Patents

Literature

35results about How to "Automatic adjustment of rotation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

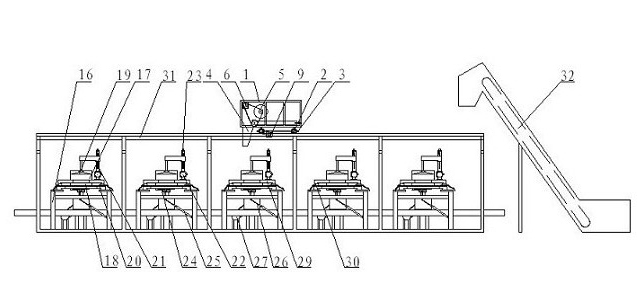

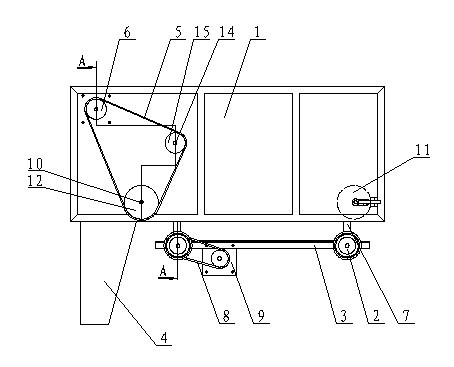

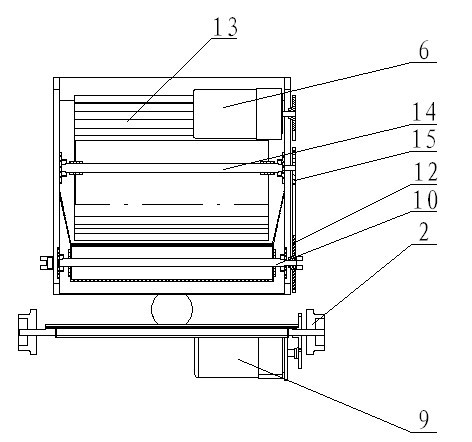

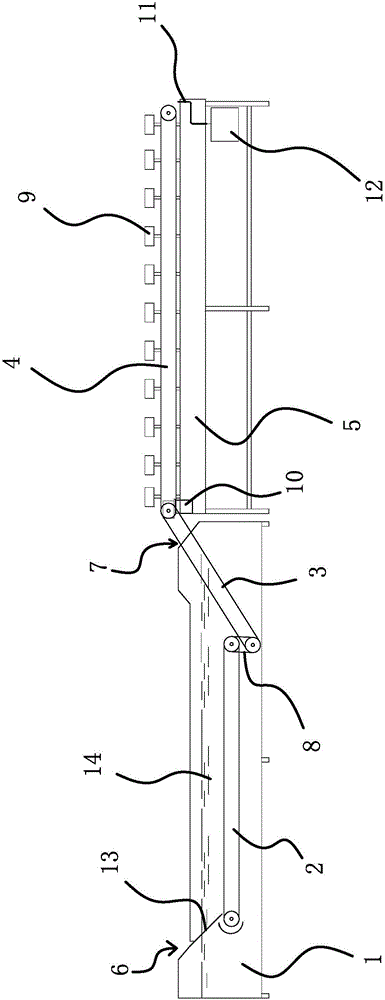

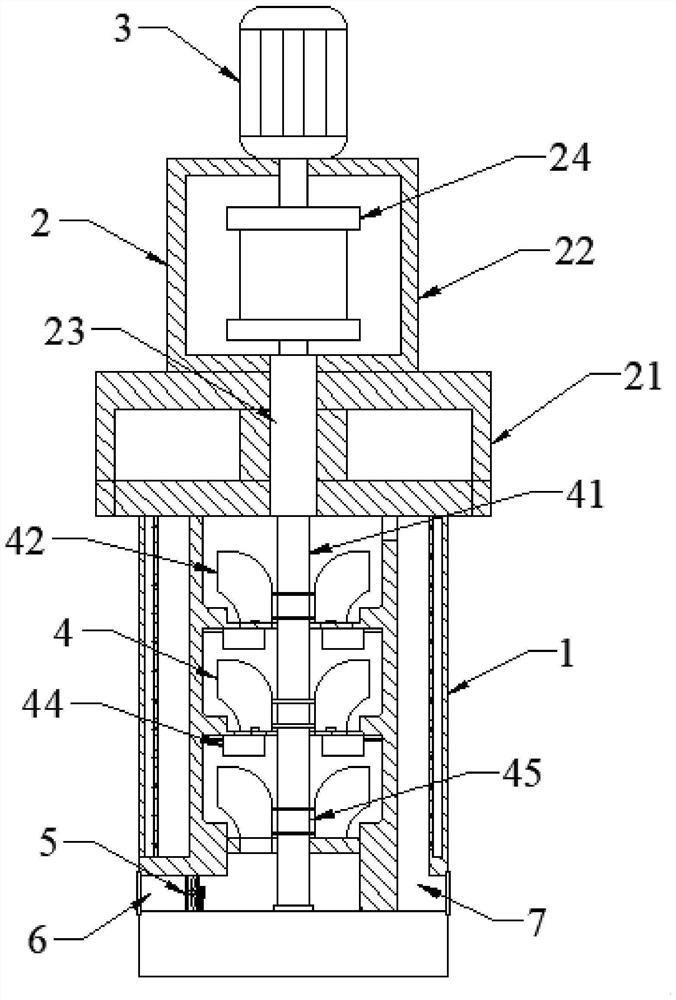

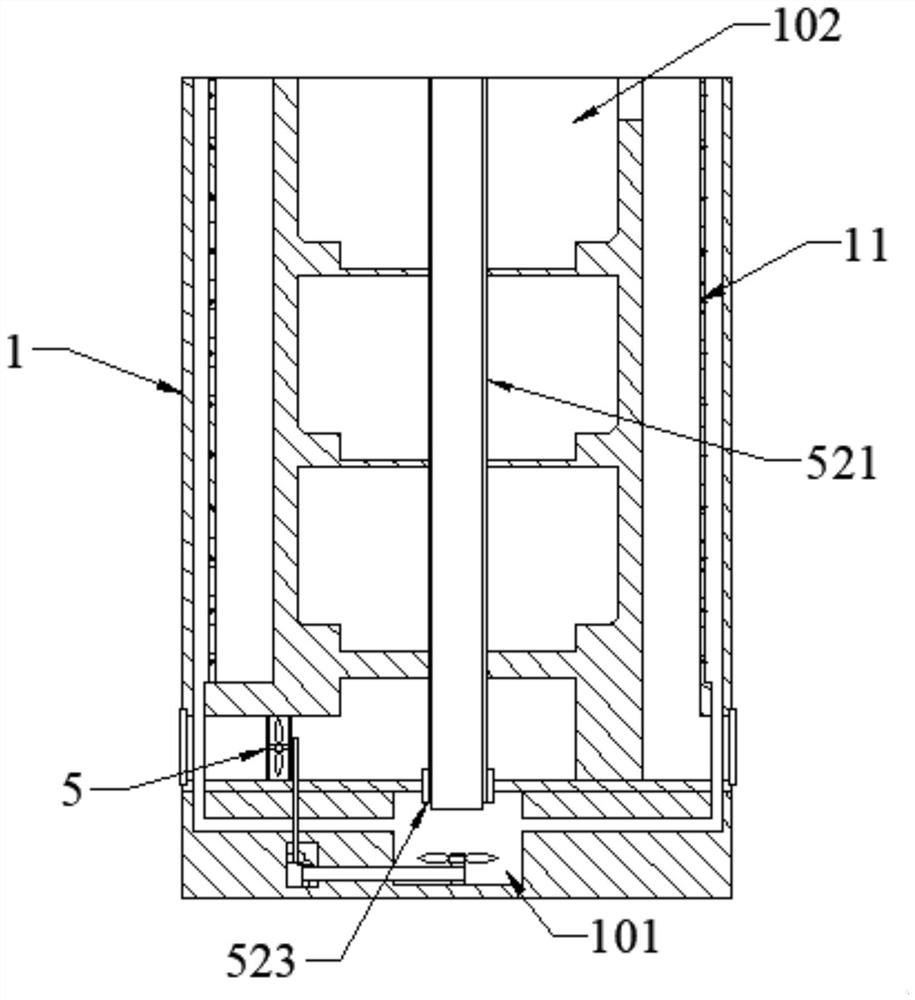

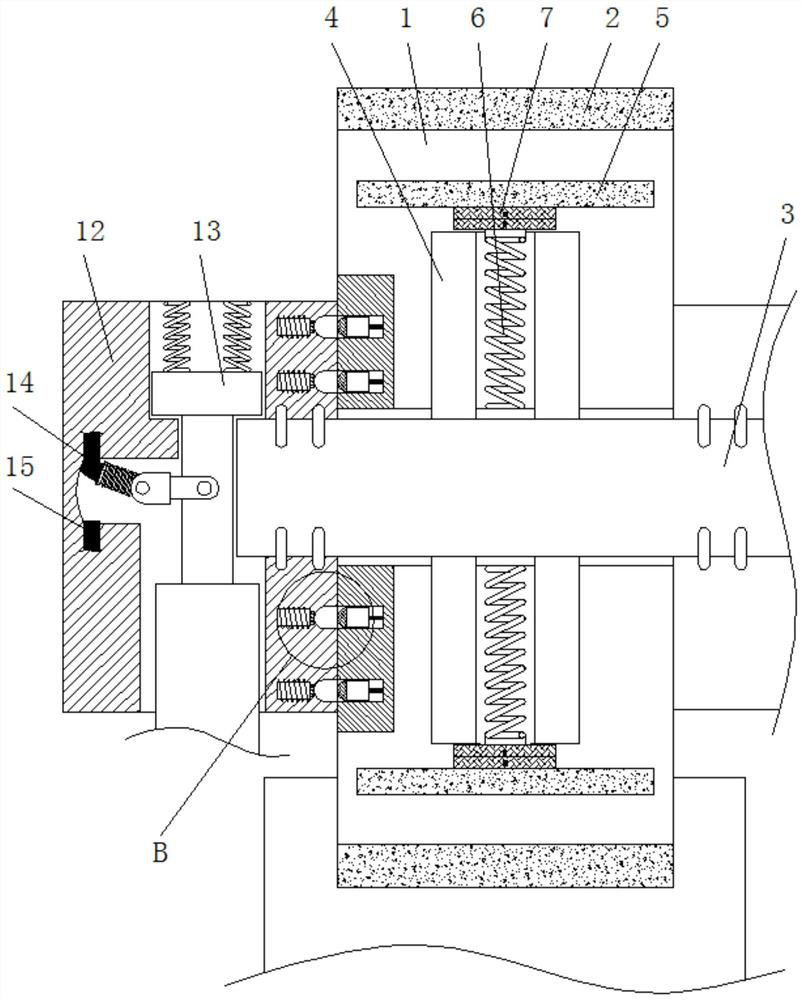

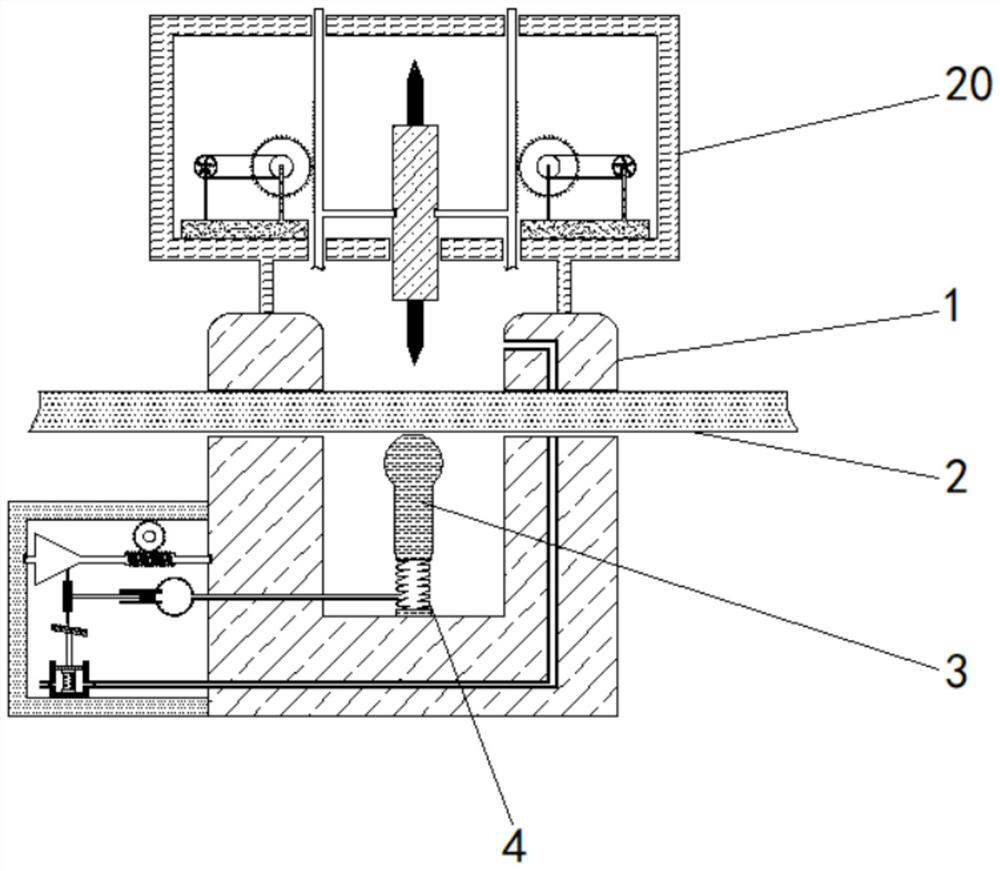

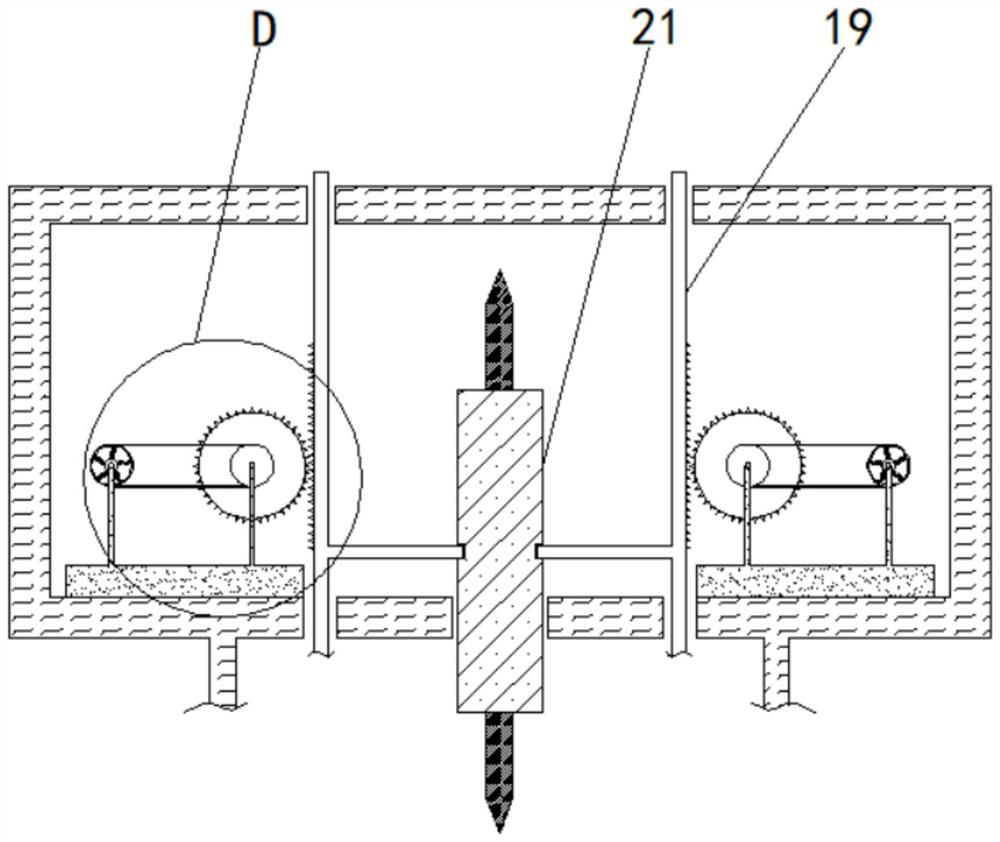

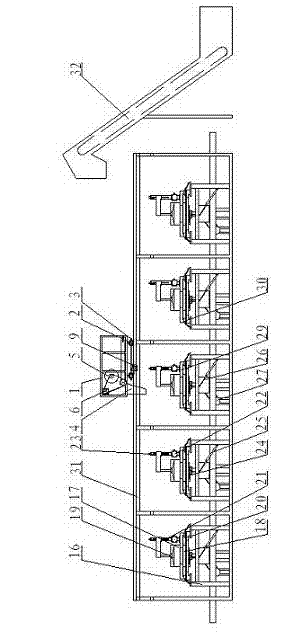

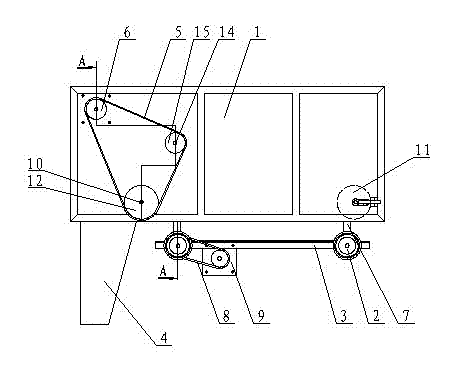

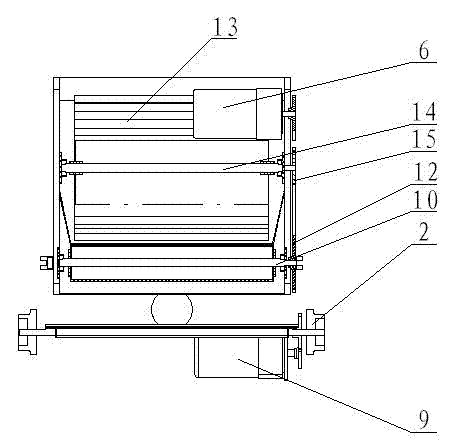

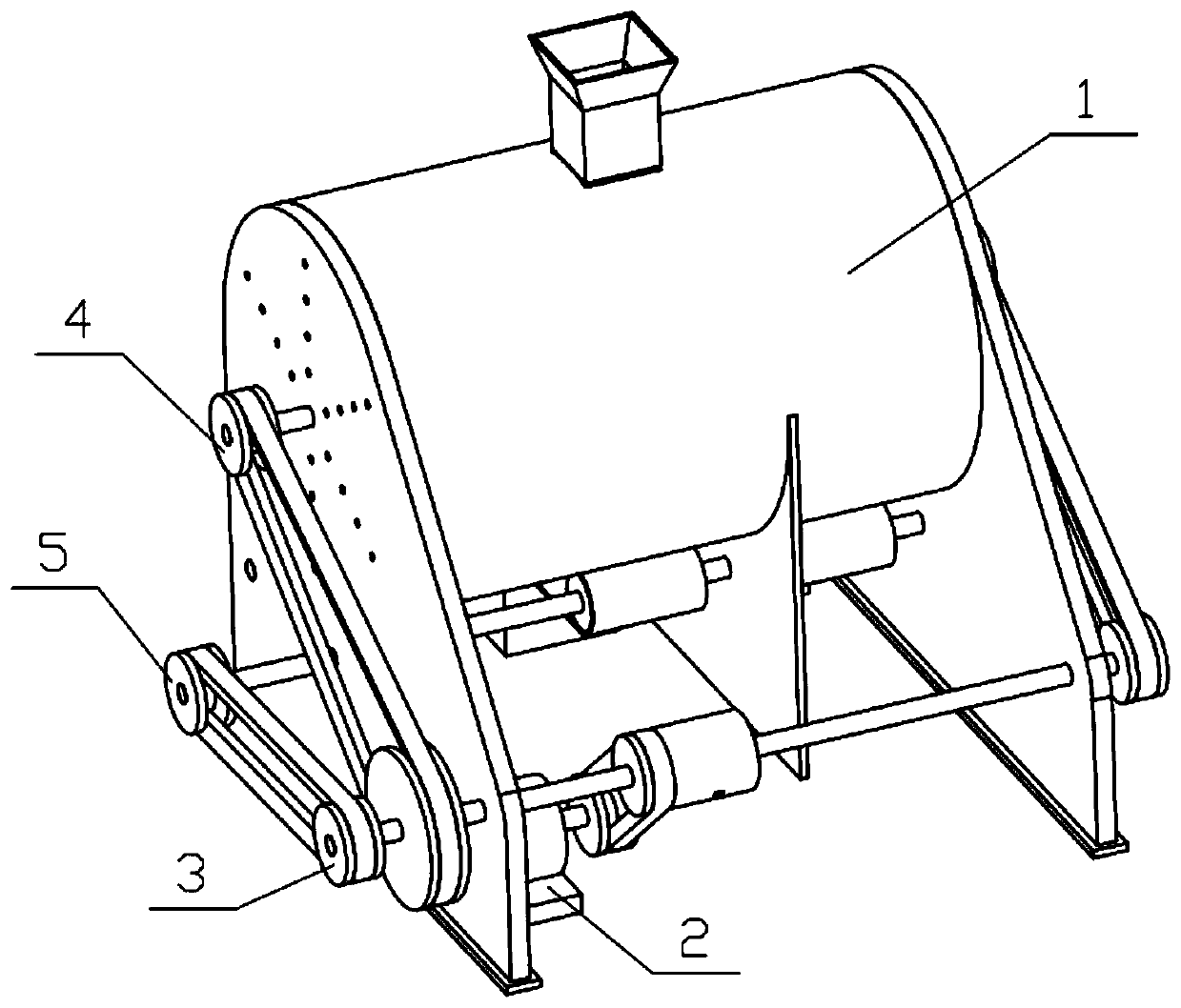

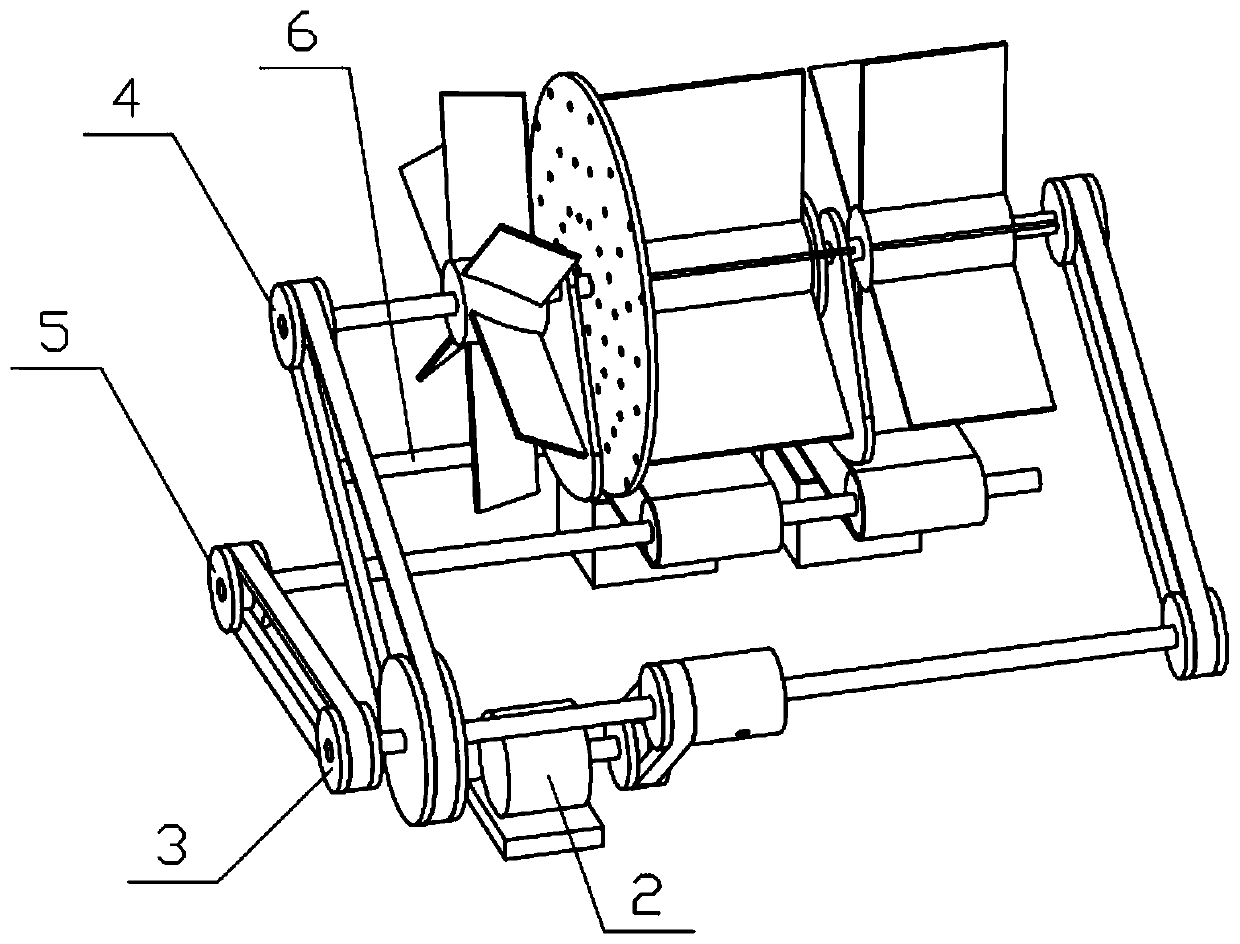

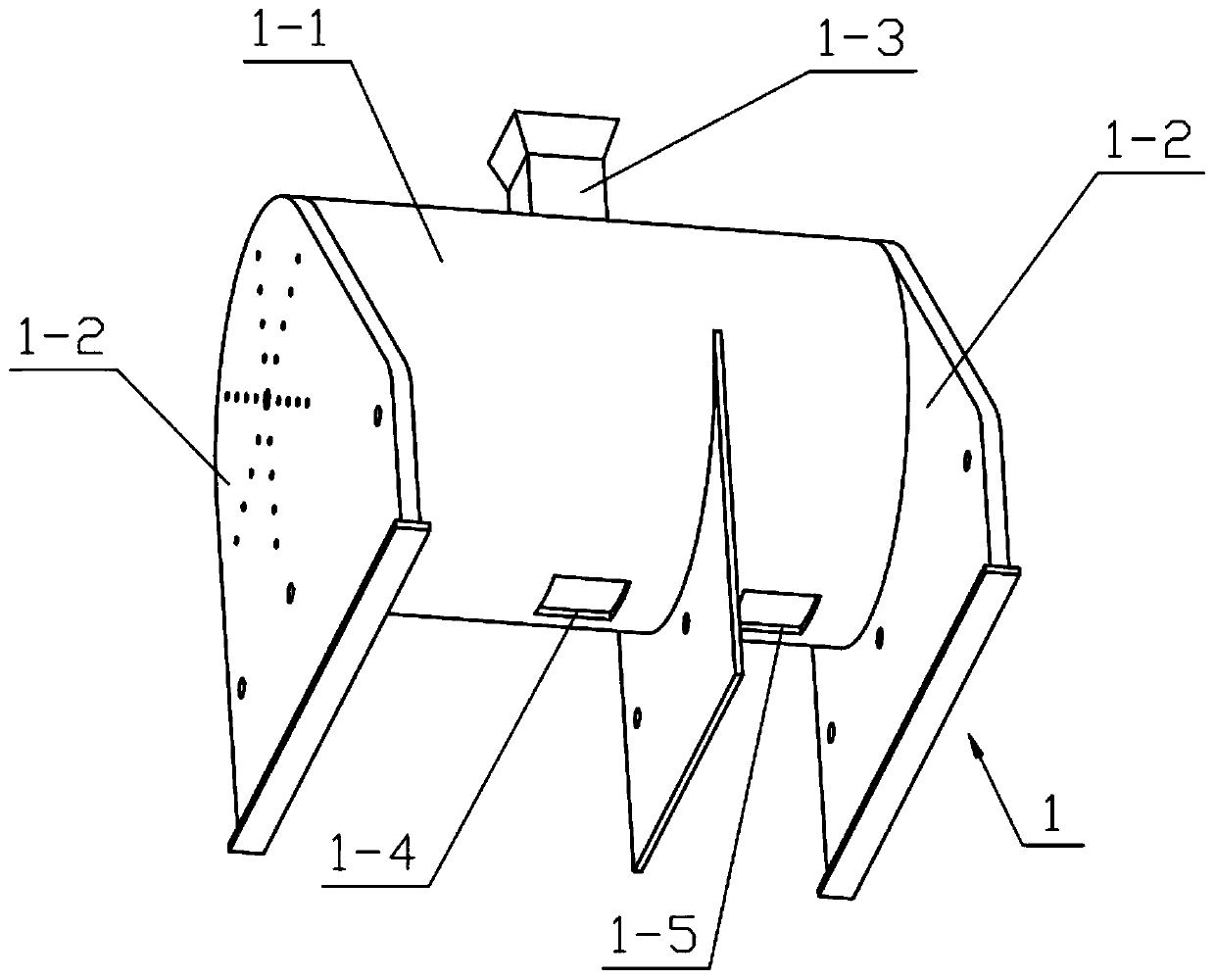

Automatic feeding device and kneading device for tea leaves

InactiveCN101884355ASave operating procedures and timeExact pressurePre-extraction tea treatmentTurning framesElectric machinery

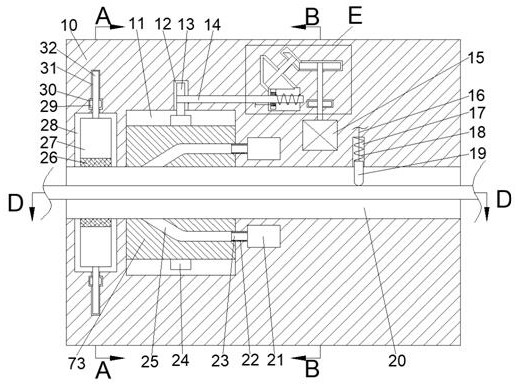

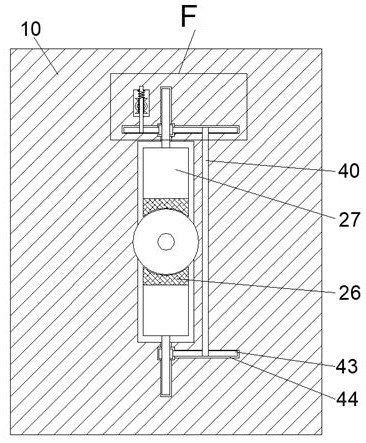

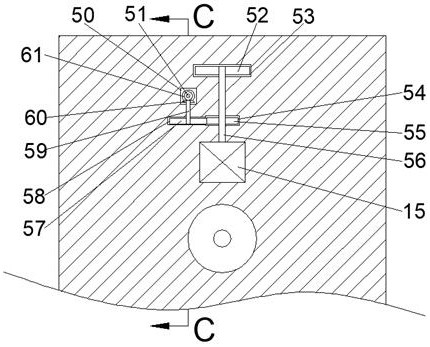

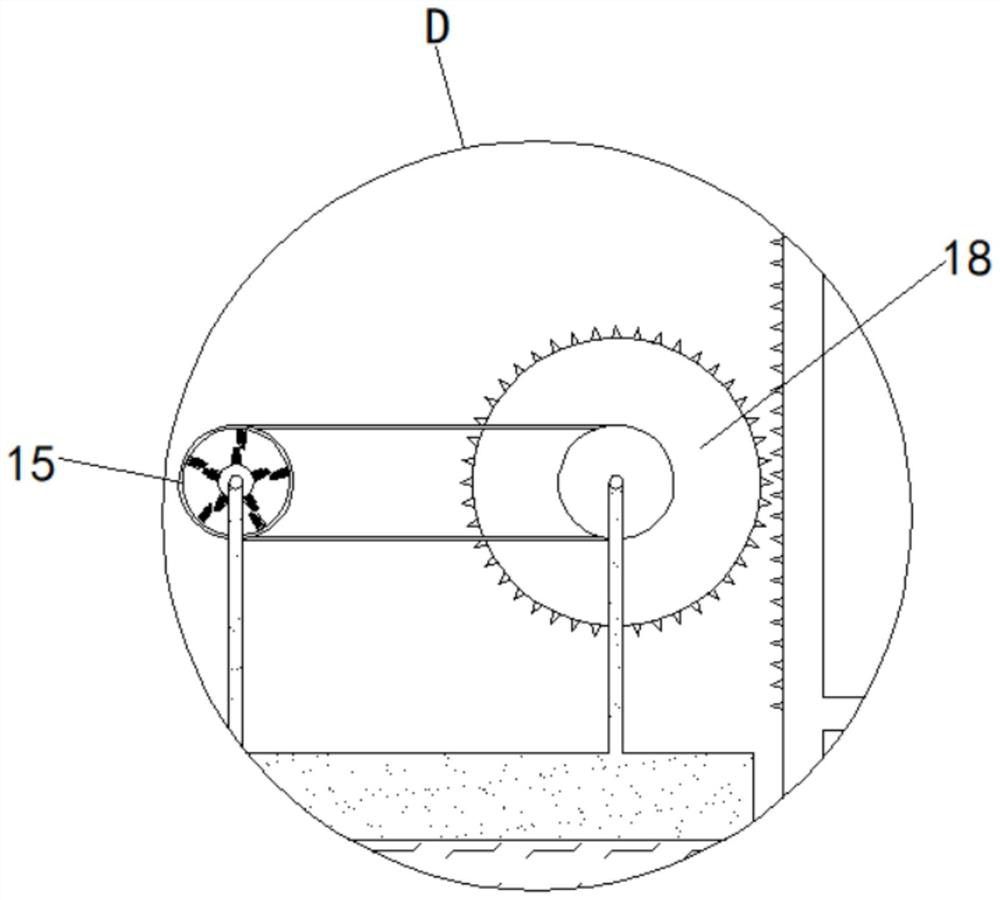

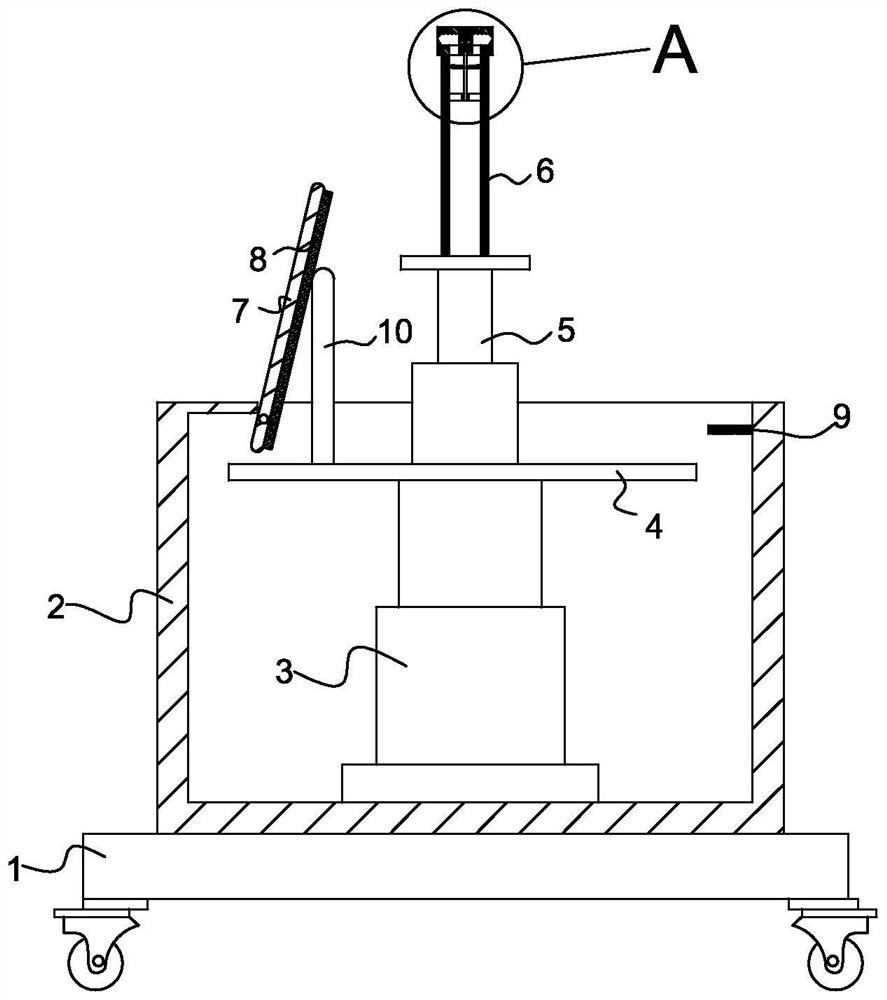

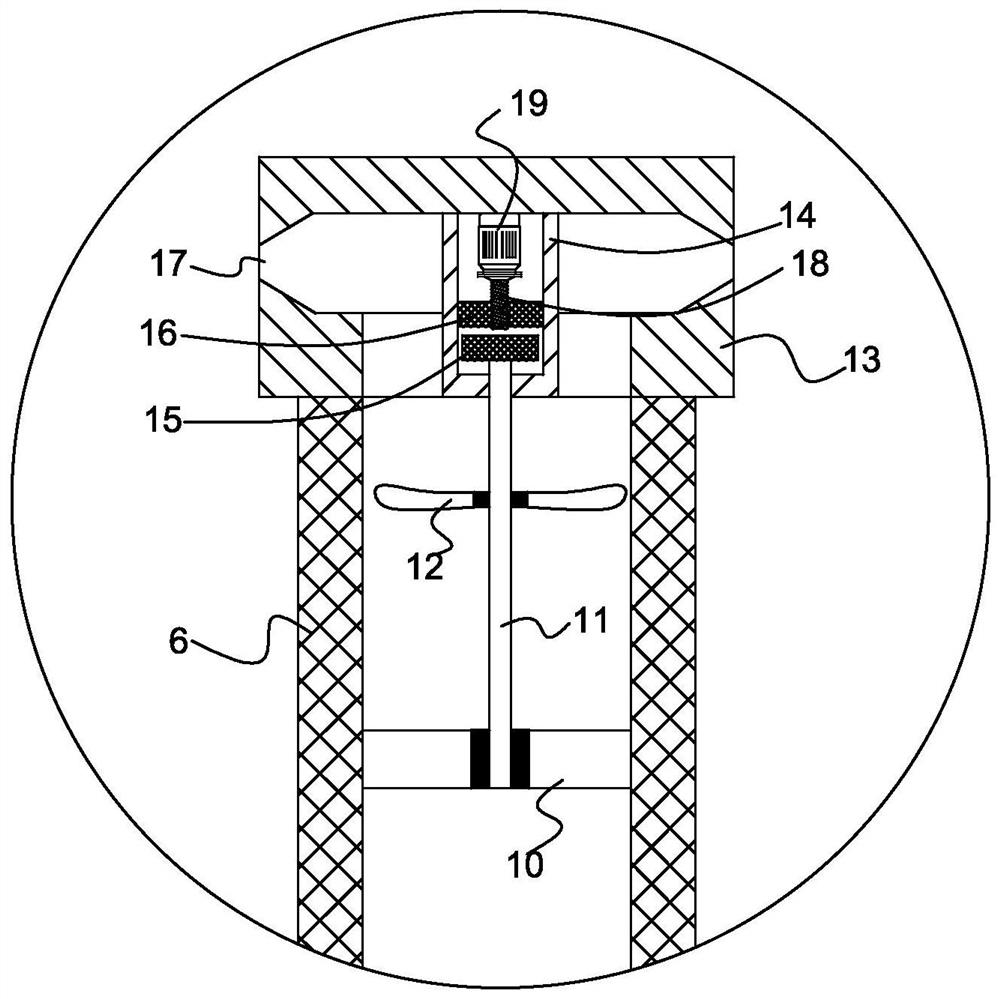

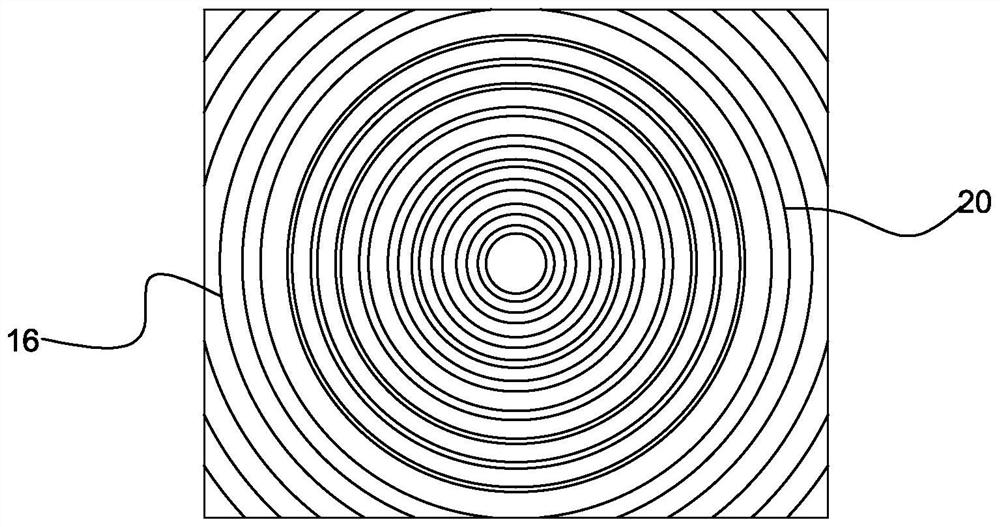

The invention discloses an automatic feeding device and a kneading device for tea leaves, wherein the automatic feeding device for the tea leaves comprises a charging box for accommodating the tea leaves; a lower end face of the charging box is provided with a frame with a wheel for walking on a rail and a discharge outlet for discharging; the discharge outlet is provided with a discharge hopper;a tea leaf transportation mechanism is arranged at the bottom of the charging box, and a leaf distributing machine is arranged above the tea leaf transportation mechanism; and both the tea leaf transportation mechanism and the leaf distributing machine are connected with a motor, which is arranged on the charging box, through a chain. The kneading device for the tea leaves comprises a stander, a power transmission mechanism for controlling the rotation of a kneading barrel, a kneading disc which is arranged below the kneading barrel, a pressure mechanism for