Light matter separation device for construction waste treatment

A construction waste and separation device technology, which is applied in the direction of solid separation, separating solids from solids with air flow, chemical instruments and methods, etc., can solve the problems that the separation speed of the separation device cannot be automatically adjusted, and achieve the effect of ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

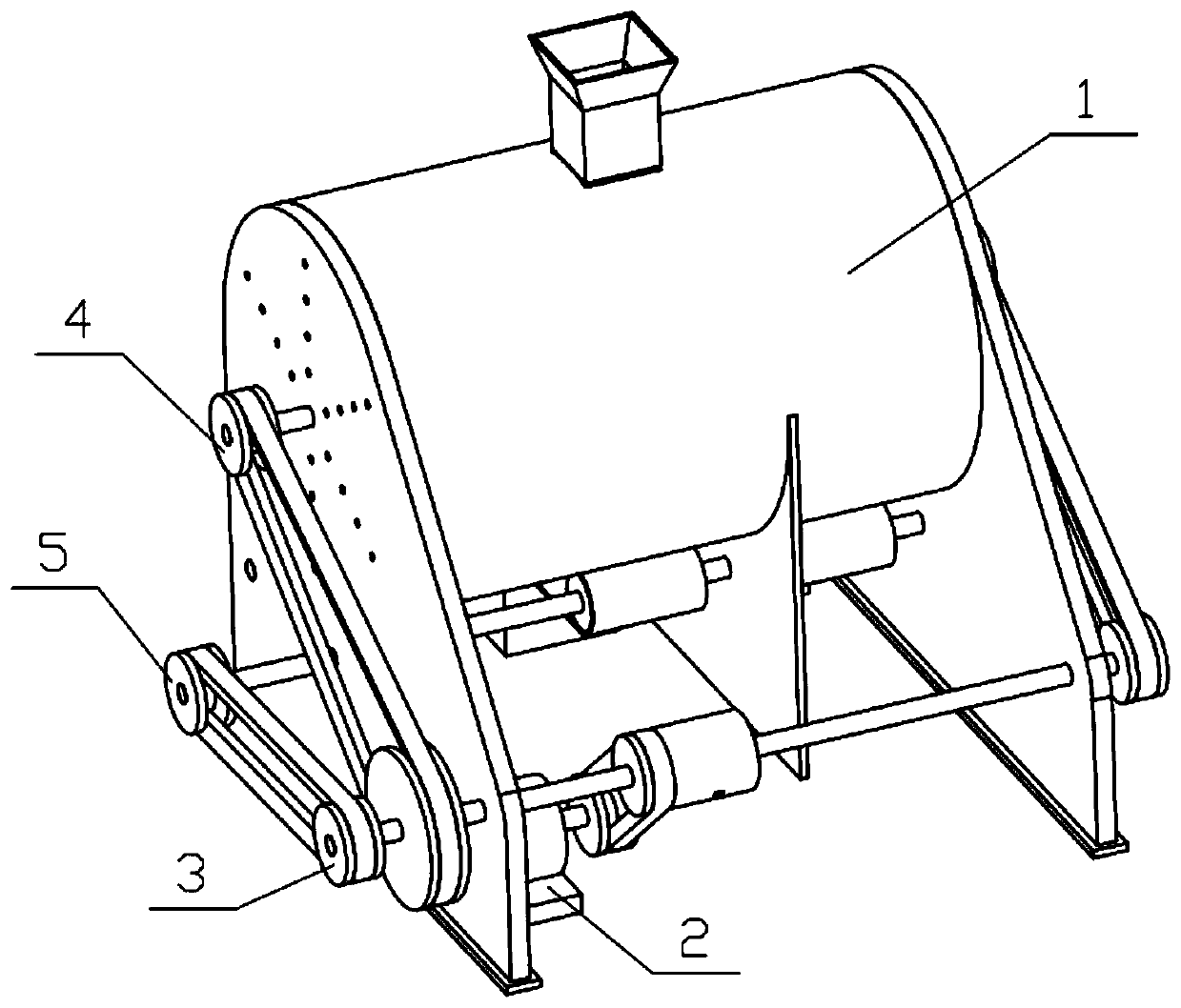

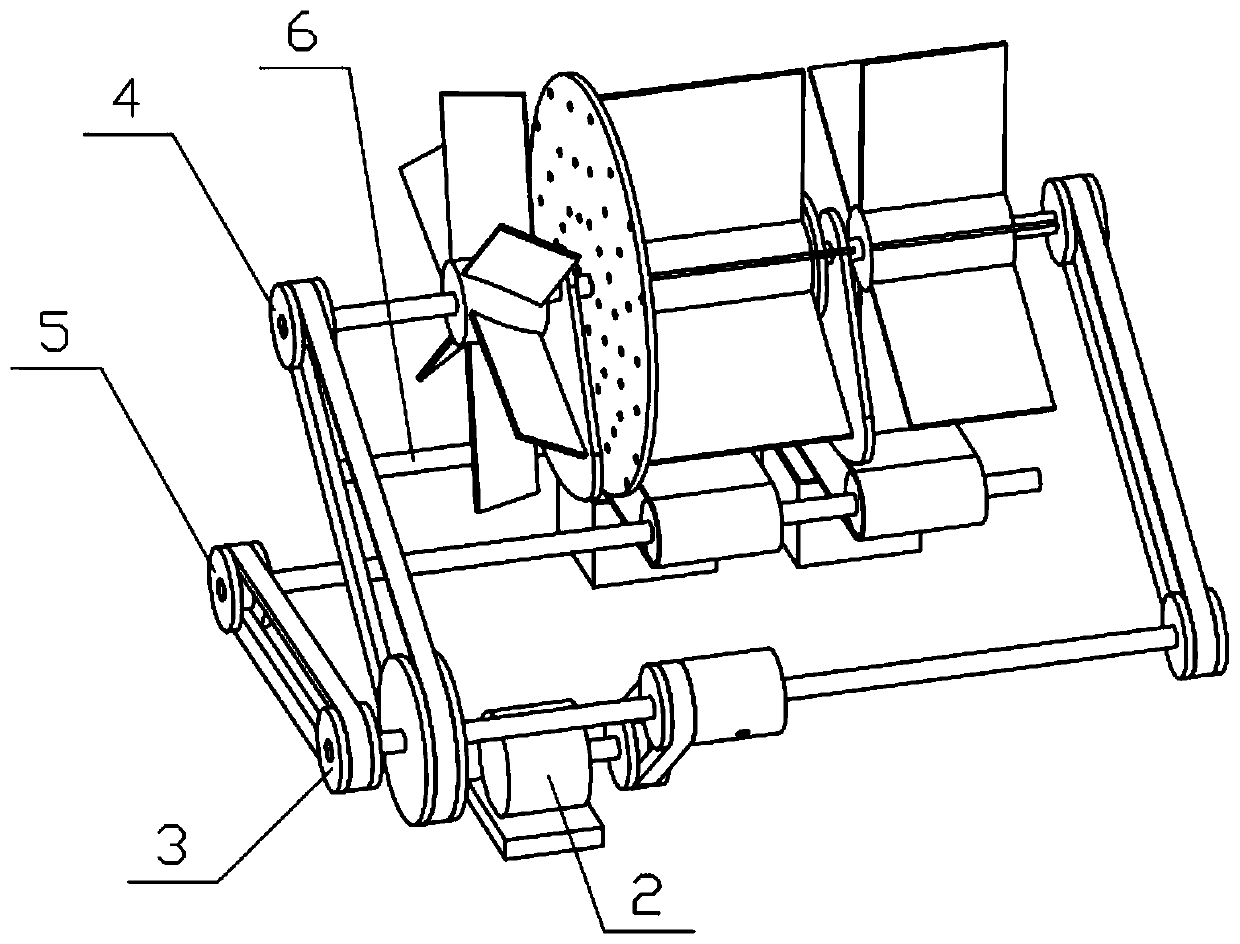

[0032] Combine below Figure 1-15Describe this embodiment, a light material separation device for construction waste treatment, including a complete machine support 1, a power mechanism 2, a differential mechanism 3, a separation mechanism 4, an active transport mechanism 5 and a passive transport mechanism 6, the power mechanism 2 A motor and a power pulley are arranged on the top, the power pulley is fixedly connected to the output shaft of the motor, the power mechanism 2 is fixedly connected to the whole machine support 1, and the differential mechanism 3 is rotatably connected to the whole machine support 1, and the differential speed Mechanism 3 and power mechanism 2 are connected by belt transmission, separation mechanism 4 is connected to the whole machine support 1 in rotation, separation mechanism 4 and differential mechanism 3 are connected by belt transmission, and active transport mechanism 5 is rotatably connected to the whole machine support 1. The transport mec...

