Machining tool and machining method for deep taper hole of liquid rocket engine cavitation pipe

A liquid rocket and tool processing technology, which is applied in the direction of manufacturing tools, metal processing equipment, reamers, etc., can solve the problems of tool wear, cutting edge breakage, edge wear, etc., to improve stability and durability, and improve boring The effect of improving the precision and reducing the wear of the cutting edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

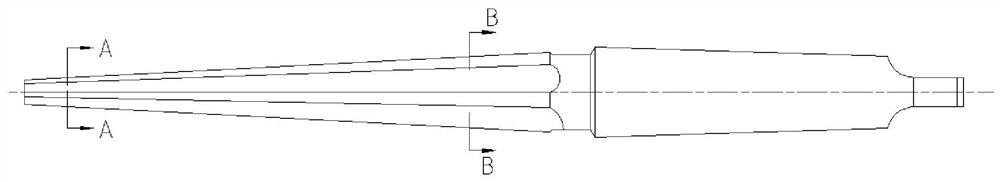

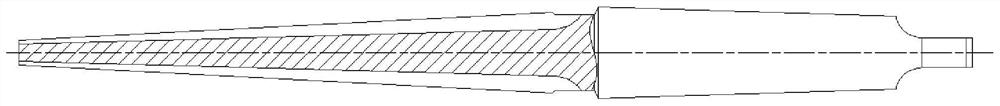

[0055] Process the deep taper hole of cavitation tube of a certain type of liquid rocket engine. The structure of the cavitation pipe is a trumpet-shaped part with a converging / expanding throat. When the liquid flows through the cavitation pipe, cavitation occurs in the throat. When the inlet pressure remains constant, the outlet flow can remain constant, and the flow rate will not change. Affected by back pressure, it can suppress the reverse transmission of pulsating pressure, so as to ensure that the system is in a stable working state.

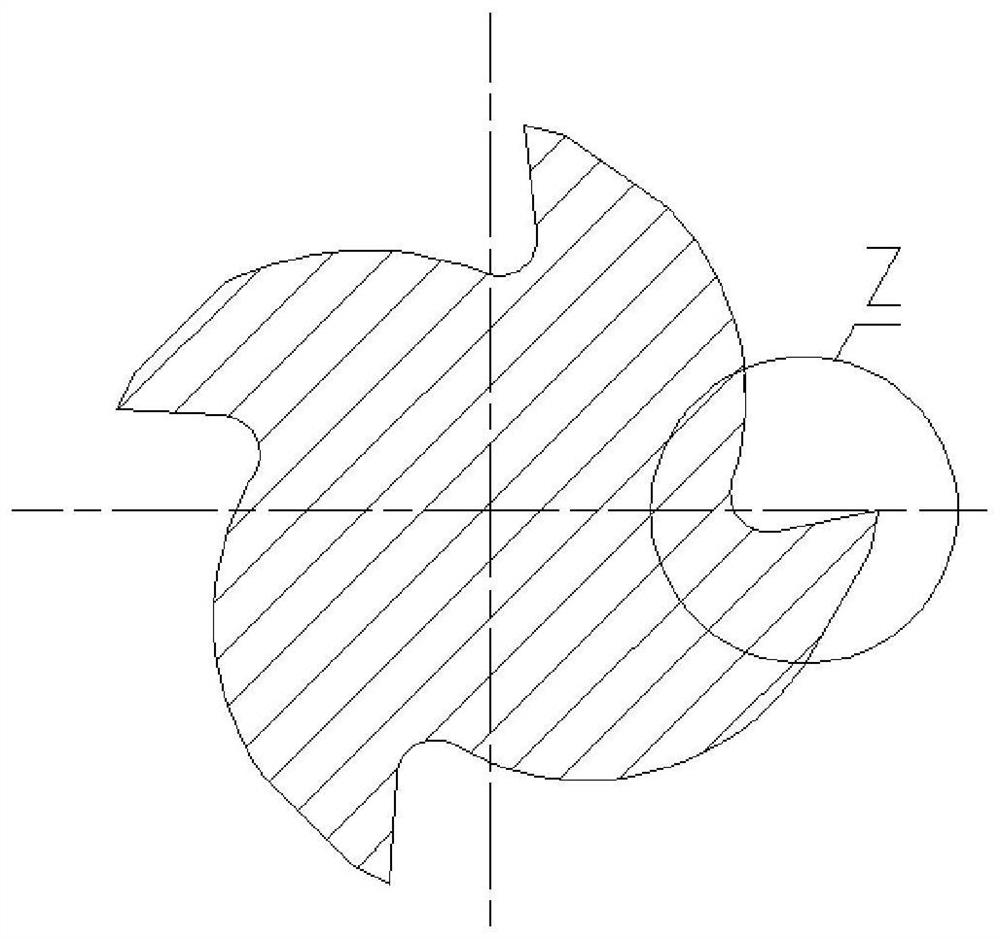

[0056] The material of the cavitation pipe is 1Cr18Ni9Ti rod, the converging section of the inner cavity is a 60° tapered hole, the inlet diameter is Φ24, and the throat diameter is Φ8.10~Φ8.22mm. One specification is processed every 0.02mm, and the tolerance of each specification is ±0.01mm . The diffuser section is a 6°±10′ deep taper hole with a taper of more than 19:1, the outlet diameter is Φ18.93mm, the connection between the conver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com