Patents

Literature

103results about How to "Stable sampling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

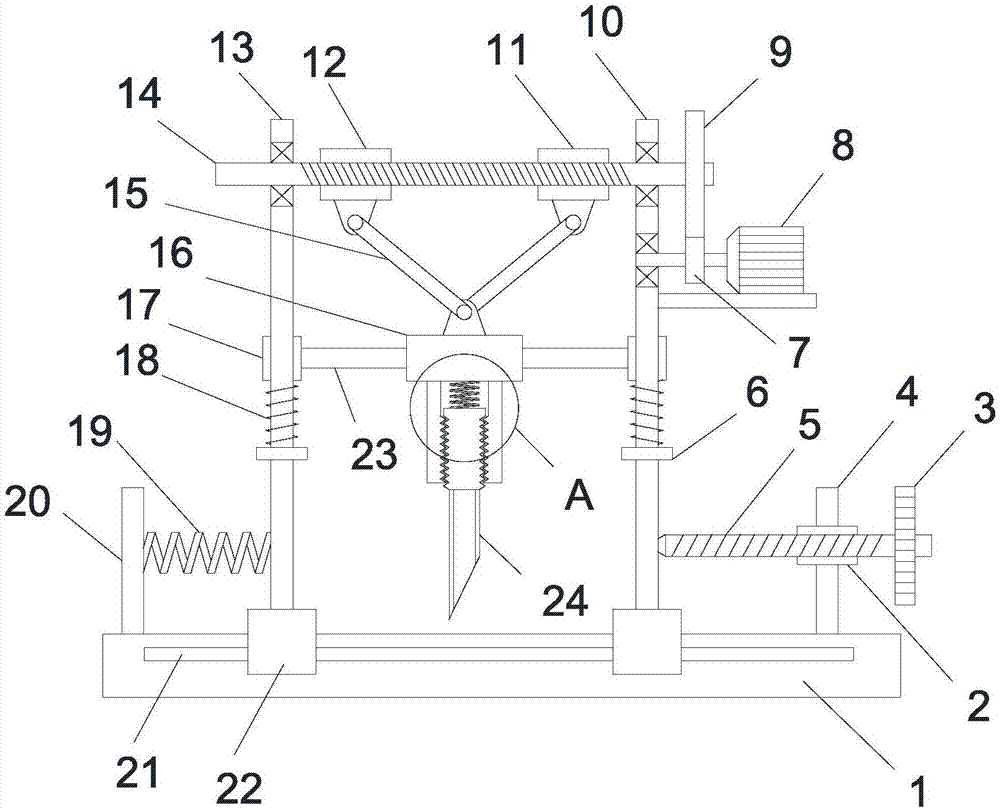

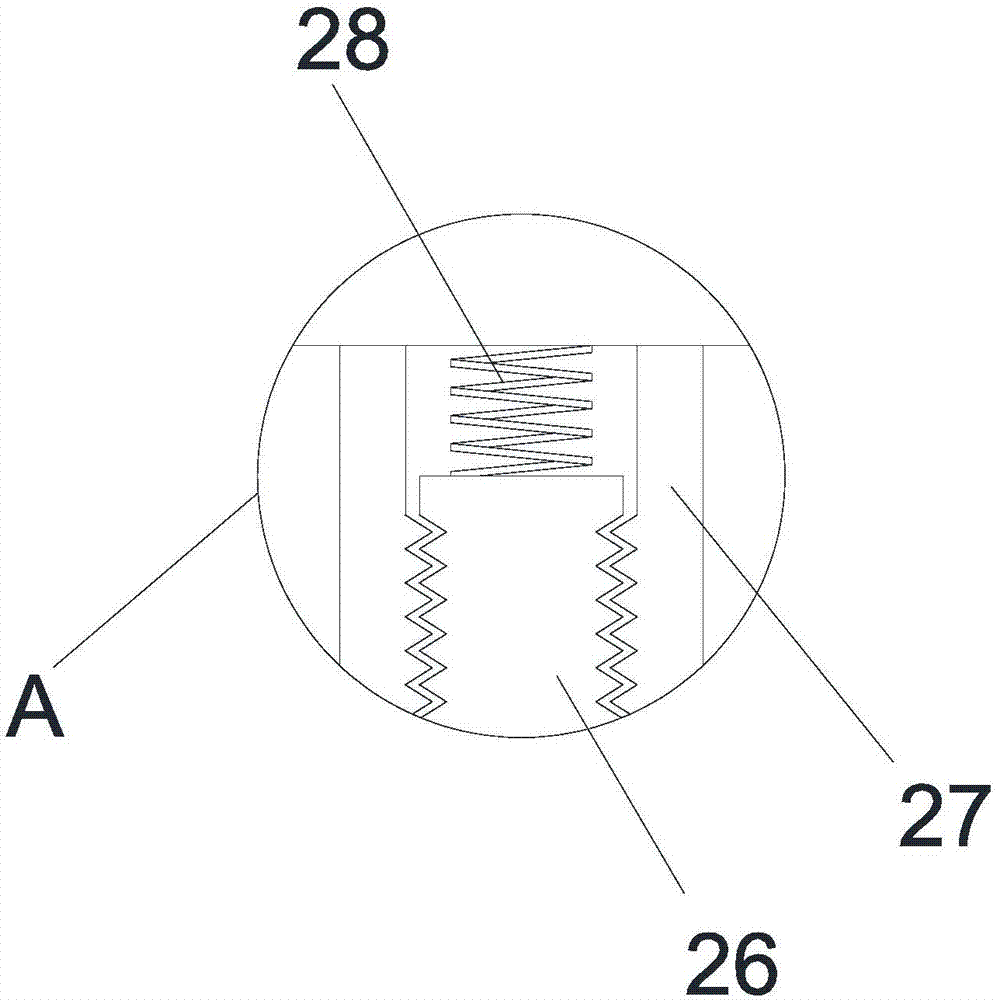

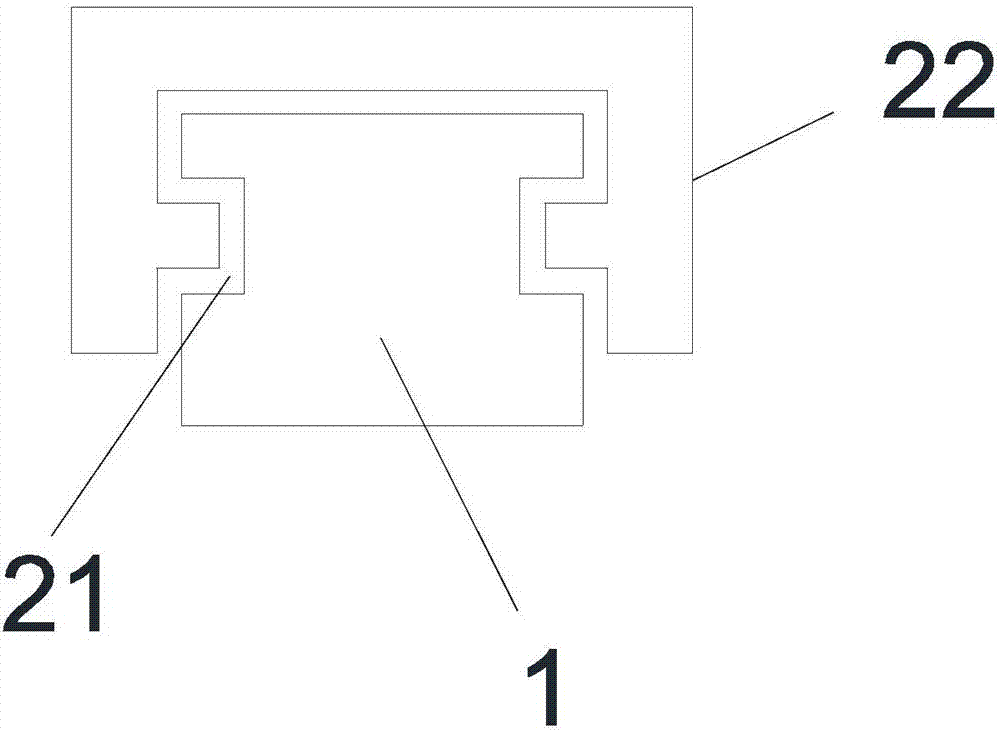

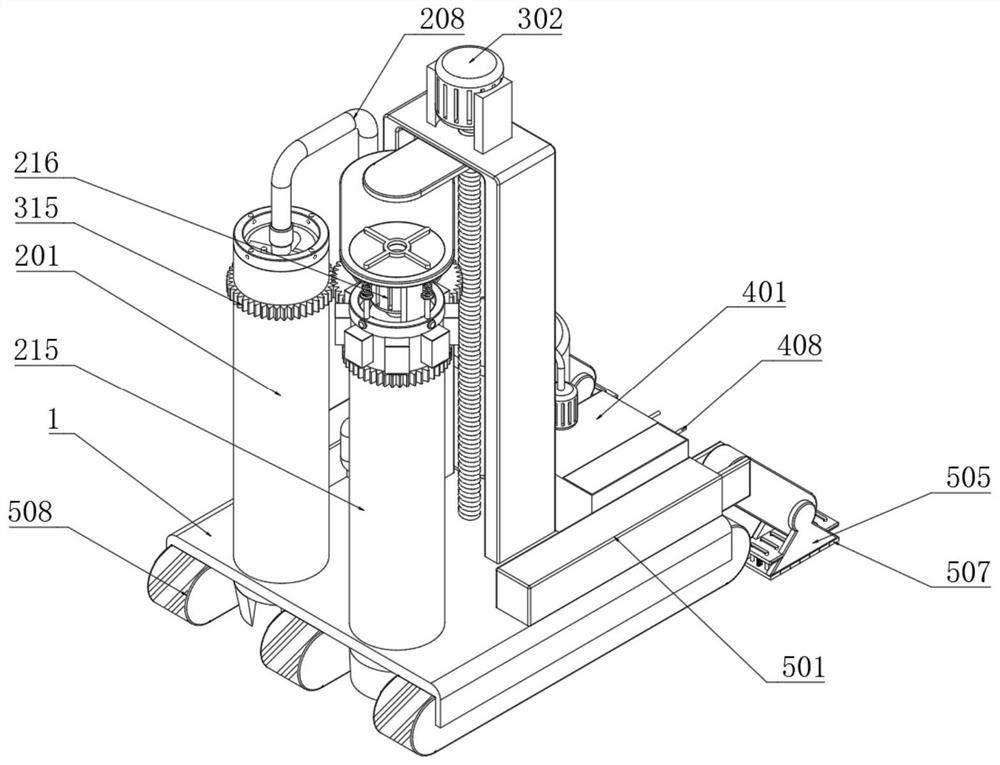

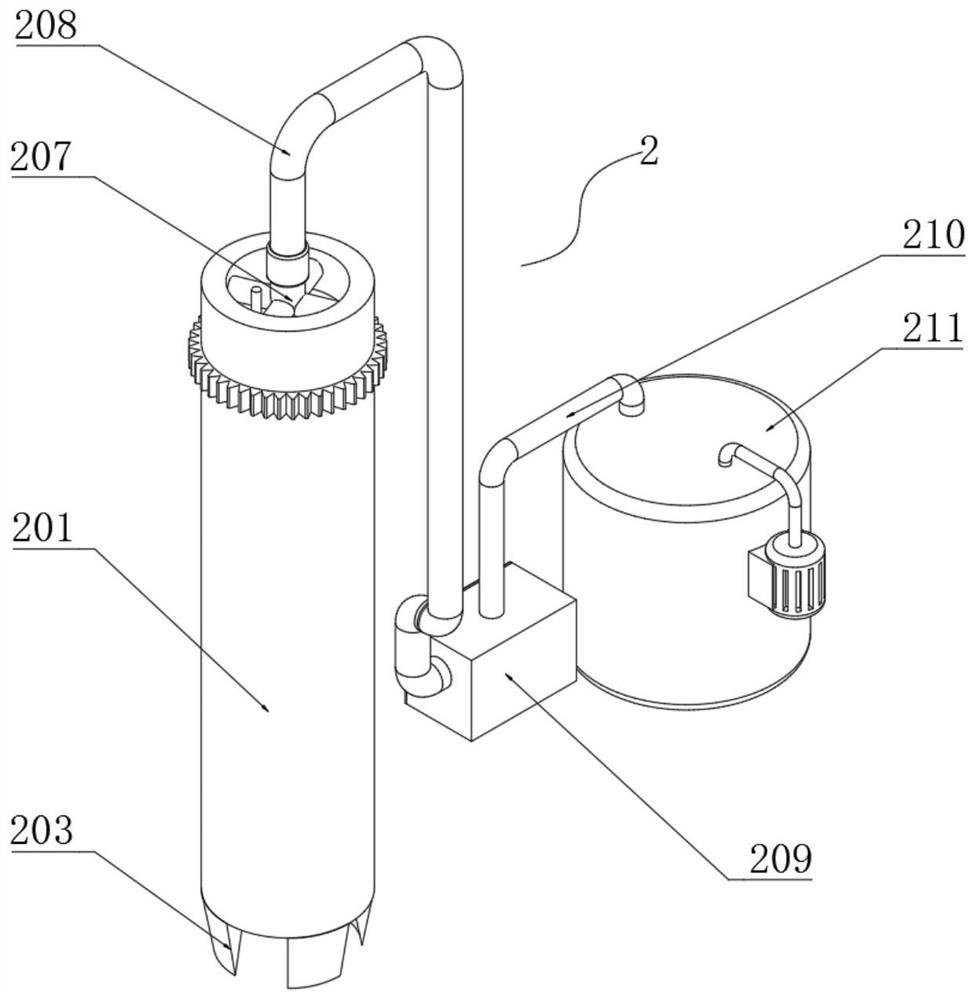

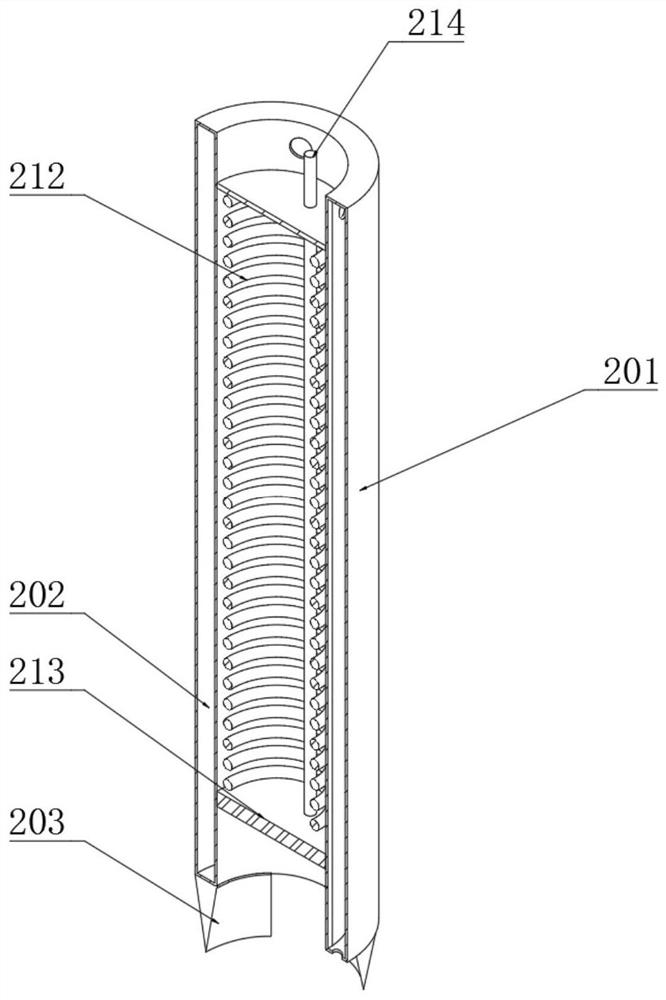

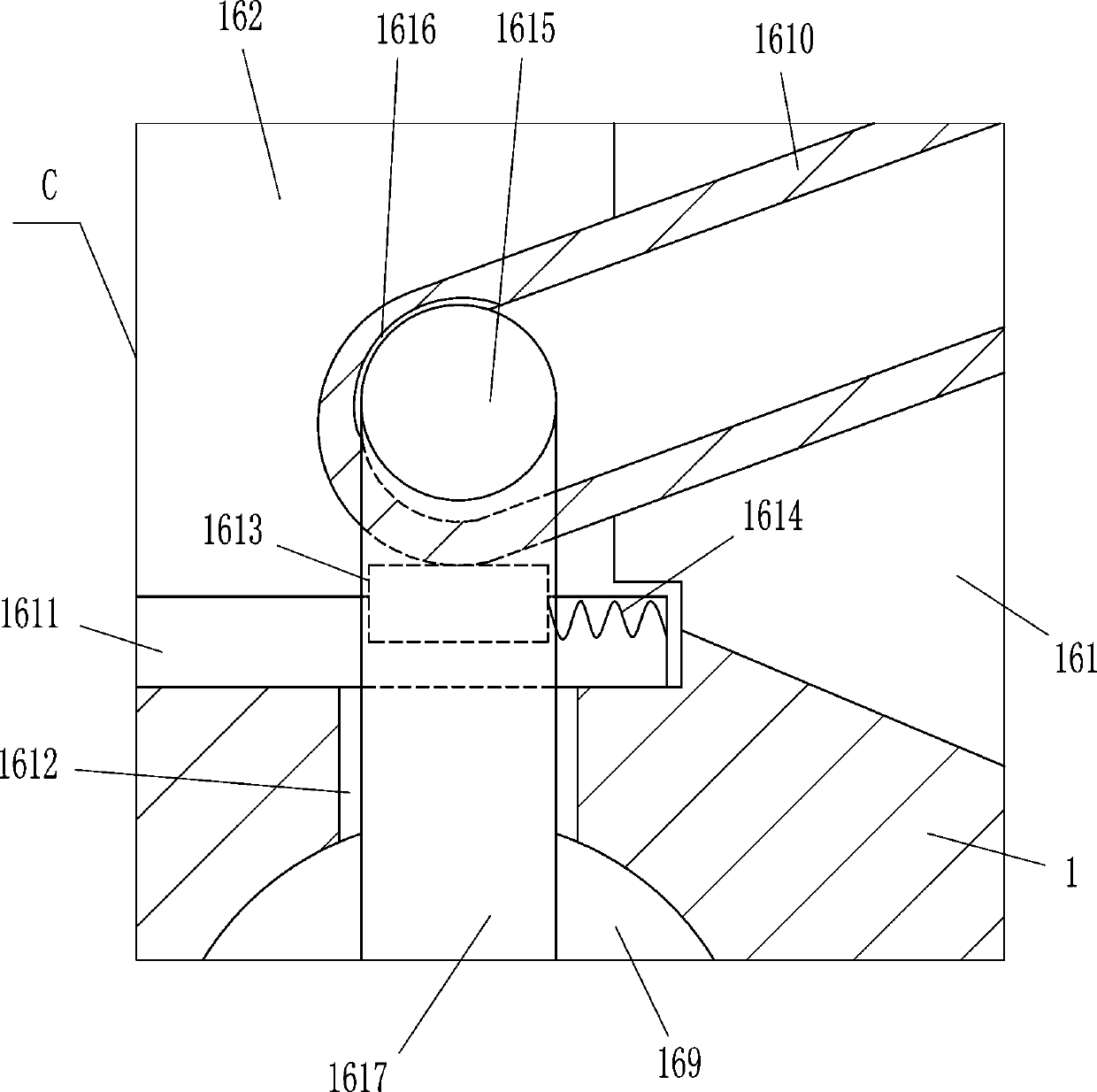

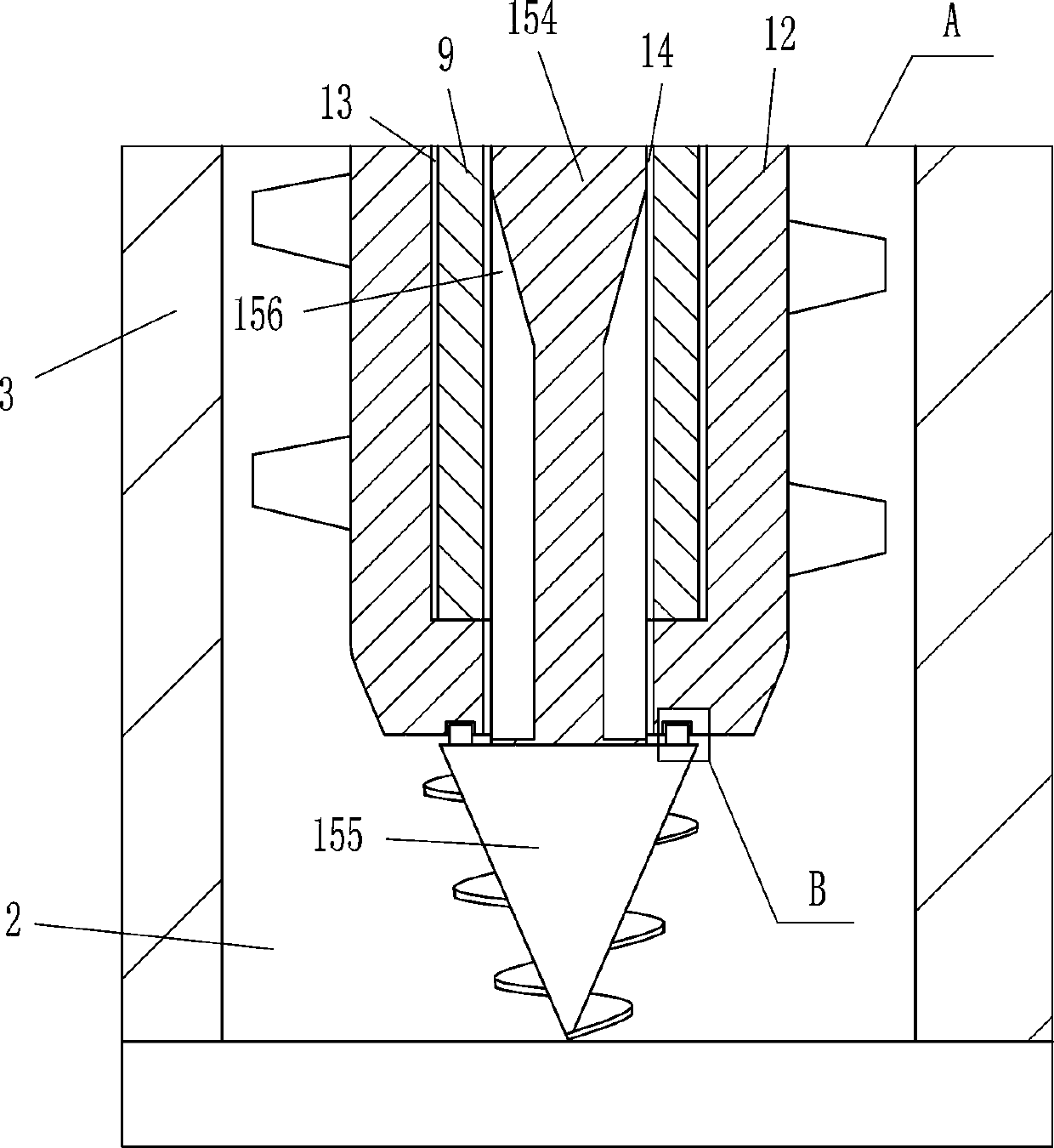

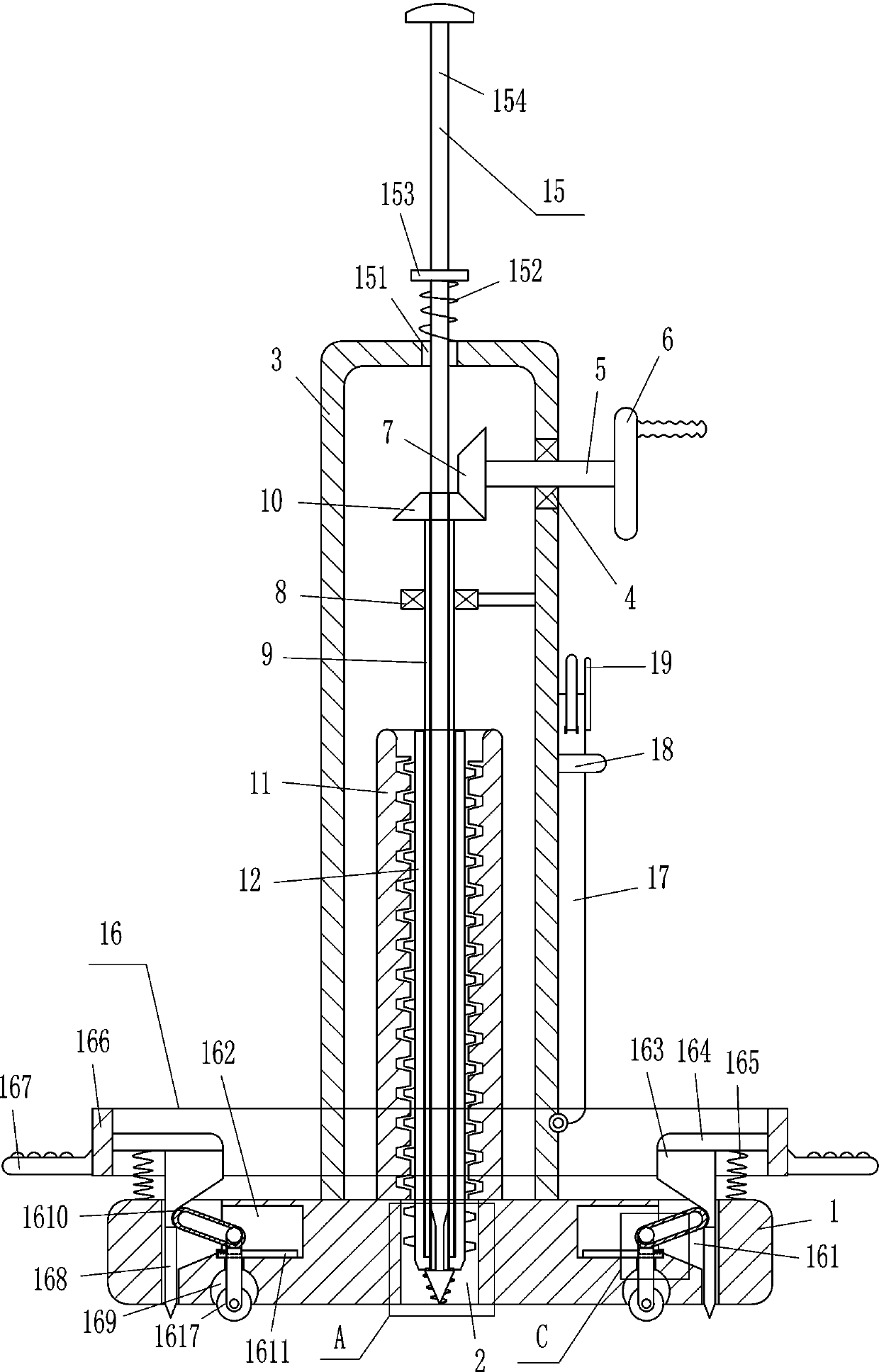

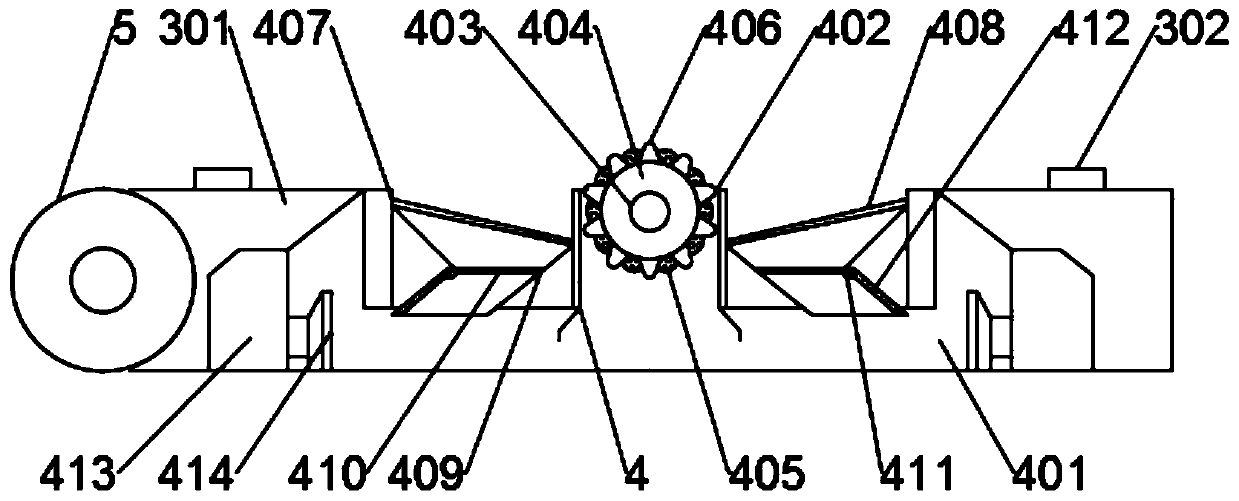

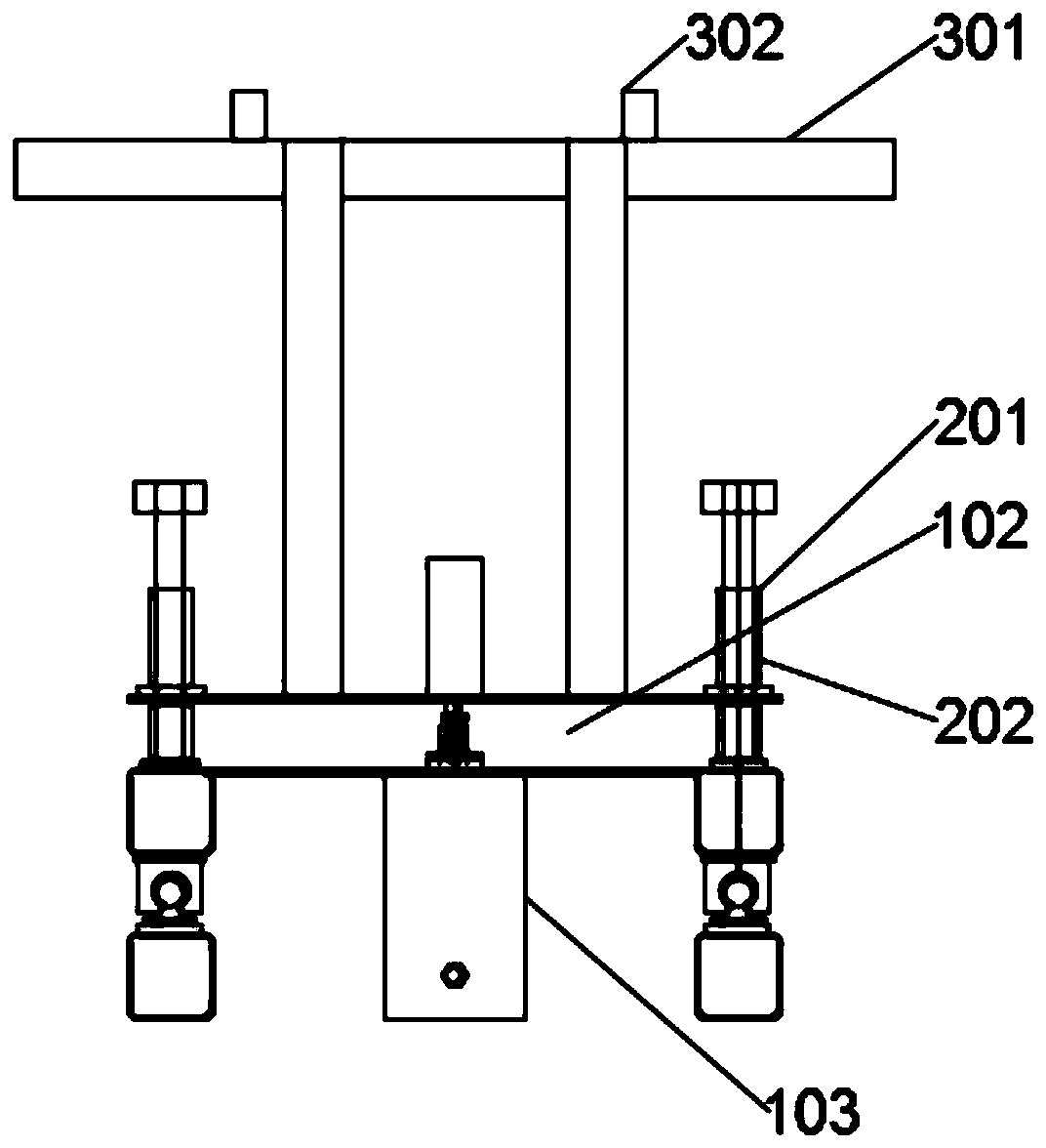

Soil sampling device for municipal construction

PendingCN107219091AAvoid damageAdjustable sampling depthWithdrawing sample devicesGear wheelAgricultural engineering

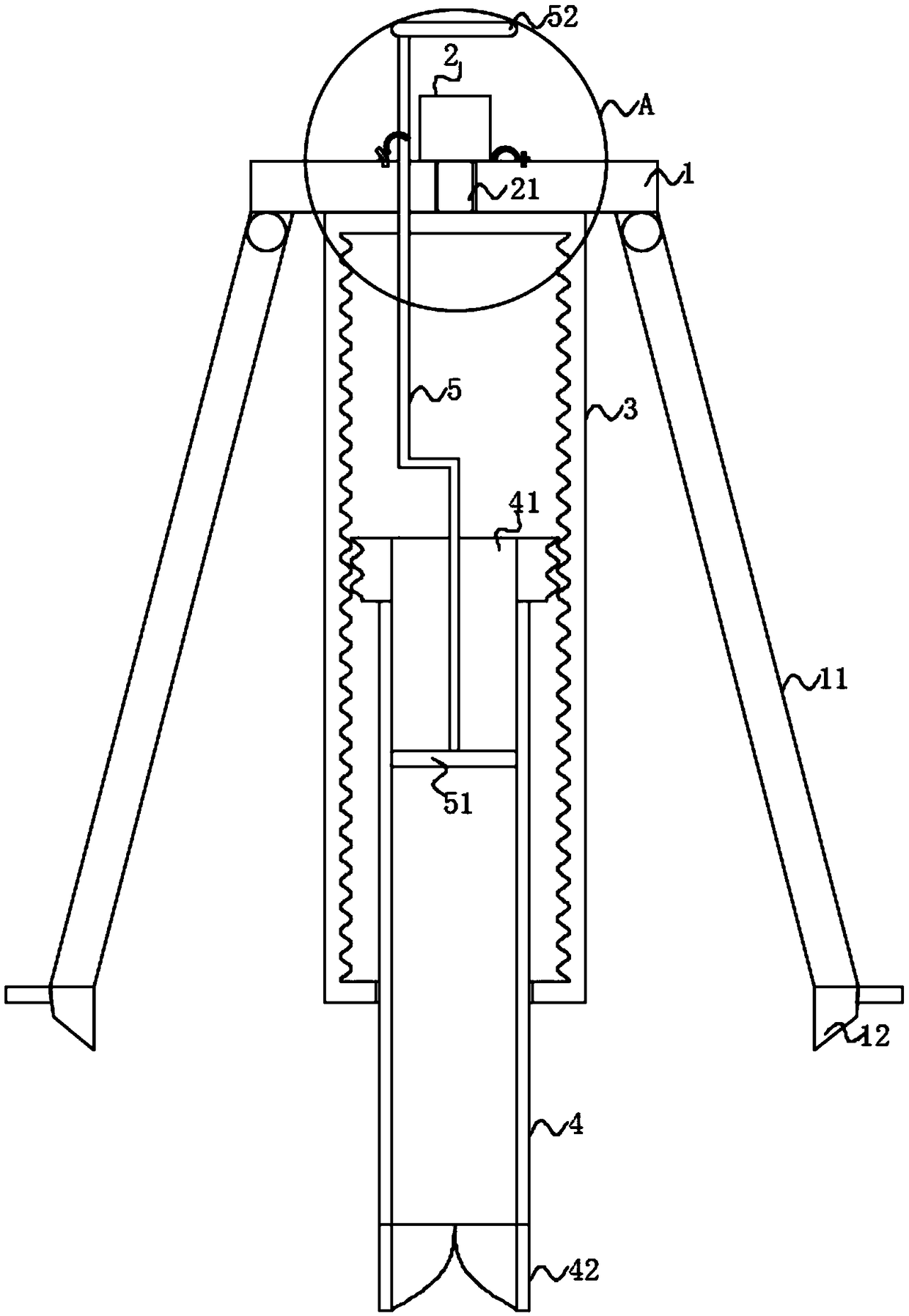

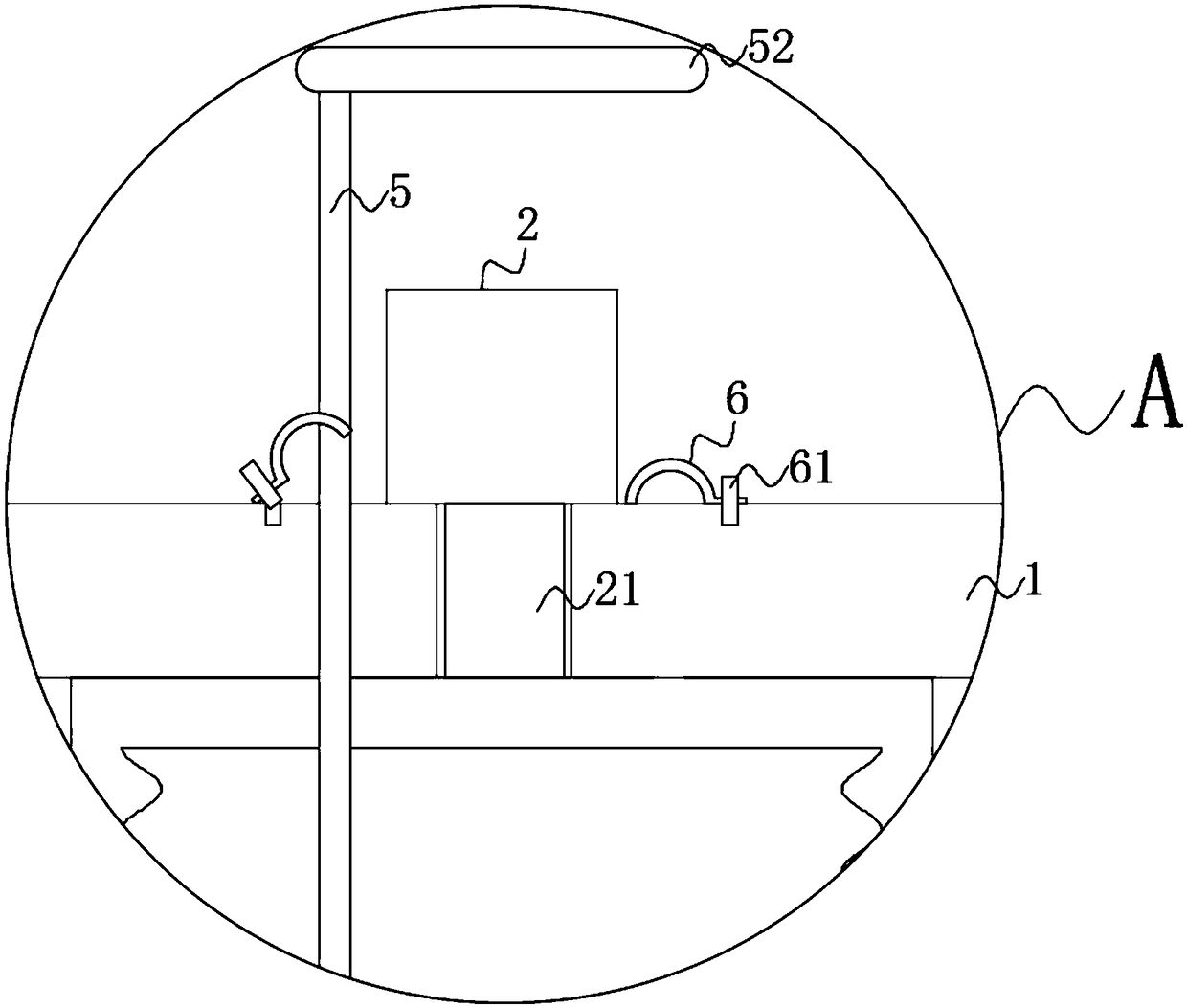

The invention discloses a soil sampling device for municipal construction. The soil sampling device comprises a bottom plate, wherein a side face of the bottom plate is provided with a slide way; the internal thread turning direction of a first casing block is reverse to that of a second casing block; lower ends of the first casing block and the second casing block are hinged with connecting rods; lower ends of the connecting rods are hinged to a connection block; a right side of a first vertical column is provided with a reducing motor; a driving gear is fixedly arranged on a motor shaft of the reducing motor; a driven gear is fixedly arranged at a right end of a lead screw; the driven gear is in meshed connection with the driving gear; a bracket is vertically and fixedly arranged at a right end of the bottom plate; a threaded sleeve is horizontally arranged on the bracket; a threaded rod is inserted into the threaded sleeve; the threaded rod is in threaded connection with the threaded sleeve in a matching way. By adopting the soil sampling device, the sampling position of a sampling pipe can be changed, so that the sampling range is enlarged; meanwhile, hard stones can be avoided in order to protect the sampling pipe from being damaged; a stud can be rotated to adjust the sampling depth of the sampling pipe, so that the adjustment flexibility is enhanced, and the practicability of the soil sampling device is improved.