controlling the pressure of a gland, and a material unloading device; and an edge of the kneading disc is provided with a blowing device for cleaning remainders in the kneading disc. The automatic feeding device and the kneading device for the tea leaves have the advantages of ingenious conception, simple structure and high degree of automation; and by using the two devices, the tea leaves can be weighed, fed, discharged automatically, unloaded and kneaded uniformly, so that the work efficiency is improved greatly.

Owner:CHONGQING ACAD OF AGRI SCI

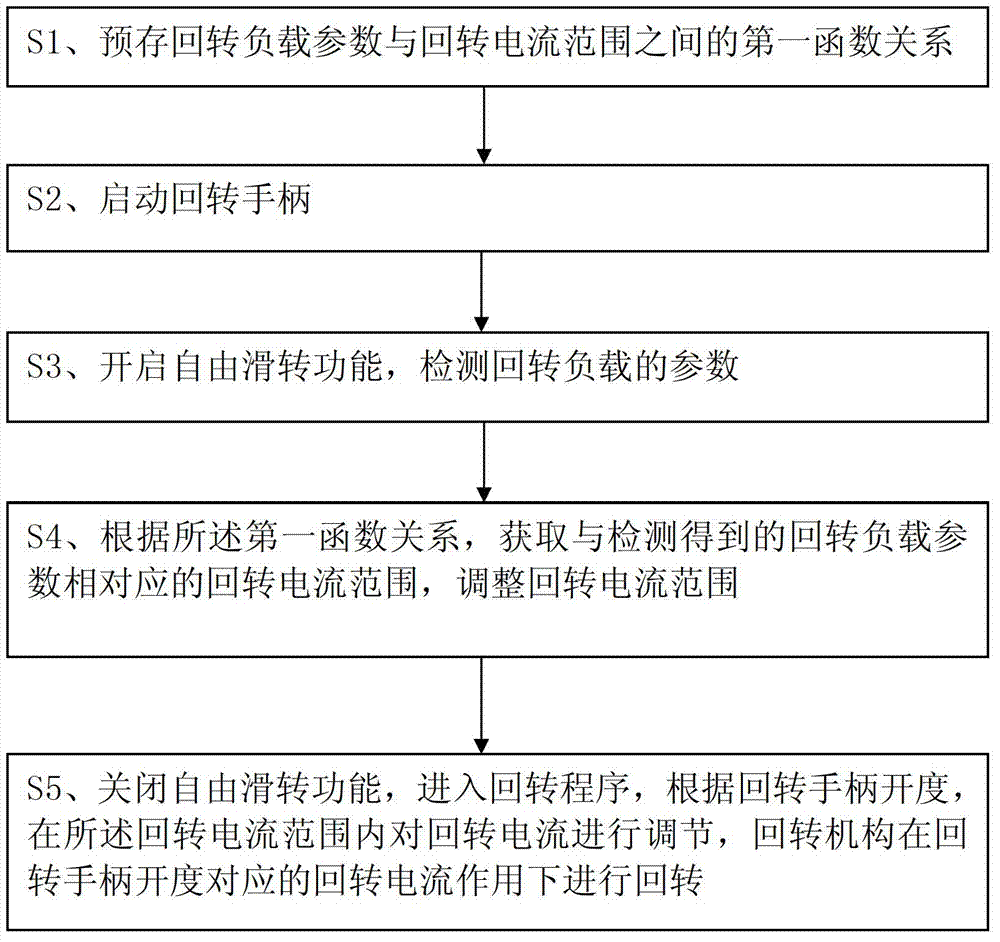

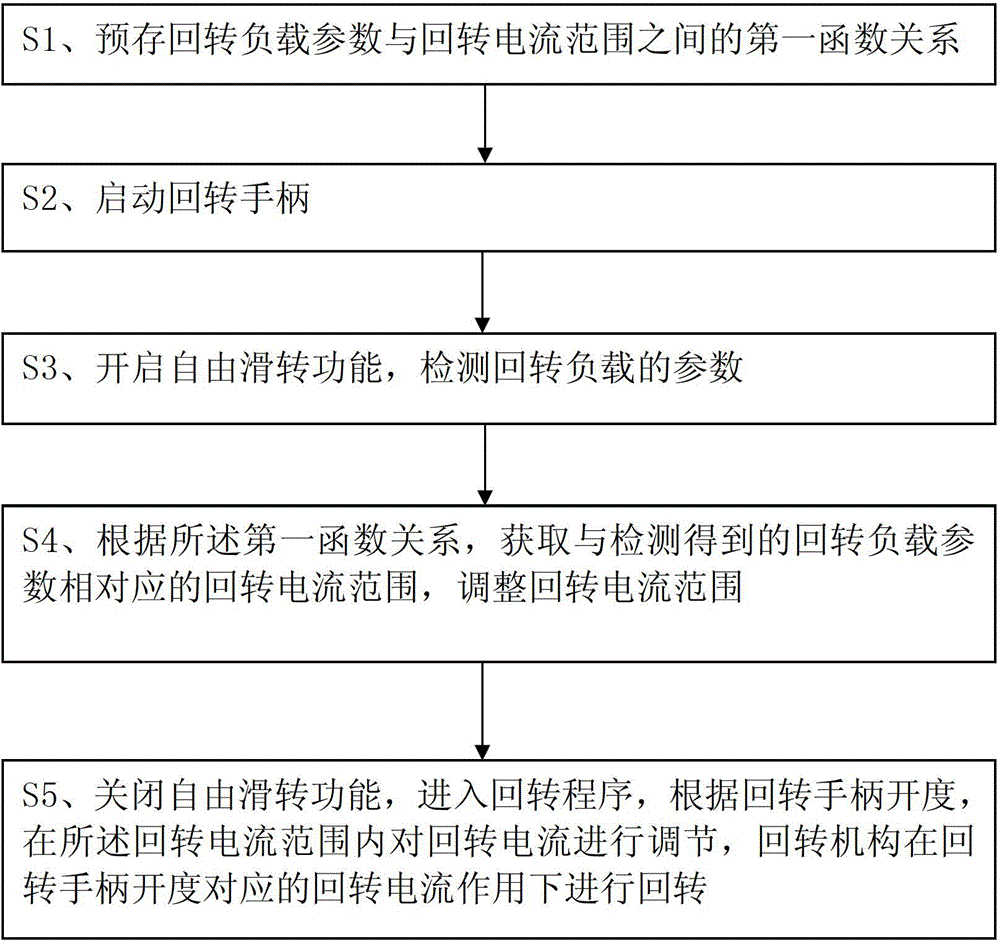

Crane rotation control system, control method and crane

InactiveCN102826454AImprove controllabilityImproves smoothness and controllability of operationLoad-engaging elementsEngineeringControllability

The invention discloses a crane rotation control system which comprises a detection module, an adjustment module and a control module, wherein the detection module is used for detecting rotation load parameters in a free trackslip state, comprising the magnitude and the direction of a rotation load torque; the adjustment module is used for pre-storing a first functional relation between the rotation load parameters and a rotation current range, acquiring the rotation current range corresponding to the rotation load parameters according to the first functional relation and adjusting the rotation current range; and the control module is used for regulating rotation current in the adjusted rotation current range according to the opening of a rotation handle and controlling a rotation mechanism to rotate under the action of the rotation current corresponding to the opening of the rotation handle. According to the control system, the rotation current range is adjusted according to a rotation load obtained by detecting in the free trackslip state, so that the rotation current can be adjusted according to the opening of the rotation handle to ensure that the rotation speed is automatically adjusted so as to improve the stability and the operation controllability of the rotation mechanism. The invention also provides a crane rotation control method and a crane.

