Laser welding machine head with automatic wire feeding function

A laser welding and laser head technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as empty welding, unable to monitor wire feeding, and affect welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

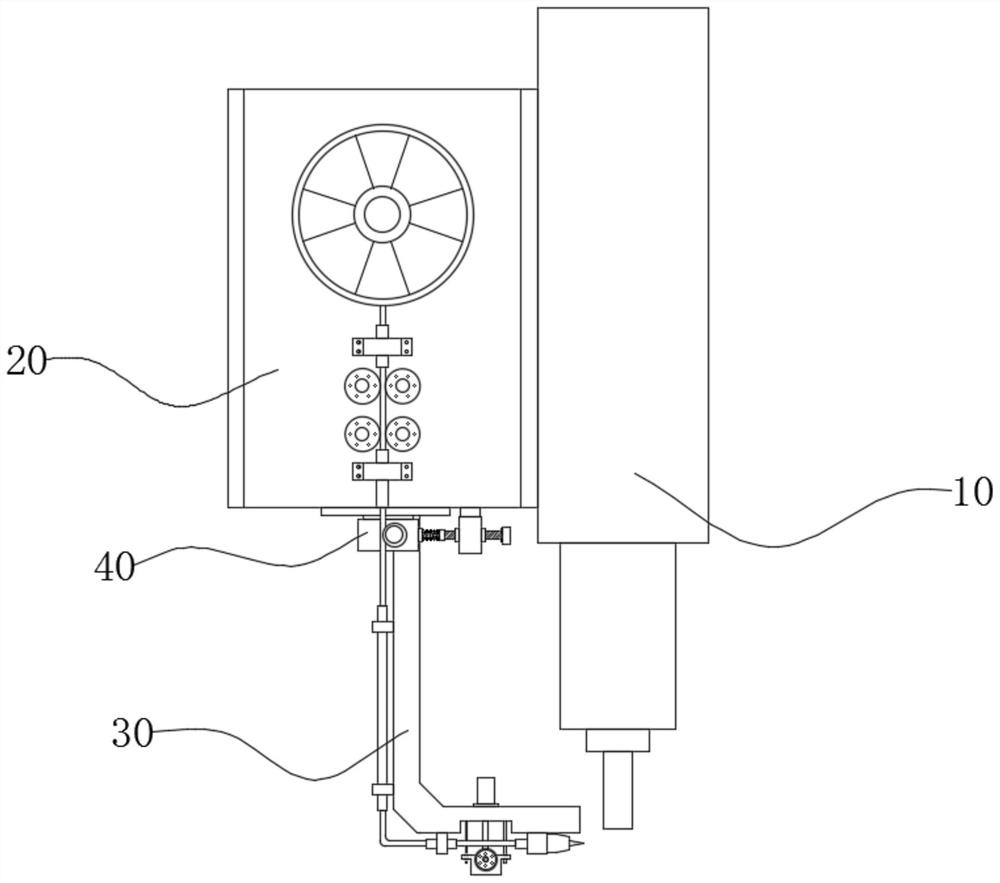

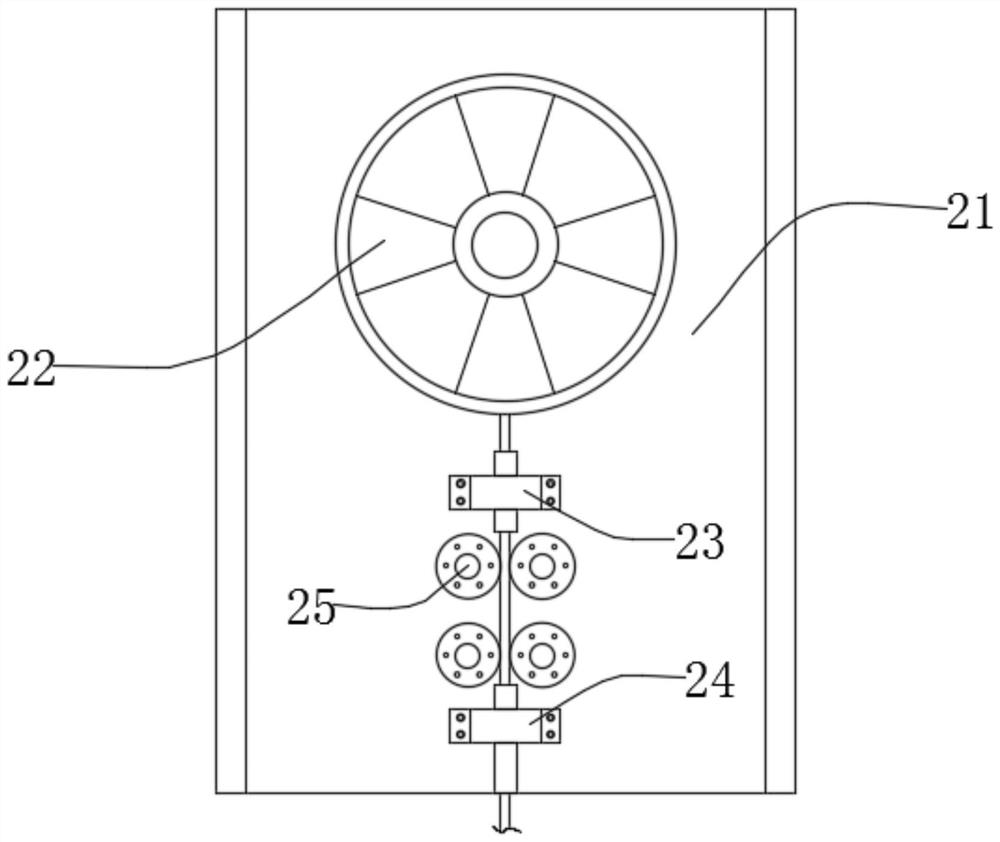

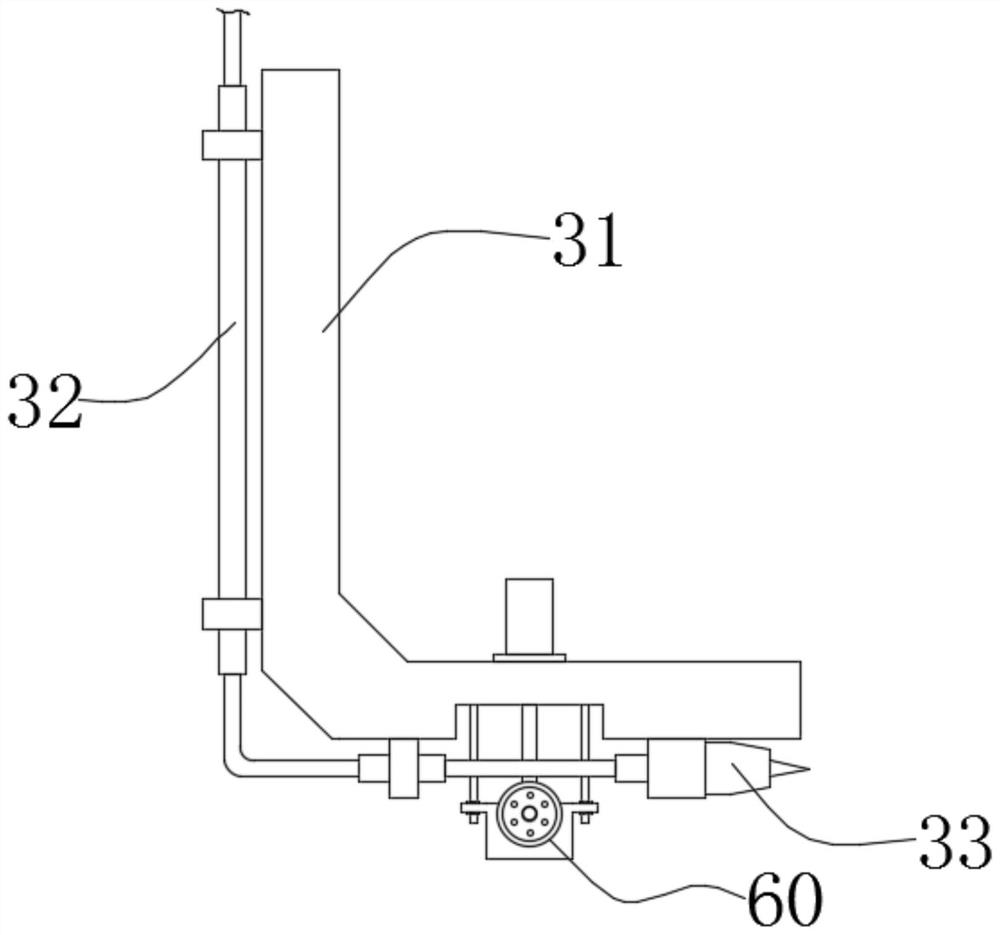

[0044] A laser welding head with automatic wire feeding function, comprising a laser head 10, a wire feeding assembly 20 and a supporting assembly 30 fixed on the wire feeding assembly 20, the wire feeding assembly 20 comprises a supporting plate 21, and the outer side wall of the supporting plate 21 is A wire feeding wheel 22 is rotatably connected, the wire feeding end of the wire feeding wheel 22 is provided with a limit seat 23 and a limit seat 2 24, and a wire feeding wheel 25 is arranged between the limit seat 1 23 and the limit seat 2 24, and the feeding wheel 25 is provided. There are four wire feeders 25 in total. The input ends of the four wire feeders 25 are all connected to the driving equipment, and the four wire feeders 25 are symmetrically distributed in a group of two. The support assembly 30 includes a bracket 31. The outer side wall is fixedly connected with a wire feeding tube 32 and a wire outlet 33, and the bottom of the wire feeding assembly 20 is fixedly ...

Embodiment 2

[0049] On the basis of the first embodiment, the function of auxiliary wire feeding is added.

[0050] An auxiliary wire feeding assembly 60 for auxiliary wire feeding is also installed on the outer side wall of the support assembly 30. The auxiliary wire feeding assembly 60 includes a wire feeding frame 61 and a hydraulic cylinder 62 installed on the outer side wall of the supporting assembly 30. The telescopic end of the hydraulic cylinder 62 is fixed A wire feeding frame 61 is connected, and an auxiliary wire feeding wheel 64 is rotatably connected to the outer side wall of the wire feeding frame 61. A servo motor 65 is installed on one side of the wire feeding frame 61, and the input shaft of the auxiliary wire feeding wheel 64 is connected with the output of the servo motor 65. The shaft is fixedly connected, and the outer side wall of the wire feeder 61 is slidably connected with two symmetrically distributed limit polished rods 63 , and one end of the limit polished rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com