Owner:邹铁梅

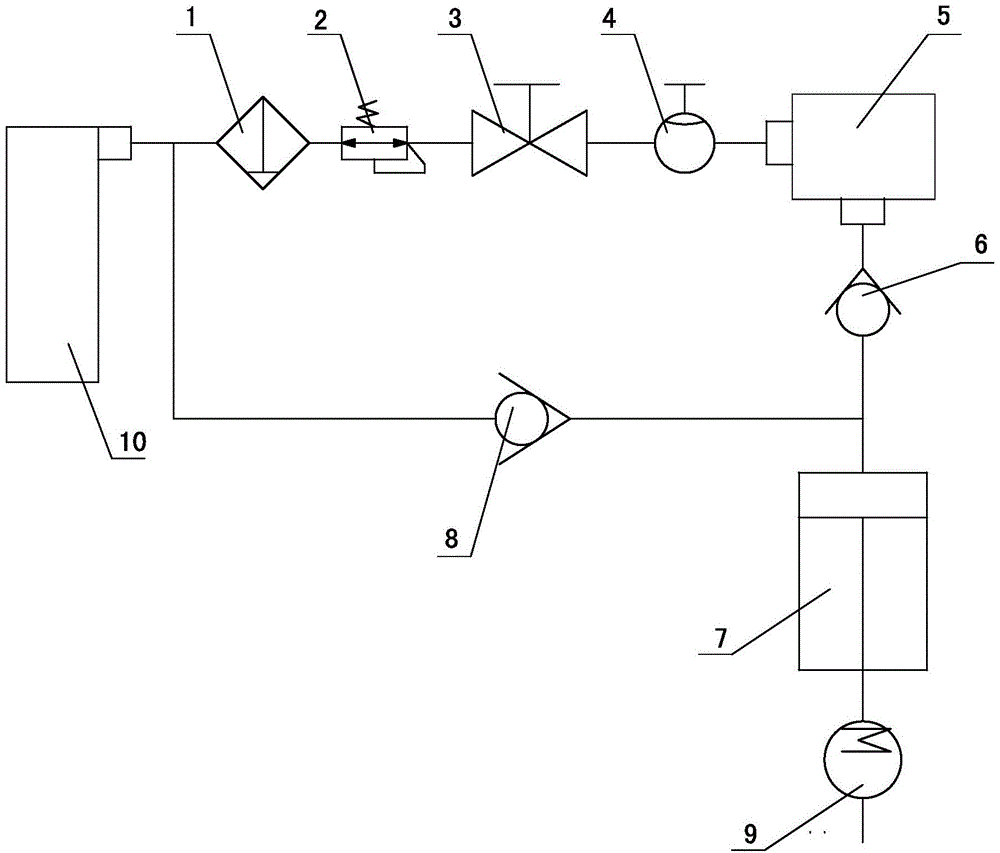

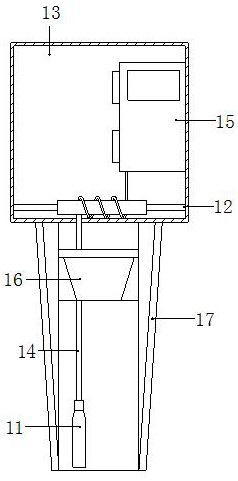

On-line monitoring sampling system for sulfur hexafluoride gas

InactiveCN103558066AAchieving zero emissionsContinuous samplingWithdrawing sample devicesDecompositionSulfur hexafluoride

The invention provides an on-line monitoring sampling system for sulfur hexafluoride gas. The on-line monitoring sampling system is characterized by comprising a filter, an electromagnetic valve, a depressurizing valve, a flow sensor, a sulfur hexafluoride decomposition product detector, a first one-way valve, a cylinder, a second one-way valve and an electric pushing rod, wherein one end of the filter is connected with electrical sulfur hexafluoride equipment, and the other end of the filter is connected with a gas inlet of the sulfur hexafluoride decomposition product detector through the electromagnetic valve, the depressurizing valve and the flow sensor in sequence; a gas outlet of the sulfur hexafluoride decomposition product detector is connected with the cylinder and the second one-way valve respectively through the first one-way valve; the other end of the second one-way valve is connected with the electrical sulfur hexafluoride equipment; a piston rod of the cylinder is fixedly connected with the electric pushing rod. According to the on-line monitoring sampling system, the high-pressure sulfur hexafluoride gas in the electrical equipment can be continuously and stably sampled, and the detection reliability of the sulfur hexafluoride decomposition product detector is ensured; after detection is finished, the sulfur hexafluoride gas can be re-filled into the equipment for cyclic utilization, so that the zero emission of tail gas is realized.