Owner:SANY HEAVY IND CO LTD (CN)

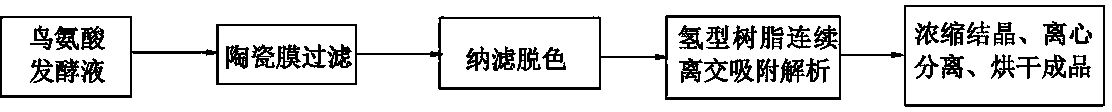

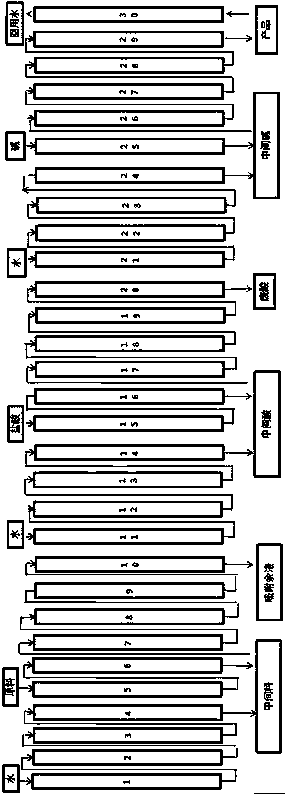

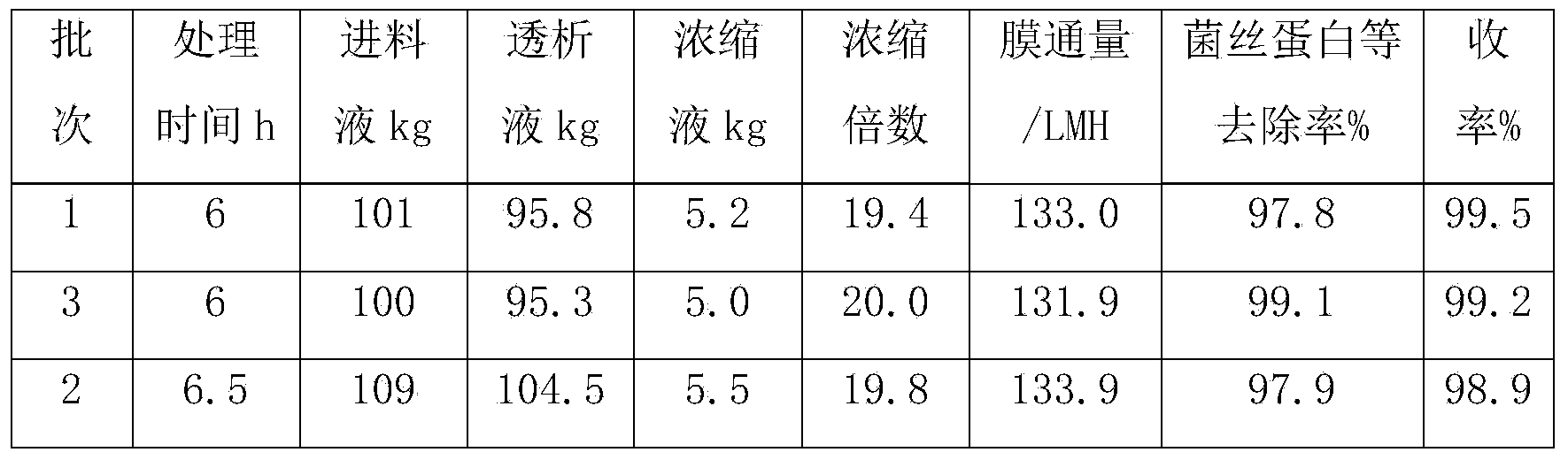

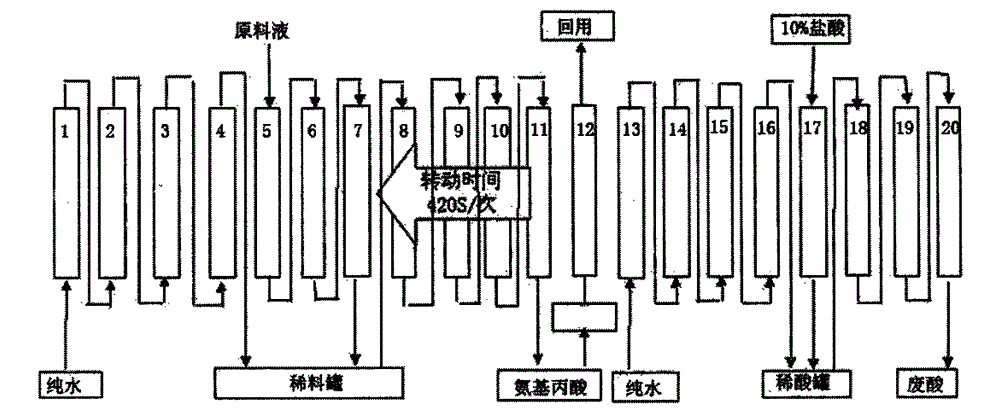

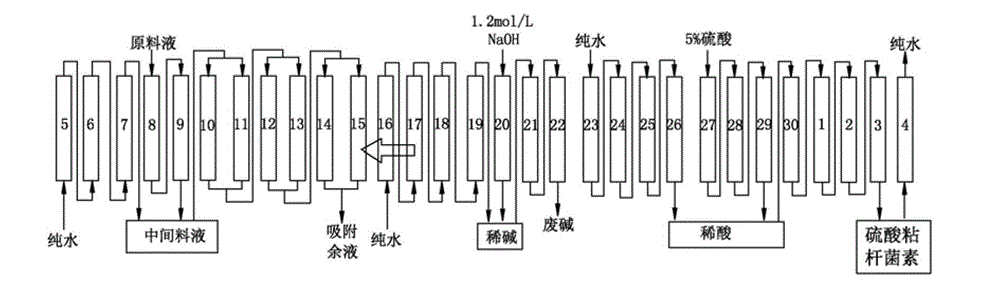

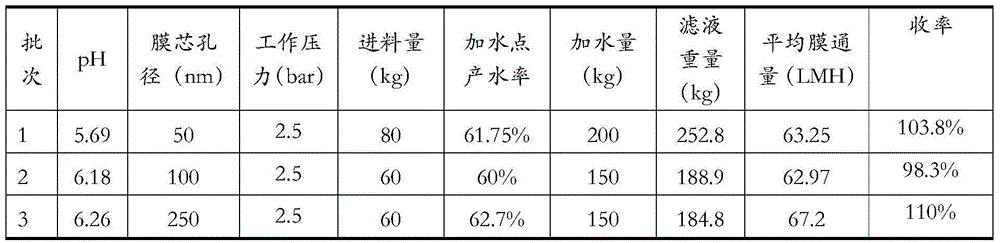

Ornithine production technology

ActiveCN103922953AImprove adsorption capacityLarge adsorption capacityOrganic compound preparationSolid sorbent liquid separationIon exchangeFermentation

The invention discloses an ornithine production technology. The ornithine production technology is characterized by comprising the following steps: step one. filtering a ornithine fermentation liquid by using a ceramic membrane so as to obtain microfiltration dialysate; step two. carrying out nanofiltration decolorization on the microfiltration dialysate, and further purifying the microfiltration dialysate so as to obtain nanofiltration dialysate; step three. carrying out continuous ion exchange adsorption-desorption on the nanofiltration dialysate by filled hydrogen cation exchange resin so as to obtain ornithined liquor; and step four. concentrating, crystallizing and centrifugally separating the continuous ion exchange adsorption-desorption ornithined liquor, and drying a finished product so as to obtain a ornithine crystal. The ornithine production technology disclosed by the invention has the beneficial effects that the yield is high, the purification effect is good, the product concentration is stable, and the production cost is low.

Owner:XIAMEN STARMEM TECH

Automatic dried tofu marinating and spread cooling device

The invention provides an automatic dried tofu marinating and spread cooling device. The device comprises a marinating box, a marinating conveyor belt, a lifting conveyor belt, a spread cooling conveyor belt and a spread cooling steel frame; the marinating box is a rectangular box body containing marinating liquid, one end of the marinating box is provided with a dried tofu feeding port, the other end of the marinating box is provided with a discharging port, the marinating conveyor belt is arranged in the marinating box, the lifting conveyor belt penetrates through the discharging port to stretch into the marinating box, one end of the lifting conveyor belt is located under the marinating conveyor belt and is in power connection with the marinating conveyor belt through an annular belt ring, the other end of the lifting conveyor belt is close to and is in power connection with the spread cooling conveyor belt, the spread cooling conveyor belt is installed on the spread cooling steel frame, a plurality of draught fans blowing air to the upper surface of the spread cooling conveyor belt are fixed to the spread cooling steel frame, and a motor driving the lifting conveyor belt to run is arranged on the spread cooling steel frame. The marinating conveyor belt, the lifting conveyor belt and the spread cooling conveyor belt are driven by the same motor, the structure is simple, the cost is low, and both resources and energy are saved.

Owner:浙江水磨坊智能科技有限公司

Extrusion molding mold for automatic coating of wires and cables

InactiveCN111958935ANo risk of burnsReduce operational safety hazardsDomestic articlesCoatingsEngineeringStructural engineering

The invention relates to the field of plastic molds, and discloses an extrusion molding mold for automatic coating of wires and cables. The extrusion molding mold includes a main box body, a cable conveying cavity is formed in the main box body in a left-right penetrating mode, lifting cavities in upper-lower symmetric are formed in the upper side and the lower side of the cable conveying cavity in a communicating mode, nut rotating cavities are formed in the end walls of the sides, away from the cable conveying cavity, of the lifting cavities, and sliding rod cavities are formed in the side,away from the cable conveying cavity, of the nut rotating cavities, wherein the sliding rod cavities extend in the direction of the side close to the cable conveying cavity and penetrate through the nut rotating cavities into the lifting cavities. A mechanism is used for clamping the head of a coating layer to instead of manually pinching by hand, so that an operator is prevented from the risks ofscalding, the potential safety hazard of worker is greatly reduced, meanwhile, a rotating coating mechanism enables the wires and cables to be coated more tighter, the coating effect is greatly increased, meanwhile, according to the diameter of the wires and cables, the rotation speed of the coating layer is automatically adjusted, and thus it is ensured that the coating layers of the wires and cables of different diameters can achieve a tight coating effect.

Owner:福州约春向科技有限公司

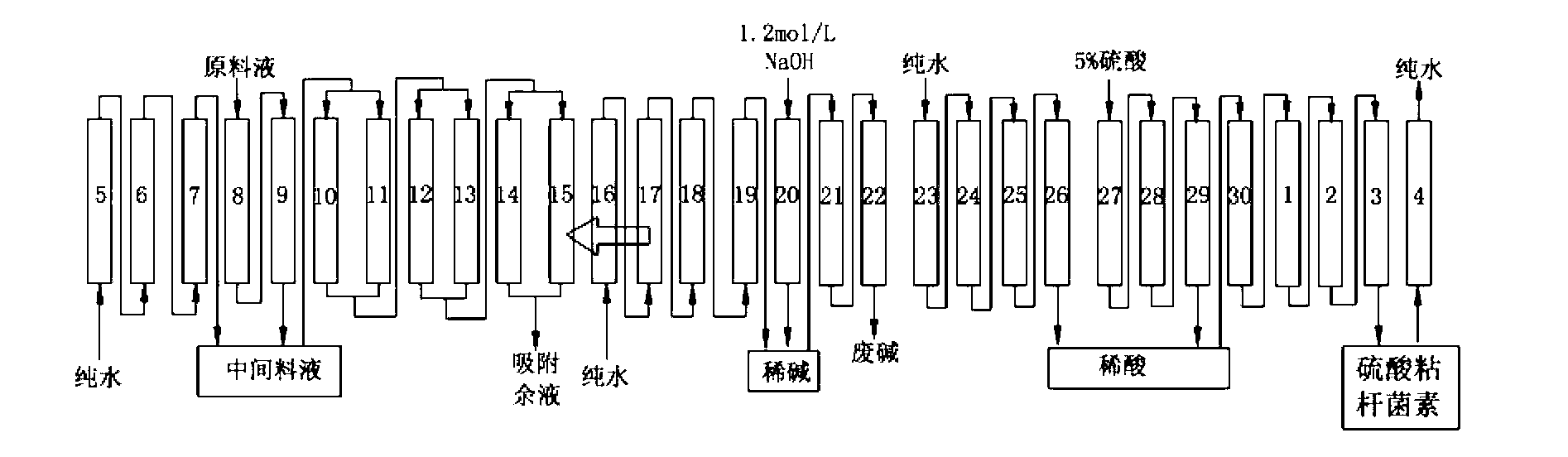

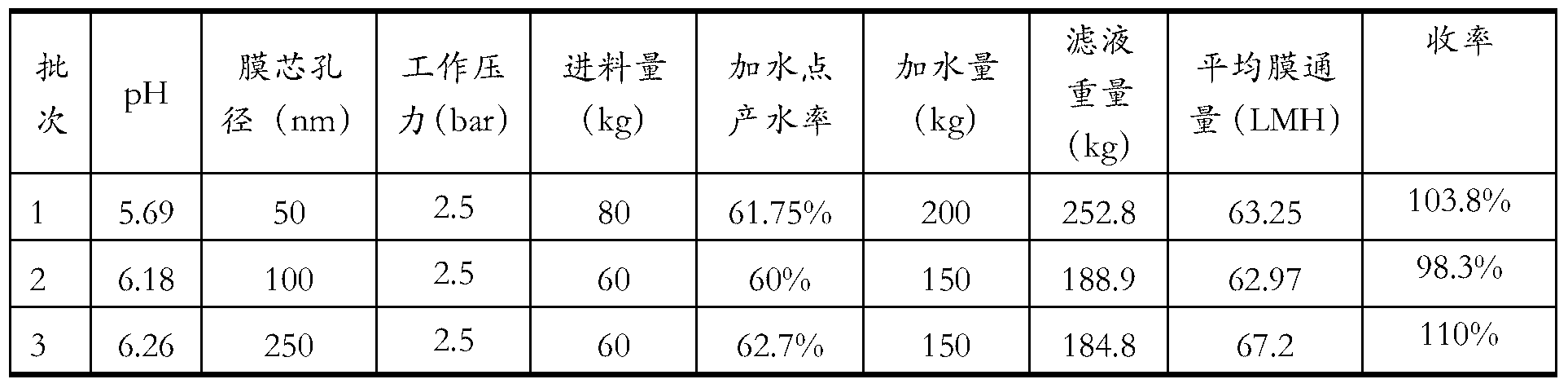

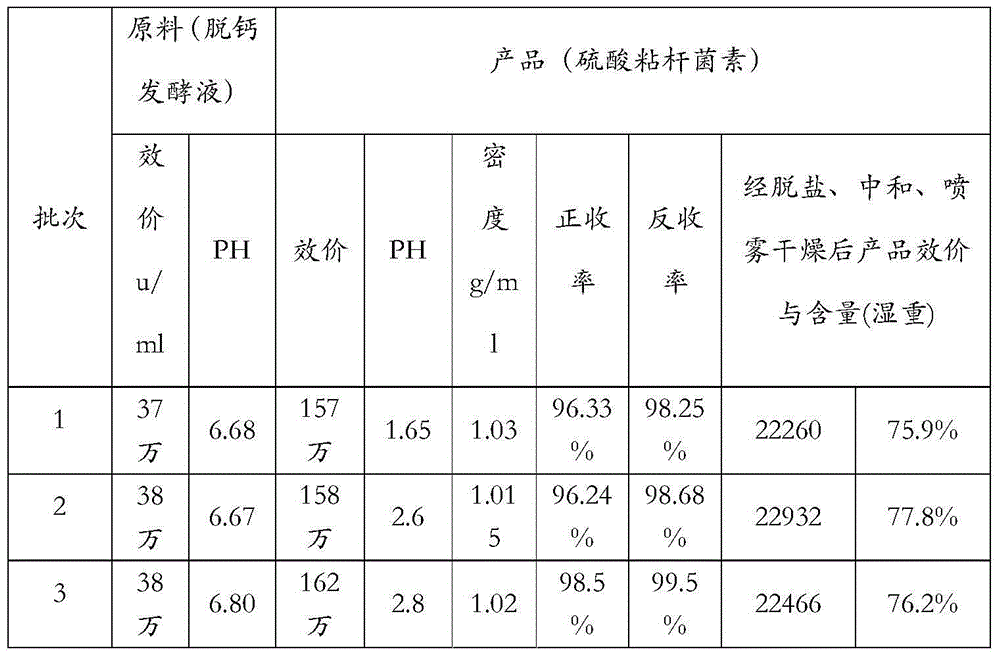

Colistin sulfate production method

ActiveCN103265622ACompact equipmentSimple systemPolymyxinsPeptide preparation methodsIon exchangeIon

The invention discloses a colistin sulfate production method, which sequentially comprises the following steps: filtering, calcium and magnesium removing-absorption desorption, concentration, desalting, neutralization and spray drying, and is characterized in that the filtering adopts ceramic membrane ultra-filtration filtering, the absorption desorption adopts a continuous ion exchange system filled with a methacrylic acid type carboxylic acid base resin or an acrylic acid carboxylic acid base resin to carry out absorption desorption, and the concentration adopts nano-filtration concentration. The production method has the following advantages that: colistin sulfate is an intracellular product, and cells can be broken when filtration is performed by using a ceramic membrane, such that the colistin sulfate in the colistin sulfate cells can be collected; the equipment is compact, the system is simplified, the pipeline is reduced, and the occupation area is small; the resin consumption is reduced; and the adopted nano-filtration has advantages of high concentration ratio, low energy consumption and the like, and the whole method has advantages of high yield, good purification effect, low production cost and the like.

