Ultrasonic vibration sleeve reaming machining device applied to air drill

A processing device and ultrasonic vibration technology are applied in the fields of fastener large-hole processing, ultrasonic vibration sleeve reaming processing device, and ultrasonic vibration drilling device, which can solve the problems of poor portability of vibration devices, limited application of vibration technology, and inability to assemble and disassemble tools. Too convenient and other problems, to achieve the effect of small and light structure, improve processing accuracy and surface quality, and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings.

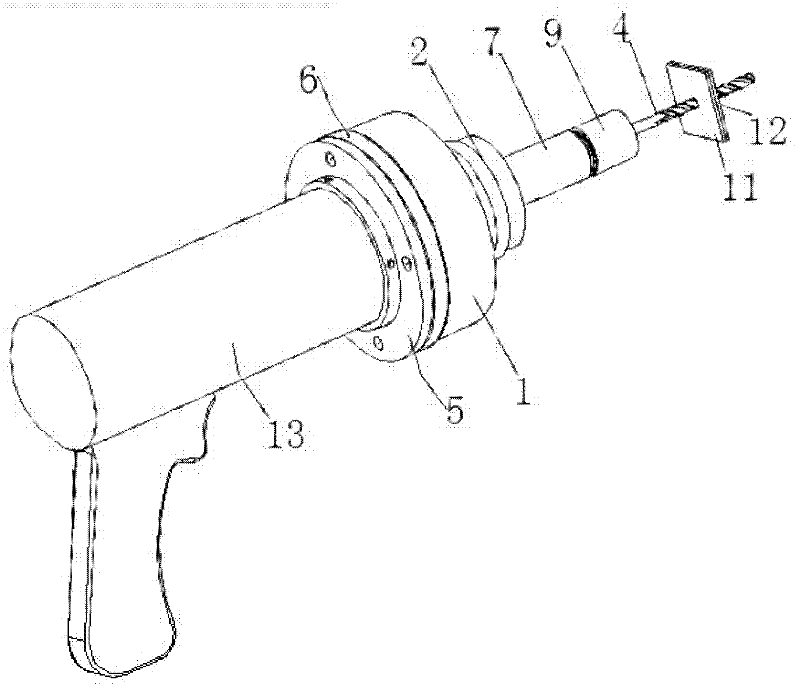

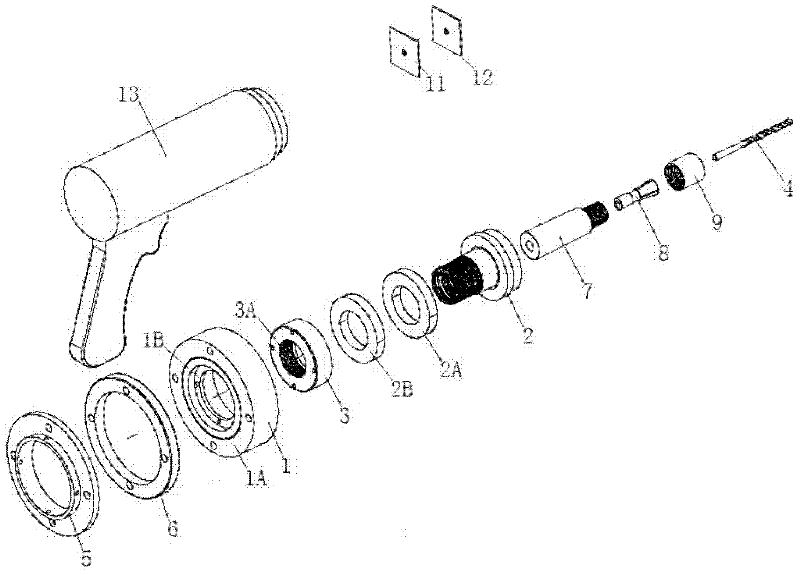

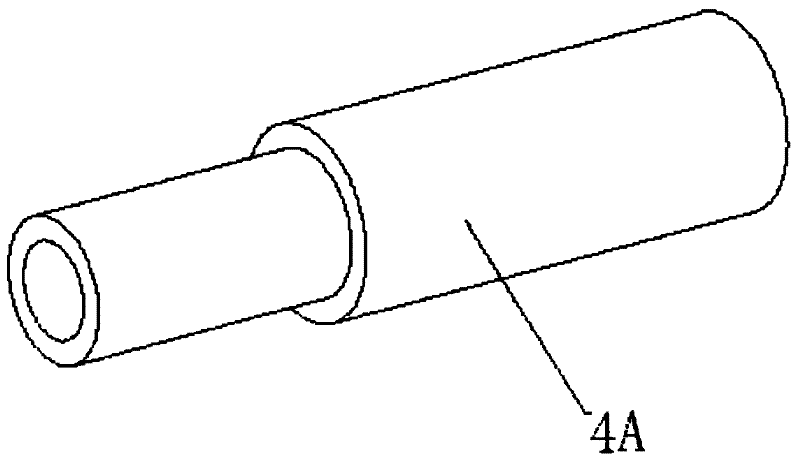

[0035] See figure 1 , Figure 1A , Figure 1B As shown, an ultrasonic vibrating sleeve reaming device applied to a gas drill of the present invention includes a slip ring 1, a front cover plate 2, A ceramic sheet 2A, B ceramic sheet 2B, a rear cover plate 3, and a flange plate. 5 and retaining ring 6, drill shaft sleeve 7, spring chuck 8, fastening cap 9; one end of the spring chuck is connected to the reamer 4 ( Figure 1A Shown) or nesting drill 4A ( Figure 1B Shown). In the present invention, the housing of the manual air drill 13 is connected to the flange 5, the main shaft of the manual air drill 13 is connected in the internal threaded hole 21 of the front cover plate 2, and the outer cylindrical section 71 of the drill shaft sleeve 7 is hot-fitted Installed in the inner cylindrical section of the front cover plate 2, the outer cylindrical section 81 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com