Owner:STATE GRID CORP OF CHINA +1

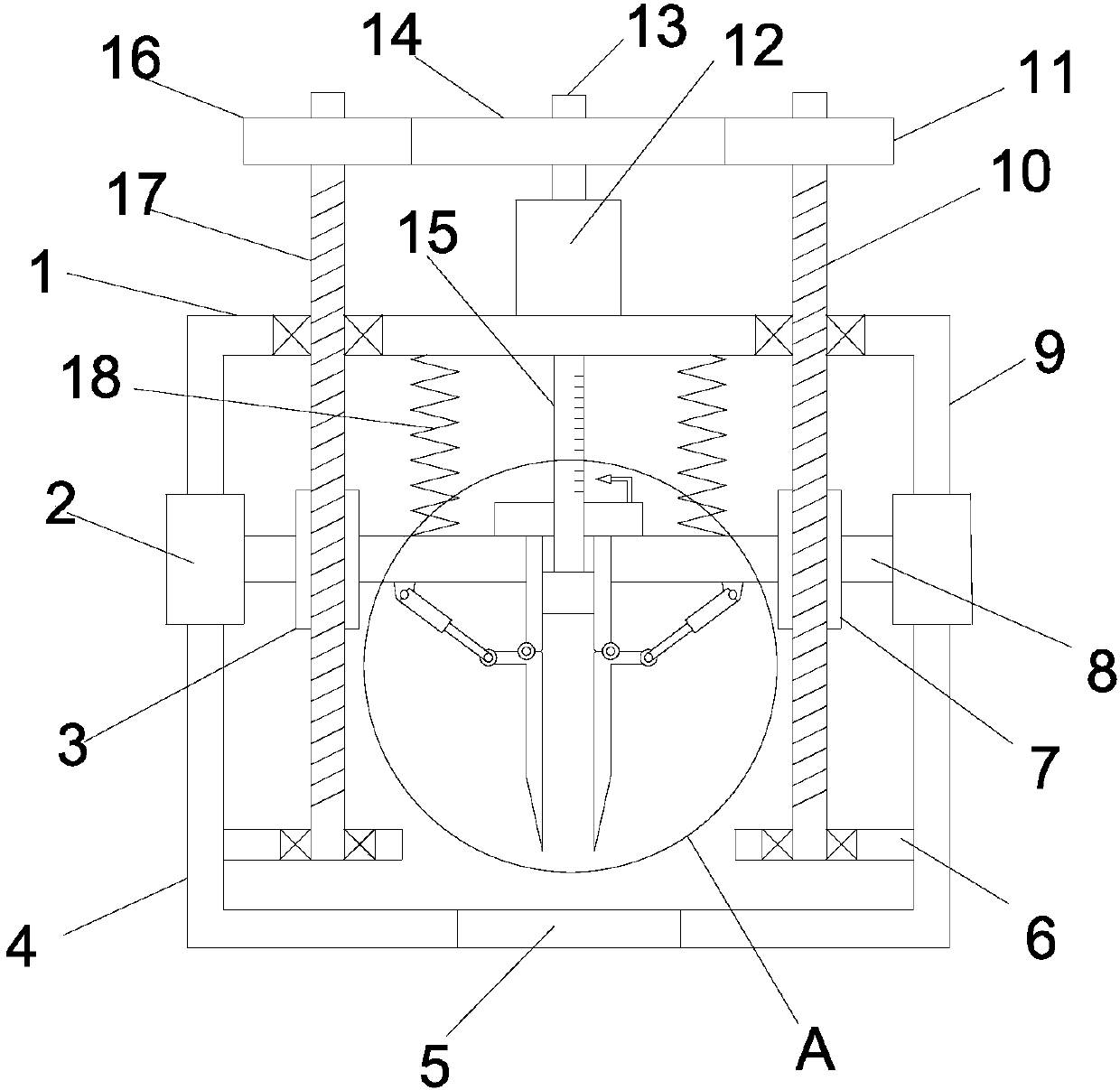

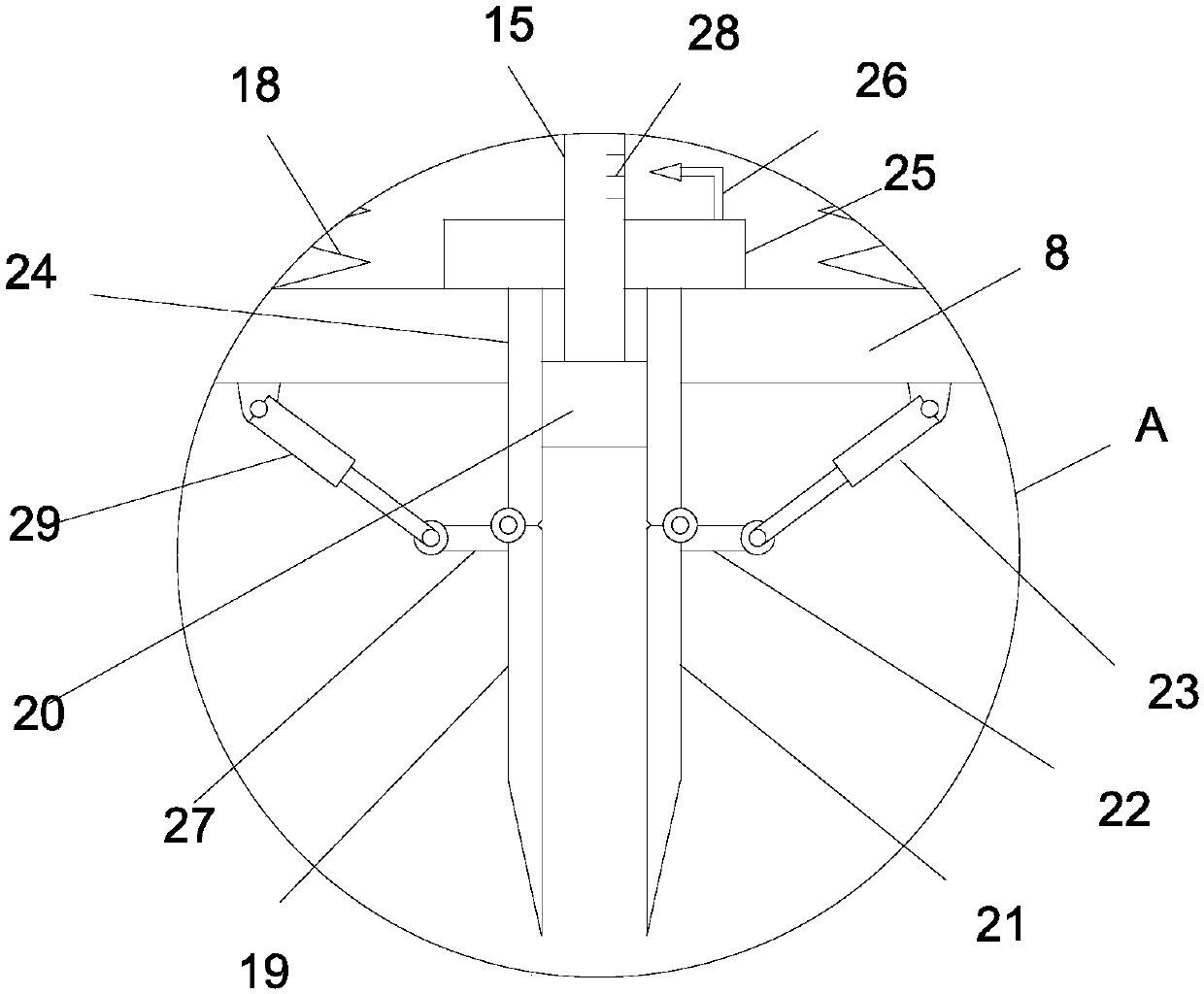

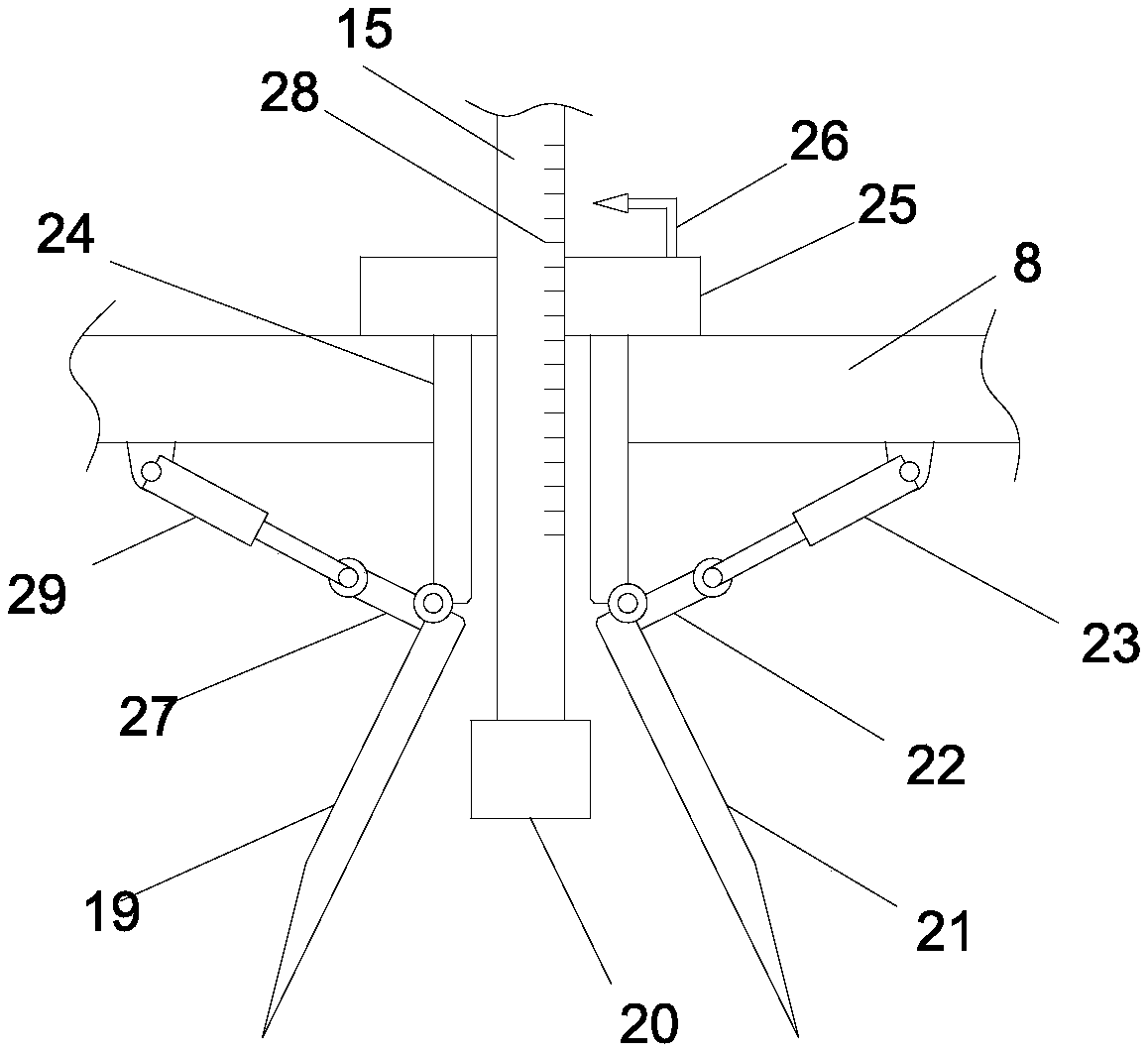

Soil sampling device for geological exploration

InactiveCN107831030AEasy to take outImprove sampling efficiencyWithdrawing sample devicesAgricultural engineeringGeological exploration

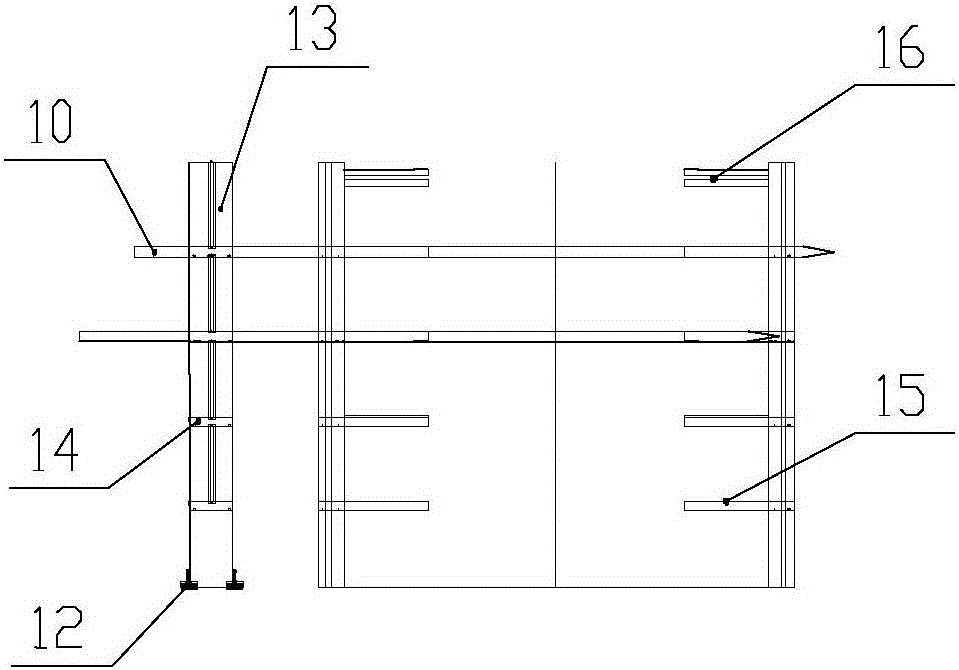

The invention discloses a soil sampling device for geological exploration, comprising a support frame, a left column and a right column are vertically and fixedly installed on the support frame, and both the left column and the right column are slidably provided with limiting sliding sleeves , the horizontal plate is fixed horizontally between the limit sliding sleeves, the sliding sleeve on the extension rod is provided with a block fixed on the upper surface of the horizontal plate, and the side wall of the extension rod is marked with a scale line. The structure of the invention is ingenious and the design is reasonable , through the rotation of the first screw rod and the second screw rod, the horizontal plate drives the first half-arc blade and the second half-arc blade downward to sample the soil, and the sampling process is more stable; the discharge push block is relatively limit-oriented The casing slides down, which is convenient to take out the sample soil between the first half-arc blade and the second half-arc blade, which improves the efficiency of soil sampling and can effectively prevent the viscous soil from adhering to the first half-arc blade It is on the inner wall of the second half-arc blade, and it is easy to clean at the same time, which is convenient for the sampling operation again.

Owner:陈云夫

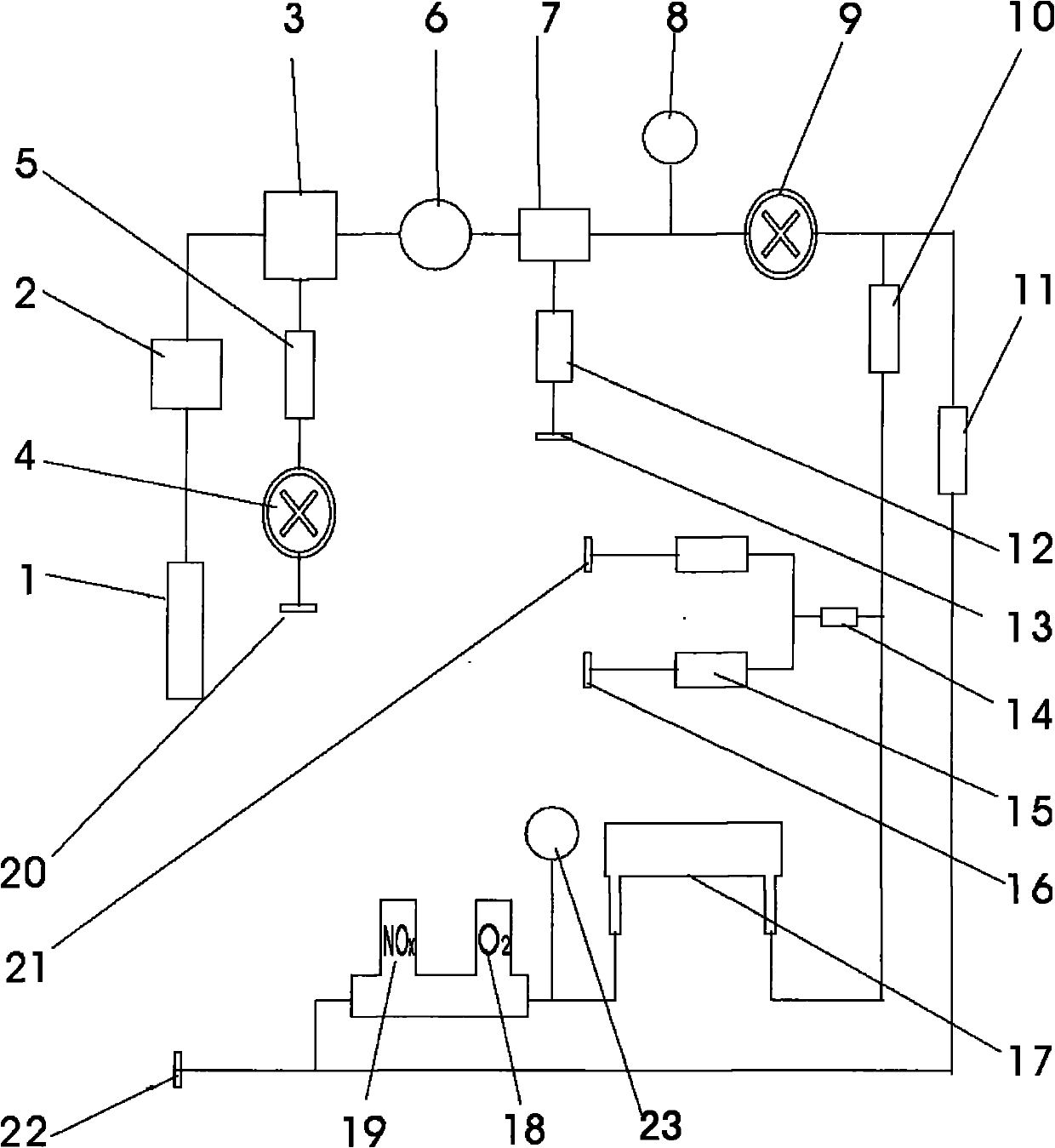

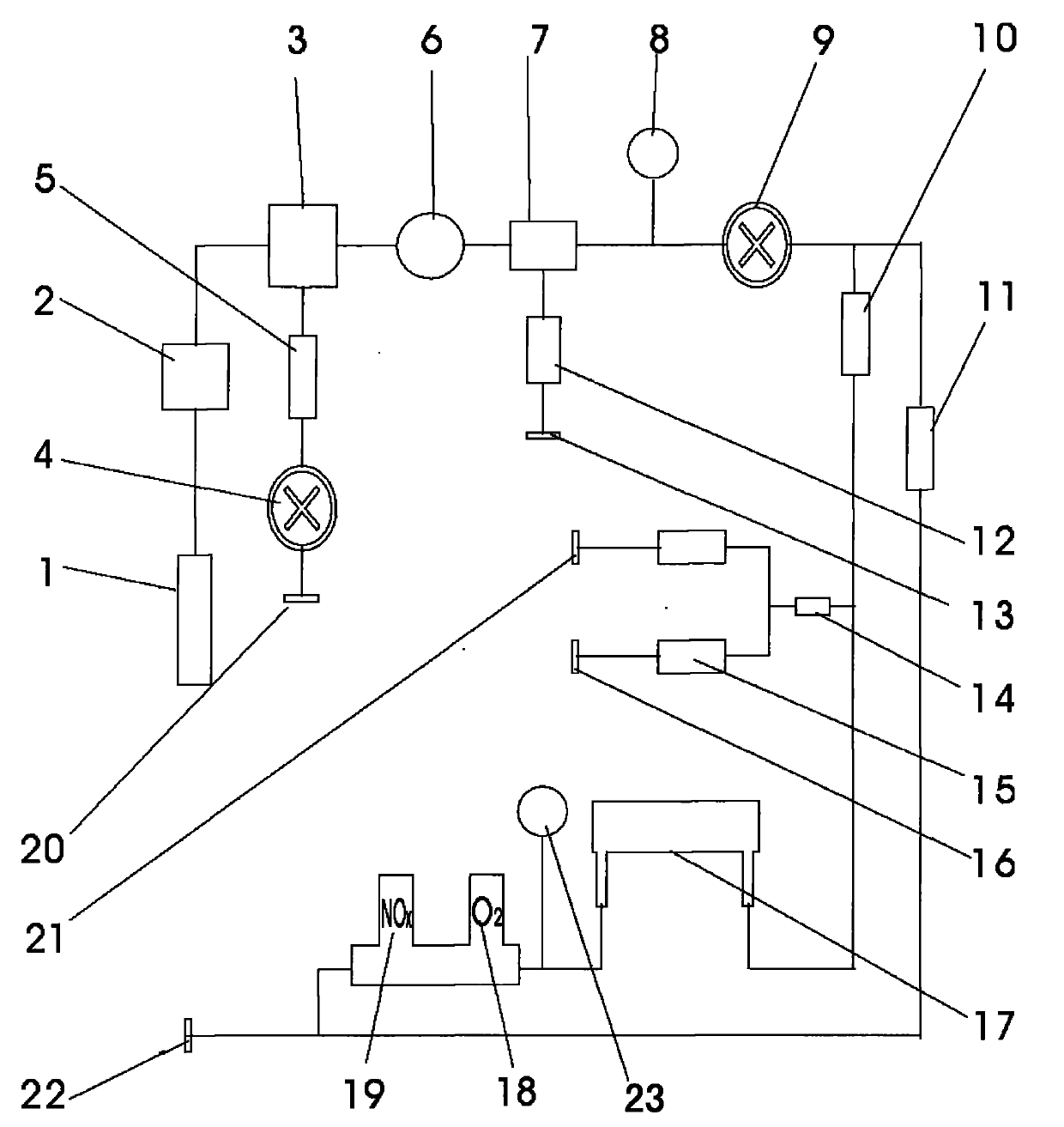

Gas circuit system for measuring automotive tail gas in real time

ActiveCN101949843AStable samplingAccurate samplingWithdrawing sample devicesTransmissivity measurementsRepeatabilityStandard samples

The invention discloses a gas circuit system for measuring automotive tail gas in real time, mainly comprising a sampling system, a water draining system, a gas exhausting system, a zero calibration system and a standard sample calibration system. The automotive tail gas is sampled in real time by the sampling system, thick particles in the sampled automotive tail gas is filtered out after the sampled automotive tail gas sequentially passes through the water draining system and the gas exhausting system, and simultaneously water and gas separation is realized to obtain the dried tail gas; the secondary filtering is carried out after the dried tail gas passes through the gas exhausting system to obtain the purified tail gas; the obtained purified tail gas is introduced into a non-scattering infrared measuring system to be performed with indicator detection, such as the concentrations of carbonic oxide, carbon dioxide and carbon hydrogen compound and the like; and additionally, the standard calibration and the zero calibration of the system can be realized by the zero calibration system and the standard sample calibration system so as to ensure the measuring precision. The gas circuit system of the invention has the advantages of stable, accurate and well-repeatable sampling, safety, reliability and the like.

Owner:WUHAN TIANHONG INSTR

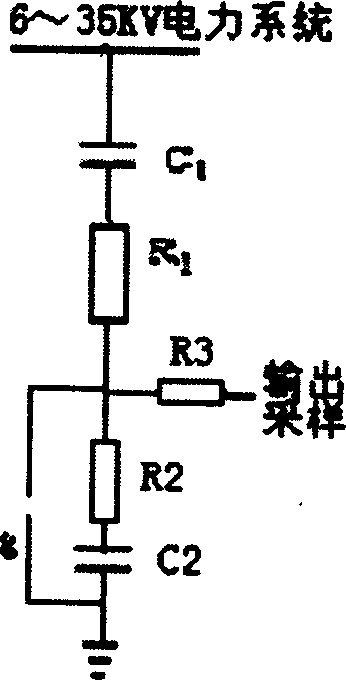

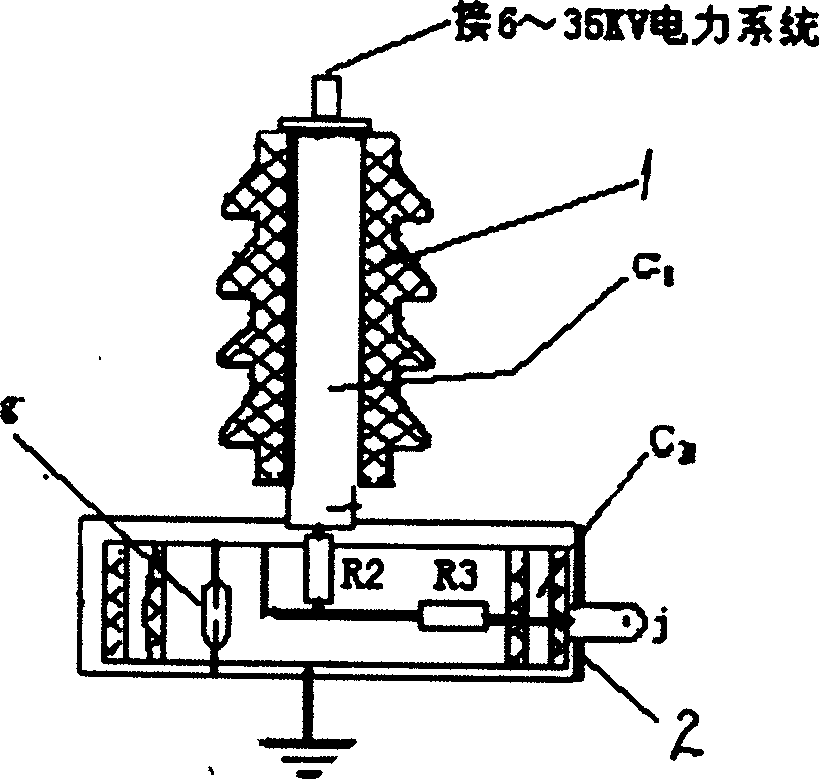

Overvoltage on-line sampler for 6-35 KV electric power system

InactiveCN1584607AReduce damage rateStable samplingCurrent/voltage measurementEmergency protective arrangements for limiting excess voltage/currentWave shapeCapacitance

An on-line sampling device consists of high voltage arm including high voltage capacity, buffer resistance and insulation outer protective sheath; and low voltage arm including low voltage capacity, protective gap, subvoltage output end and metal shielded outer sheath. It has response characteristic below 15-100 nanosecond and can catch overvoltage signal in transient state with sampling voltage of 3-35kv.