Owner:XIAMEN STARMEM TECH

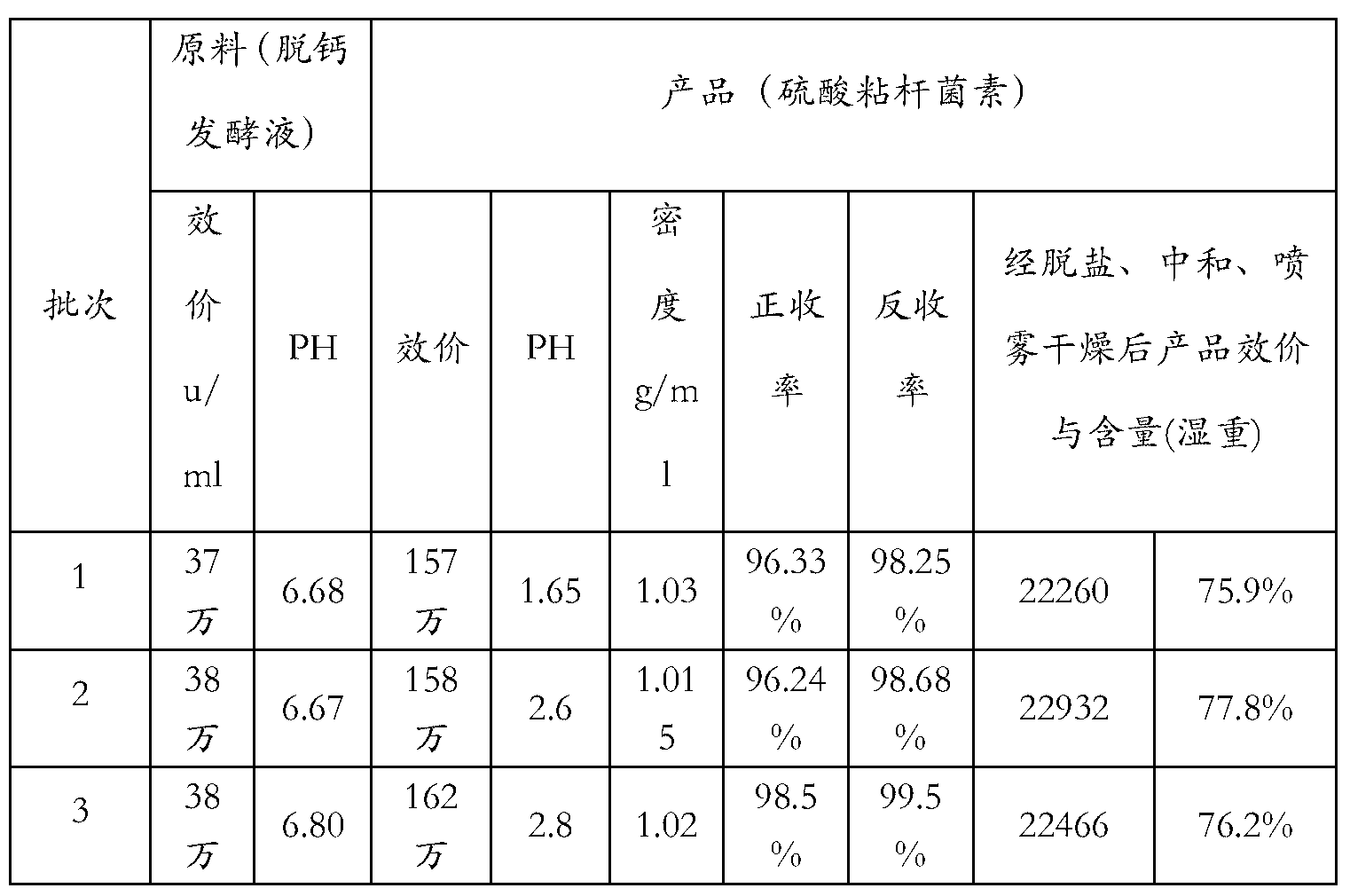

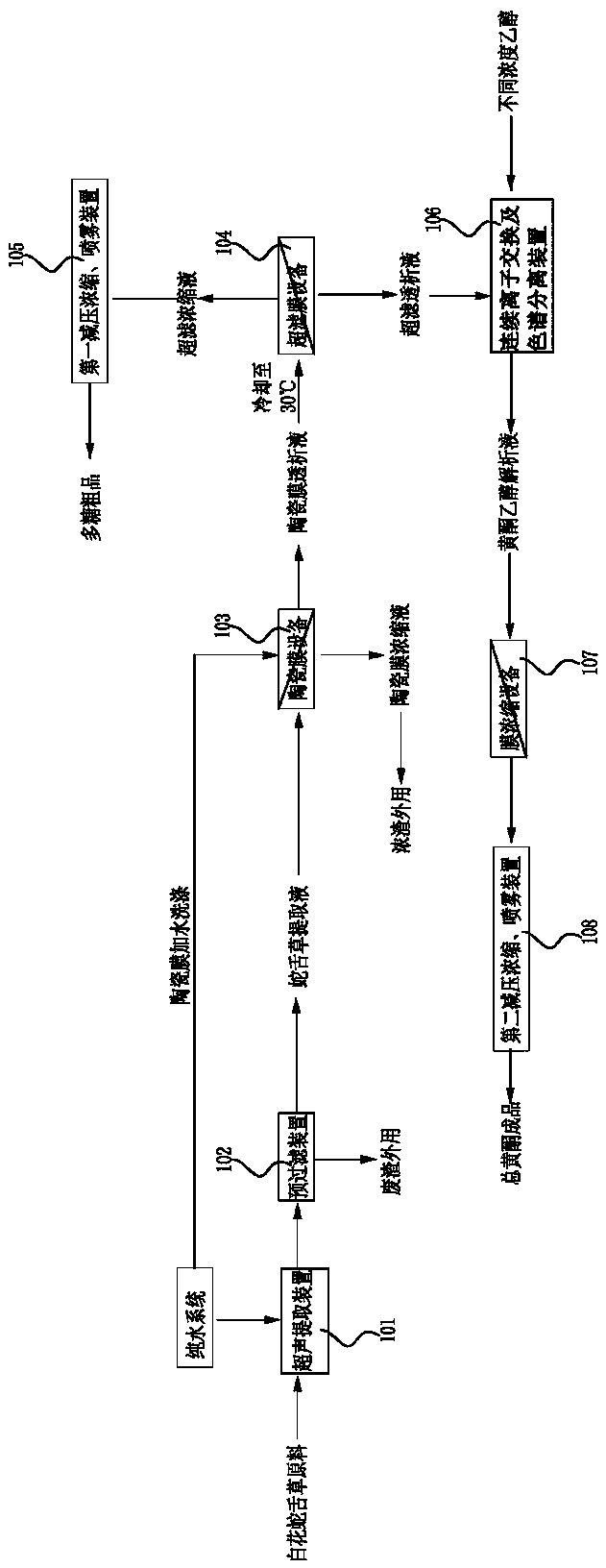

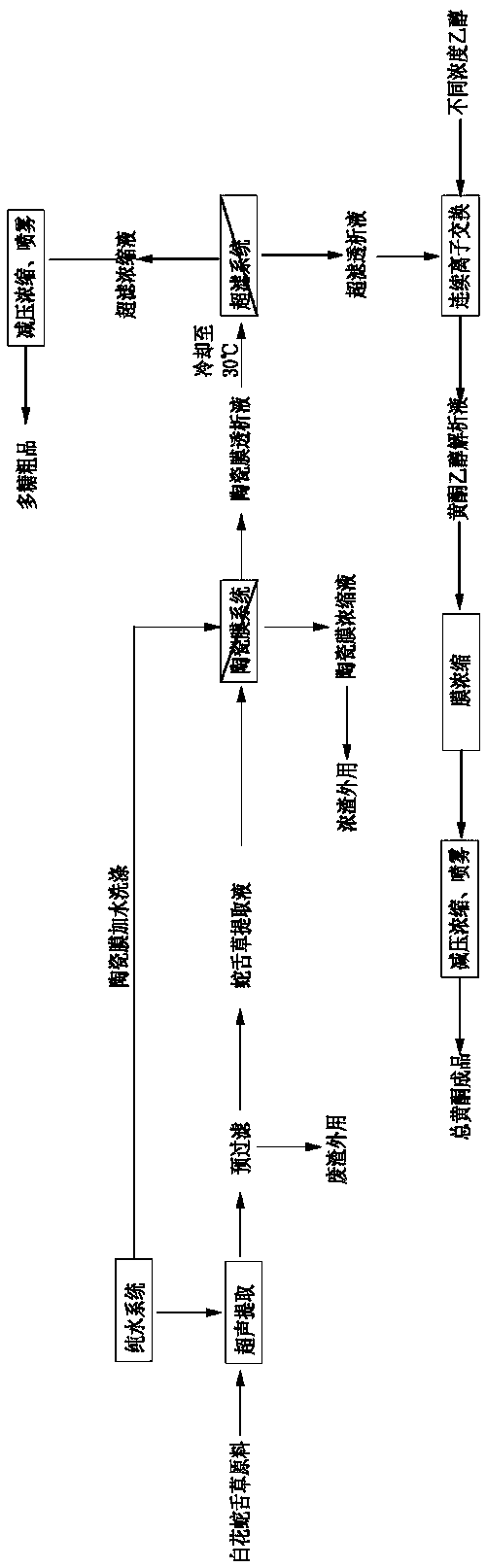

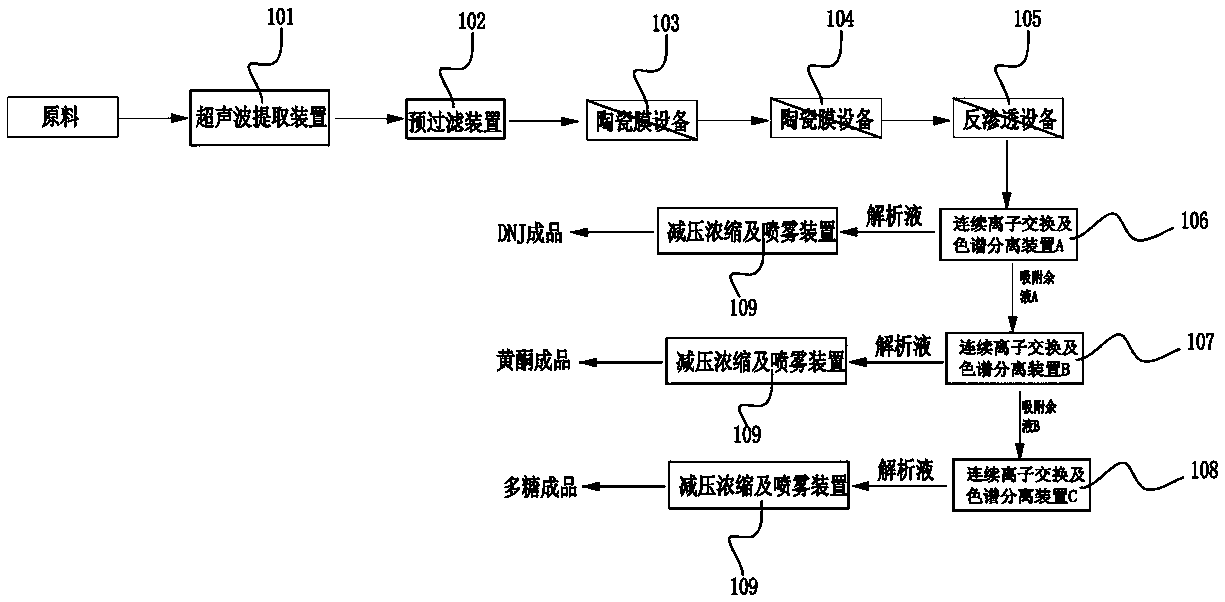

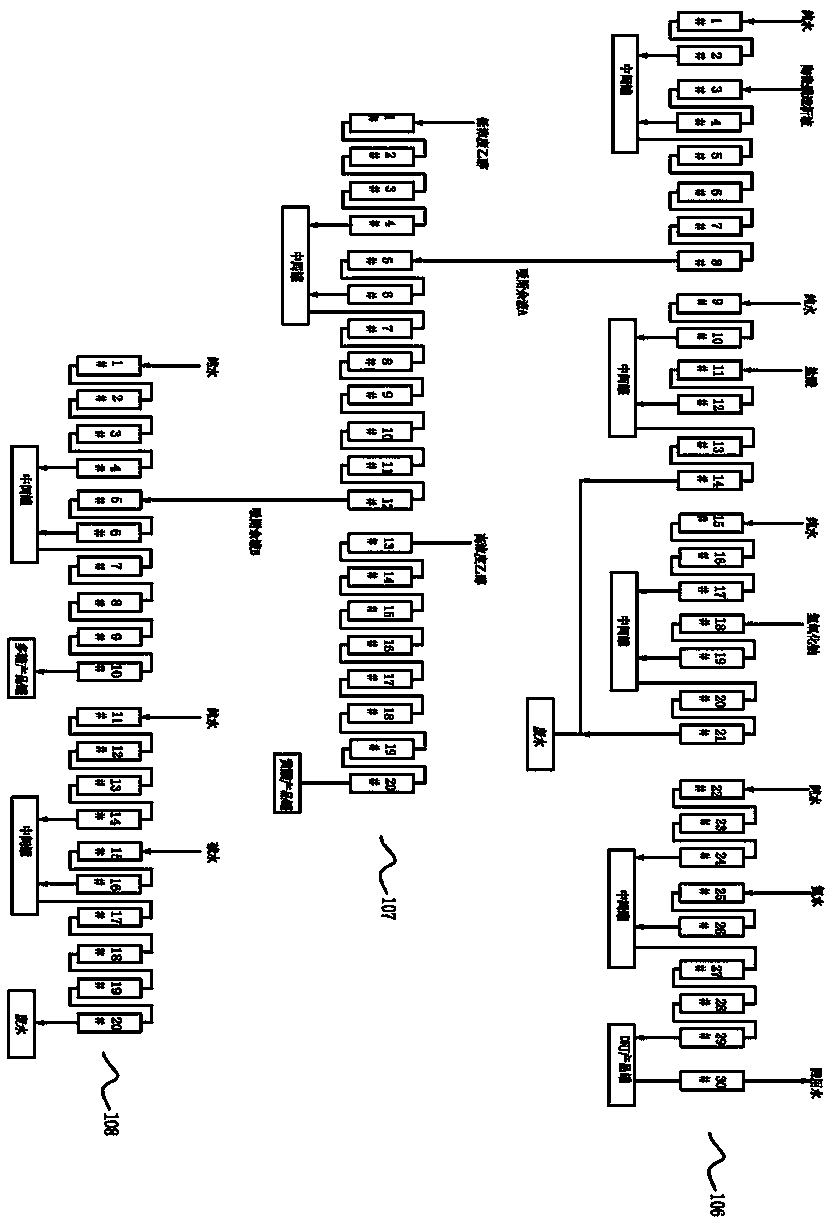

System and method for separating and purifying flavones and polysaccharide from oldenlandia diffusa

ActiveCN107698691AHigh removal rateRealization of separation and purificationOrganic chemistryChemical industryChromatographic separationOphioglossum

The invention discloses a system for separating and purifying flavones and polysaccharide from oldenlandia diffusa. The system is characterized by comprising an ultrasonic extraction device, a pre-filtering device and ceramic membrane equipment which are connected in sequence, wherein a dialyzate outlet of the ceramic membrane equipment is connected with ultrafiltration membrane equipment; a concentrated liquid outlet of the ultrafiltration membrane equipment is connected with a first vacuum concentration and spraying device; the dialyzate outlet is connected with a continuous ion exchange andspectrum separation device; the continuous ion exchange and spectrum separation device and the dialyzate outlet are sequentially connected with membrane concentration equipment and a second vacuum concentration device and spraying device. The invention further discloses a method for separating and purifying flavones and polysaccharide from oldenlandia diffusa. The system is simple in process, capable of achieving separation and purification of flavones and polysaccharide from oldenlandia diffusa rapidly at a time, short in production cycle, possible in continuous material feeding and discharge, stable in operation, high in product content, full-automatic in operation, capable of saving a great amount of labor and materials and applicable to industrial popularization.

Owner:XIAMEN FILTER & MEMBRANE TECH

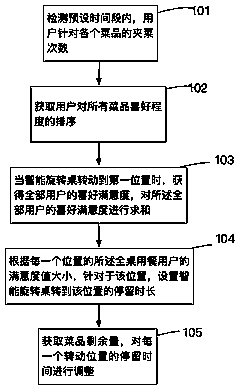

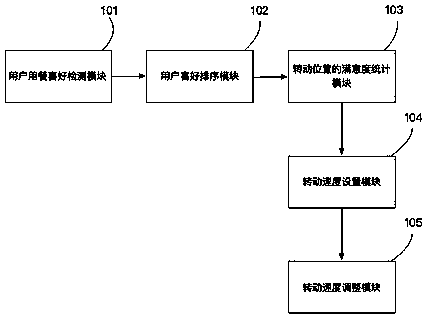

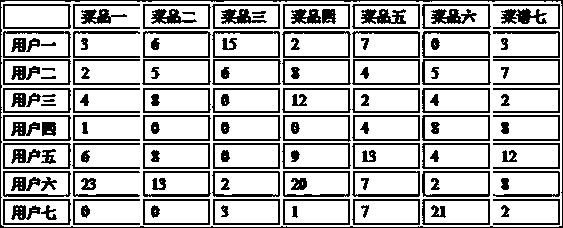

Method and system for individually adjusting rotating speed of intelligent rotating table

InactiveCN110363685AMeet dining needsAutomatic adjustment of rotation speedCustomer relationshipCharacter and pattern recognitionUser satisfactionPersonalization

The invention provides a method and a system for individually adjusting the rotating speed of an intelligent rotating table. The method comprises the following steps: detecting the number of times that a user picks up dishes for each dish within a preset time period; obtaining the preference degree of the first user for the first dish according to the frequency of eating the first dish by the first user; counting the preference degree of the first user for the second dish according to the same principle; according to the same principle, when the dishes are rotated to the second user, the scores of the n dishes closest to the dishes are added together to serve as the rotating position of the current rotating table, and the favorite satisfaction degree of the second user is improved; according to the satisfaction value of the dining user of the whole table at each position, setting the staying duration of the intelligent rotary table rotating to the position for the position; for each rotating position of the intelligent rotating table, the higher the user satisfaction value of the whole table is, the longer the residence time of the intelligent rotating table at the position is. According to the method and the system, the dining requirements of people on the whole table can be comprehensively met to the maximum extent according to different user taste preferences. The rotating speed of the intelligent rotating table is automatically adjusted.

Owner:韶关市启之信息技术有限公司

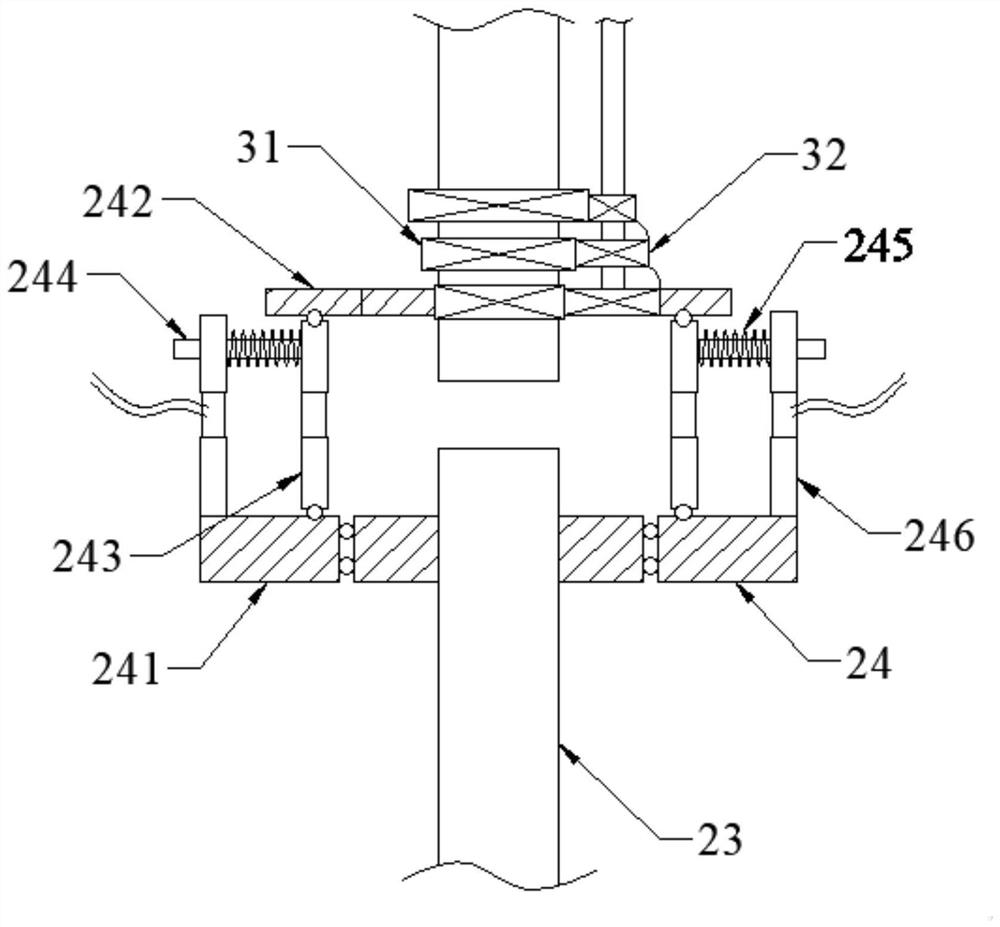

Light vertical multi-stage centrifugal pump

ActiveCN113266574AAutomatic adjustment of rotation speedNot tiredPump componentsPump controlElectric machineryEngineering

The invention discloses a light vertical multi-stage centrifugal pump which comprises a pump body, a coupling mechanism, a motor, an operation mechanism and an air exhaust mechanism, the pump body is arranged on a working plane in the vertical direction, the coupling mechanism is fixedly arranged over the pump body, the motor is arranged at the top end of the coupling mechanism, and the output end of the motor penetrates through and extends into the coupling mechanism. One end of the operation mechanism is connected with the coupling mechanism, and the other end of the operation mechanism penetrates through and extends into the pump body. A water outlet pipeline and a water inlet pipeline are symmetrically arranged in the pump body with respect to the central axis, one end of the water outlet pipeline and one end of the water inlet pipeline communicate with a water pipe and provided with valves, and the other end of the water outlet pipeline and the other end of the water inlet pipeline communicate with the operation mechanism. An existing multi-stage centrifugal pump cannot be automatically adjusted according to changes of liquid pressure in a pump body, on one hand, the working efficiency of the centrifugal pump is reduced, and energy loss is increased; and on the other hand, pump shaft fatigue can be caused frequently after long-term use, and a motor bearing is damaged.

