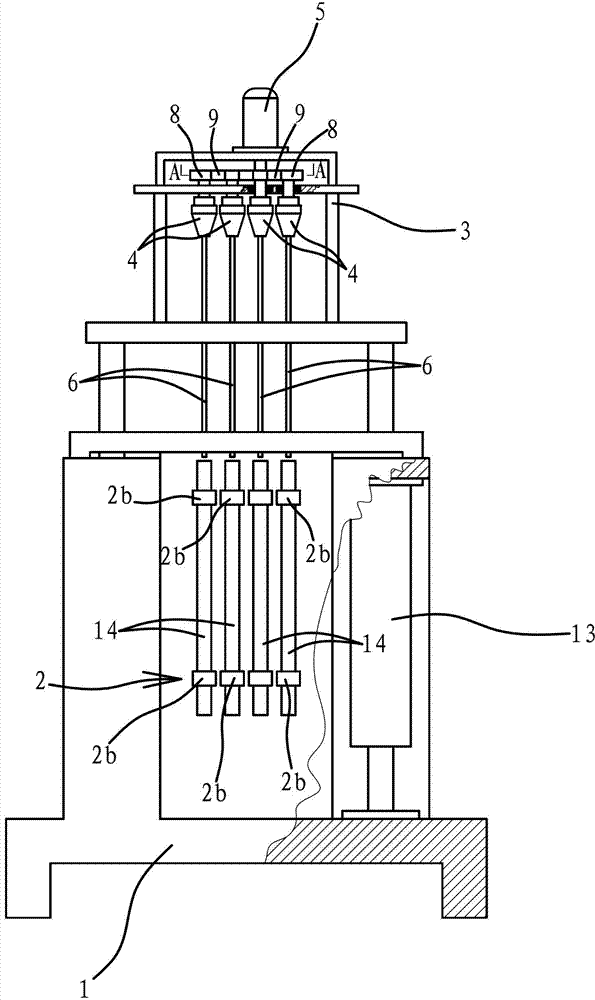

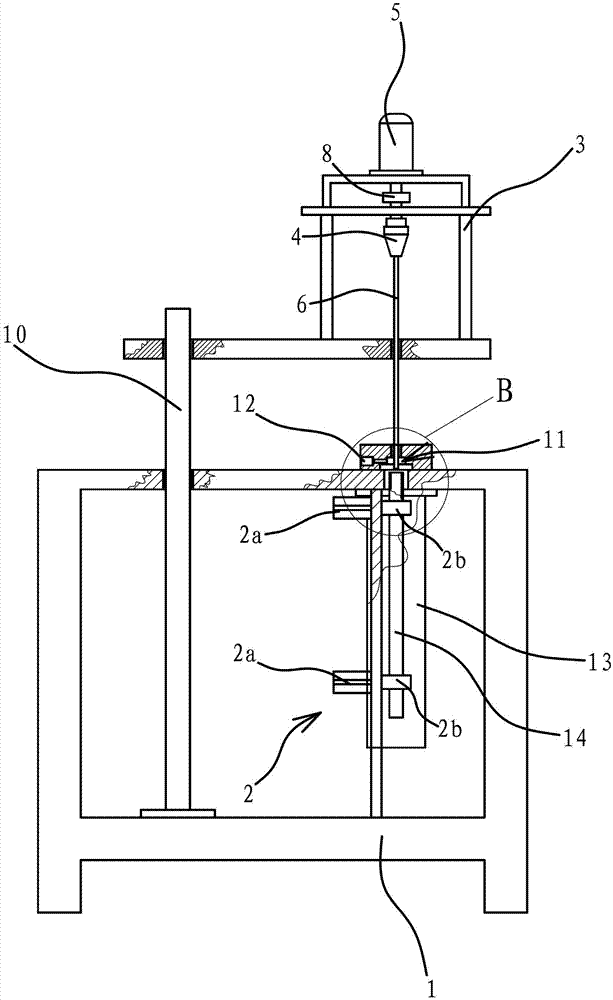

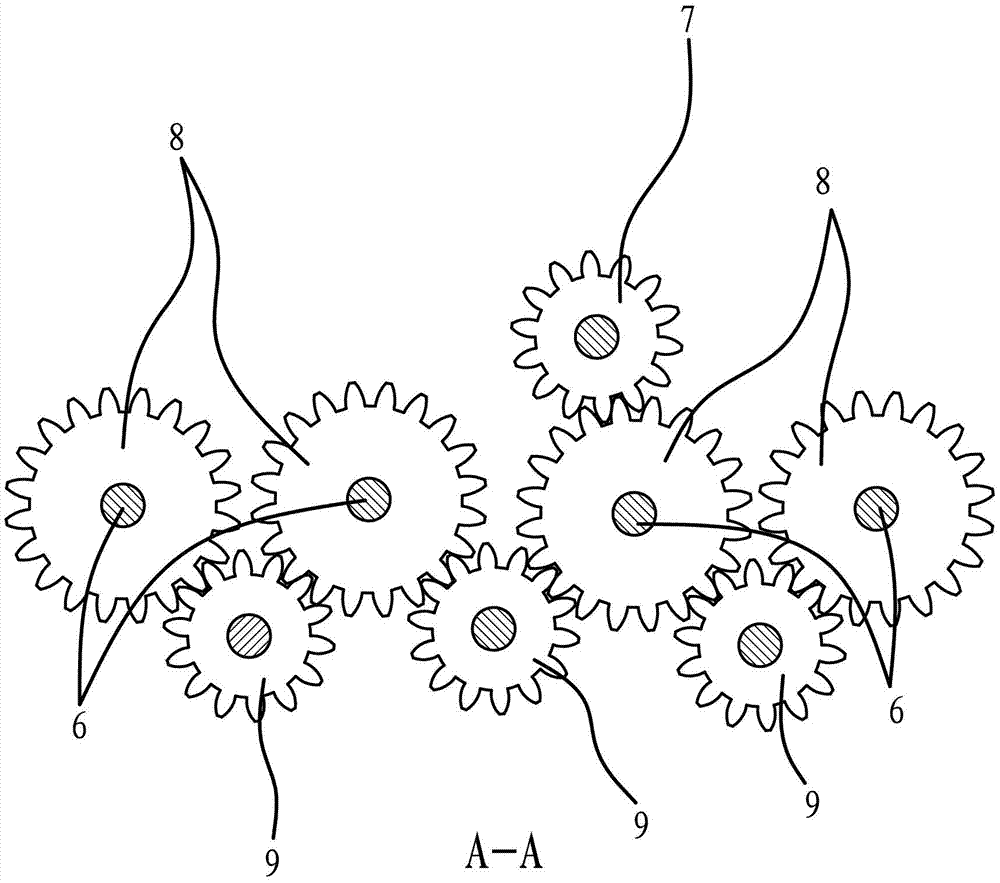

[0033] like Figures 1 to 5 As shown, a rocker shaft inner hole deburring machine includes a base 1, and four clamping mechanisms 2 are arranged on the base 1. The clamping mechanism 2 includes two V-shaped chucks 2b and can drive the corresponding V-shaped chucks 2b Two air cylinders 2a for opening and closing, the cylinder body of the air cylinder 2a are all connected on the base 1 . The rocker shaft 14 is clamped by the two V-shaped chucks 2b, so that when the rocker shaft 14 is fixed on the V-shaped chuck 2b, it can be kept facing the tool 6, which has a better positioning effect. As another solution, the clamping mechanism 2 is a clamping cylinder 2 a fixedly connected to the base 1 , and the jaws of the clamping cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com