Owner:席世友

Rock-soil detection device for geological exploration

PendingCN113063623AAvoid Overturning Mixed SituationsAvoid dry conditionsWithdrawing sample devicesPreparing sample for investigationSoil scienceRock core

The invention discloses a rock-soil detection device for geological exploration. A cutting knife is hinged to the bottom end of a rock sampling barrel, a pressing spring is welded to one end of a pulling rope, a transmission motor is installed at the top end of a soil sampling barrel, a sealing limiting plate is clamped to the inner side of a discharging opening, and a soil collecting box is clamped to the side end of an installation connecting frame. Rock is sampled through the rock sampling barrel, the angle of the cutting knife is changed through the pulling rope and the pressing spring, so that the cut rock core can be conveniently and rapidly lifted, personnel can conveniently and visually observe, the soil is sampled through the soil sampling barrel and the auger, and the soil is discharged through the discharging port, the soil at different depths can be rapidly screened when needing to be collected, the situation that the soil is mixed together to influence the detection result is avoided, rock collection and soil collection are separated, mutual interference is avoided, and the situation that the detection result deviates due to mutual influence is avoided.

Owner:李晟

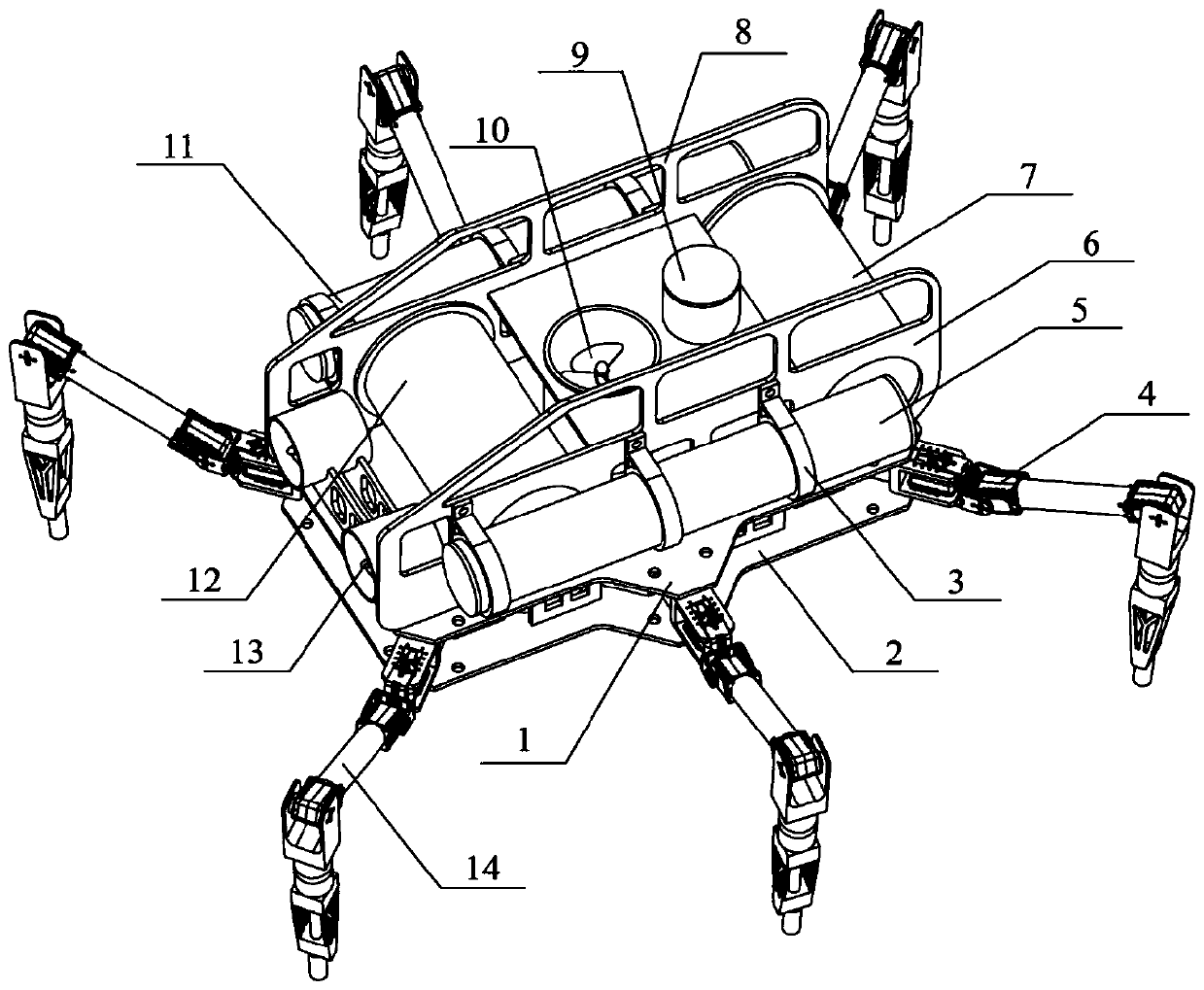

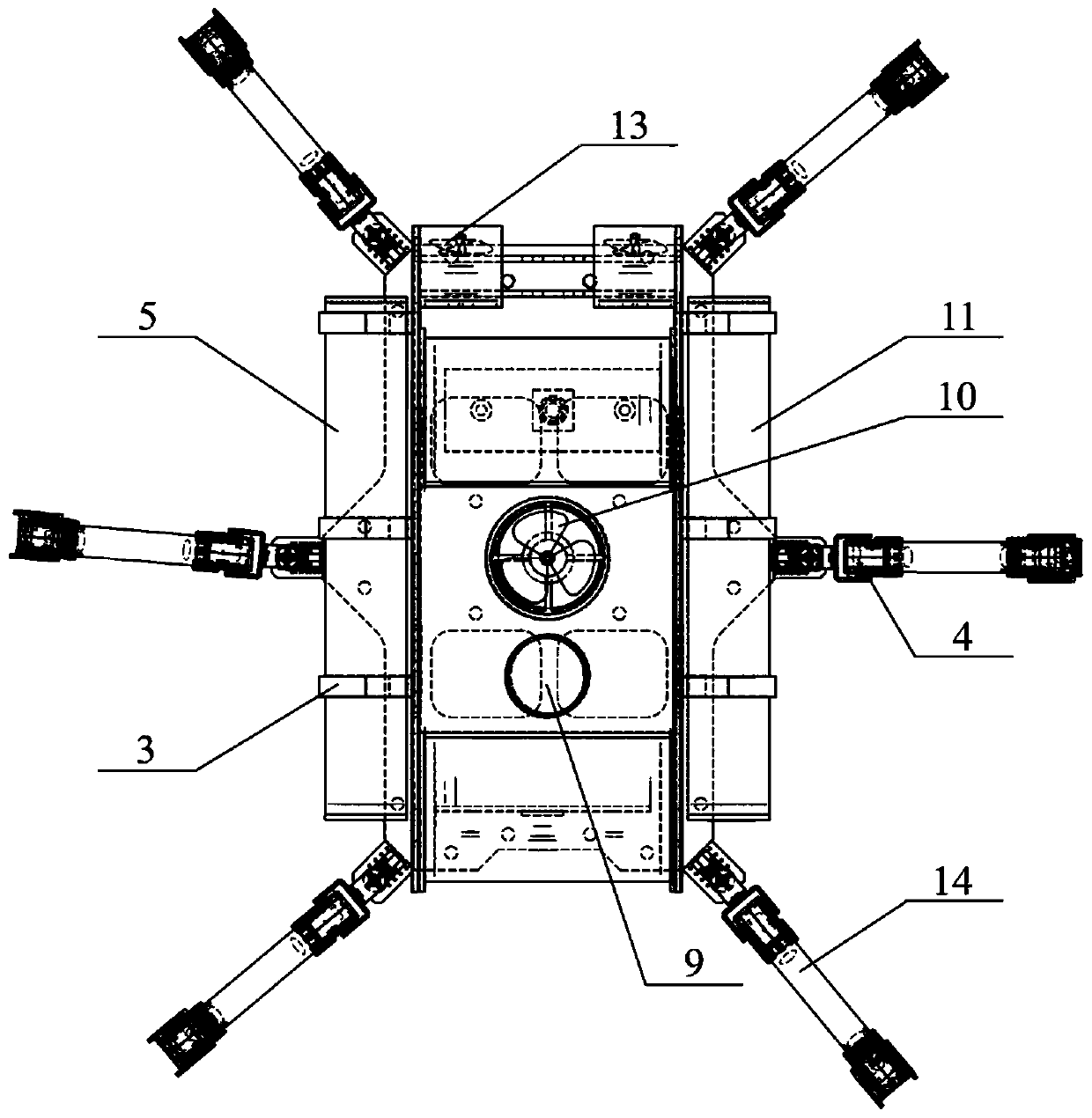

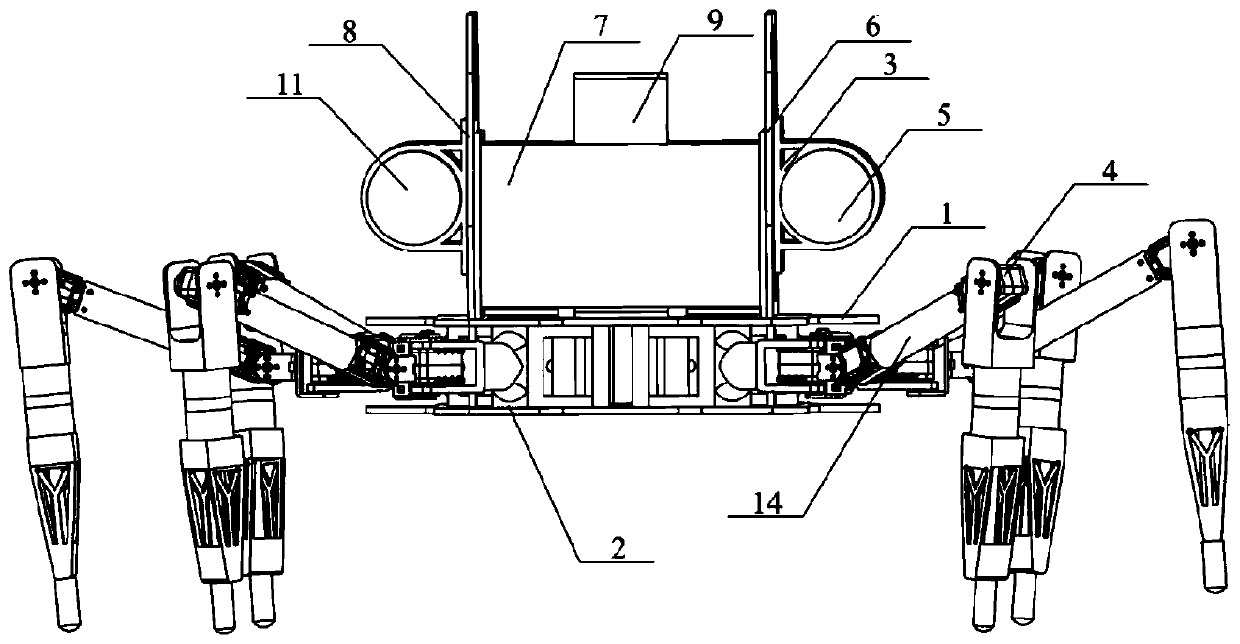

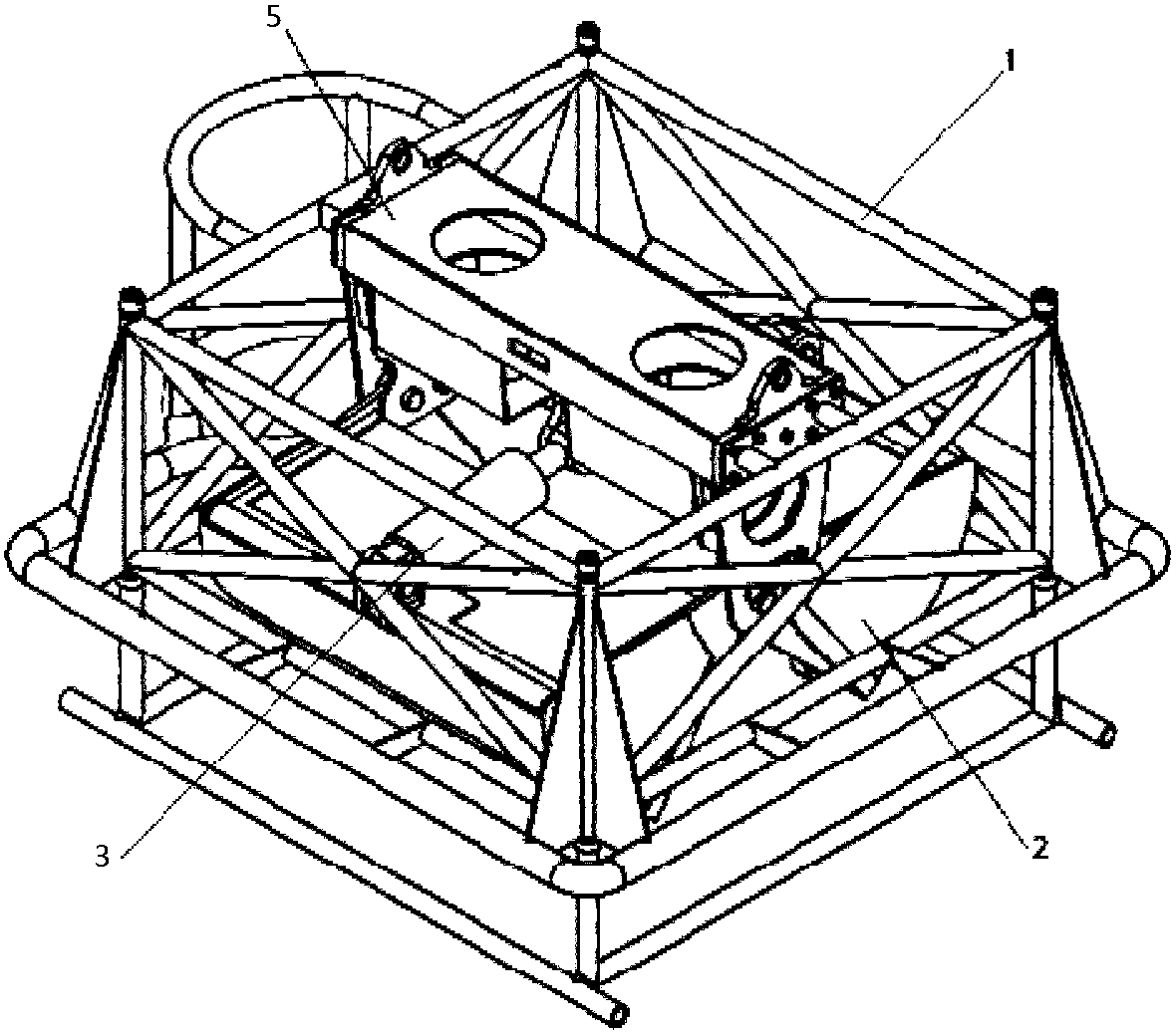

Robot suitable for underwater cruising and seabed crawling and control method

The invention relates to a robot suitable for underwater cruising and seabed crawling. The robot comprises an underwater cruising module and a seabed crawling module; the underwater cruising module comprises a left wing panel, a right wing panel, a front horizontal sealed cabin, a rear horizontal sealed cabin, an electronic cabin, a vertical thruster, a left longitudinal suction and drain tank, aright longitudinal suction and drain tank and a horizontal differential thruster; the seabed crawling module comprises a support structure and a plurality of mechanical legs; the underwater cruising module is arranged on the support structure; and each mechanical leg surrounds the support structure, and one ends of the mechanical legs are rotatably connected with the support structure. The robot can cruise quickly in the ocean or crawl stably on the seabed, and integrates the high-efficiency and wide-range mobile abilities of a cruising type underwater robot and the precise mobile operation ability and the anti-ocean-current ability of a crawling type underwater robot.

Owner:HARBIN INST OF TECH

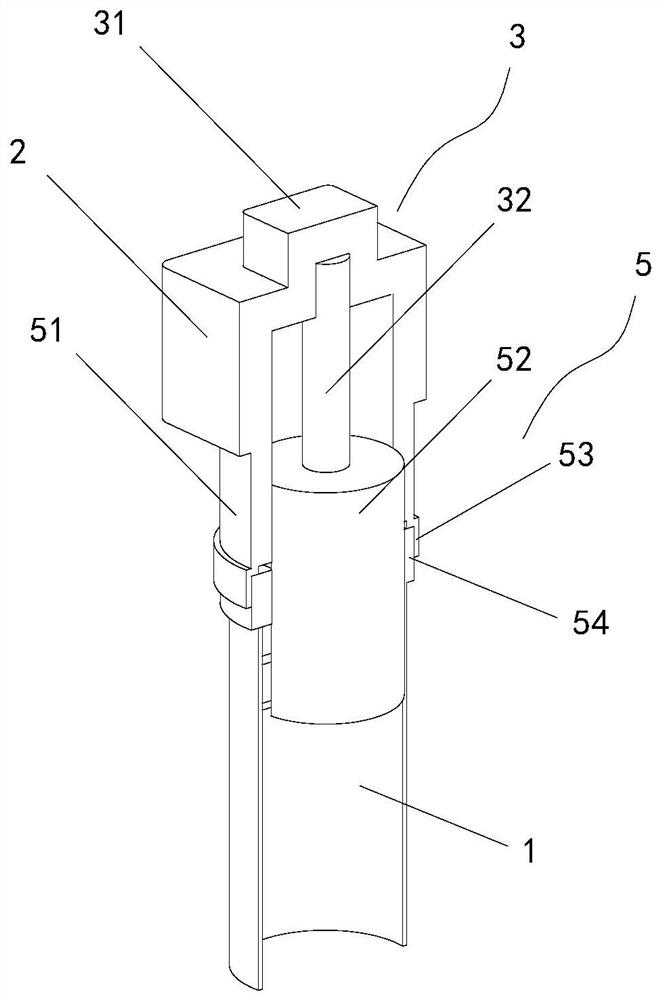

Soil sampler used for geological detection

InactiveCN110361225AGuaranteed purityAvoid enteringWithdrawing sample devicesSoil scienceDrive shaft

The invention discloses a soil sampler used for geological detection and belongs to the technical field of geological detection. The soil sampler comprises a drill rod; the bottom of the drill rod isconnected with a sampling cylinder; the bottom of the sampling cylinder is connected with a drill head; a plurality of sampling scrapers are distributed at intervals of equal central angles in the sampling cylinder; a plurality of outlets which are in one-to-one correspondence with the opening surfaces of the sampling scrapers are formed in the cylindrical wall of the sampling cylinder; the outlets are provided with opening-closing mechanisms which can open and close the outlets; a sampling driving mechanism which is used for pushing the sampling scrapers out of the outlets or retracting the sampling scrapers is arranged in the sampling cylinder; the sampling driving mechanism includes a driving shaft; the driving shaft is provided with protruding driving blocks; the number of the protruding driving blocks is equal to the number of the sampling scrapers; the driving shaft servers as the rotation axis of the protruding driving blocks; each protruding driving block is tangent to the backof the scraper corresponding to the protruding driving block; and a reset spring is connected between the back of each sampling scrapper and the driving shaft. According to the soil sampler of the invention, the sampling scrapers can be flexibly pushed out or retracted, and therefore, soil from other soil layers can be prevented from entering the sampling cylinder, and the purity of a sample canbe effectively ensured.

Owner:甘肃高斯年代科技有限公司

Bioscience soil sampling detection device

InactiveCN110967215AEasy to sampleSimple structureWithdrawing sample devicesSoil scienceElectric machinery

Owner:HUBEI UNIV

Soil sampling device

ActiveCN110658017AStable samplingSampling effectWithdrawing sample devicesAgricultural engineeringStructural engineering

The invention relates to a sampling device, and aims to design a soil sampling device which provides convenient for soil sampling, is more stable during sampling and does not influence sampling. The soil sampling device comprises a base, a frame ,a first bearing seat, a rotating shaft, a rocking handle, a first bevel gear and the like, a first through hole is formed in the middle of the base, theframe is fixedly connected to the middle of the top of the base, the first bearing seat is embedded into the upper portion of the right side of the frame, the rotating shaft is connected into the first bearing seat, and the rocking handle is fixedly connected to the right end of the rotating shaft. The rocking handle is rocked to rotate forwards, so that an auger bit moves downwards to a designated position, a T-shaped rod is pushed to drive the auger bit to be inserted into the soil, so that the soil falls into an annular collecting groove. Thus, a user does not need to dig holes with a smalliron shovel and then use a sampler for sampling, convenience is achieved, the device can sample soil more stably by means of fixing device, and influence of movement on soil sampling is avoided.

Owner:SUZHOU CTI TECH

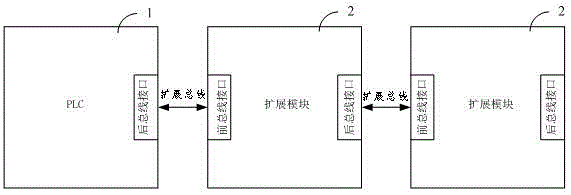

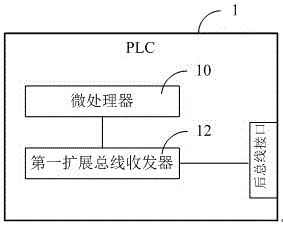

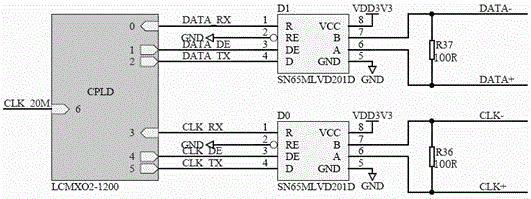

PLC control system and PLC extension bus implementation method

ActiveCN105116830AImplement multi-point samplingStable samplingProgramme control in sequence/logic controllersTransceiverControl system

The invention discloses a PLC control system, which comprises a PLC and a plurality of extension modules, wherein the PLC is cascaded with the plurality of extension modules by adopting extension buses; the PLC comprises a microprocessor and a first extension bus transceiver, the microprocessor is used for controlling communication between the PLC and the plurality of extension modules, and the first extension bus transceiver is used for exchanging data with the first stage extension module through a PLC rear bus interface; and each extension module comprises an extension microprocessor and a second extension bus transceiver, the extension microprocessor is used for controlling communication between the extension module and the PLC, and the second extension bus transceiver is used for exchanging data with the previous stage extension module or the PLC through a corresponding stage front bus interface and exchanging data with the next stage extension module through a corresponding stage rear bus interface. The invention further discloses a corresponding PLC extension bus implementation method. Through implementing the technical scheme of the invention, the speed of a PLC extension bus can be increased, the cost is reduced, and the anti-interference capability in the sampling process is high.