Owner:SHANGHAI RAYBON MACHINERY GRP

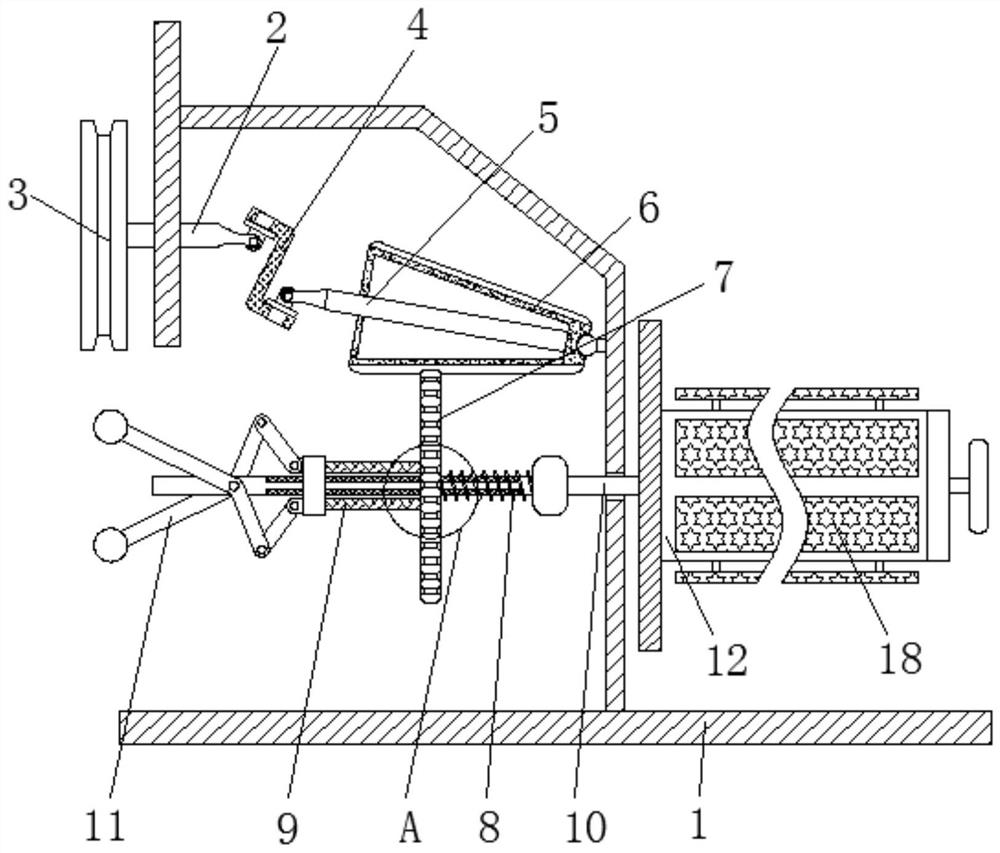

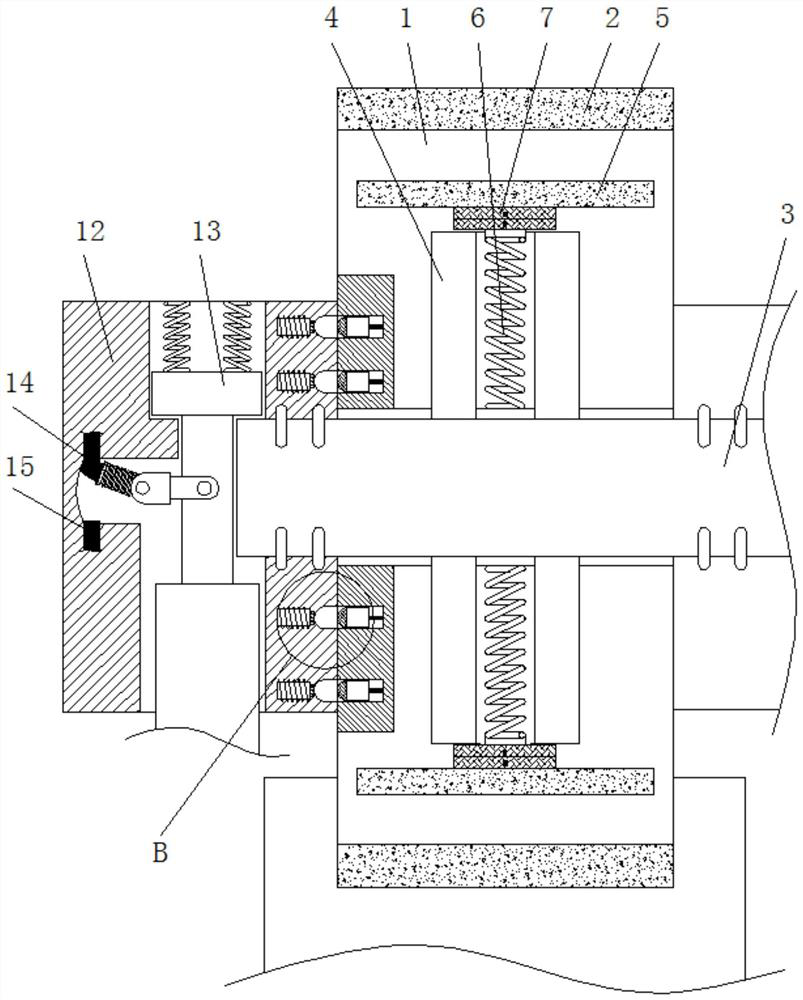

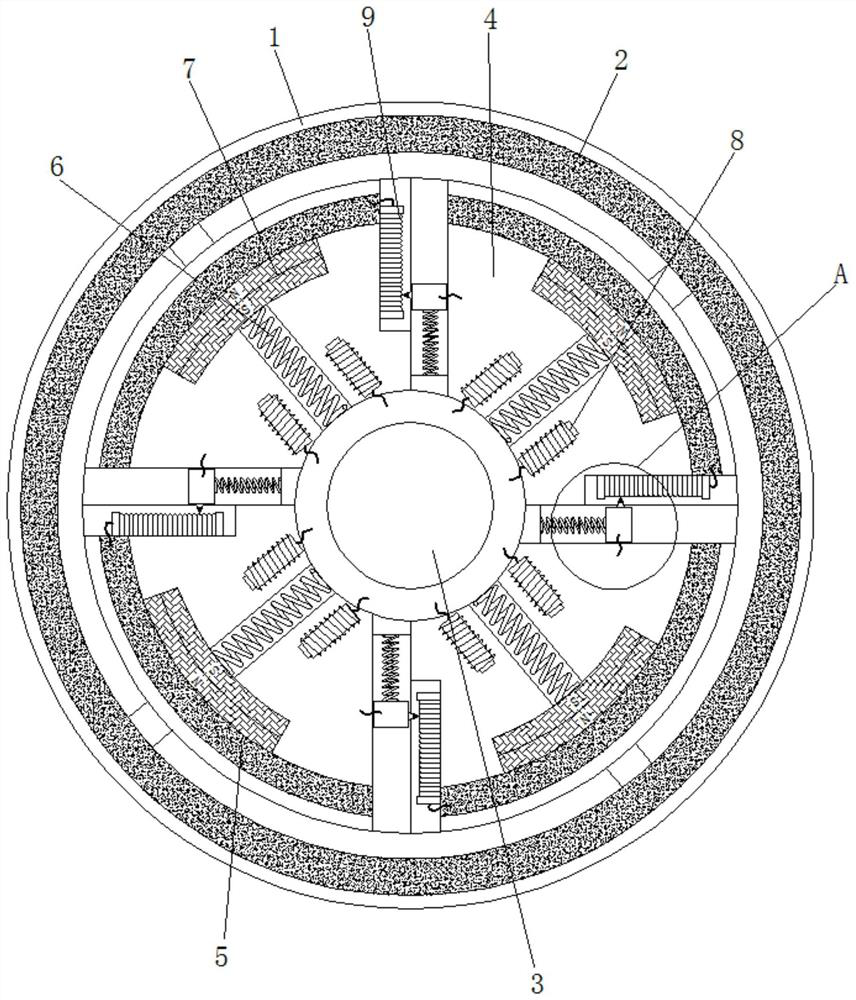

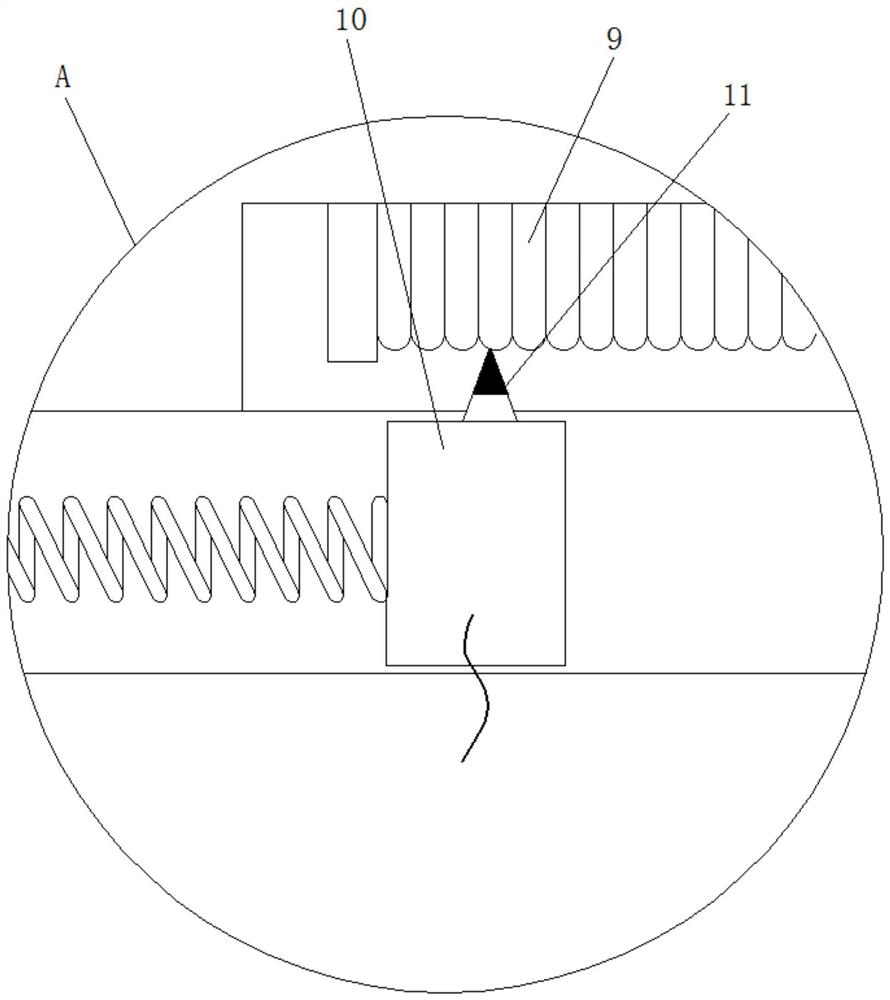

Constant velocity spinning take-up roll fixing device based on circular linear velocity law

InactiveCN111847108AAvoid breakingAutomatic adjustment of rotation speedFilament handlingYarnSpinning

The invention relates to the technical field of spinning and yarn manufacturing and discloses a constant velocity spinning take-up roll fixing device based on a circular linear velocity law. The constant velocity spinning take-up roll fixing device comprises a supporting rack, wherein a spindle is movably connected in the supporting rack; a transmission wheel is fixedly connected outside the spindle; a turning block is hinged outside the spindle; an oblique shaft is hinged outside the turning block; a velocity regulating wheel is fixedly connected outside the oblique shaft; a movable gear is in engaged connection outside the velocity regulating wheel; a spring is fixedly connected outside of the movable gear; and a slide block is fixedly connected outside the movable gear. By matching thespindle, the transmission wheel, the turning block, the oblique shaft, the velocity regulating wheel, the movable gear, the spring, the slide block, a take-up roll and a velocity regulating rod in use, an effect of regulating the rotating velocity of a take-up shaft automatically is achieved, and the stability of the rotating velocity of a positioning block is guaranteed effectively, so that a take-up effect is guaranteed. A condition that a yarn which is too high in rotating velocity is broken is avoided effectively, so that the quality of a product is guaranteed and the economical waste is reduced.

Owner:湖州益浩毛纺原料有限公司

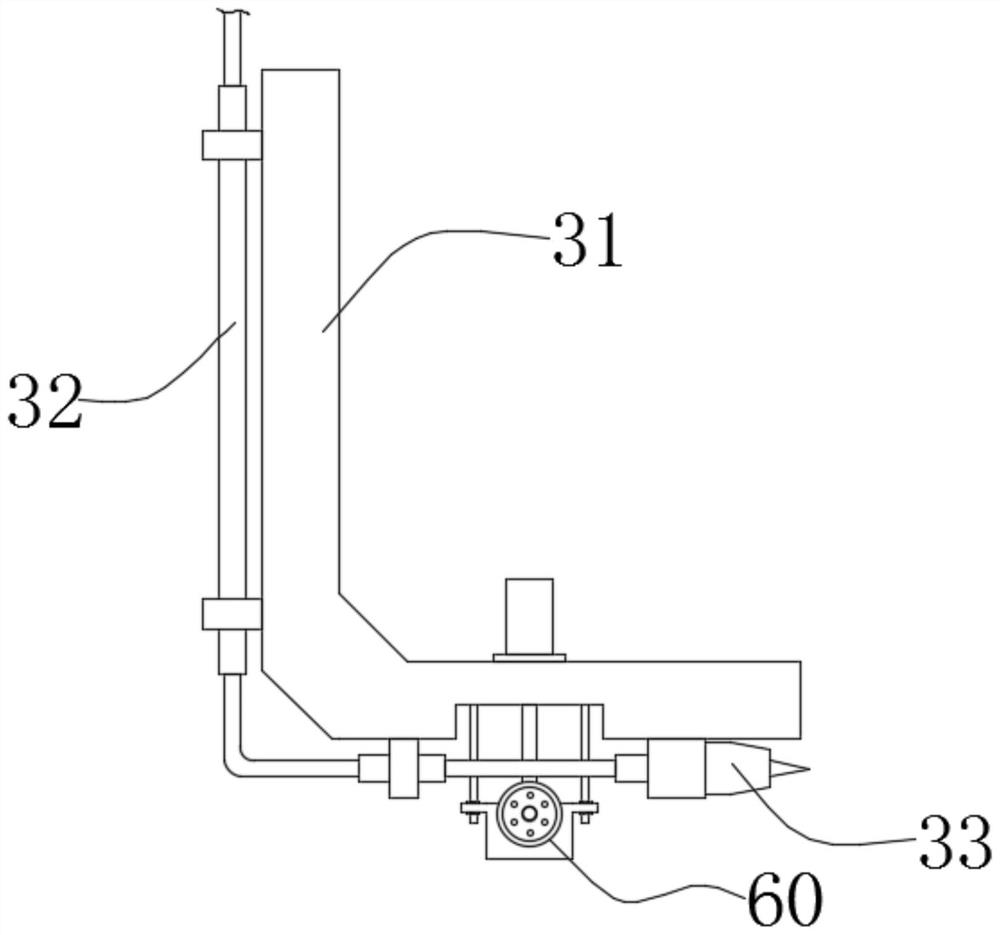

Laser welding machine head with automatic wire feeding function

PendingCN114769864AAutomatic monitoring of wire feedingAutomatic adjustment of rotation speedLaser beam welding apparatusEngineeringSingle chip

The invention relates to the technical field of laser welding, and discloses a laser welding head with an automatic wire feeding function, which comprises a laser head, a wire feeding assembly and a support assembly fixed on the wire feeding assembly, the bottom of the wire feeding assembly is fixedly connected with a detection assembly, and the detection assembly comprises a detection plate. The top of the detection plate is in sliding connection with the wire feeding assembly through a sliding rail, and the outer side wall of the detection plate is rotationally connected with a detection wheel; during wire feeding, a welding wire can drive the detection wheel to rotate, so that the rotary encoder on the detection wheel can detect the rotating speed of the detection wheel, and when the rotating speed is lower than or higher than a preset value, the rotary encoder can control the driving equipment through the single chip microcomputer, so that the wire feeding wheel on the driving equipment can adapt to the wire feeding speed according to the detected value; in this way, the wire feeding condition can be automatically monitored, when the wire feeding speed is too fast or too slow or the wire clamping phenomenon occurs, the wire feeding speed can be automatically adjusted, a user is reminded, and maintenance is conducted in time.

Owner:深圳市恒川激光技术有限公司

Shelf structure for vacuum freeze drying equipment

InactiveCN113465339AAutomatic adjustment of rotation speedEvenly heatedDrying solid materials without heatDrying chambers/containersFreeze-dryingEngineering

The invention relates to the technical field of biological medicine manufacturing, and discloses a shelf structure for vacuum freeze drying equipment. The shelf structure comprises a shelf seat; the upper end of the shelf seat is rotatably connected with a rotary shelf; a sealing lantern ring is arranged between the shelf seat and the rotary shelf; and the front end and the rear end of the shelf seat are respectively provided with a liquid inlet and a liquid outlet. A combined structure of the shelf seat and the rotary shelf is used for replacing a traditional shelf, so that the rotary shelf can rotate on the shelf seat, materials located on the rotary shelf can be evenly heated, the temperature difference between the materials on the rotary shelf is reduced, the consistency of the quality of the materials is improved, in addition, the temperatures of the front end and the rear end of the rotary shelf are measured through a front-end temperature sensing bulb and a rear-end temperature sensing bulb, the effect of automatically adjusting the rotating speed of the rotary shelf according to a temperature difference value is achieved through the combined action of a water quantity control mechanism and the area change of arc-shaped wheel blades, and the automation of temperature adjustment is improved.

Owner:程小婷

Self-locking walking machine capable of preventing overspeed rotation

ActiveCN112156428AAvoid pushingWon't hurtMovement coordination devicesCardiovascular exercising devicesMetal stripsEngineering

The invention relates to the technical field of fitness equipment, and discloses a self-locking walking machine capable of preventing overspeed rotation, which comprises a fixing frame, a friction plate is fixedly connected to the inner surface of the fixing frame, a rotating shaft is rotatably connected to the interior of the fixing frame, and a rotating disc is fixedly connected to the surface of the rotating shaft; a pressing plate is slidably connected to the interior of the rotating disc, a reset spring is fixedly connected to the bottom of the pressing plate, a magnetic block is fixedlyconnected to the lower end of the pressing plate, an electromagnetic column is fixedly connected to the interior of the rotating disc, and a resistance strip is fixedly connected to the surface of therotating disc. A trigger rod on the surface of a sliding rod is connected with the upper end of a metal strip, so that a rotating column can be fixedly connected with a fixing frame through a stop block, and the effects that automatic locking can be achieved when no person uses the walking machine, a child is prevented from pushing the pedal with hands, the child is protected from being injured by the pedal, and the using safety is improved are achieved.

Owner:台州市博跃塑业有限公司

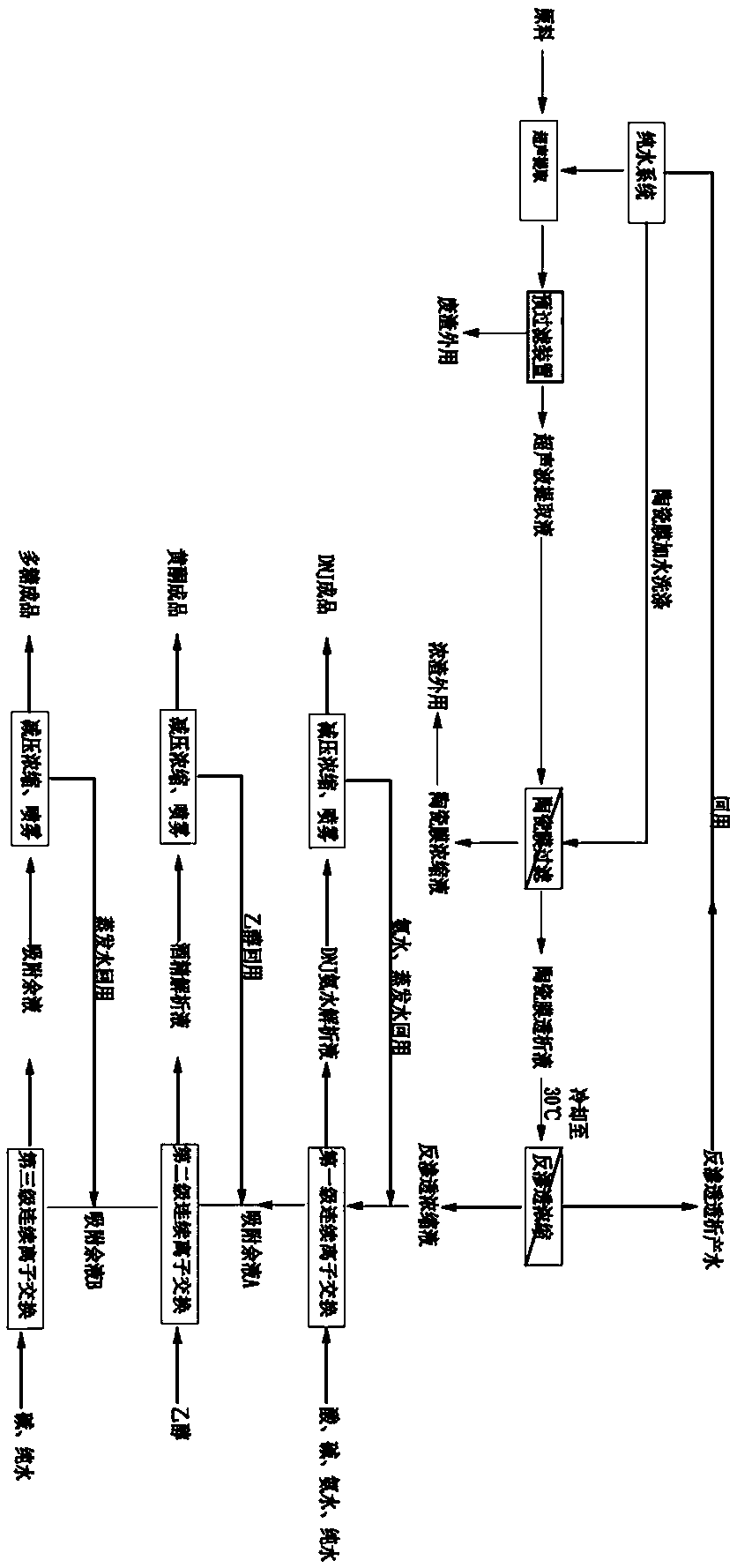

Method and system for continuously extracting DNJ, flavonoids and polysaccharides from moraceae plant

PendingCN107721909AAchieve continuous separationAchieve purificationOrganic chemistryMetabolism disorderBiotechnologyMoraceae

The invention discloses a method for continuously extracting DNJ, flavonoids and polysaccharides from a moraceae plant. The method is characterized by comprising the following steps: performing ultrasonic extraction on raw materials, performing ceramic membrane filtration, performing reverse osmosis concentration and performing consecutive ion exchange for three times to respectively obtain the DNJ, the flavonoids and the polysaccharides. The invention further comprises a system for continuously extracting the DNJ, the flavonoids and the polysaccharides from the moraceae plant. The method andthe system disclosed by the invention are simple in process, capable of quickly realizing the separation and the purification of mulberry leaf and mulberry twig extracts at a time, continuous in feeding and discharging, stable in operation, high in product content and fully-automatic in system operation, saves a large quantity of manpower and material resources and is suitable for industrial popularization.

Owner:GUANGXI WEHAND BIO PHARMA CO LTD +1

An intelligent cable cutting device based on new materials

ActiveCN112059073BReduce extrusion pressureShorten speedApparatus for cutting/splicing cablesBrakeAir spring

The invention relates to the technical field of new materials, and discloses an intelligent cable cutting device based on new materials, which includes a base, the side of the base is interspersed with a cable, the bottom of the cable is provided with a push rod, and the push rod The bottom is fixedly connected with an air spring, and the left side of the air spring is fixedly connected with a transition air box through a hose. The left side of the transition air box is interspersed with an air guide tube, and the inside of the air guide tube is slidably connected with an extruded air tube. The bottom of the receiving plate is fixedly connected with a linkage rod, the bottom of the linkage rod is fixedly connected with a liquid pushing plate, the side of the liquid pushing plate is slidingly connected with a water tank, and the right side of the water tank is fixedly connected with a Spray tube. The cable intelligent cutting device based on new materials, through the cooperation of air spring and transmission wheel, can automatically adjust the rotation speed of the cutting wheel according to the extrusion force when cutting the cable, and prevent the cutting surface from tilting.

