Automatic speed control layered high-power breeze generator

A high-power, layered technology, applied in the direction of engines, wind turbines, machines/engines, etc., can solve the problems that three-leaf wind turbines cannot be used to generate electricity, the price is unacceptable to ordinary families, and the utilization rate of wind power is not high. Improve wind utilization, increase air pressure, and improve the effect of strong wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

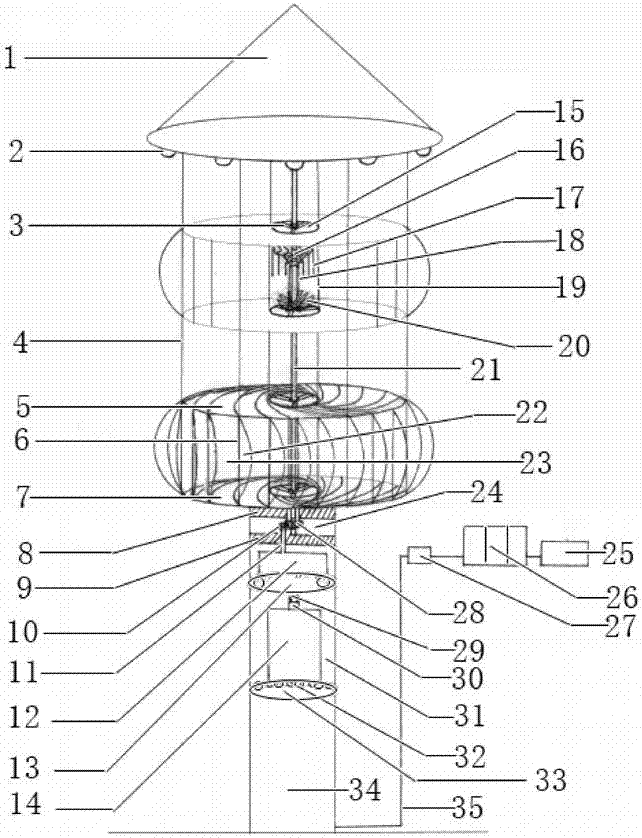

[0020] like figure 1 As shown, an automatic speed control layered high-power breeze generator is composed of four parts: a pole mechanism, a wind wheel mechanism, a power generation mechanism, and a charging mechanism. The pole mechanism consists of a central shaft 21, a top cover 1, an electrical appliance Interface 2, main support 9, secondary support 8, upper partition 13, transmission compartment 24, motor compartment 31, lower partition 33, air intake hole 32, electric pole 34, the electric pole 34 is a cavity structure, the main Support 9 and secondary support 8 are all arranged on the top of pole 34 and secondary support 8 is positioned at the top of main support 9, and the lower end of central axis 21 is fixed on the main support 9, and the upper end of central axis 21 passes secondary support 8 and extends to secondary Outside the bracket 8, the top cover 1 is arranged on the top of the central axis 21, and a plurality of electrical interfaces 2 are arranged at the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com