Owner:深圳市合信自动化技术有限公司

Sampling device for soft soil area reconnaissance and detection

InactiveCN110646237AAchieving Simultaneous SamplingReduce labor intensityWithdrawing sample devicesSoil scienceEngineering

The invention discloses a sampling device for soft soil area reconnaissance and detection, related to the field of environment detection devices. The sampling device comprises a support base and standbars, a sampling head is arranged under the support base, and an upper end face is provided with an air cylinder for driving the sampling head to move; a side wall of the sampling head is verticallyprovided with a groove, and a switch board is vertically connected in the groove in a sliding manner; the inside of the sampling head is provided with a cavity, a bottom wall of the groove is providedwith a plurality of sliding holes communicated with the cavity at intervals, and the inside of each sliding hole is horizontally connected with a sampling tube in a sliding manner; one end, facing towards the groove, of the sampling tube is opening; and a driving mechanism for driving the sampling tube to slide horizontally is arranged in the cavity. The sampling device provided by the inventionhas the following advantages and effects: a plurality of sampling tubes at different altitudes are arranged, thus, synchronous sampling of soil layers of different depth is realized, sampling times isreduced, meanwhile, labor intensity of workers is reduced greatly, and the effect of conveniently acquiring soil layer samples of different depth is realized.

Owner:浙江华圭环境检测有限公司

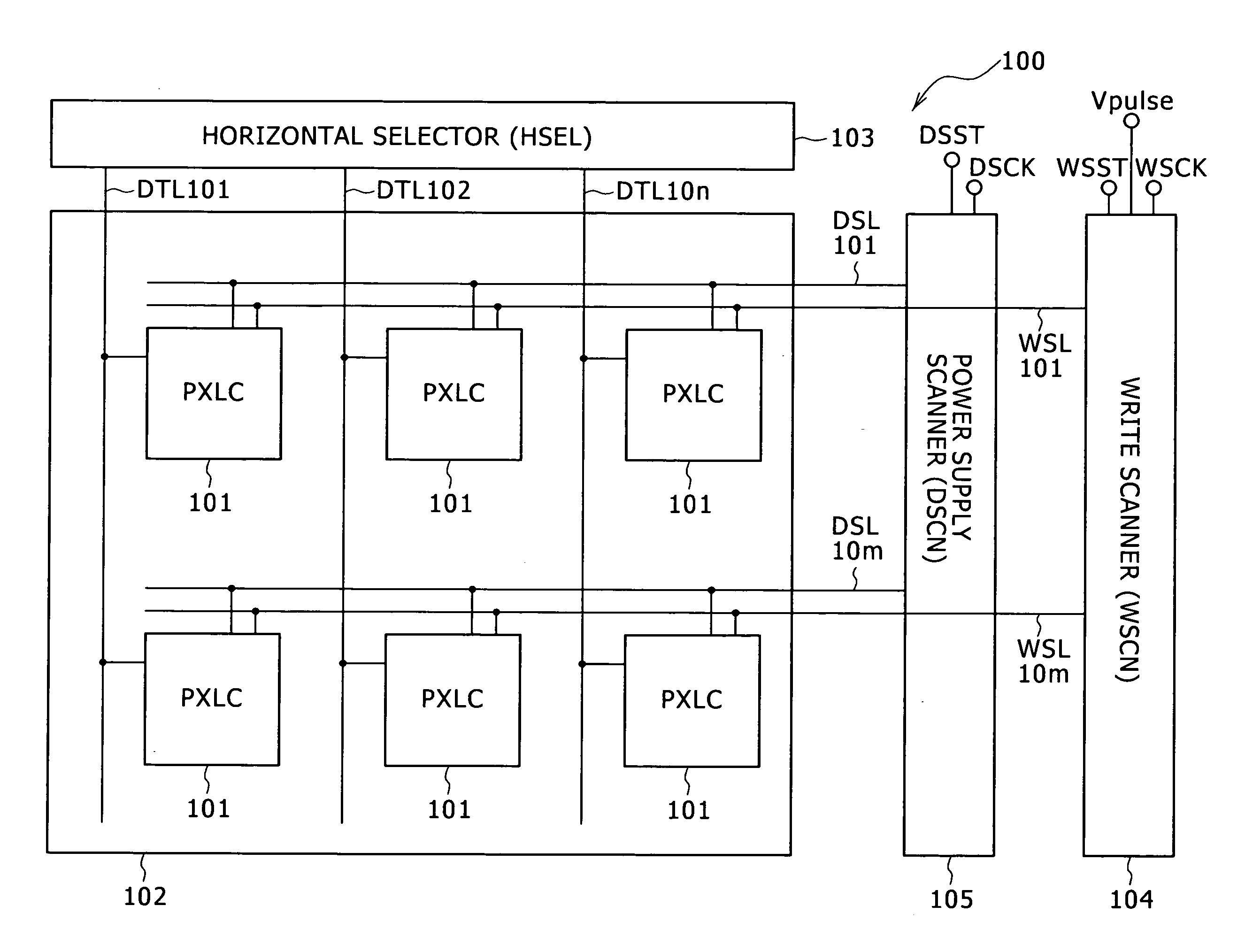

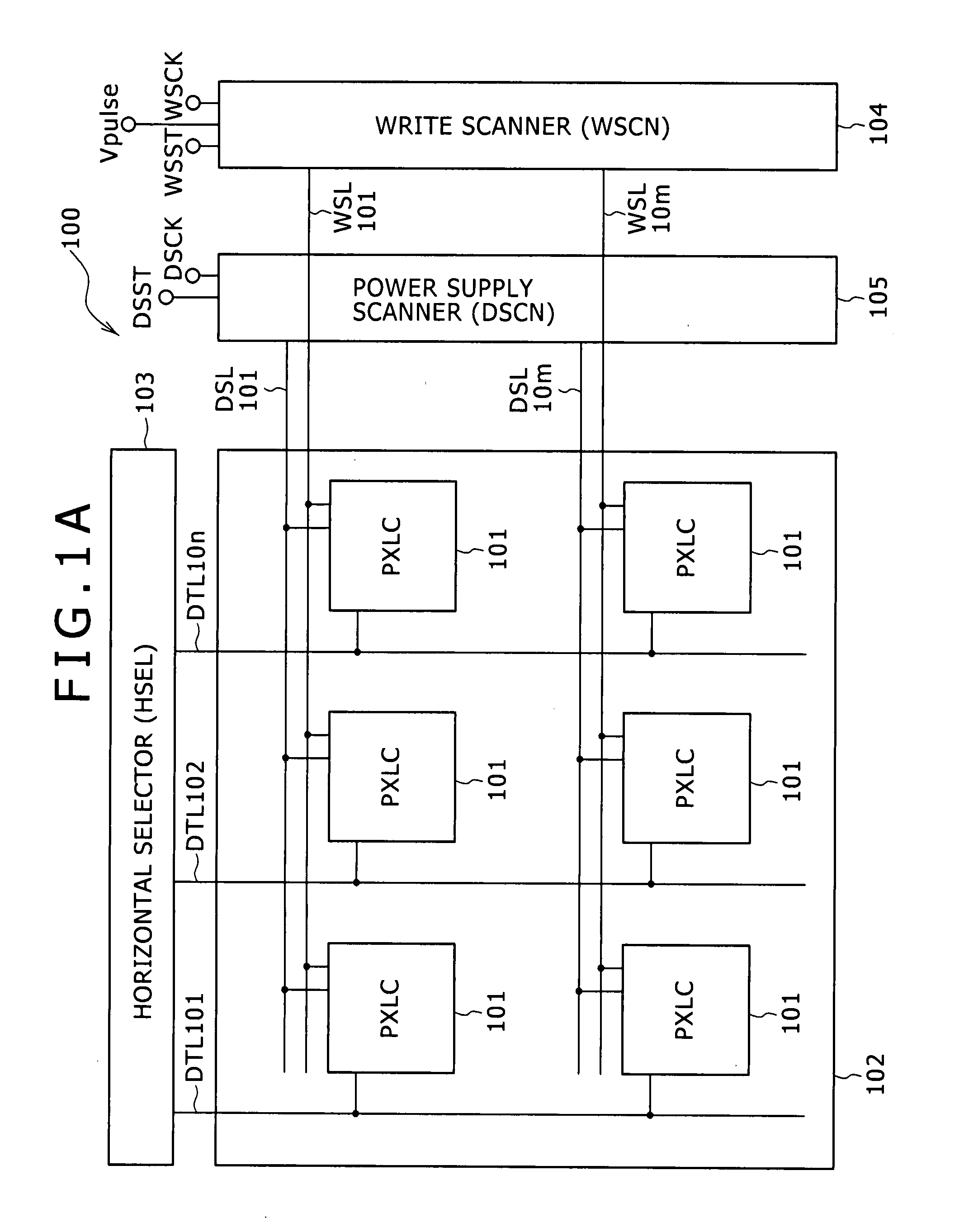

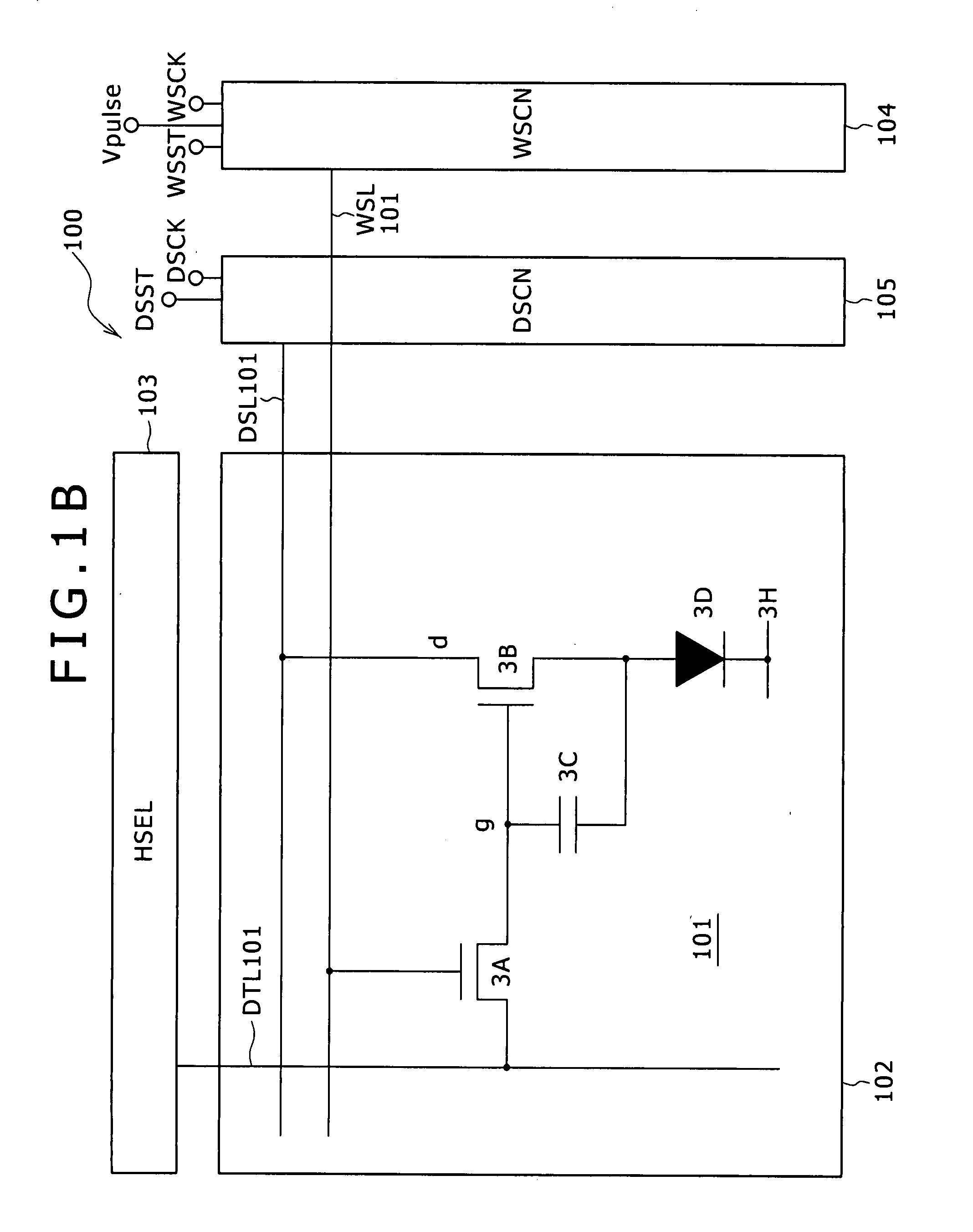

Display apparatus

ActiveUS20080129660A1Quality improvementLarge area of pixelStatic indicating devicesDigital storageShift registerControl signal

Disclosed herein is a display apparatus including: a pixel array; and a driver configured to drive the pixel array. The pixel array including rows of scanning lines, columns of signal lines, a matrix of pixels disposed at crossings of the scanning lines and the signal lines, and feeding lines associated with respective rows of the pixels, the pixels including respective sampling transistors having respective gates connected to the scanning lines, the driver including a main scanner configured to supply control signals to the scanning lines, the main scanner including a shift register, output buffers connected respectively between the shift register and the scanning lines, and a pulse power supply configured to supply power supply pulses, each having a predetermined pulse duration, to the output buffers, wherein the main scanner outputs power supply pulses supplied from the pulse power supply as the control signals to the respective scanning lines in response to a shift pulse output from the shift register.

Owner:JOLED INC

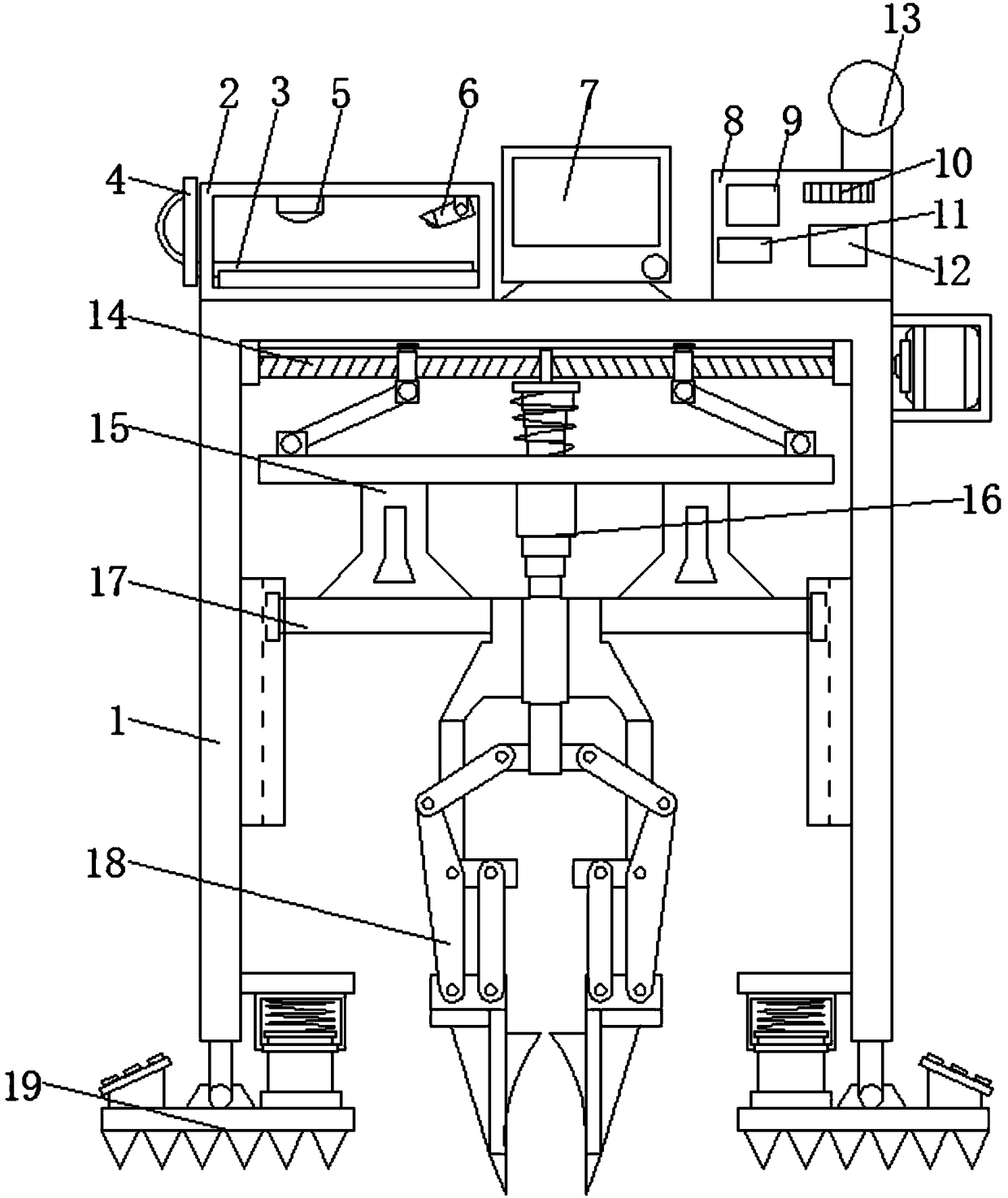

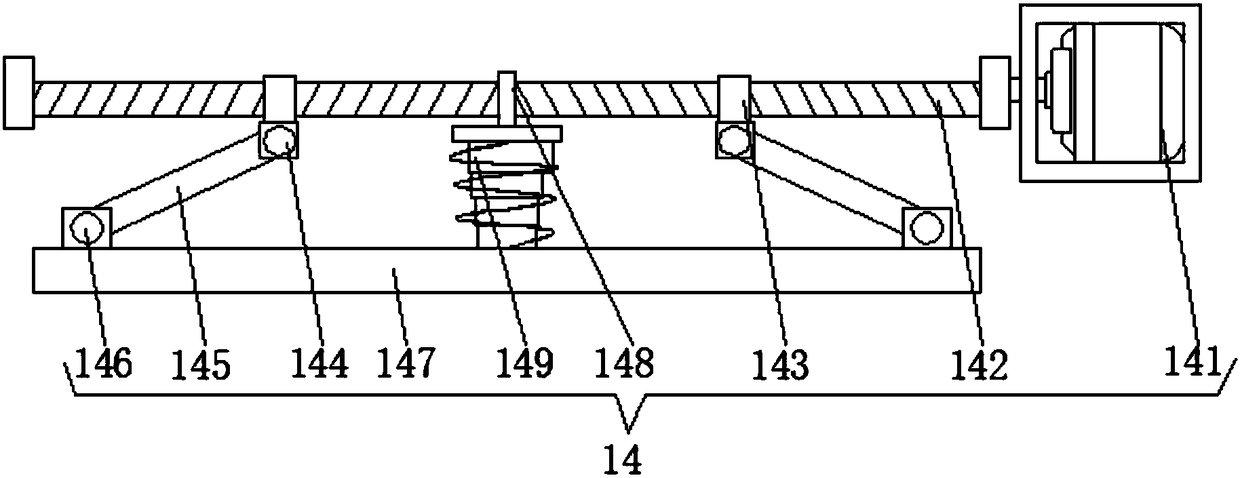

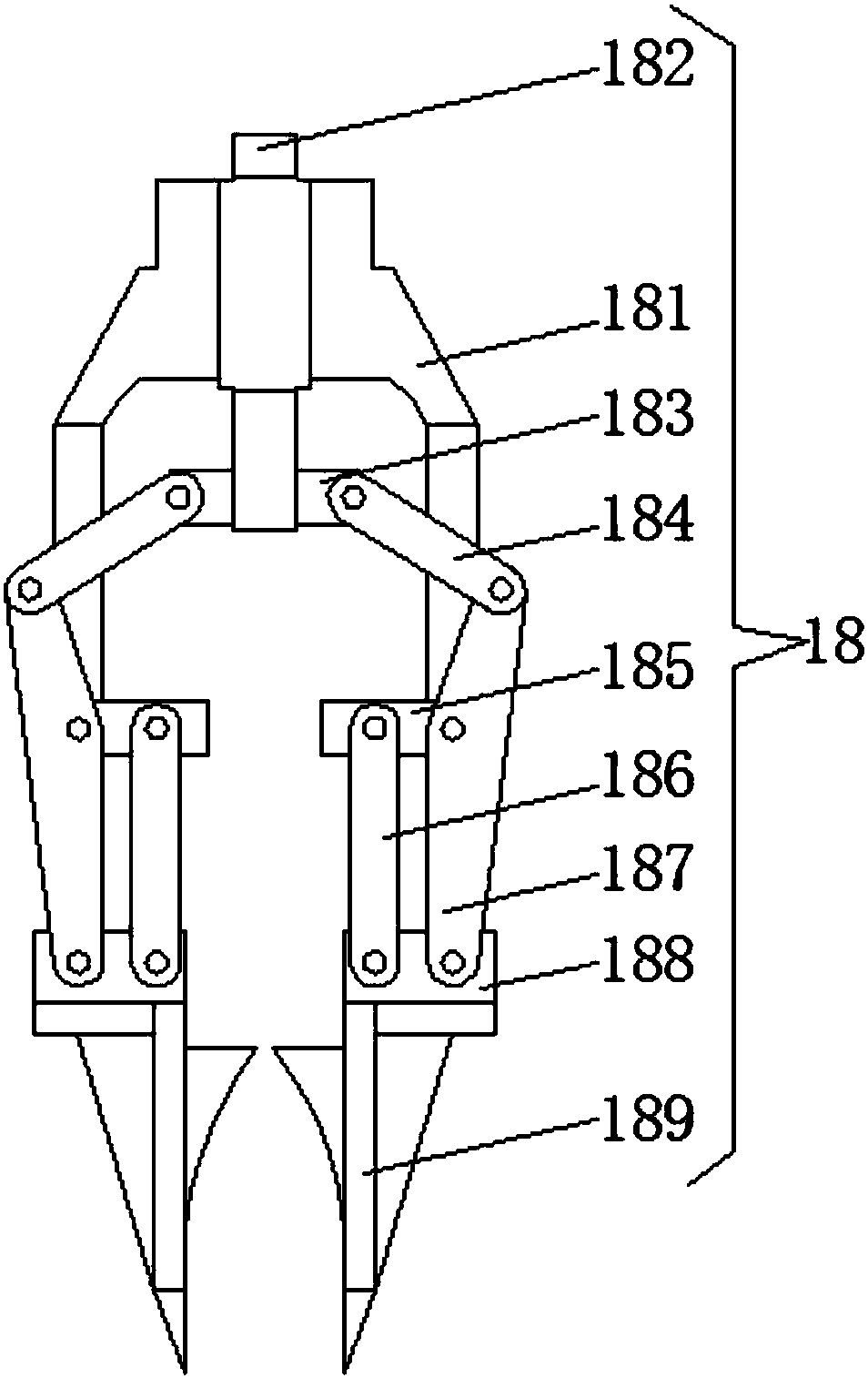

Garden sampling equipment and working method thereof

InactiveCN108535449AEasy accessEasy to move downWithdrawing sample devicesEarth material testingThe InternetWorking set

Relating to the technical field of garden equipment, the invention discloses garden sampling equipment and a working method thereof. The equipment includes an outer frame, a top frame is fixedly connected to the left side at the top of the outer frame, the bottom of the top frame inner wall is in sliding connection with a load plate, the left side of the load plate runs through the top frame and extends to the outside of the top frame. The garden sampling equipment based on the Internet of Things facilitates downward movement of devices, so that a sampling device can well enter the soil without manual operation, the labor amount of people is alleviated, soil sampling becomes convenient, and the sampling process is stable, at the same time the equipment is convenient for taking out of the sampled soil, can well insert devices into the ground for fixation, prevents device collapse in the sampling process, improves the device stability, also can achieve timely preliminary analysis of thecollected soil samples, and subjects the analysis result to remote transmission, is convenient for testers to know the soil information in time, and facilitates the arrangement of the follow-up work.