Owner:南通飞海电子科技有限公司

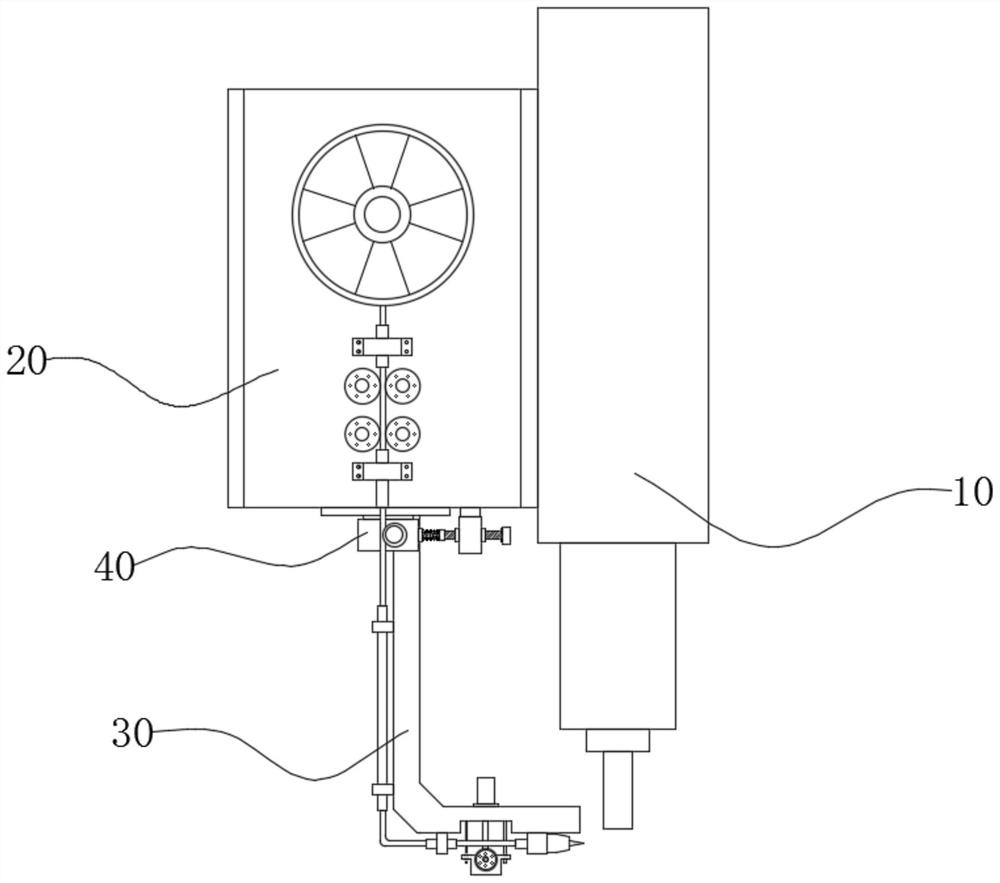

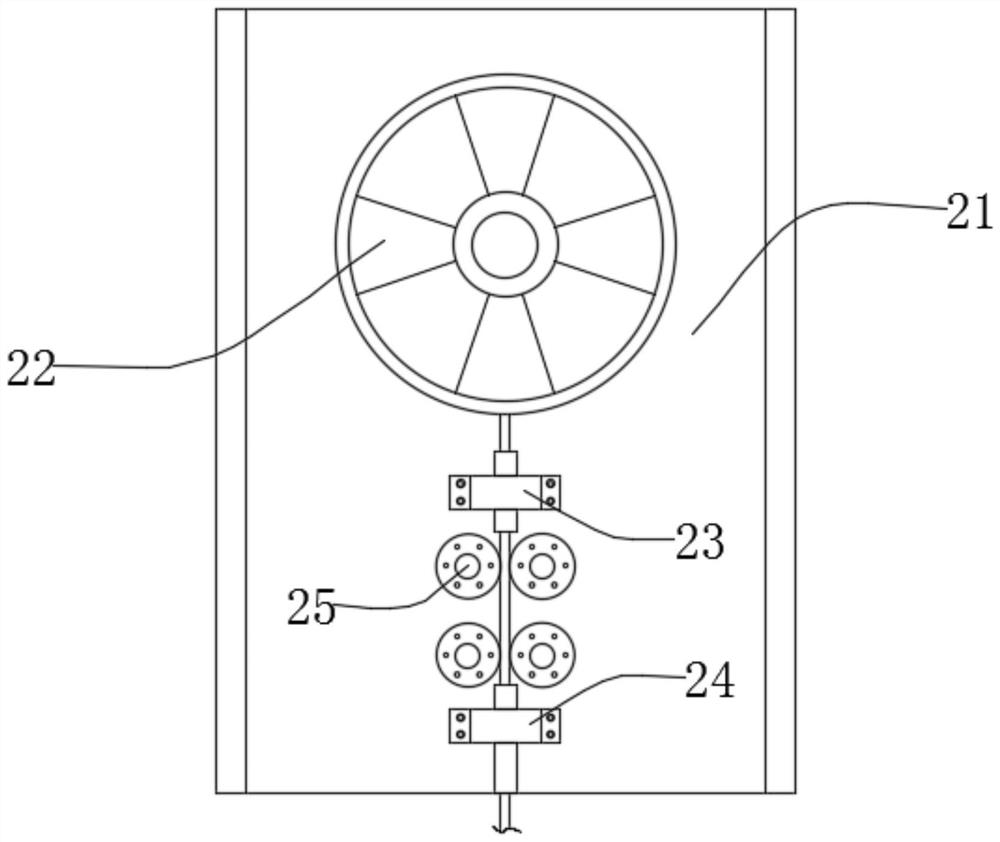

Spraying equipment based on artificial intelligence

PendingCN114600748AAutomatic adjustment of rotation speedSimple structureWatering devicesMovable spraying apparatusMobile vehicleEngineering

The spraying equipment based on artificial intelligence is simple in structure and capable of achieving automatic spraying and adjustment and comprises an intelligent mobile vehicle capable of moving, a spraying cylinder arranged on the mobile vehicle and used for containing liquid and a spraying assembly connected with the spraying cylinder and used for spraying, the spraying assembly comprises a spraying box, the spraying box is provided with an open groove, and the open groove is communicated with the intelligent mobile vehicle. A spraying gun used for penetrating out of the open groove to spray liquid is arranged at the position, located at the open groove, in the spraying box through a lifting device, and an automatic spraying device used for spraying of the automatic spraying gun is arranged on the spraying gun.

Owner:柯红香

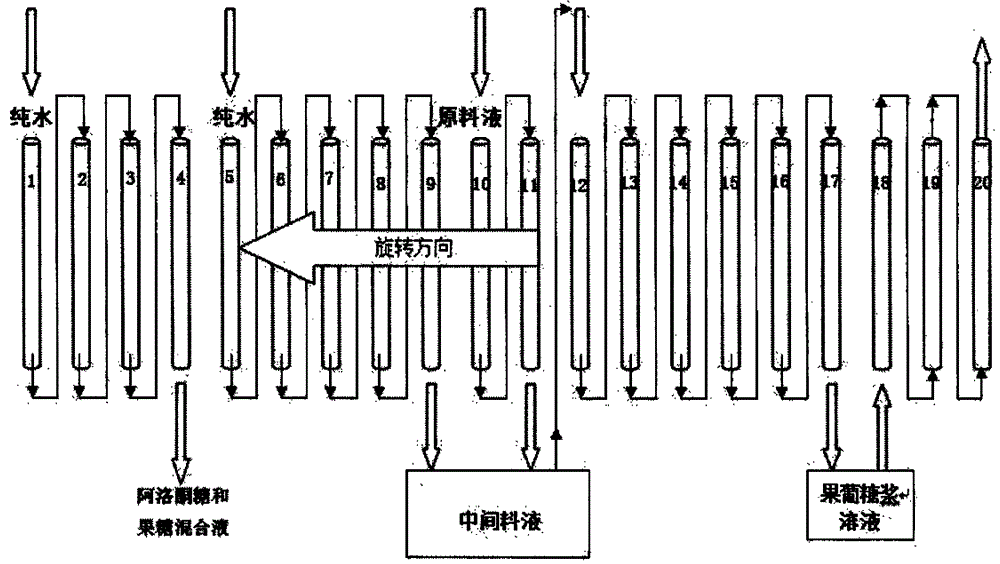

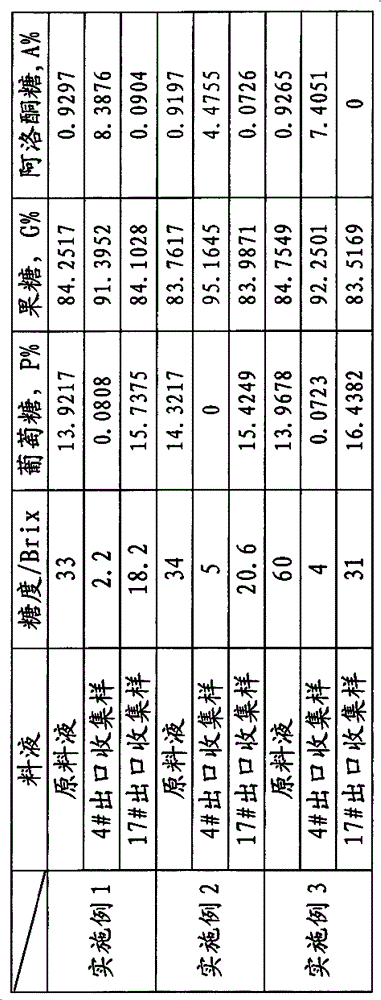

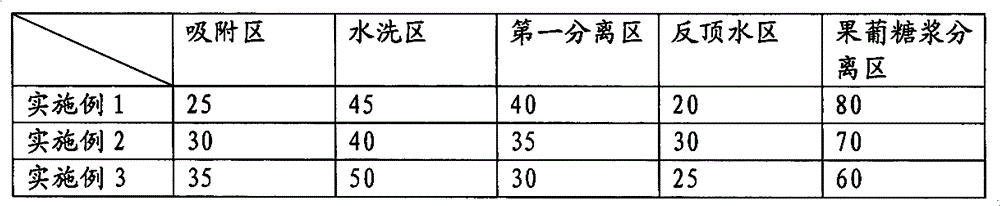

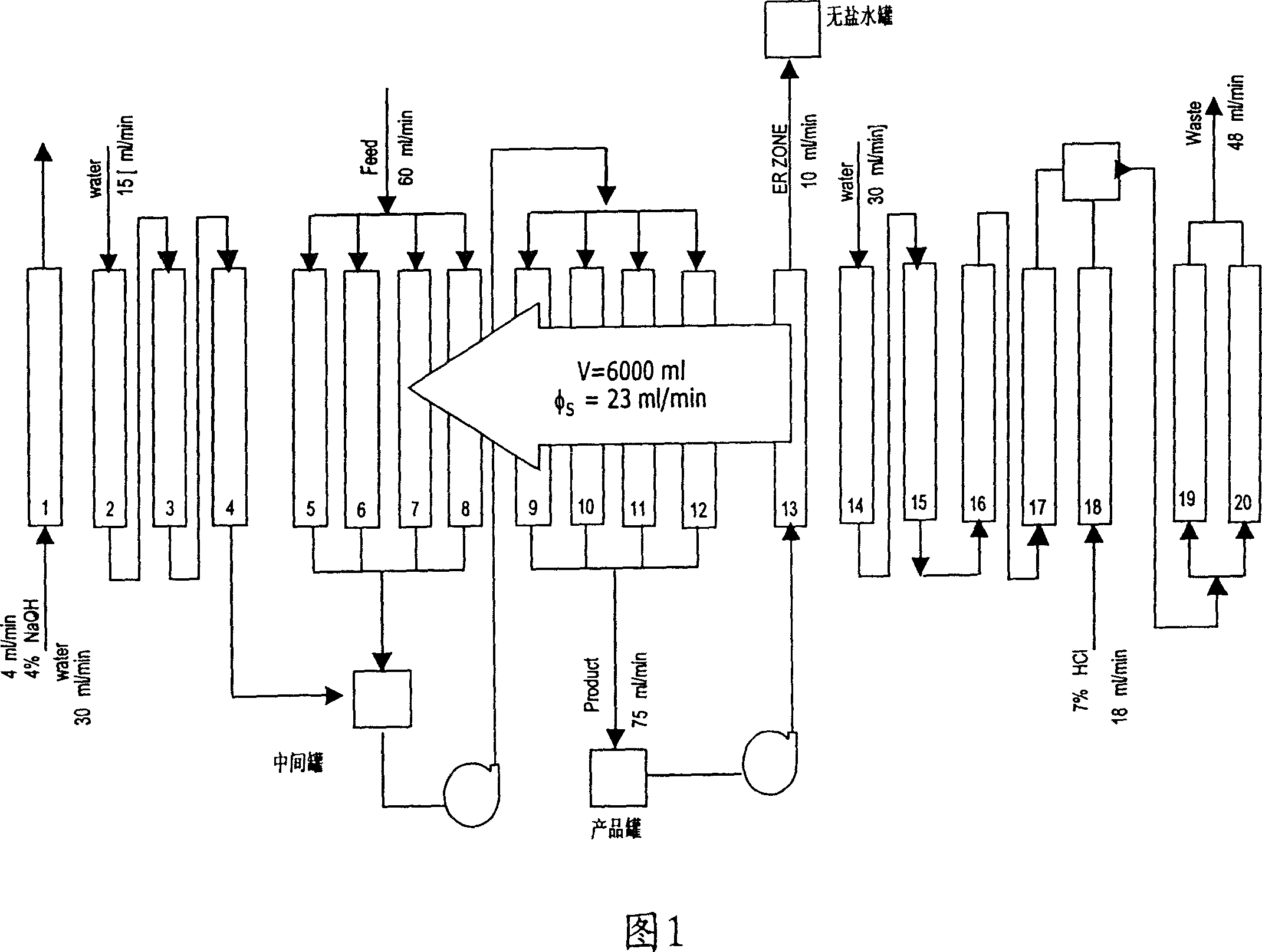

Method for separating glucose and allulose from high fructose corn syrup

ActiveCN102876817BSmall footprintComposition is stableFood preparationGlucose productionHigh concentrationChromatographic separation

The invention discloses a method for separating glucose and allulose from high fructose corn syrup, which is characterized in that the separation of glucose and allulose is realized by continuous chromatographic separation by using a continuous chromatographic separation system filled with calcium ion chelating resin. With the above technical scheme, the method for separating glucose and allulose by continuous chromatographic separation of the invention has the beneficial effects of compact equipment, simplified system, reduced pipelines, and less land occupation; because of the continuous running under non-interrupted operation, the product components and concentration are maintained to be stable basically; the method has good operating flexibility, can automatically adjust the rotation speed according to the change of production loads; the operation cost and the equipment investment are low; the separation effect is good; the separated high fructose corn syrup has a high purity; a mixed solution of allulose and fructose can be obtained with a high concentration and high value, and a high-concentration allulose solution can be obtained by further separation and concentration; and the method has significant economic benefits.

Owner:XIAMEN STARMEM TECH

Crane rotation control system, control method and crane

InactiveCN102826454BImprove stabilityImprove controllabilityLoad-engaging elementsCurrent rangeLoad torque

The invention discloses a crane rotation control system which comprises a detection module, an adjustment module and a control module, wherein the detection module is used for detecting rotation load parameters in a free trackslip state, comprising the magnitude and the direction of a rotation load torque; the adjustment module is used for pre-storing a first functional relation between the rotation load parameters and a rotation current range, acquiring the rotation current range corresponding to the rotation load parameters according to the first functional relation and adjusting the rotation current range; and the control module is used for regulating rotation current in the adjusted rotation current range according to the opening of a rotation handle and controlling a rotation mechanism to rotate under the action of the rotation current corresponding to the opening of the rotation handle. According to the control system, the rotation current range is adjusted according to a rotation load obtained by detecting in the free trackslip state, so that the rotation current can be adjusted according to the opening of the rotation handle to ensure that the rotation speed is automatically adjusted so as to improve the stability and the operation controllability of the rotation mechanism. The invention also provides a crane rotation control method and a crane.

Owner:SANY HEAVY IND CO LTD (CN)