specific Embodiment approach 2

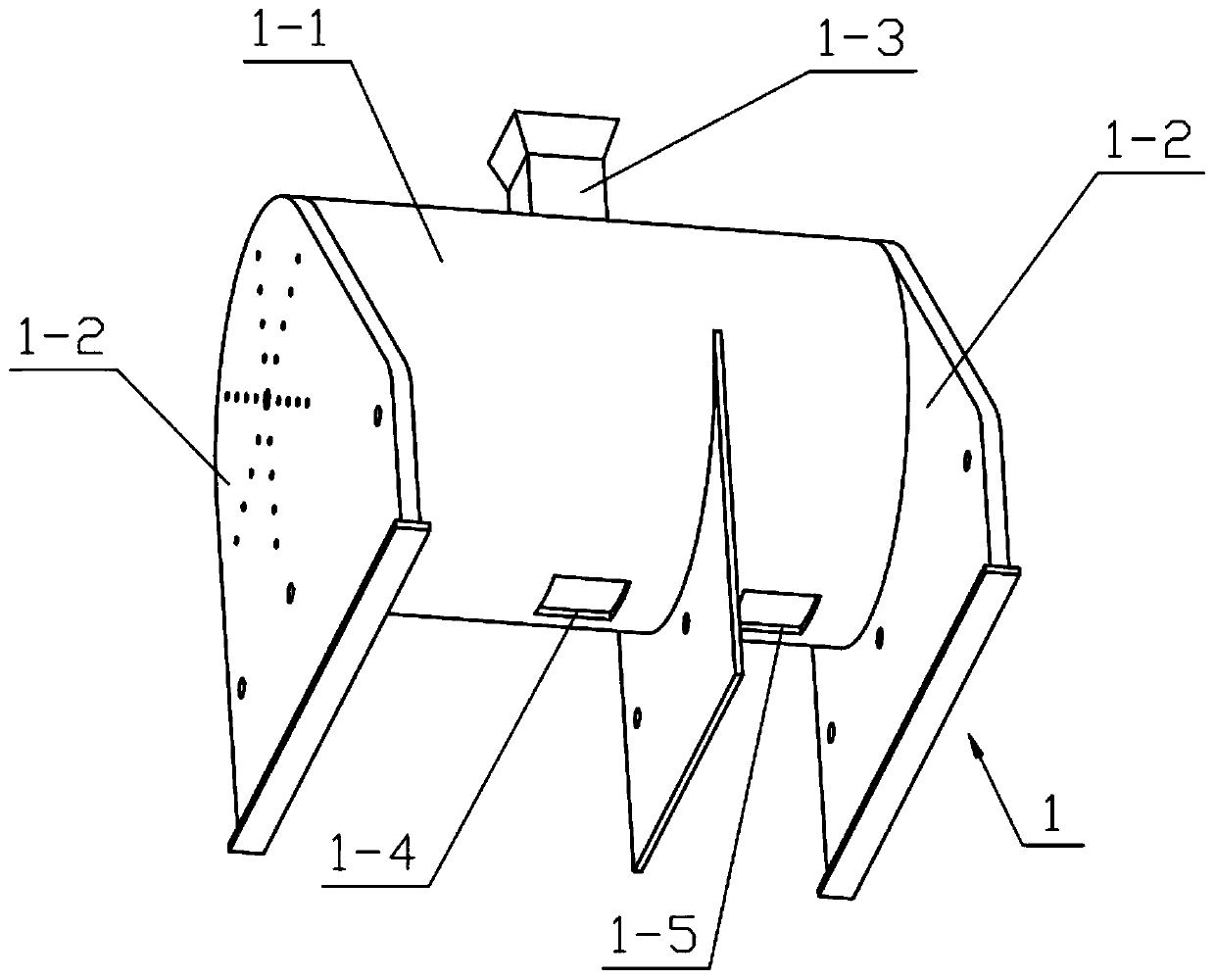

[0034] Combine below Figure 1-15 Describe this embodiment, this embodiment will further explain Embodiment 1, the whole machine support 1 includes a separation support 1-1, a side plate 1-2, a material feeding frame 1-3, a waste material outlet 1-4 and a light material outlet 1-5, two side plates 1-2 are provided, and a plurality of circular through holes I are respectively provided on the two side plates 1-2, and the two side plates 1-2 are respectively fixedly connected to the separation bracket 1- The left and right ends of 1, the feeding rack 1-3 is fixedly connected to the upper end of the separation bracket 1-1, and the waste material outlet 1-4 and the light material outlet 1-5 are respectively arranged on the left and right sides of the lower end of the separation bracket 1-1; Each side plate 1-2 is provided with a plurality of circular through holes I to ensure that the wind force generated by the fan 4-5 will not form air convection in the separation bracket 1-1 to ...

specific Embodiment approach 3

[0036] Combine below Figure 1-15 Describe this embodiment, this embodiment will further explain the second embodiment, the differential mechanism 3 includes differential shaft I3-1, differential shaft II3-2, differential pulley I3-3, differential large pulley 3-4, differential pulley II3-5, differential pulley III3-6, differential small shaft 3-7, differential bevel gear I3-8, differential bevel gear II3-9 and differential bevel gear III3- 10. The differential pulley Ⅰ 3-3 includes the differential pulley housing 3-3-1 and the differential pulley body 3-3-2, and the differential pulley body 3-3-2 is fixedly connected to the differential pulley housing The left end of 3-3-1, the differential bevel gear II 3-9 and the differential pulley III 3-6 are respectively fixedly connected to the left and right ends of the differential shaft I 3-1, the differential pulley II 3-5 and the differential bevel gear Ⅰ3-8 are respectively fixedly connected to the left and right ends of the dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com