Owner:严白双

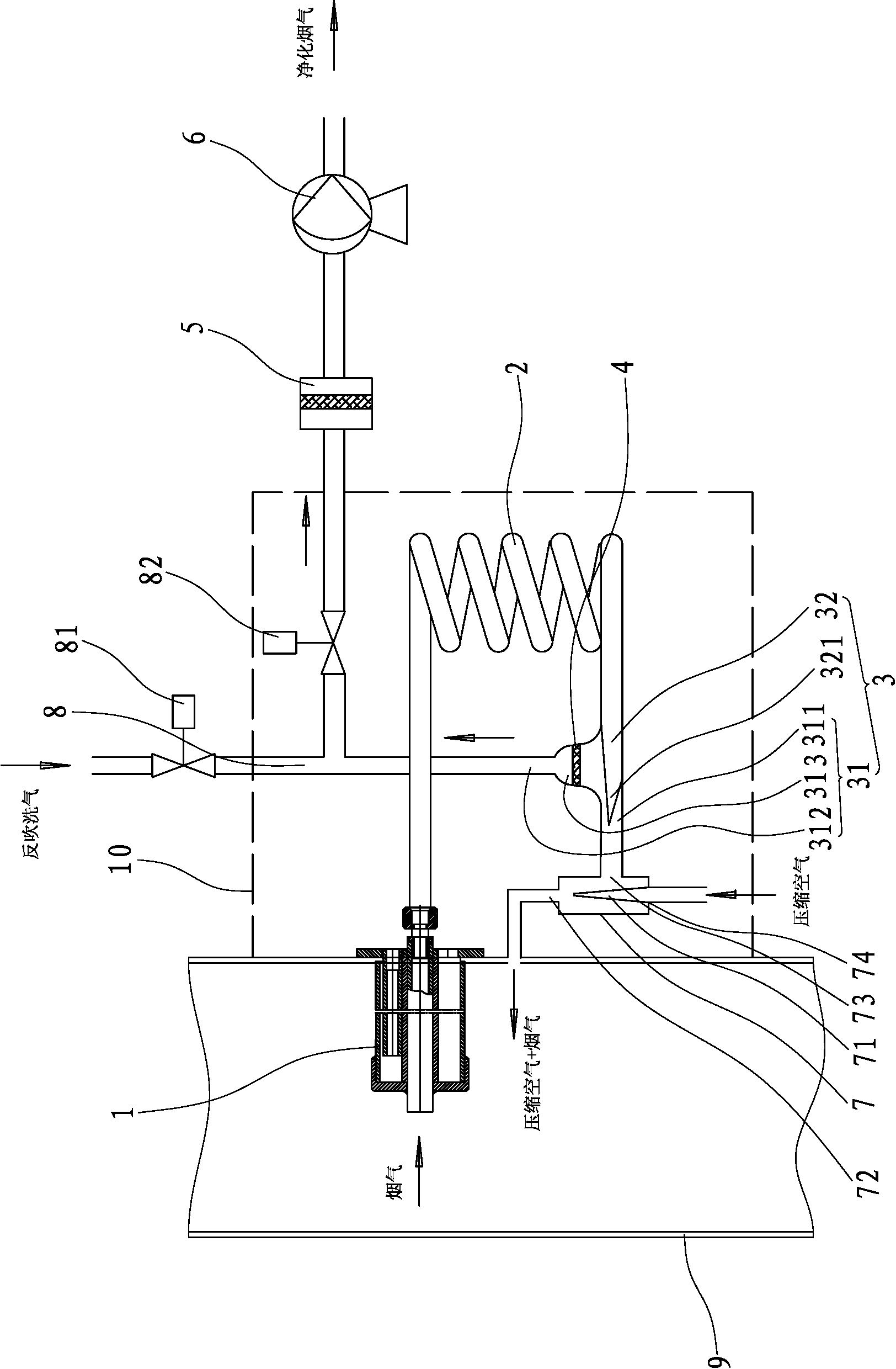

Centrifugal type high-temperature sampling probe system

ActiveCN104236961AHigh speedStable samplingWithdrawing sample devicesPreparing sample for investigationAir pumpEngineering

The invention discloses a centrifugal type high-temperature sampling probe system. An inlet of a high-temperature sampling probe is connected with a flue; an outlet of the high-temperature sampling probe is connected with an inlet of a centrifugal helical rail; an inertia gas-dust separator consists of a T-shaped pipe and an isolation pipe; the isolation pipe is inserted into one end of a transverse pipe of the T-shaped pipe and is sleeved by the transverse pipe of the T-shaped pipe; the outer end of the isolation pipe is connected with an outlet of the centrifugal helical rail; the inner end of the isolation pipe is positioned at a joint of the transverse pipe and a vertical pipe of the T-shaped pipe; an inclined incision is formed in the inner end of the isolation pipe; the back surface of the inclined incision is just opposite to the vertical pipe of the T-shaped pipe; an ejector is mounted at the other end of the transverse pipe of the T-shaped pipe; an ejection pipe connected with compressed air is arranged in the ejector; an outlet of the ejector is connected to the flue; an inertia filter is mounted in the vertical pipe of the T-shaped pipe; the vertical pipe is connected with one end of a three-way pipe, another end of the three-way pipe is connected with back purging gas through a valve, and a valve, a fine filter and a gas extraction pump are mounted at the third end of the three-way pipe in sequence. The centrifugal type high-temperature sampling probe system can fulfill the aim of long-time stable sampling.

Owner:厦门格瑞斯特环保科技有限公司

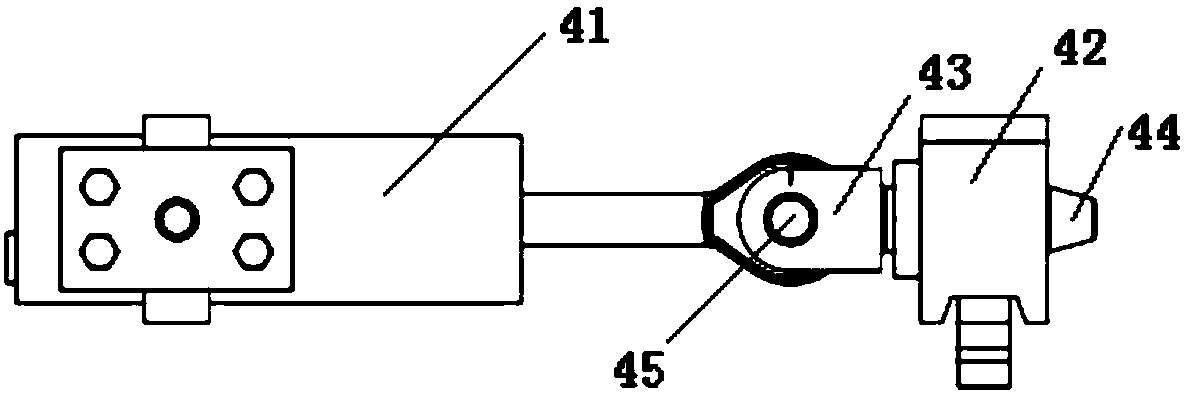

Mine coil sampling repairing device

ActiveCN108918182AIncrease flexibilityThe sampling process is smoothWithdrawing sample devicesDrill bitEngineering

The invention provides a mine coil sampling repairing device. The device comprises a main frame, brackets are symmetrically and fixedly welded at two ends of an external lower surface of the main frame; a mounting rod is fixedly welded at a lower end of each bracket; a rotating tube is rotatably arranged in a lower end of a first drill stem in a tubular type, second sampling slots are formed at afront sidewall and a back sidewall of the lower end, and first sampling slots are arranged at a left side and a right side of the lower end; a second drill stem is spirally and fixedly arranged at thelower end of the first drill stem through the thread; the second drill stem is arranged at the middle lower part in the main frame, and a third motor is fixedly arranged at the inner side of a sliding rod; a drill is rotatably connected with the outer surface of the lower end of the second drill stem and arranged above a sampling port; the sampling port is formed at the middle of the lower wall of the main frame. The repairing device disclosed by the invention is strong in flexibility, simple for use, conforming to various use conditions, and high in practicability.

Owner:禹州市宜鑫建材有限公司

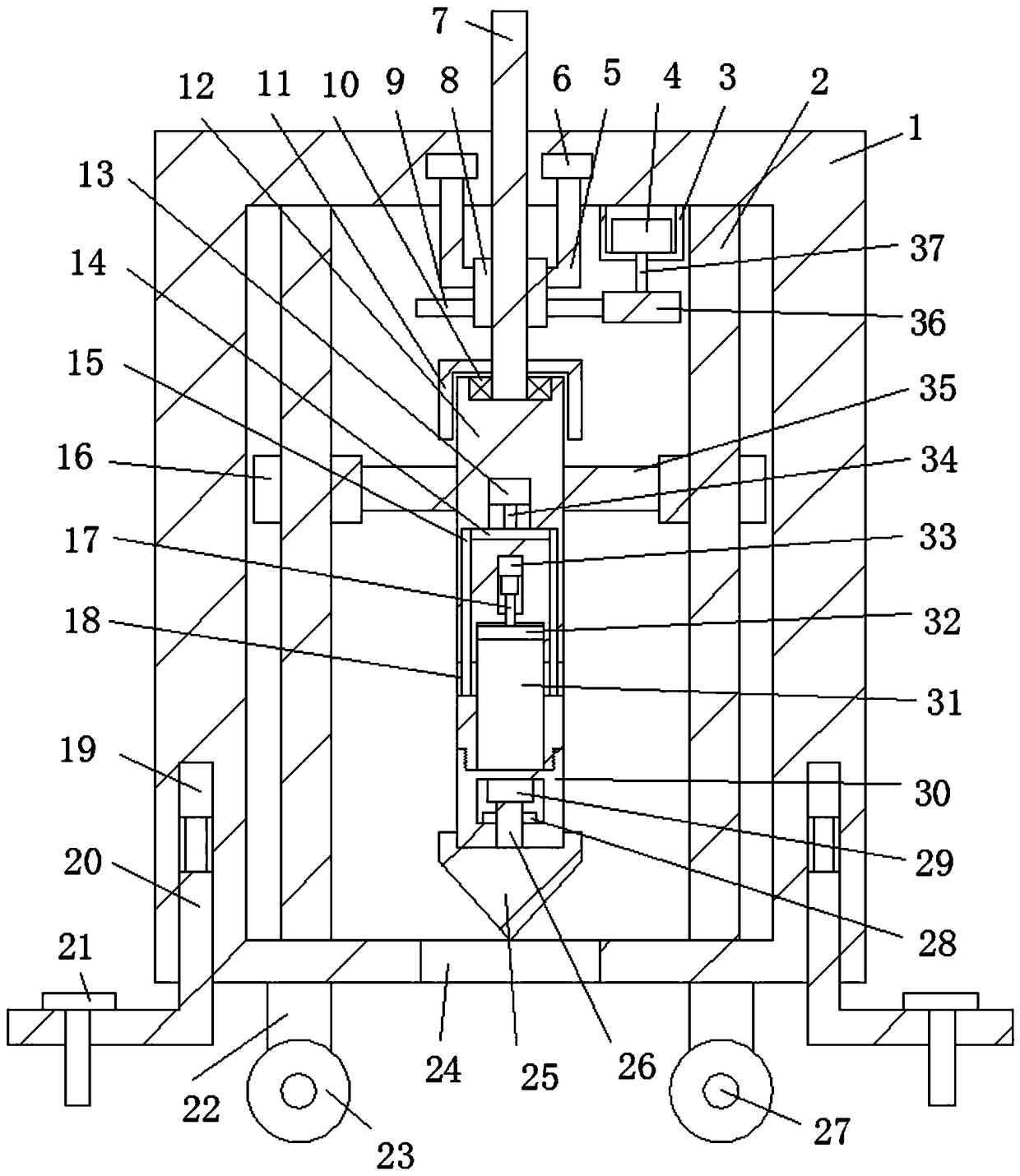

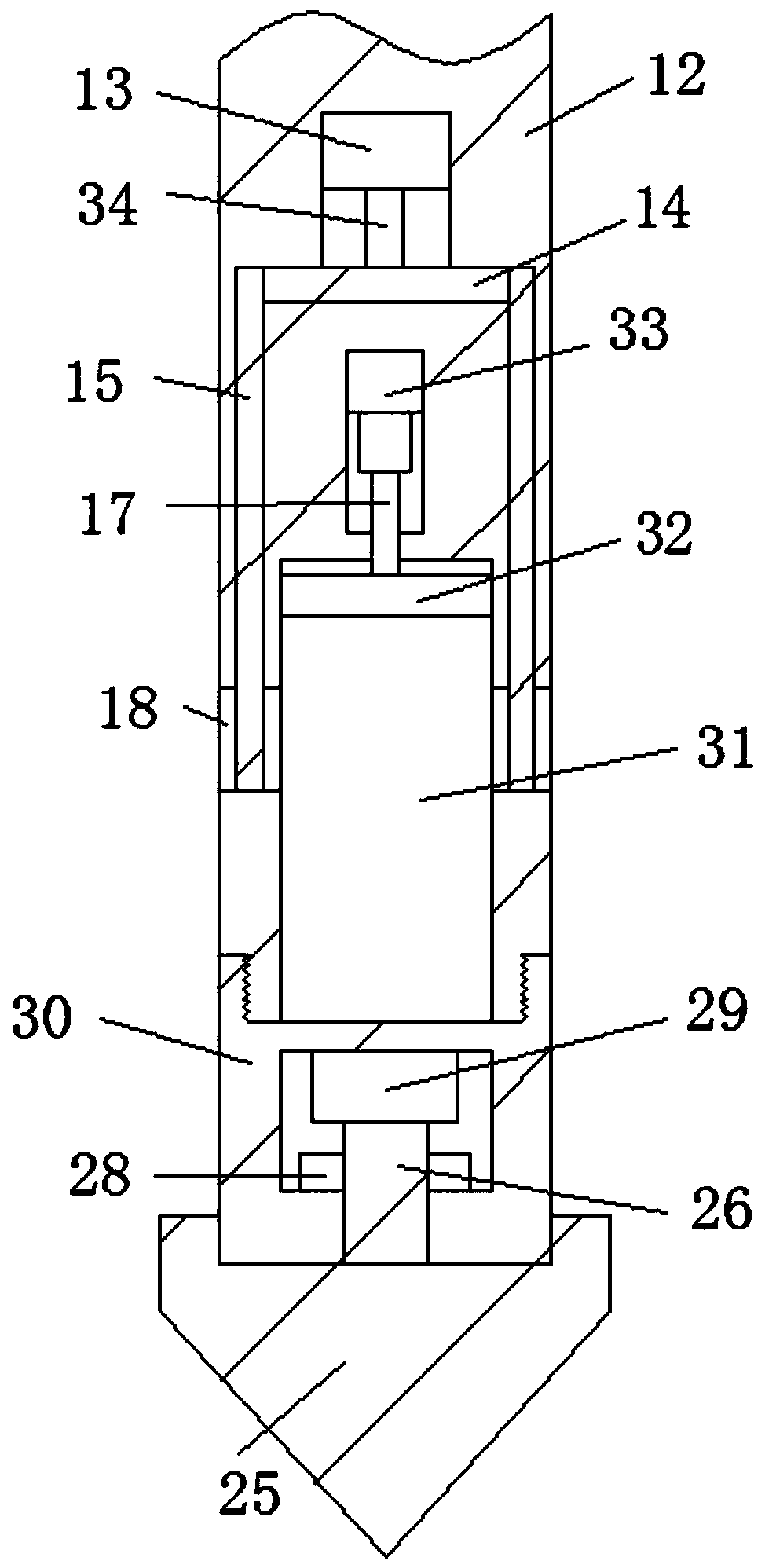

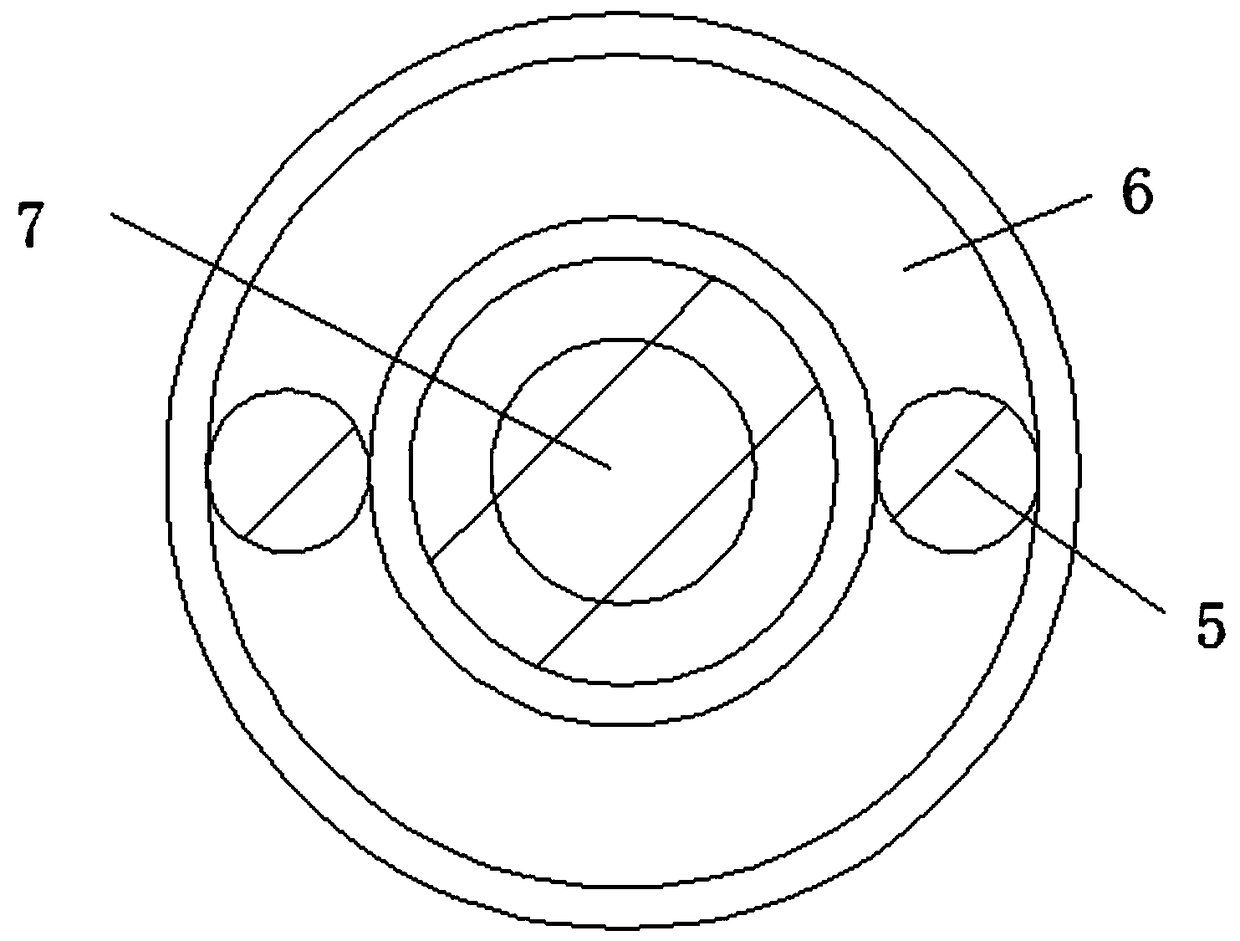

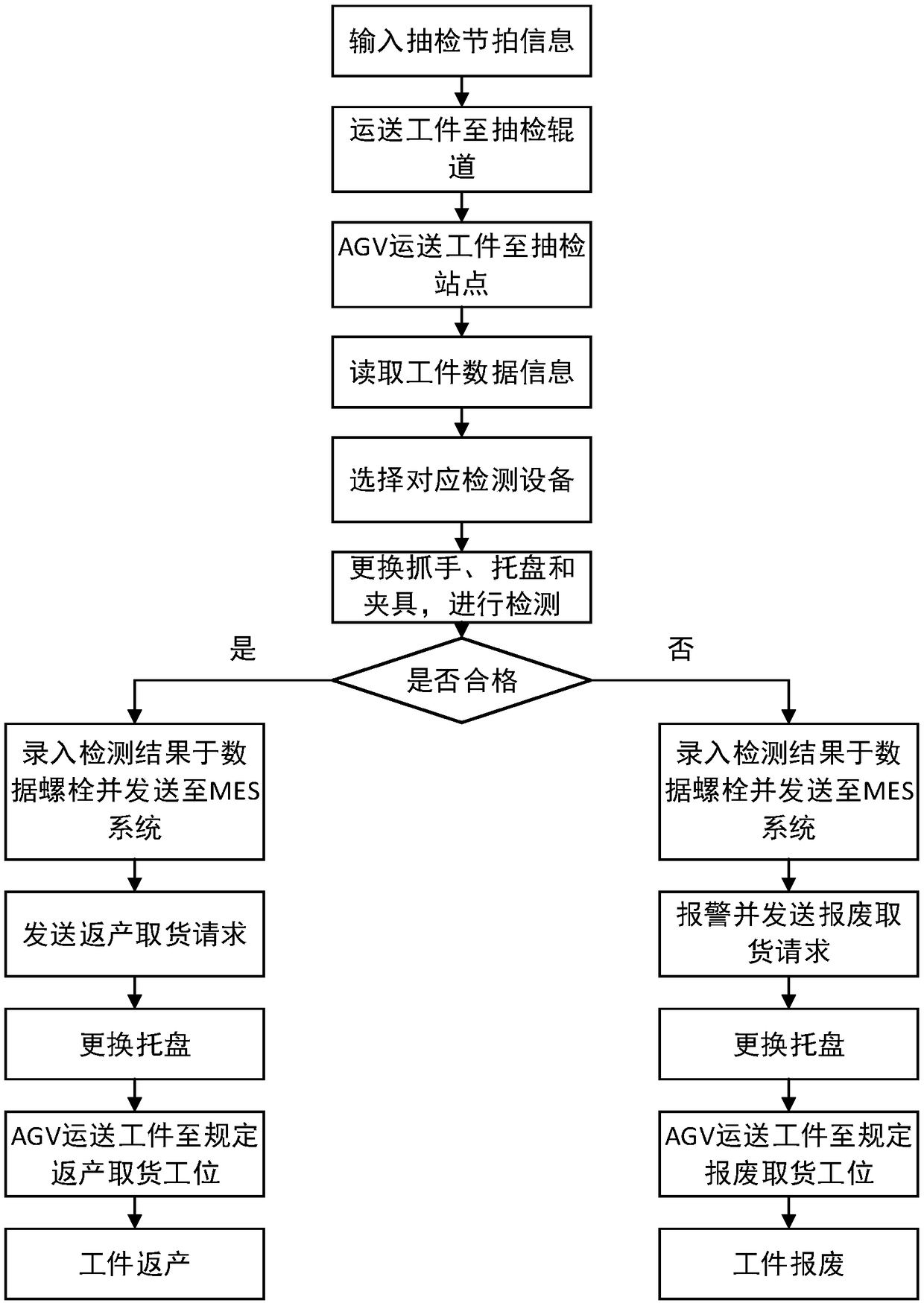

Multi-station automatic sampling inspection and production returning method based on AGV

ActiveCN109240238ARealize full monitoringImprove quality controlElectric/hybrid propulsionTotal factory controlPersonalizationTechnician

The invention provides a multi-station automatic sampling inspection and production returning method based on an AGV. The method comprises the following steps: step 1, conveying a workpiece to a to-be-inspected area; step 2, enabling the AGV to convey the workpiece from the to-be-inspected area to an inspection area; step 3, enabling an inspection device to inspect the workpiece; if the workpieceis inspected to be qualified, entering the step 4; and if the workpiece is inspected to be unqualified, entering the step 5; step 4, returning the workpiece for production; and step 5, alarming to prompt and performing waste disposal on the unqualified workpiece. The multi-station automatic sampling inspection and production returning method have the following advantages: with the utilization of an AGV trolley, the automation and intellectualization of a to-be-inspected workpiece in an entire process from submission to production returning are completed; by introducing an MES system, the individual inspection and information summarization of a workpiece having different requirements for different stations are guaranteed; and with the utilization of an RFID technology, the whole-process monitoring on a single to-be-inspected workpiece is implemented. Therefore, the defects of low efficiency, relatively large fault tracking difficulty, large manpower cost investment, relatively high demand on experience of a technician and the like in the traditional sampling inspection and production returning scheme are solved.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