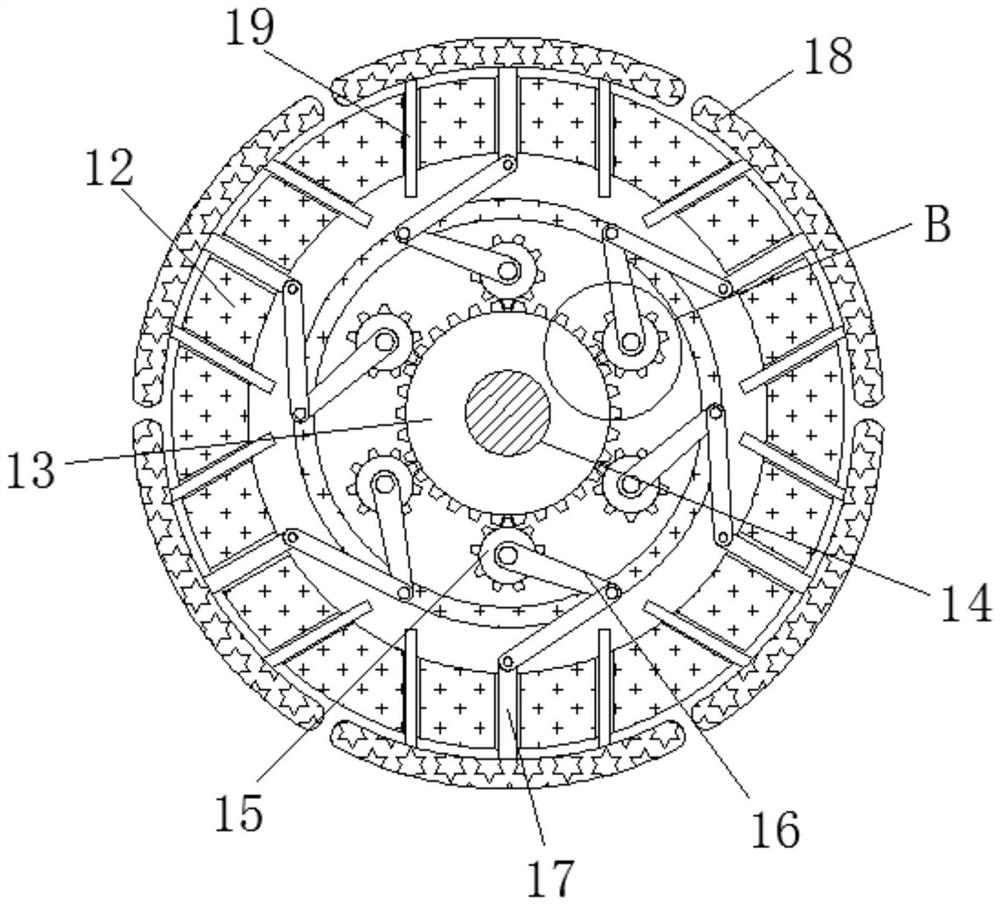

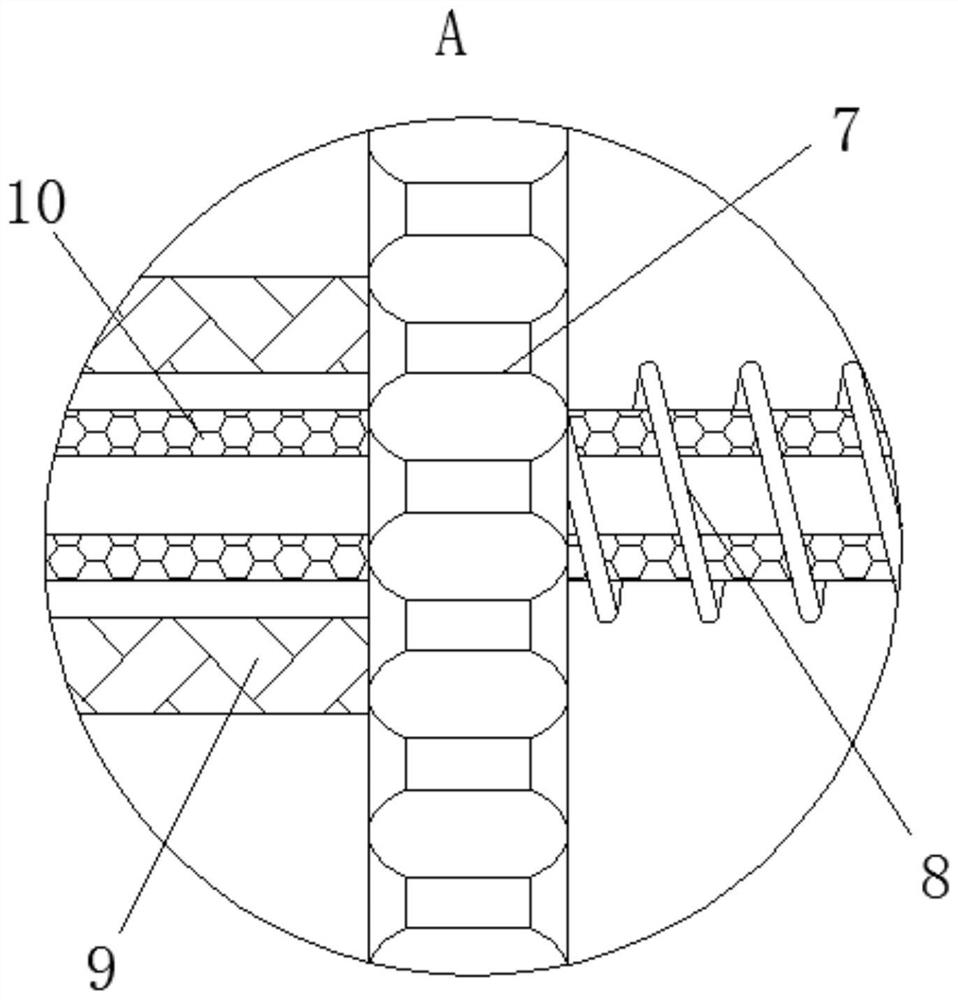

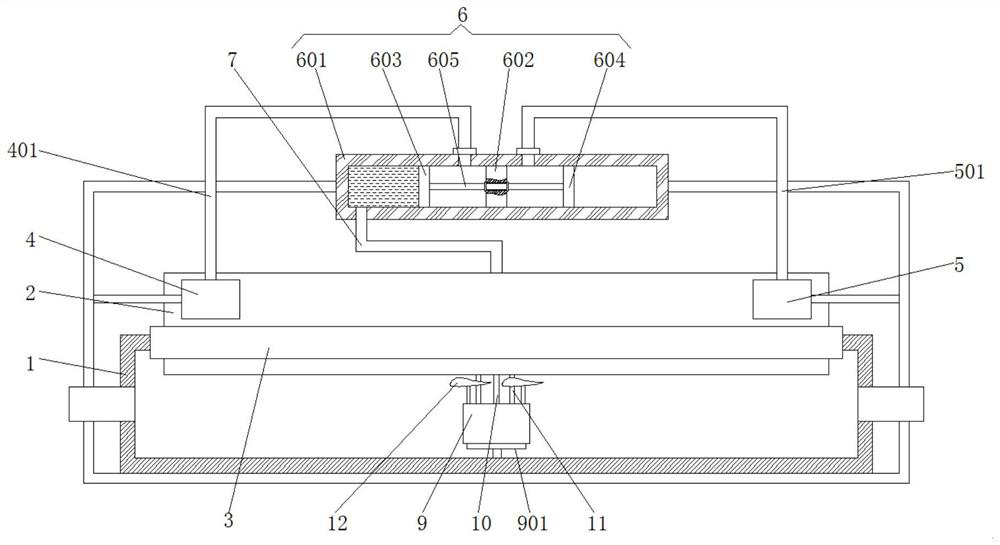

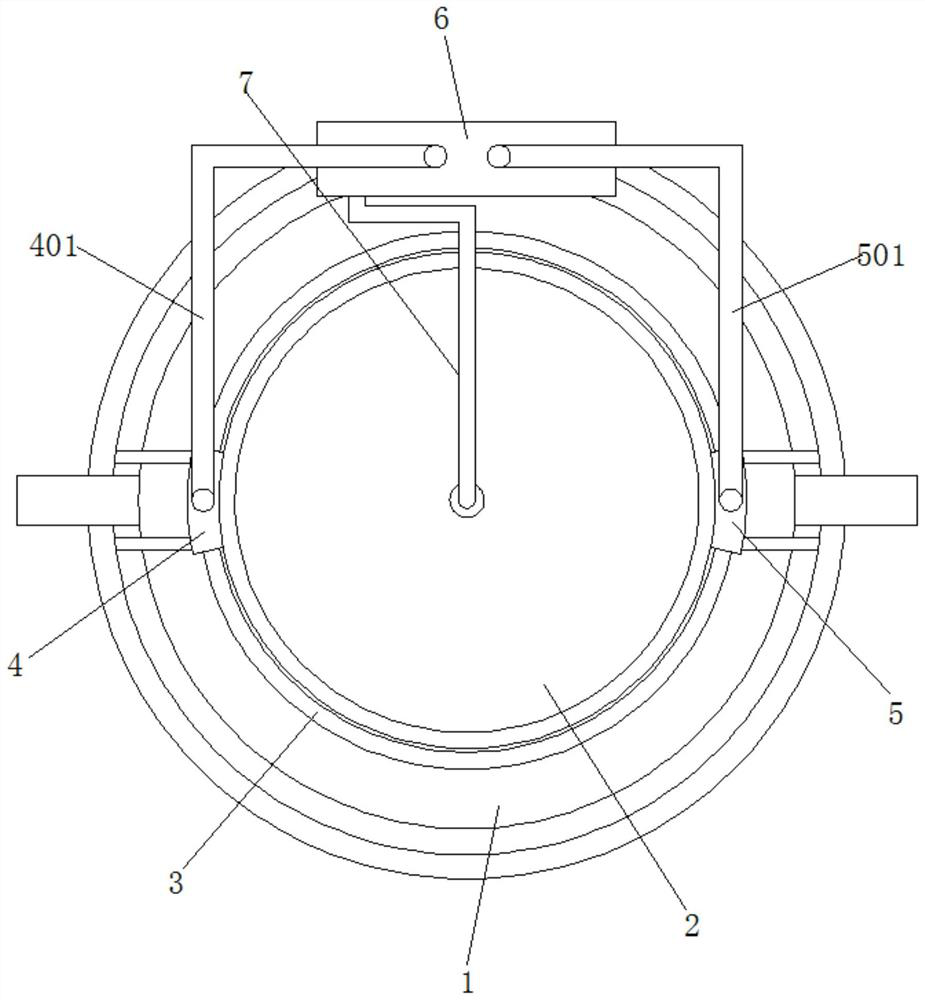

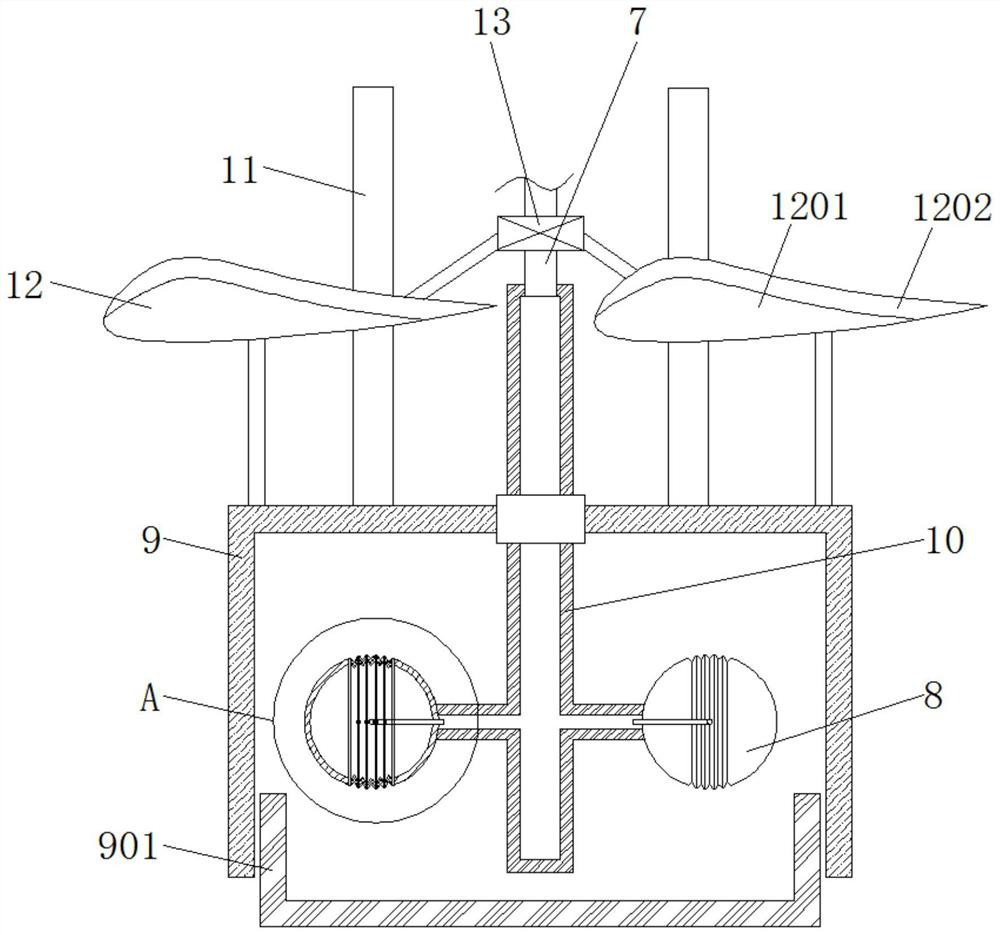

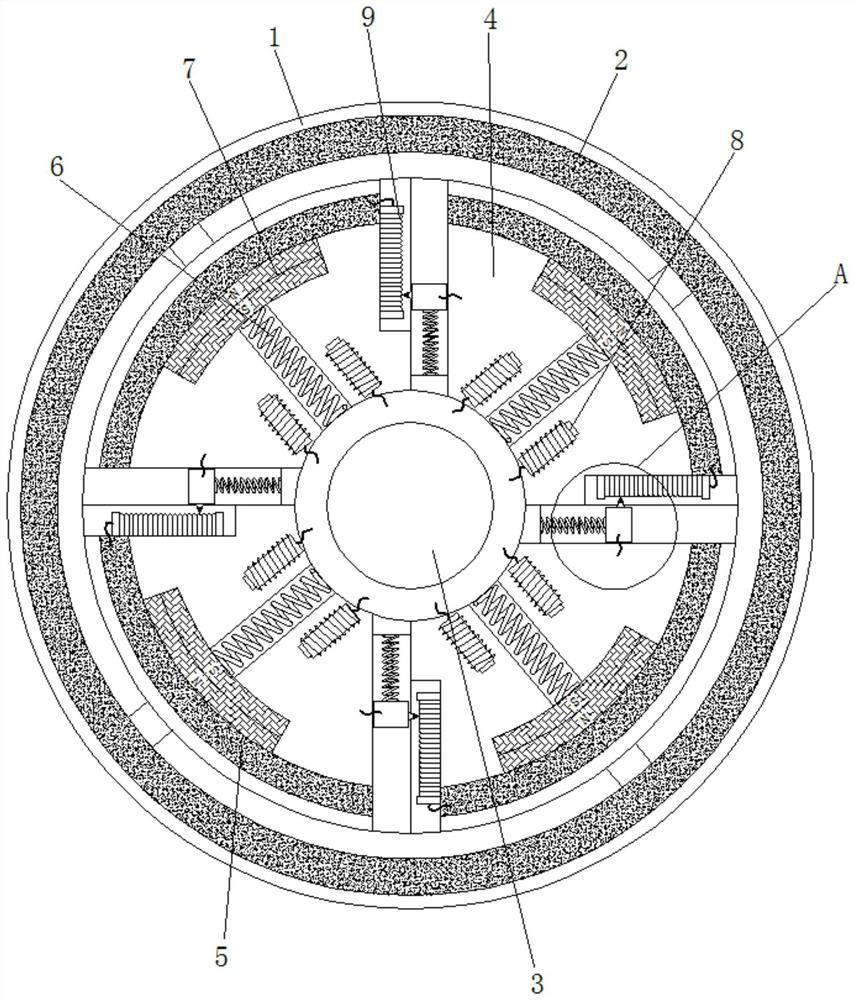

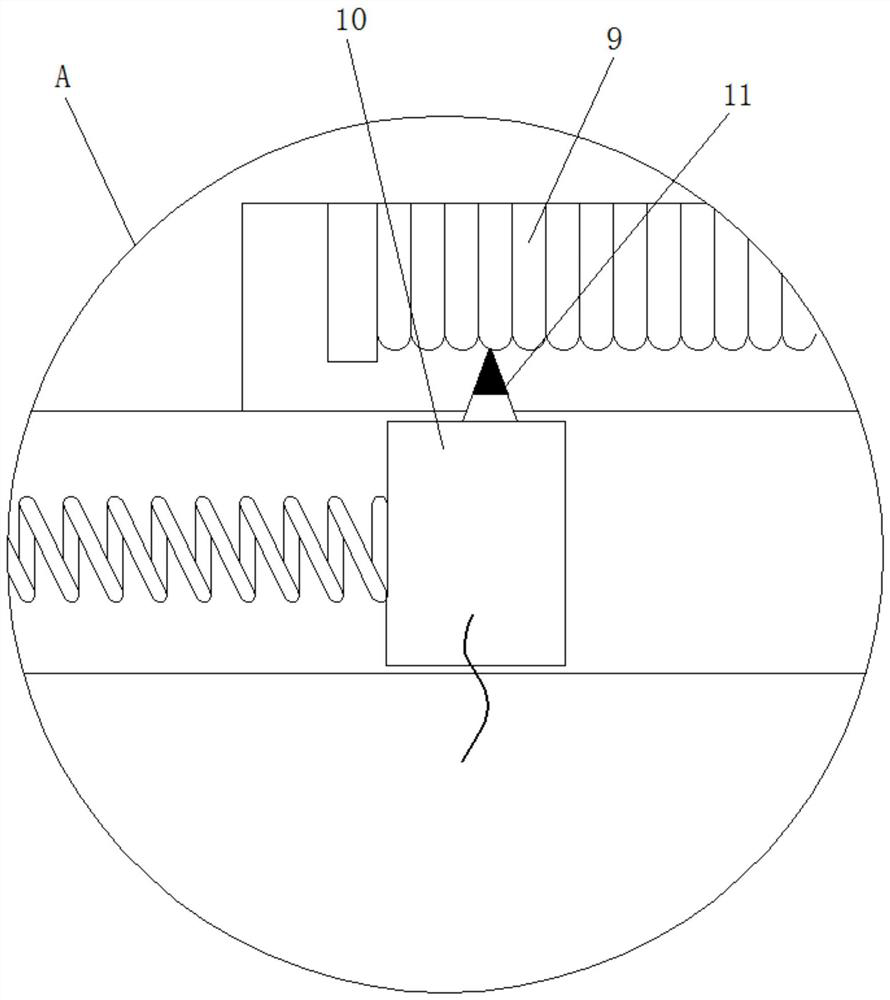

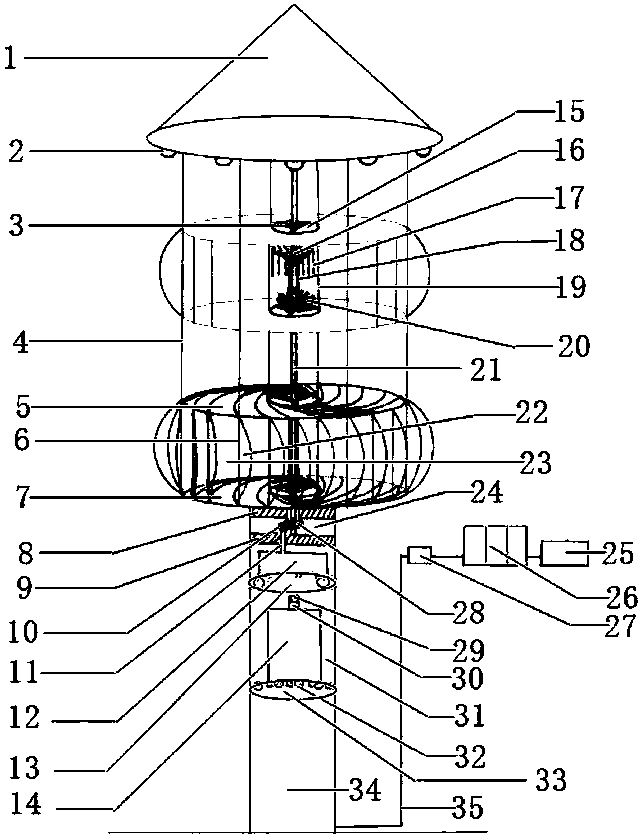

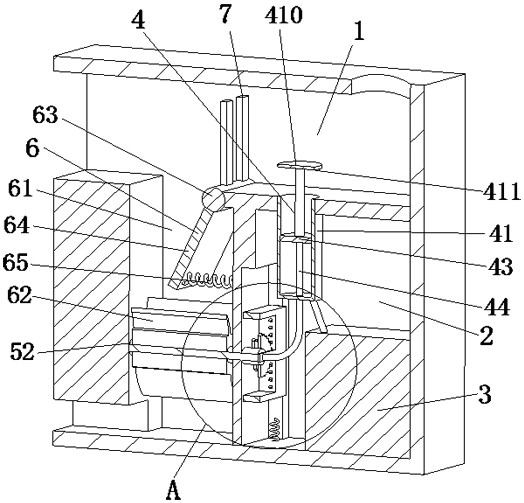

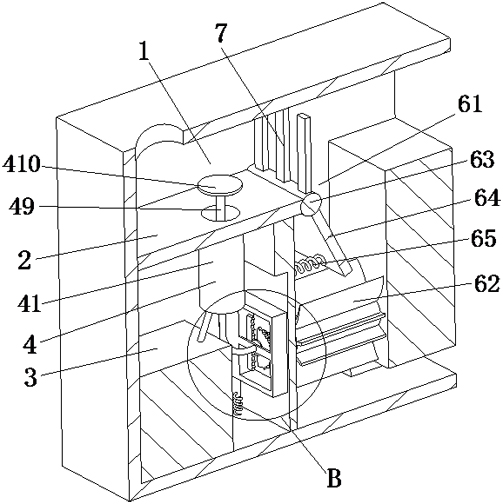

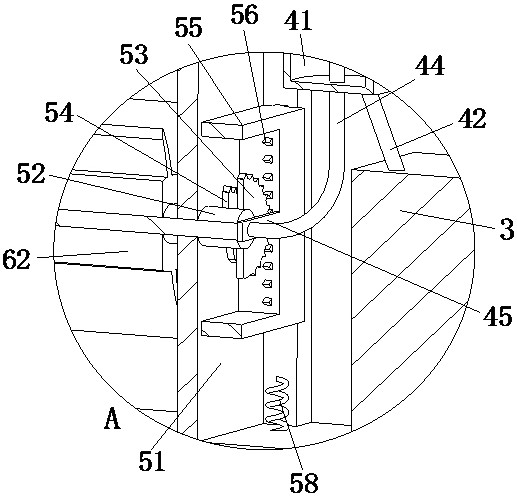

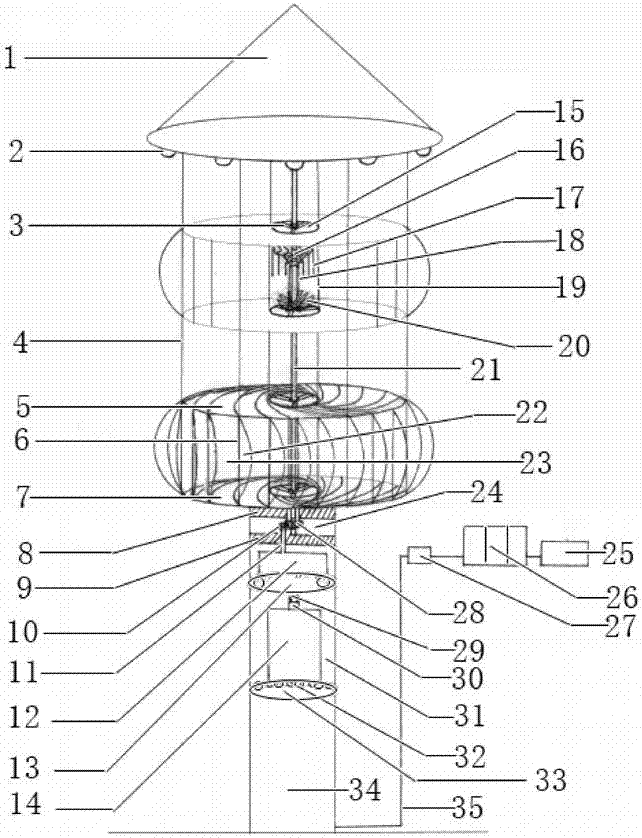

A layered high-power wind generator with automatic speed control

ActiveCN107191326BIncrease powerImprove wind resistanceWind motor controlRenewable energy generationAutomatic controlControl layer

The invention belongs to the technical field of wind power generation devices and particularly relates to an automatic speed control layered high-power breeze generator. The invention aims at providing the automatic speed control layered high-power breeze generator which is not limited by the wind direction. The automatic speed control layered high-power breeze generator is composed of an electric pole mechanism, a wind wheel mechanism, a power generation mechanism and a charging mechanism. The electric pole mechanism is composed of a central shaft, a top cover, electric appliance interfaces, a primary bracket, a secondary bracket, an upper partition plate, a transmission cabin, a motor cabin, a lower partition plate, air inlet holes and an electric pole. The primary bracket and the secondary bracket are both arranged on the upper portion of the electric pole, and the secondary bracket is located above the primary bracket. The lower end of the central shaft is fixed to the primary bracket. The top cover is arranged at the top end of the central shaft. The multiple electric appliance interfaces are arranged at the edge of the lower end of the top cover. The upper partition plate and the lower partition plate are arranged in a cavity structure of the electric pole in sequence from top to bottom. The motor cabin is formed between the upper partition plate and the lower partition plate. The transmission cabin is formed between the primary bracket and the secondary bracket.

Owner:王渊芃

An initial rainwater automatic monitoring and processing device

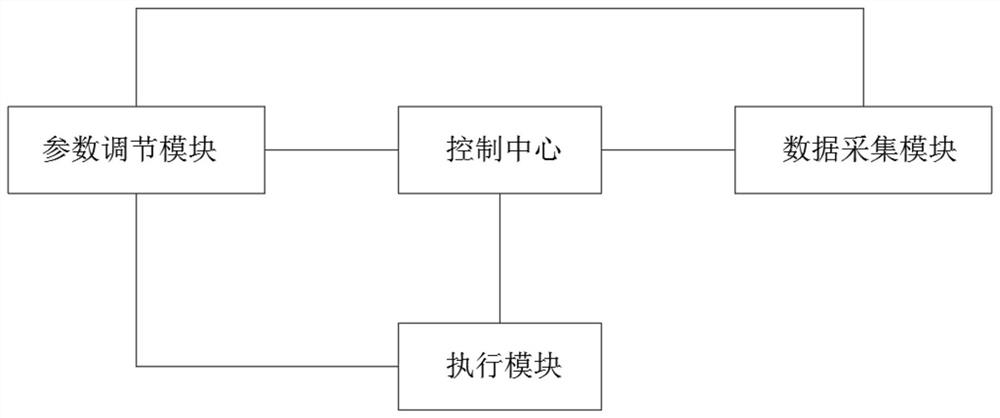

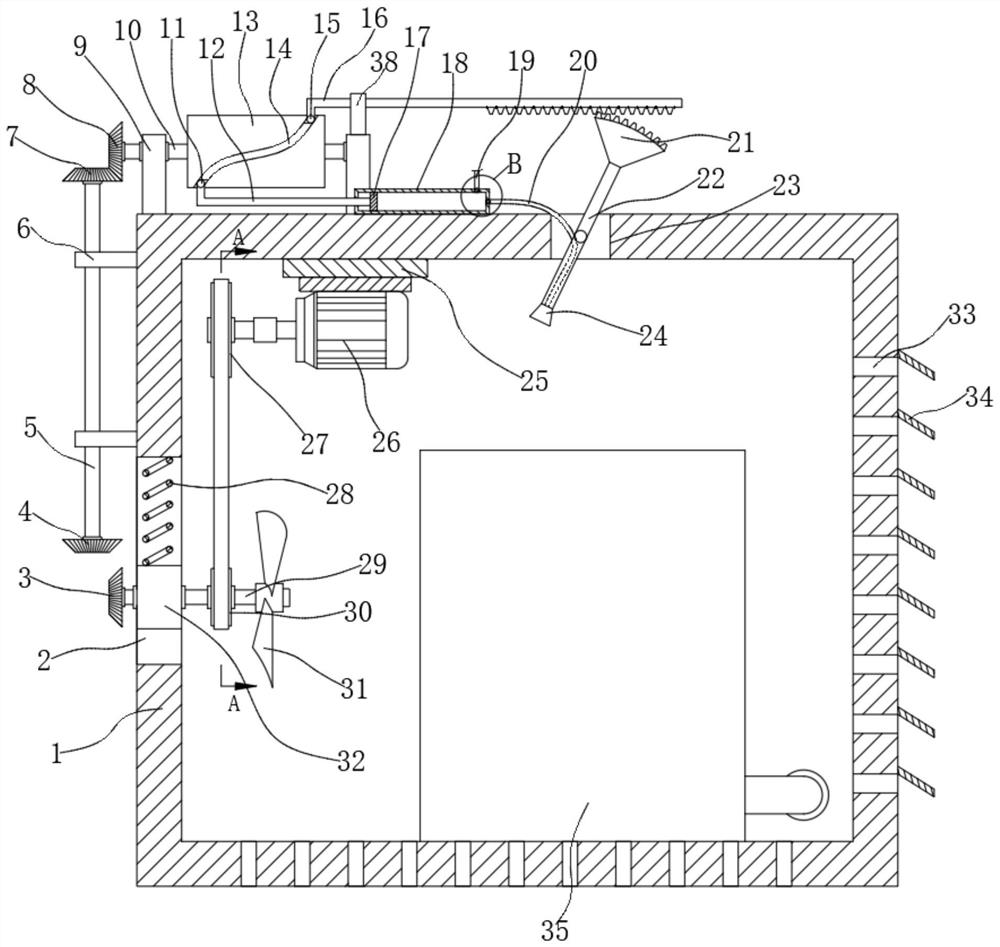

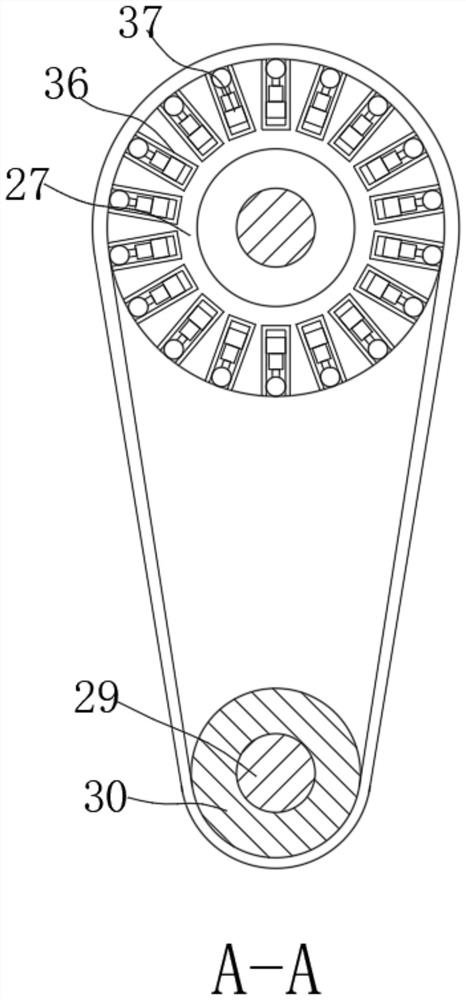

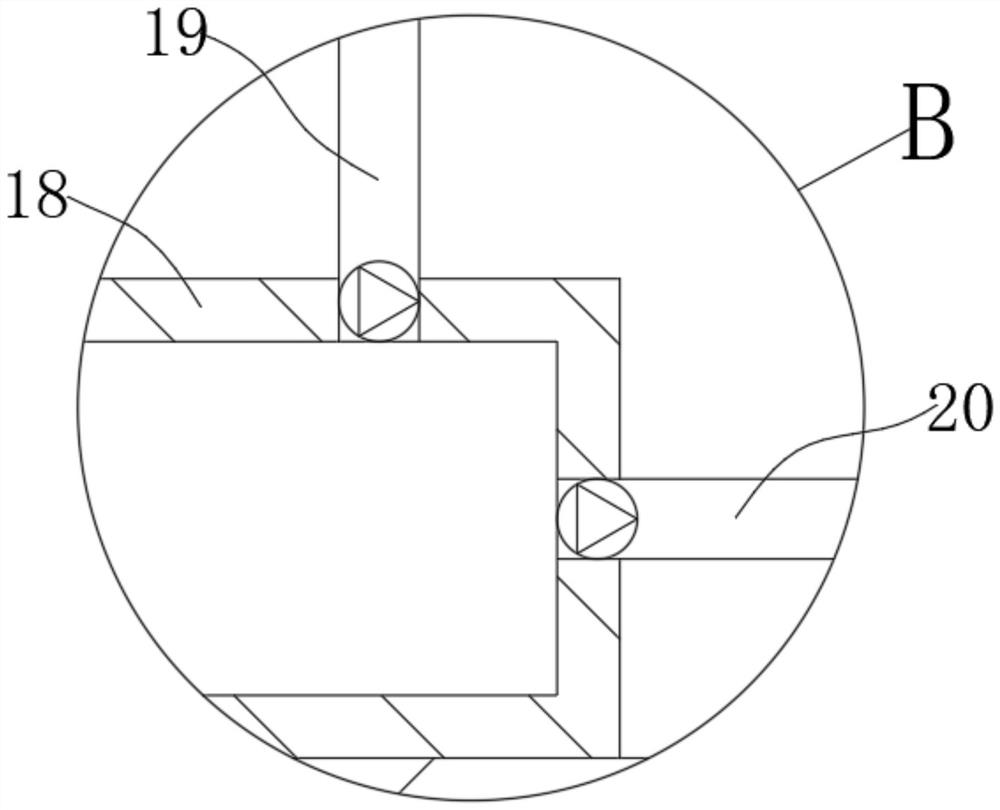

ActiveCN113155539BStable samplingAutomatic adjustment of rotation speedWithdrawing sample devicesTesting waterWater flowEnvironmental engineering