Manufacture technology for anti-corrosion, low-cost, refined and environment-friendly stainless steel wire

InactiveCN110760755AImprove liquidityHigh speedProcess efficiency improvementElectric furnaceFurnace temperatureElectric arc furnace

The invention discloses a manufacture technology for an anti-corrosion, low-cost, refined and environment-friendly stainless steel wire. The manufacture technology comprises the technological steps that ingredients including ferrochrome and ferronickel are used; the ingredients are successively put into an electric arc furnace for heating and melting; contents of each of the elements are detected,and temperature preservation is conducted during detection; each of the chemical ingredients is adjusted again according to detection results; then, slagging is conducted; and slagging-off and steeltapping are carried out when a furnace temperature reaches 1650 DEG C; a spiral flow duct of which the height is lower than the bottom wall of a furnace cavity is disposed at an outlet of the electricarc furnace; the detected elements include C, Si, Mn, Cr, Ni, P and S; after entry of molten steel in a primary forging furnace, a mixed gas of Ar (N2) + O2 is blown into the furnace, the content ofN is detected, and a blowing process is divided into an oxidation stage, a reduction stage and a refinement stage; continuous casting is carried out; and the wire is manufactured after continuous rolling. The manufacture technology disclosed by the invention has the beneficial effects that the molten steel with the uniform ingredients can be obtained through opening or closing of a molten steel valve during molten steel taking, so accuracy of the detection results is increased, cost is reduced and production efficiency is increased; and on the premise that stainlessness is not reduced, the content of Ni is reduced, but a corrosion resisting rate is increased.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

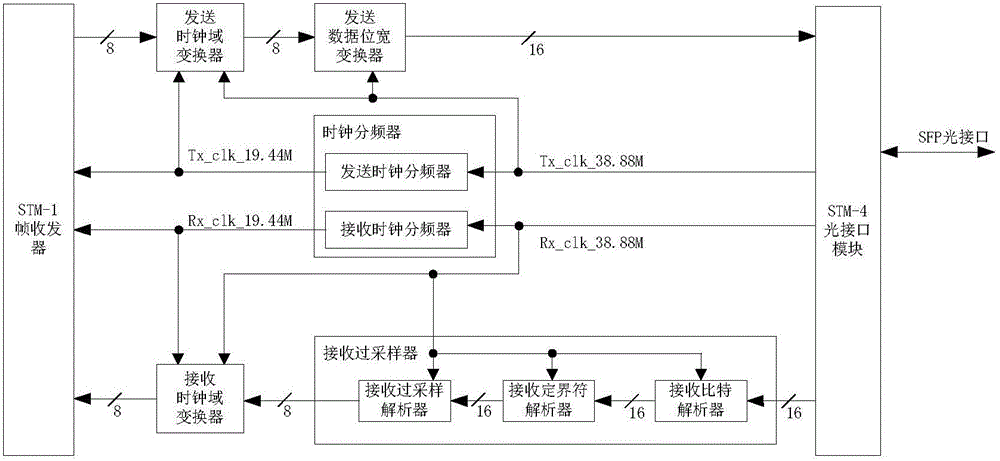

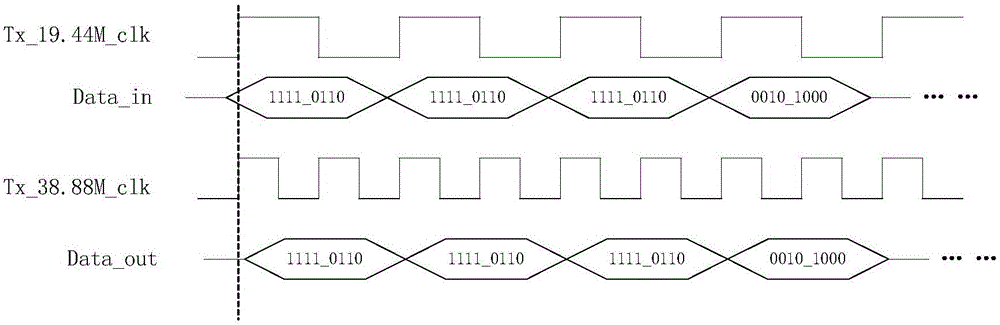

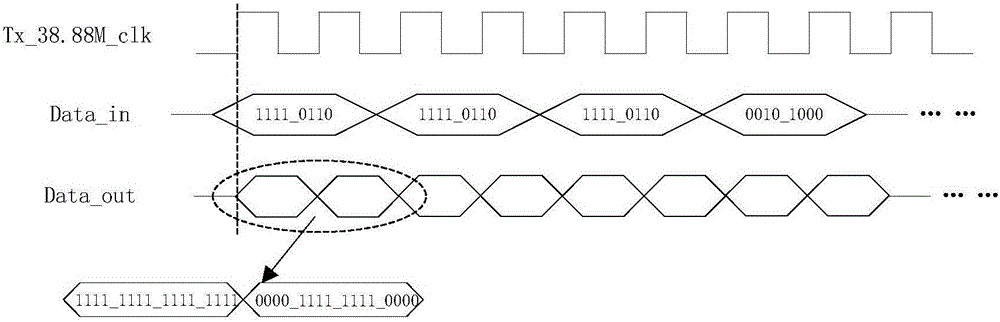

Method and device for realizing SDH optical interface of STM-1 by employing oversampling method

ActiveCN106209292ASave resourcesSimplify programming complexityTime-division multiplexTransceiverData translation

The invention discloses a method and device for realizing an SDH optical interface of STM-1 by employing an oversampling method. The method comprises (1), a sending path that an STM-1 transceiver generates STM-1 data frames under clock frequency of 19.44 M, conversion of a clock domain from 19.44 M to 38.88 M is carried out on the data frames through a sending clock domain converter, under the clock frequency of 38.88 M, each piece of 1-bit data is copied into 4-bit data through a sending data bit width converter, the data is sent to an STM-4 optical interface module for sending; and a receiving path that STM-1 signals from an STM-4 optical interface are received, oversampling of four times per level is carried out on the signals under the clock frequency of 38.88 M, an STM-1 frame header is found, conversion from 4-bit to 1-bit is carried out on the data, the data is converted into signals under the 19.44 M through a receiving clock domain converter, and the signals are sent to the STM-1 transceiver for frame decoding.

Owner:TIANJIN DEVISER ELECTRIC INSTR

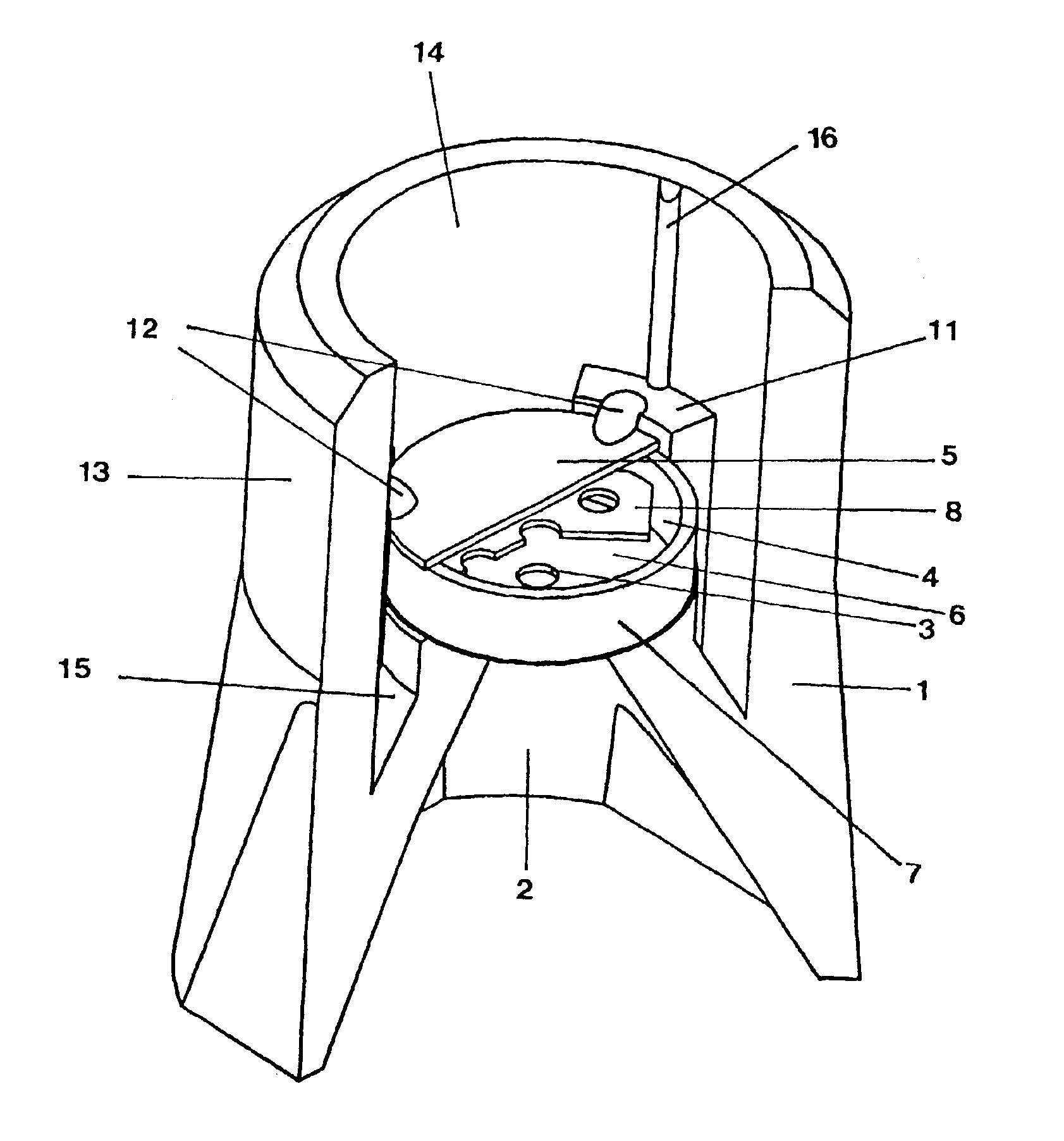

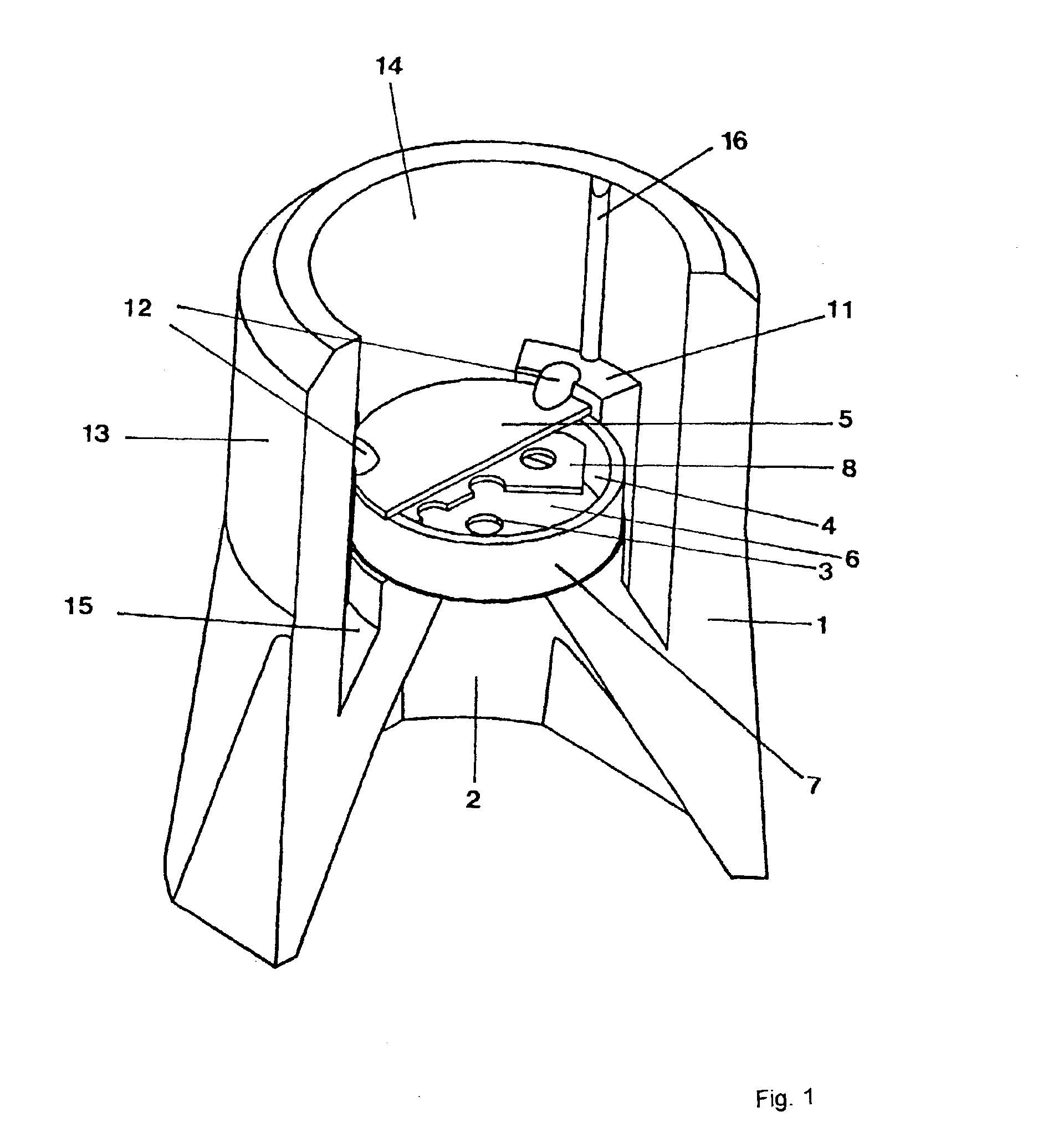

Sampler for melts, in particular for slags lying on a molten metal

A sampler is provided for melts, in particular for slags lying on a molten metal, the sampler having a single- or multi-part body for arrangement in a support. The sampler has an inlet and a sample chamber with two opposing chamber walls, wherein an inlet opening is arranged in one chamber wall. In order to make possible homogeneous and stable samples, an intermediate plate with at least one through opening is arranged inside of the sample chamber spaced from the chamber walls.

Owner:HERALUS ELECTRO NITE INT NV

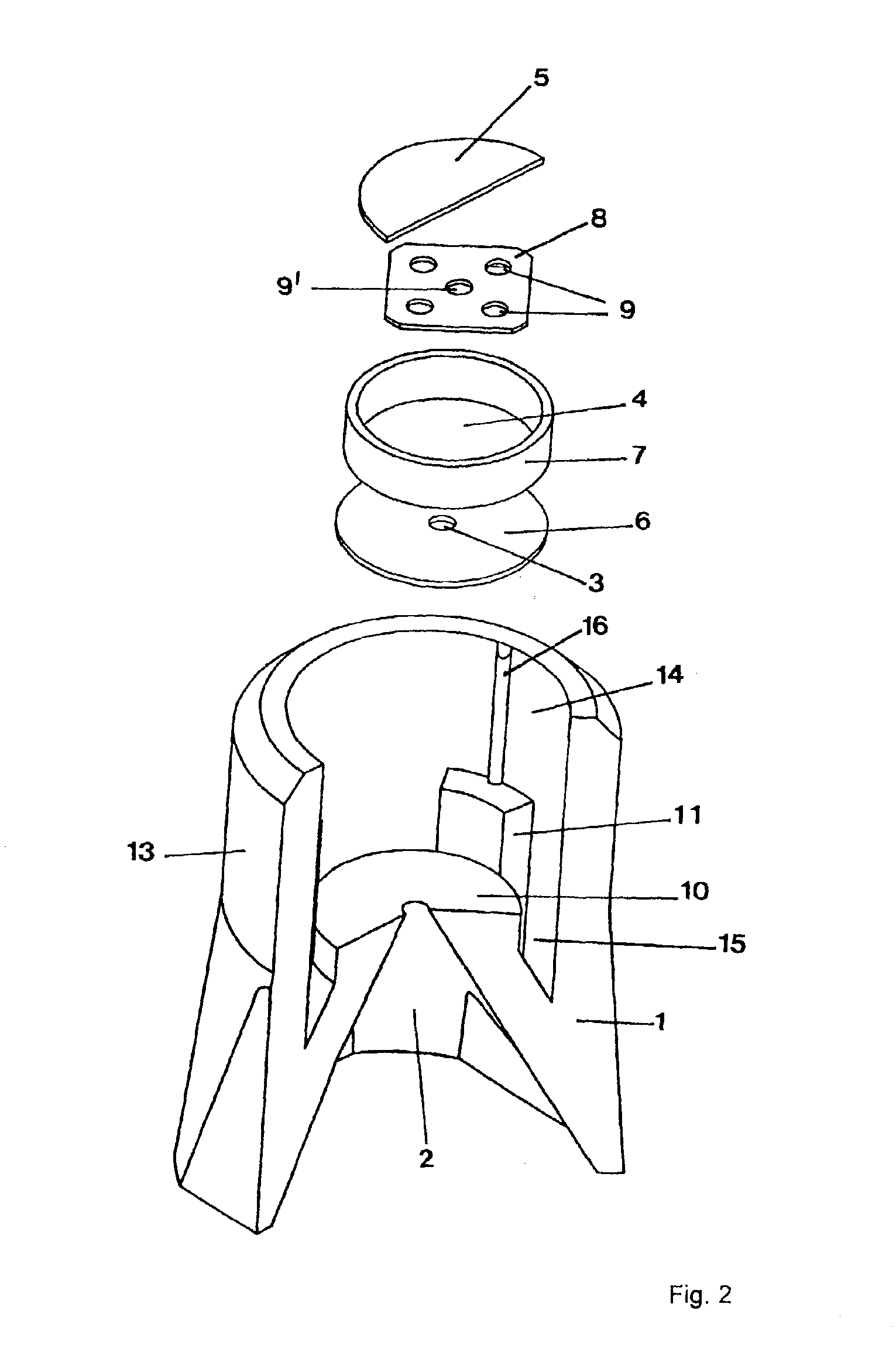

Automatic sampling surface density measurement mechanism for gypsum board production line

The invention discloses an automatic sampling surface density measurement mechanism for a gypsum board production line. The mechanism comprises a set of horizontal moving air cylinder system, a set ofvertical lifting moving air cylinder system and a set of weight measuring system; the vertical lifting moving air cylinder system is connected to the horizontal moving air cylinder system in a sliding manner; the weight measuring system is mounted at the top end of the lifting moving air cylinder system and is used for detecting the weight of a sample; the weight measuring system comprises a sampling weighing platform; a plurality of weight sensors used for detecting the weight of the sample are arranged on the sampling weighing platform; and a sample cleaning mechanism is further mounted onthe sampling weighing platform. The sample can be automatically taken out on the high-speed production line to measure the surface density, so that the operation process of measuring the surface density by manual sampling at present is replaced; and the sample can be automatically cleaned, so that the accuracy of a surface density detection result can be improved.

Owner:NINGBO BEIXIN BUILDING MATERIAL +1

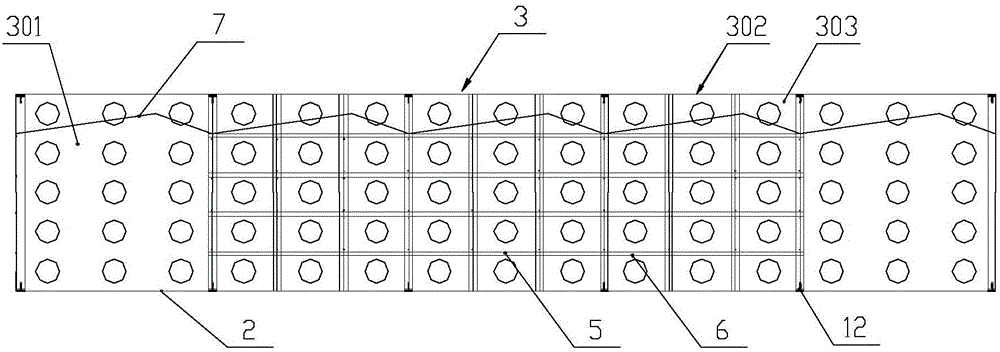

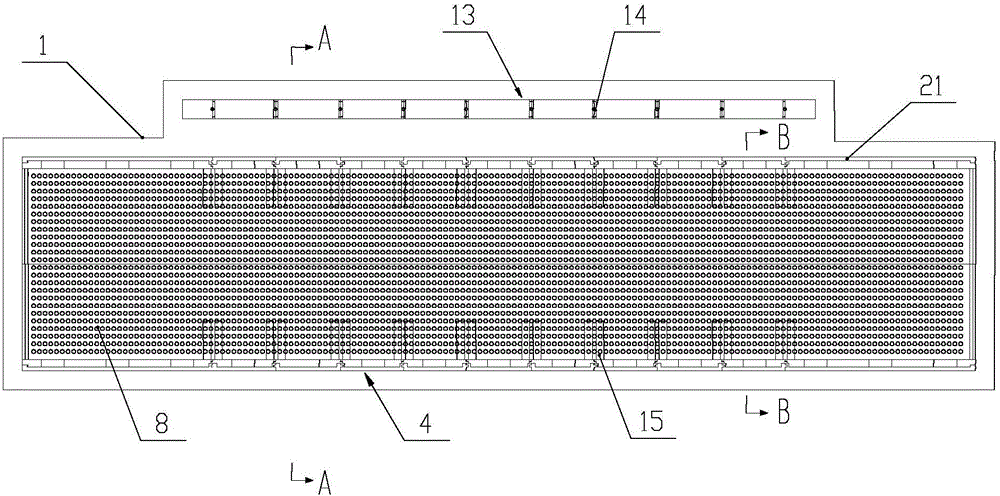

Experimental apparatus and method for hyporheic zone under field riverbed evolution

ActiveCN106053763AReasonable designEffect of water flow characteristicsEarth material testingField experimentWater filter

The invention relates to an experimental apparatus for a hyporheic zone under field riverbed evolution, comprising a foundation pit excavated at the bottom of a riverbed; water-filtering geotextile is spread at the bottom of the foundation pit, a rectangular container formed by splicing and enclosing a plurality of combined plastic plates is arranged above the geotextile, and the bottom of the rectangular container is fixed to the riverbed; the combined plastic plates are each composed of a plurality of plastic plates with round holes, a sampling hole is provided between upper and lower plastic plates, the outside of each sampling hole is covered with veneer, and the inside of each sampling hole is covered with thin film; grit accumulated in wavy form is contained in the rectangular container, a plastic mesh is spread above the grit, the plastic mesh is lapped to the combined plastic plates through lap fasteners. By setting up a river slope and physiochemically analyzing water coverage on the sand slope and by using the experimental apparatus to perform layered sectional sampling on the inside of the sand slope, riverbed evolution in the hyporheic zone riverbed is obtained; by using the reasonably designed experimental apparatus, it is easy to perform field experiments under complex geographic conditions.