The invention relates to the technical field of initial rainwater treatment, and discloses an automatic initial rainwater monitoring and processing device, which includes a detection box arranged on the lower side of a municipal drainage channel, and a rainwater detector is arranged inside the detection box, and the rainwater detection box The inside of the upper end is provided with a sampling mechanism that communicates with the rainwater detector. The sampling mechanism is connected with a reciprocating mechanism for sampling rainwater. The reciprocating mechanism is connected with a driving mechanism. The reciprocating mechanism includes a In the square groove inside the box, a rotating shaft is pierced on the side of the rainwater detection box close to the driving mechanism, and the side wall of the rotating shaft is provided with a first toothed disc and a second toothed disc. The initial rainwater monitoring and processing device is provided with a driving mechanism that can drive the reciprocating mechanism and the sampling mechanism to work according to the water flow in the municipal drainage channel; the reciprocating mechanism can ensure that the sampling mechanism can smoothly sample real-time running water.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Automatic feeding device and kneading device for tea leaves

InactiveCN101884355BEasy to unloadUniform feedingPre-extraction tea treatmentTurning framesElectric machinery

The invention discloses an automatic feeding device and a kneading device for tea leaves, wherein the automatic feeding device for the tea leaves comprises a charging box for accommodating the tea leaves; a lower end face of the charging box is provided with a frame with a wheel for walking on a rail and a discharge outlet for discharging; the discharge outlet is provided with a discharge hopper;a tea leaf transportation mechanism is arranged at the bottom of the charging box, and a leaf distributing machine is arranged above the tea leaf transportation mechanism; and both the tea leaf transportation mechanism and the leaf distributing machine are connected with a motor, which is arranged on the charging box, through a chain. The kneading device for the tea leaves comprises a stander, a power transmission mechanism for controlling the rotation of a kneading barrel, a kneading disc which is arranged below the kneading barrel, a pressure mechanism for controlling the pressure of a gland, and a material unloading device; and an edge of the kneading disc is provided with a blowing device for cleaning remainders in the kneading disc. The automatic feeding device and the kneading device for the tea leaves have the advantages of ingenious conception, simple structure and high degree of automation; and by using the two devices, the tea leaves can be weighed, fed, discharged automatically, unloaded and kneaded uniformly, so that the work efficiency is improved greatly.

Owner:CHONGQING ACAD OF AGRI SCI

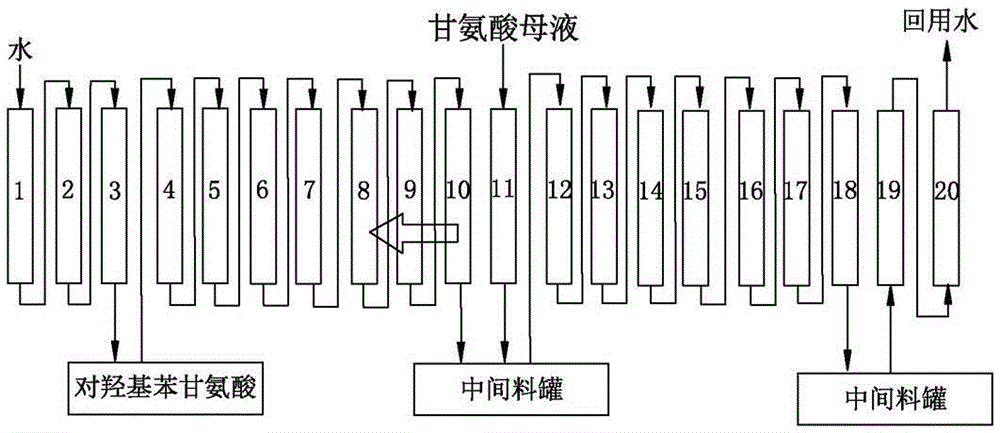

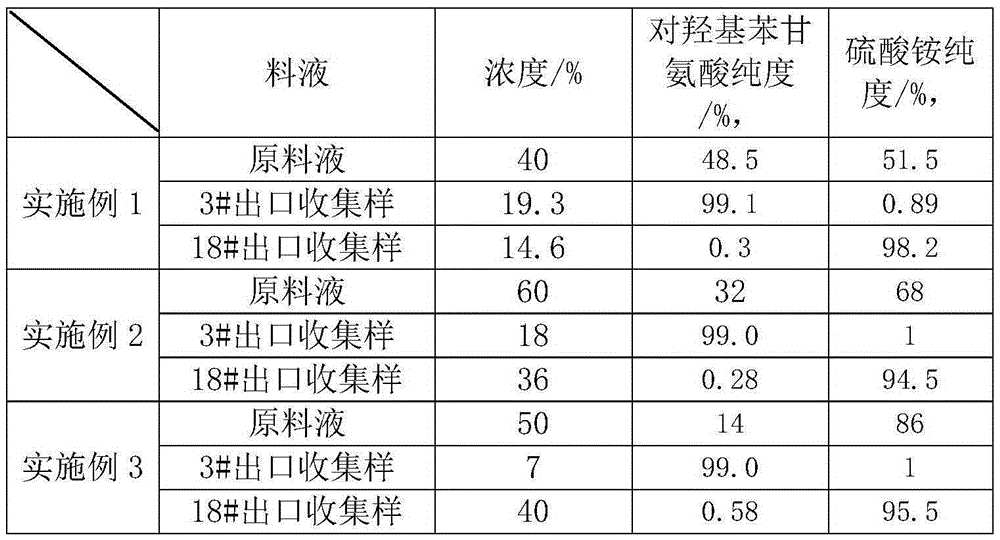

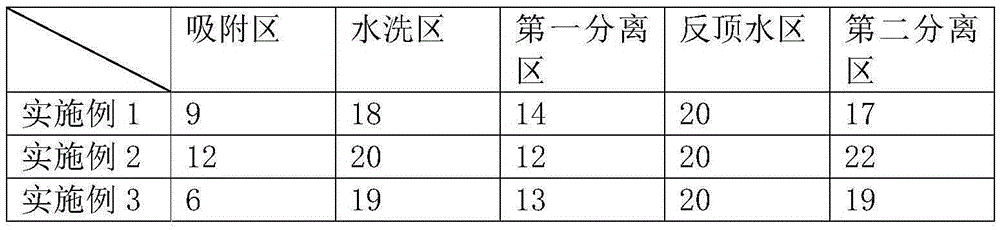

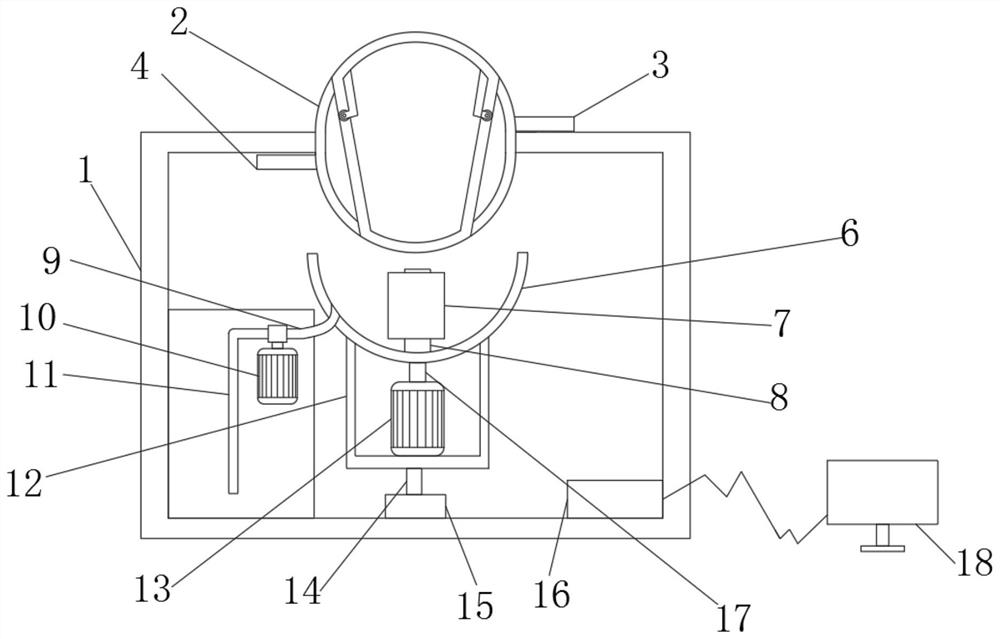

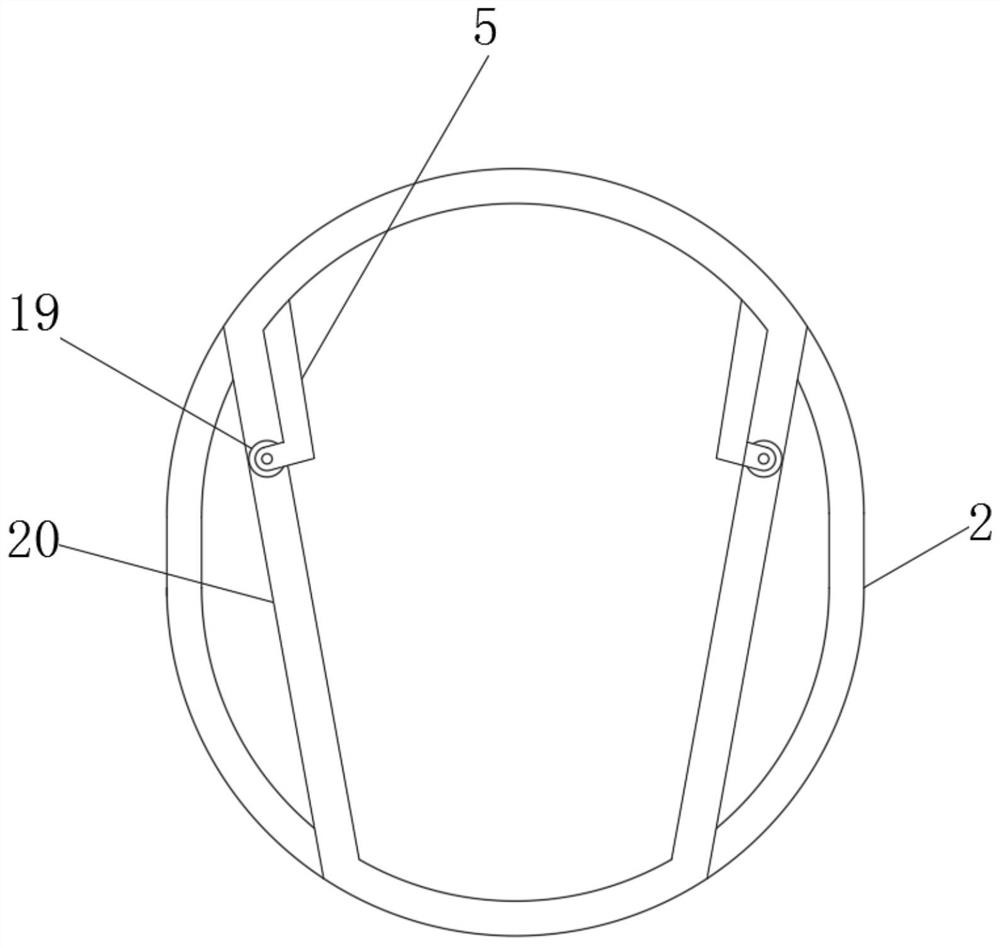

A method for separating p-hydroxyphenylglycine and ammonium sulfate from glycine mother liquor

ActiveCN103483213BSmall footprintComposition is stableOrganic compound preparationAmmonium sulfatesChromatographic separationGlycine

The invention discloses a method for separating p-hydroxyphenylglycine and ammonium sulfate from glycine mother liquor, which is characterized in that the pH of glycine mother liquor containing p-hydroxyphenylglycine and ammonium sulfate is adjusted to 3.0-8.0, Under the conditions, enter the continuous chromatographic separation system filled with strong acid type cation exchange resin, use water as the eluent to elute, collect the eluent and residual liquid respectively, and obtain two products, p-hydroxyphenylglycine and ammonium sulfate, and realize p-hydroxyphenylglycine Efficient separation of glycine and ammonium sulfate. The beneficial effects of the present invention are: compact equipment, simplified system, reduced pipeline and less occupied area; due to continuous operation under non-interrupted operation, the composition and concentration of the product remain basically stable; The change of rotation speed is automatically adjusted; the operating cost and equipment investment are reduced; the separation effect is good, and the purity of p-hydroxyphenylglycine after separation is high.

Owner:XIAMEN STARMEM TECH

Cylinder sleeve cleaning device and cylinder sleeve cleaning system

InactiveCN113680778AQuick cleanEliminate the disadvantages of traditional manual cleaningHollow article cleaningElectric machineEngineering

The invention discloses a cylinder sleeve cleaning device and a cylinder sleeve cleaning system, and relates to the technical field of cleaning equipment. The cylinder sleeve cleaning device is characterized in that a placing bin is arranged in a spherical bin, the upper end opening diameter of the placing bin is larger than the lower end opening diameter of the placing bin, so that cylinder sleeves of different specifications can be placed into the placing bin, and the cleaning device can be adapted to cylinder sleeves with various specifications; the cylinder sleeve is stably kept in the placing bin through a pressing block, then a cleaning rod and a cleaning cotton sleeve on the cleaning rod stretch into the inner wall of the cylinder sleeve through a lifting assembly, therefore, cleaning of the surface of the inner wall of the cylinder sleeve is rapidly completed, and the defects of traditional manual cleaning are overcome; and by means of the cylinder sleeve cleaning system, the pressing angle of the pressing block and the water inflow of a cleaning assembly pumped into an arc-shaped sealing bin through a water pump can be automatically adjusted according to the specification of the cylinder sleeve, and meanwhile the rotating speed of a rotating motor is automatically adjusted.

Owner:ZYNP GRP ANHUI CO LTD

Pressure supply equipment for wastewater treatment

PendingCN114427528AImprove cooling effectSpeed up evaporationPositive displacement pump componentsLiquid fuel engine componentsElectric machineryEngineering

The invention discloses pressure supply equipment for wastewater treatment, which comprises a pressure supply cabinet and a pressure supply pump, the pressure supply pump is fixed on the cavity inner wall of the bottom of the pressure supply cabinet, the cavity inner wall of the pressure supply cabinet far away from the top of the pressure supply pump is provided with a blowing mechanism, and the top of the pressure supply cabinet is provided with a spraying mechanism. A transmission mechanism is arranged between the blowing mechanism and the spraying mechanism, and heat dissipation holes are formed in the outer wall, away from the motor fixing base, of the pressure supply cabinet. By arranging the air blowing mechanism, the transmission mechanism and the spraying mechanism, the effect of adjusting the heat dissipation degree according to the temperature of the pressure supply pump is achieved, when the temperature is too high, the heat dissipation effect is improved by increasing the rotating speed of rotating fan blades and spraying water to the surface of the pressure supply pump for cooling, and when the temperature is reduced, the spraying mechanism is automatically closed, and the cooling effect is improved. And meanwhile, the rotating speed of the rotating fan blades is reduced, so that the intelligent heat dissipation function is achieved.

Owner:徐风雪

A walking machine capable of preventing excessive rotation and being capable of self-locking

ActiveCN112156428BAvoid pushingWon't hurtMovement coordination devicesCardiovascular exercising devicesMetal stripsClassical mechanics

The invention relates to the technical field of fitness equipment, and discloses a self-locking stroller that prevents over-rotation from rotating, including a fixed frame, the inner surface of the fixed frame is fixedly connected with a friction plate, and the inner surface of the fixed frame is connected with a friction plate. There is a rotating shaft, the surface of the rotating shaft is fixedly connected with a rotating disc, the inside of the rotating disc is slidingly connected with a pressing plate, the bottom of the pressing plate is fixedly connected with a return spring, the lower end of the pressing plate is fixedly connected with a magnetic block, the rotating Electromagnetic columns are fixedly connected to the inside of the disk, and resistance strips are fixedly connected to the surface of the rotating disk. The trigger lever on the surface of the slide bar is connected to the upper end of the metal bar, so that the stopper can fix the rotating column with the fixed frame, so that it can be automatically locked when no one is using it, preventing children from pushing the pedals by hand, and protecting children It will not be injured by the pedal, which improves the safety effect of use.

Owner:台州市博跃塑业有限公司

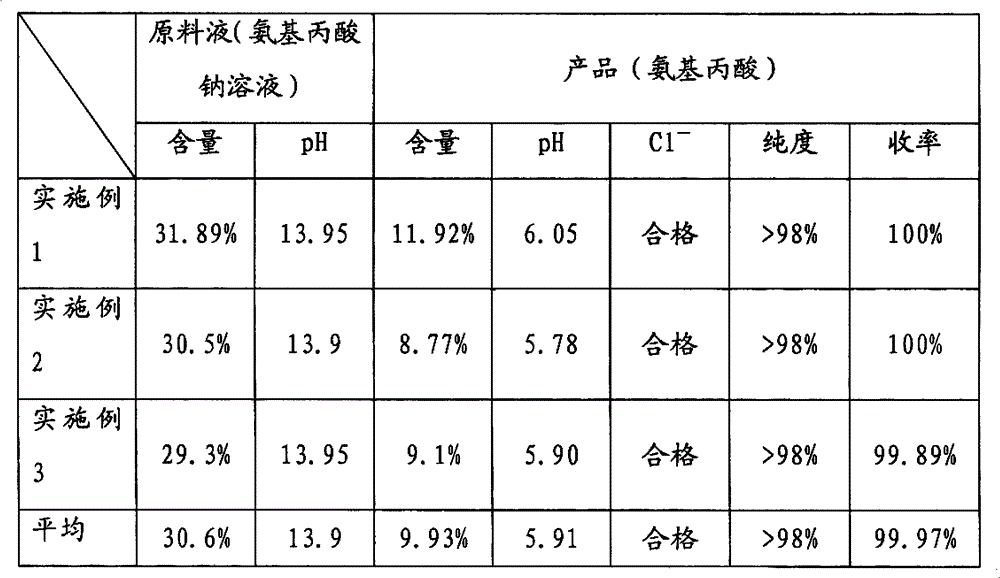

A kind of method that sodium aminopropionate is converted into aminopropionic acid

ActiveCN102838498BSmall footprintReduce consumptionOrganic compound preparationAmino-carboxyl compound preparationPropanoic acidIon exchange

Owner:XIAMEN STARMEM TECH

Light matter separation device for construction waste treatment

ActiveCN108655003BEasy to separateTransmission speed automatically increasesGas current separationSubstance removalPetroleum engineering

Owner:池爱方

Automatic speed control layered high-power breeze generator

ActiveCN107191326AIncrease powerImprove wind resistanceWind motor controlMachines/enginesAutomatic controlControl layer

The invention belongs to the technical field of wind power generation devices and particularly relates to an automatic speed control layered high-power breeze generator. The invention aims at providing the automatic speed control layered high-power breeze generator which is not limited by the wind direction. The automatic speed control layered high-power breeze generator is composed of an electric pole mechanism, a wind wheel mechanism, a power generation mechanism and a charging mechanism. The electric pole mechanism is composed of a central shaft, a top cover, electric appliance interfaces, a primary bracket, a secondary bracket, an upper partition plate, a transmission cabin, a motor cabin, a lower partition plate, air inlet holes and an electric pole. The primary bracket and the secondary bracket are both arranged on the upper portion of the electric pole, and the secondary bracket is located above the primary bracket. The lower end of the central shaft is fixed to the primary bracket. The top cover is arranged at the top end of the central shaft. The multiple electric appliance interfaces are arranged at the edge of the lower end of the top cover. The upper partition plate and the lower partition plate are arranged in a cavity structure of the electric pole in sequence from top to bottom. The motor cabin is formed between the upper partition plate and the lower partition plate. The transmission cabin is formed between the primary bracket and the secondary bracket.

Owner:王渊芃

Method for converting sodium gulonate to gulonic acid in Vit C production

ActiveCN100349848CInnovativeSave pipesOrganic compound preparationCarboxylic compound preparationVitamin CIon exchange

The invention discloses a method to convert gulonic sodium into gulonic acid in VC production by continual ion exchange device with strong-acid cation exchange resin and disc-convey continual counter adsorption system. This invention has continuity to increase resin utility and decrease agent usage with well benefit.

Owner:SANDA FILM SCI & TECH XIAMEN

A kind of production method of colistin sulfate

ActiveCN103265622BSmall footprintReduce consumptionPolymyxinsPeptide preparation methodsHigh concentrationDesorption

The invention discloses a colistin sulfate production method, which sequentially comprises the following steps: filtering, calcium and magnesium removing-absorption desorption, concentration, desalting, neutralization and spray drying, and is characterized in that the filtering adopts ceramic membrane ultra-filtration filtering, the absorption desorption adopts a continuous ion exchange system filled with a methacrylic acid type carboxylic acid base resin or an acrylic acid carboxylic acid base resin to carry out absorption desorption, and the concentration adopts nano-filtration concentration. The production method has the following advantages that: colistin sulfate is an intracellular product, and cells can be broken when filtration is performed by using a ceramic membrane, such that the colistin sulfate in the colistin sulfate cells can be collected; the equipment is compact, the system is simplified, the pipeline is reduced, and the occupation area is small; the resin consumption is reduced; and the adopted nano-filtration has advantages of high concentration ratio, low energy consumption and the like, and the whole method has advantages of high yield, good purification effect, low production cost and the like.

Owner:XIAMEN STARMEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com