Owner:HOHAI UNIV

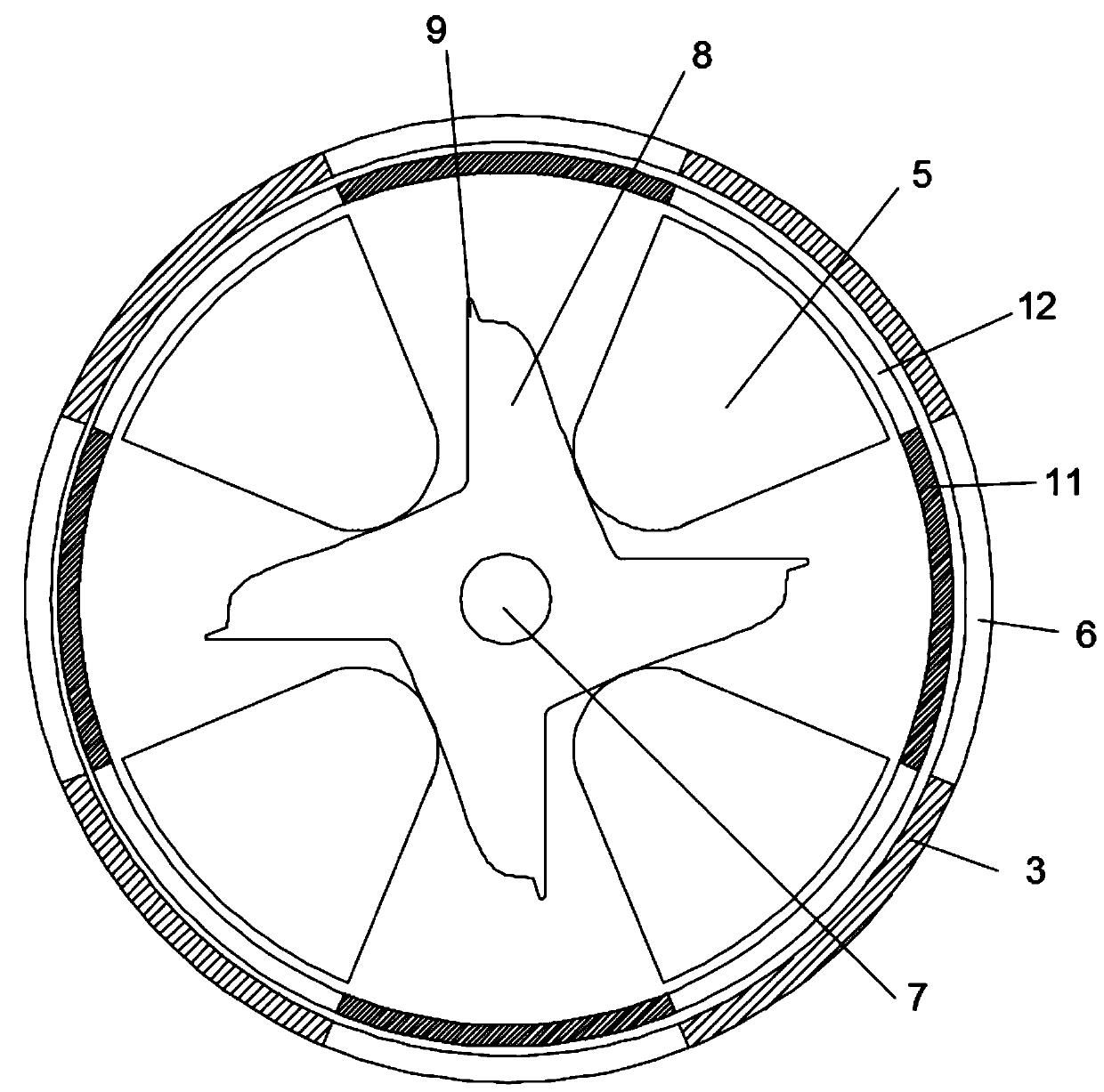

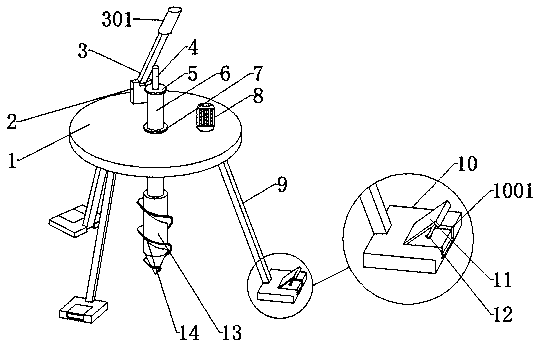

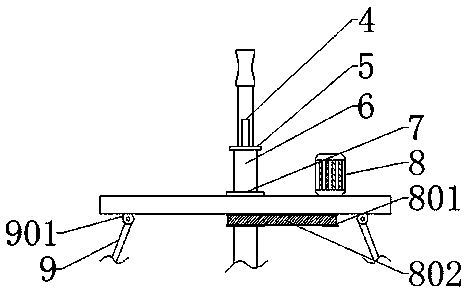

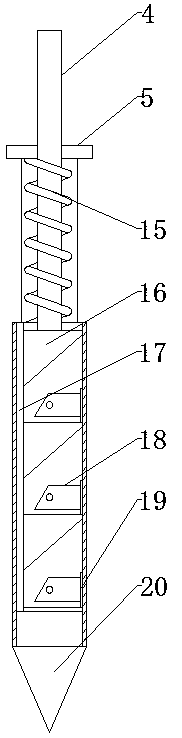

Automatic sampling device for building site construction soil

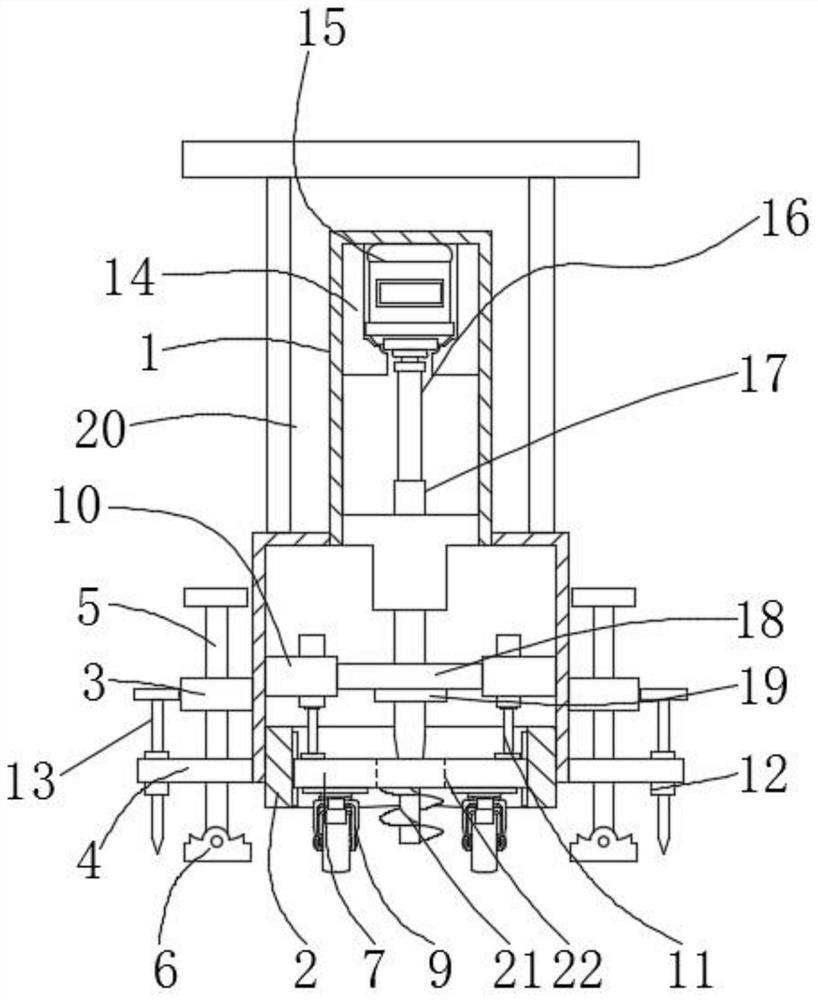

InactiveCN108951596AEasy to sampleStable samplingIn situ soil foundationArchitectural engineeringScrew thread

The invention discloses an automatic sampling device for building site construction soil. The automatic sampling device for building site construction soil comprises a base; the outer end of the baseis movably connected with a scaffold through a rotating shaft; the middle of the upper end of the base is fixedly connected with a motor; the rotating shaft end at the lower end of the motor is fixedly connected with a threaded barrel through a rotary shaft; an inner cavity of the threaded barrel is in threaded connection with a nut; the lower end of the nut fixedly communicates with a sampling barrel; the lower end of the sampling barrel is fixedly connected with a blade drill; a push plate is movably inserted at the upper end of an inner cavity of the sampling barrel; a push rod is fixedly connected to the upper end of the push plate; the upper end of the push rod movably penetrates through the base and is fixedly connected with a fixing ring; and a buckle is fixedly connected to the upper end of the base through a fastening bolt. Through arrangement of the motor, the threaded barrel, the nut, the sampling barrel, the push rod, the fixing ring and the buckle, the effect of convenient, quick, time-saving and labor-saving sampling is achieved by starting the motor and using the buckle.

Owner:清远市知途自动化科技有限公司

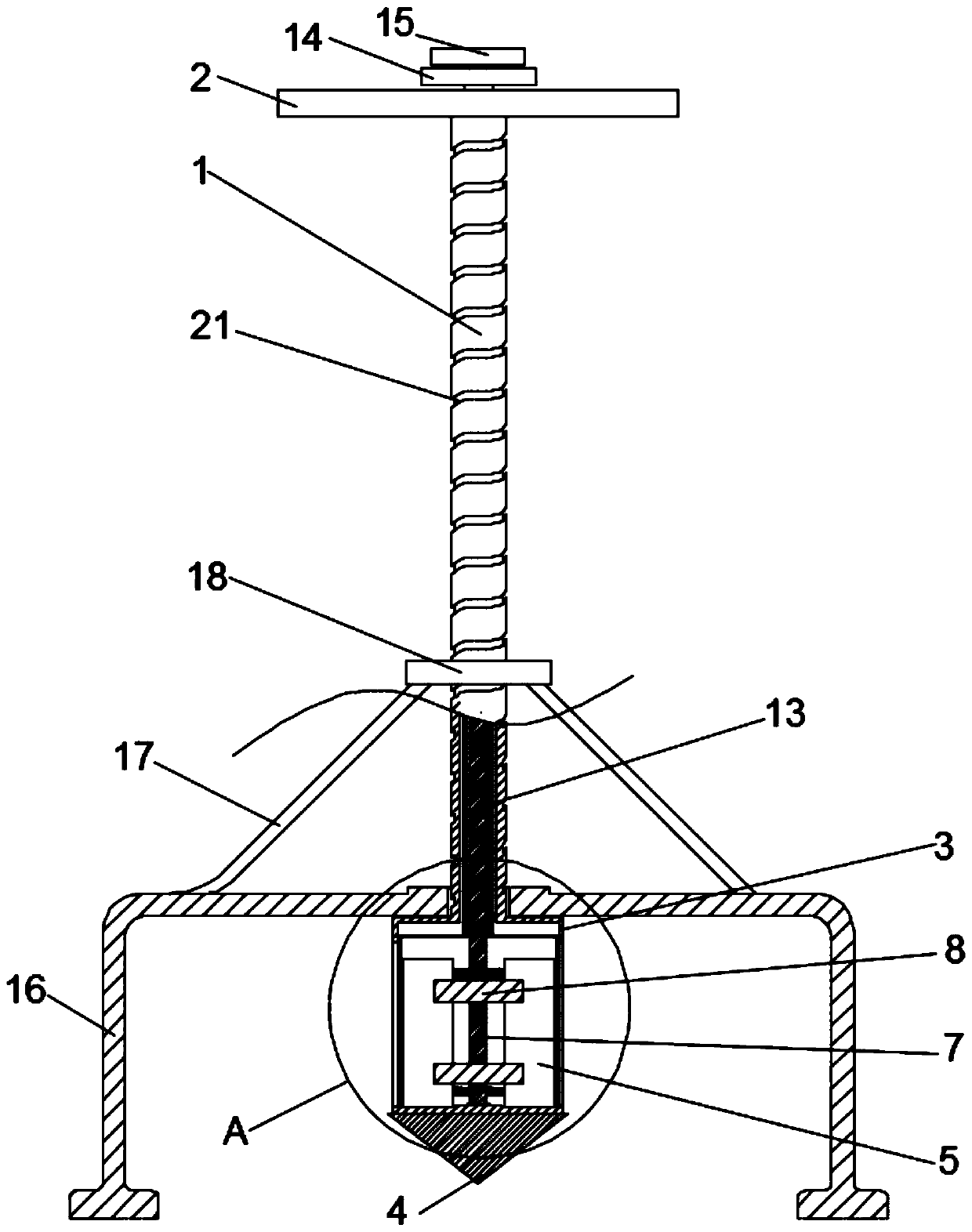

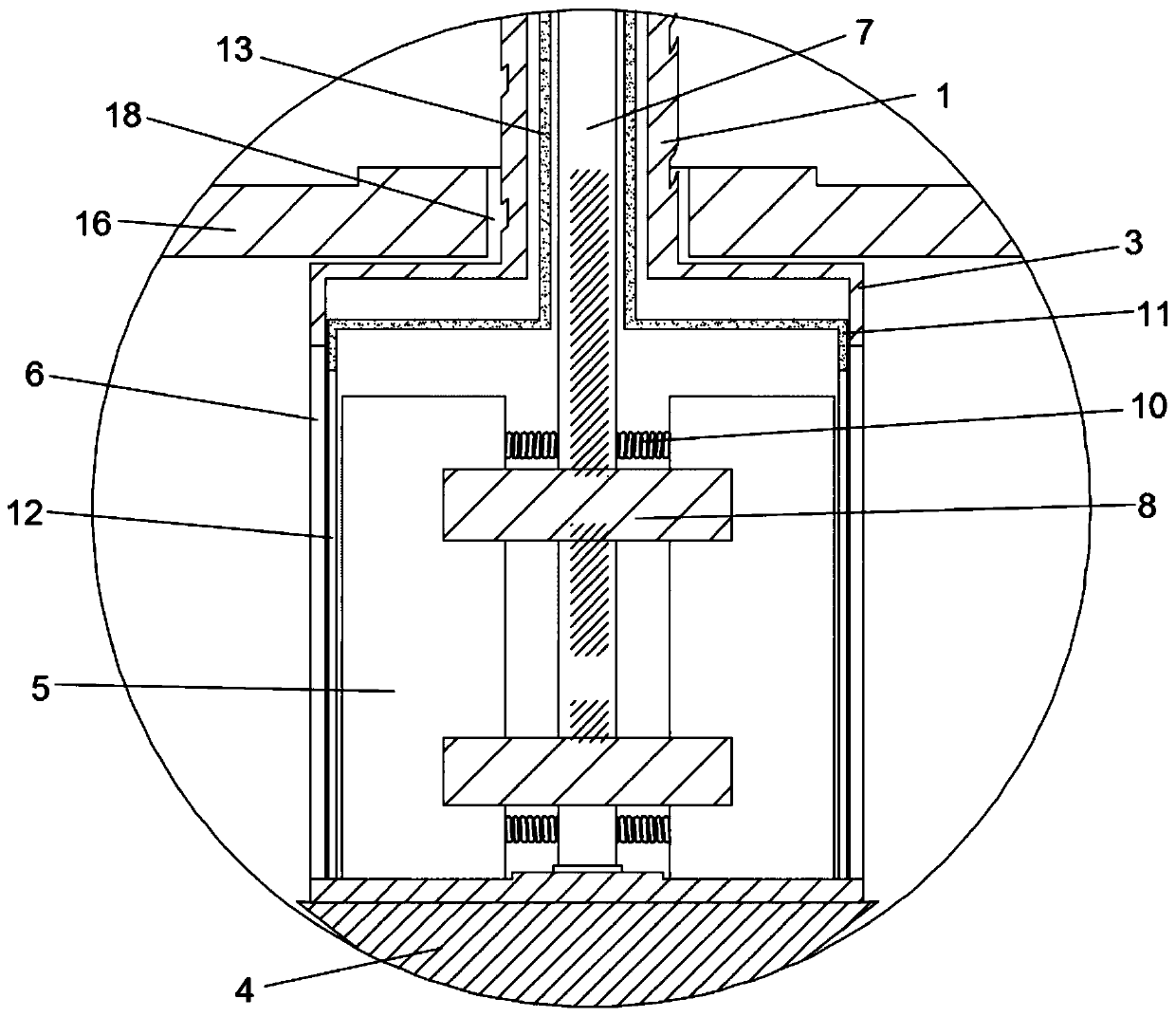

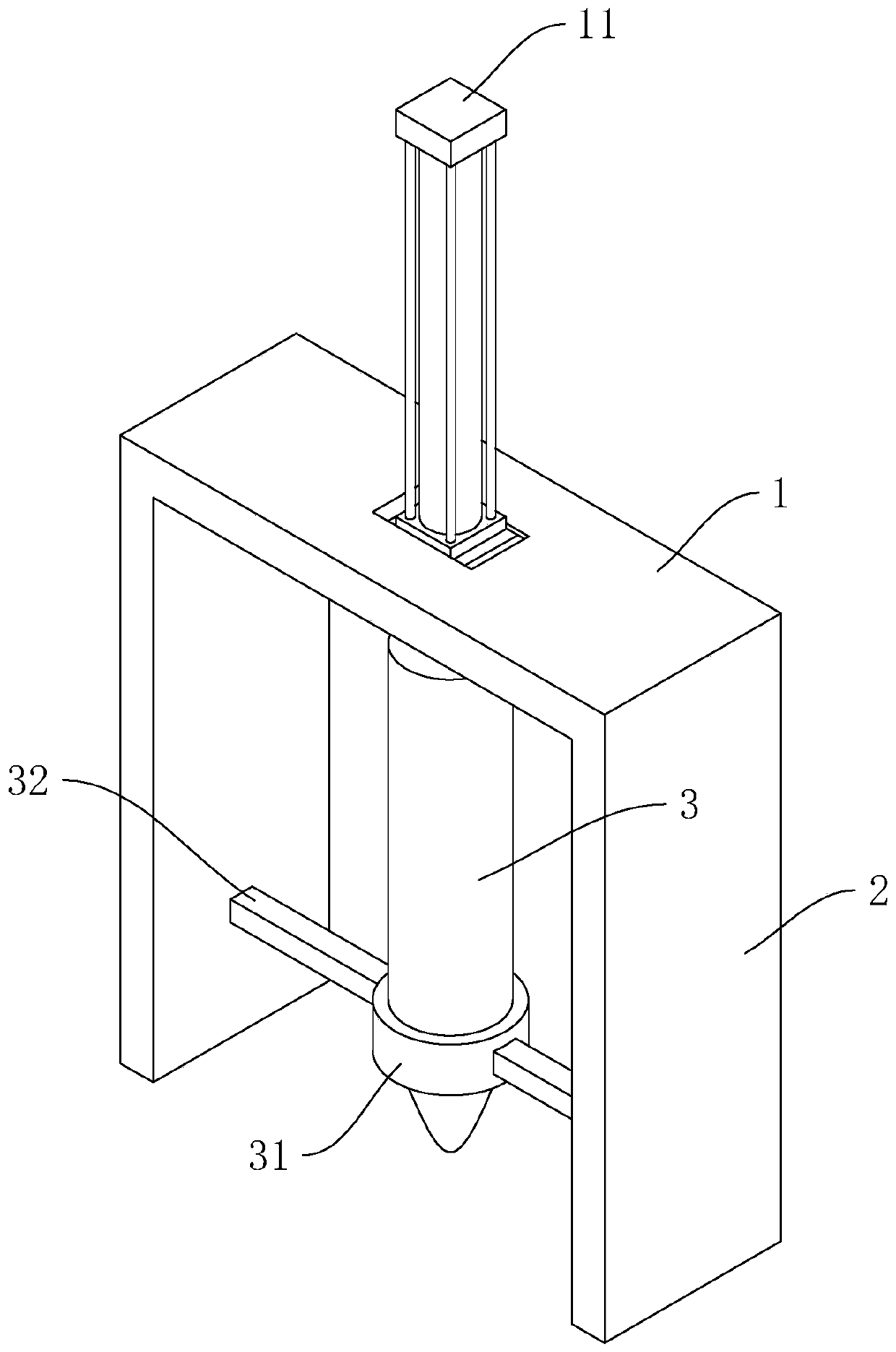

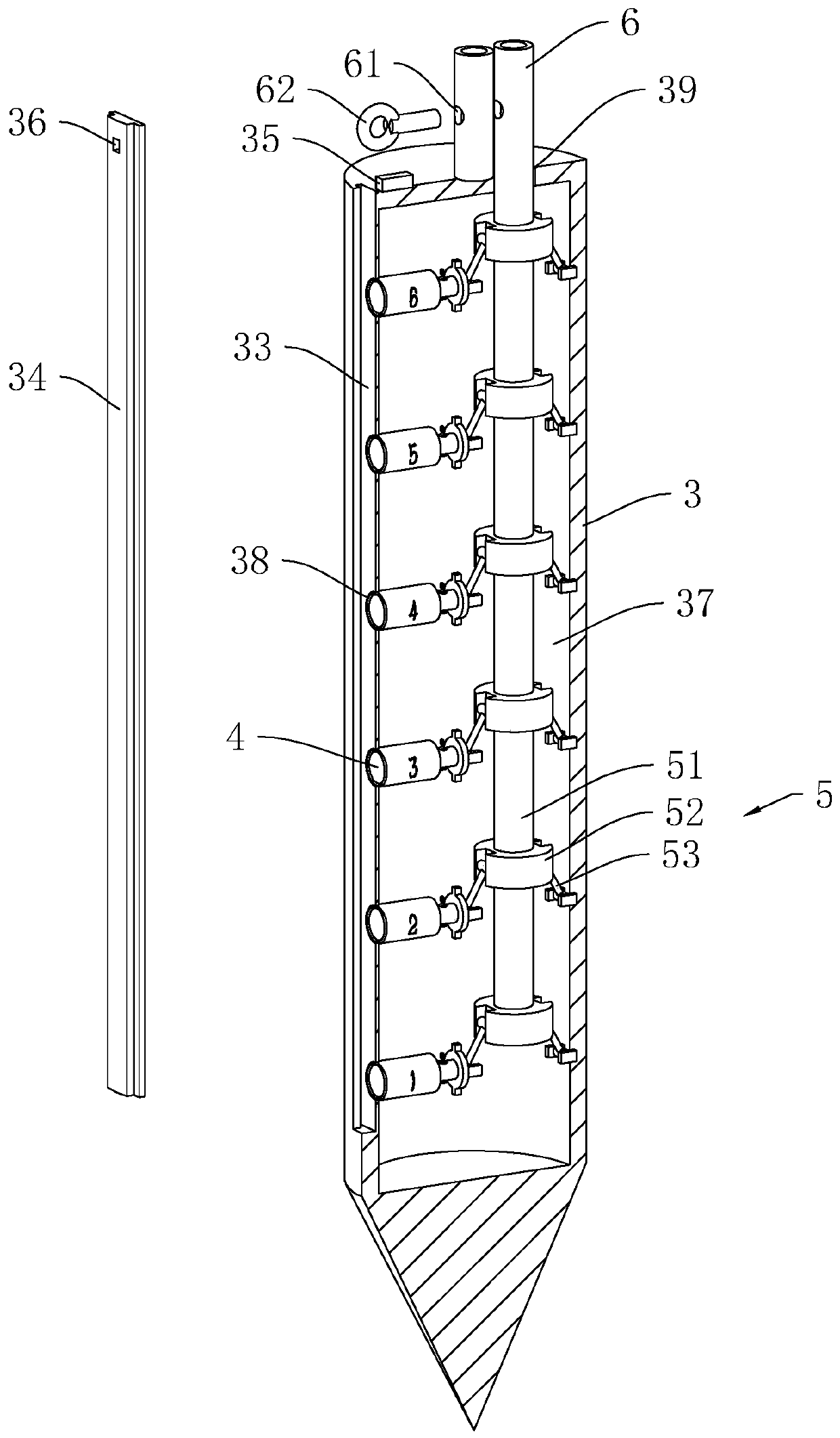

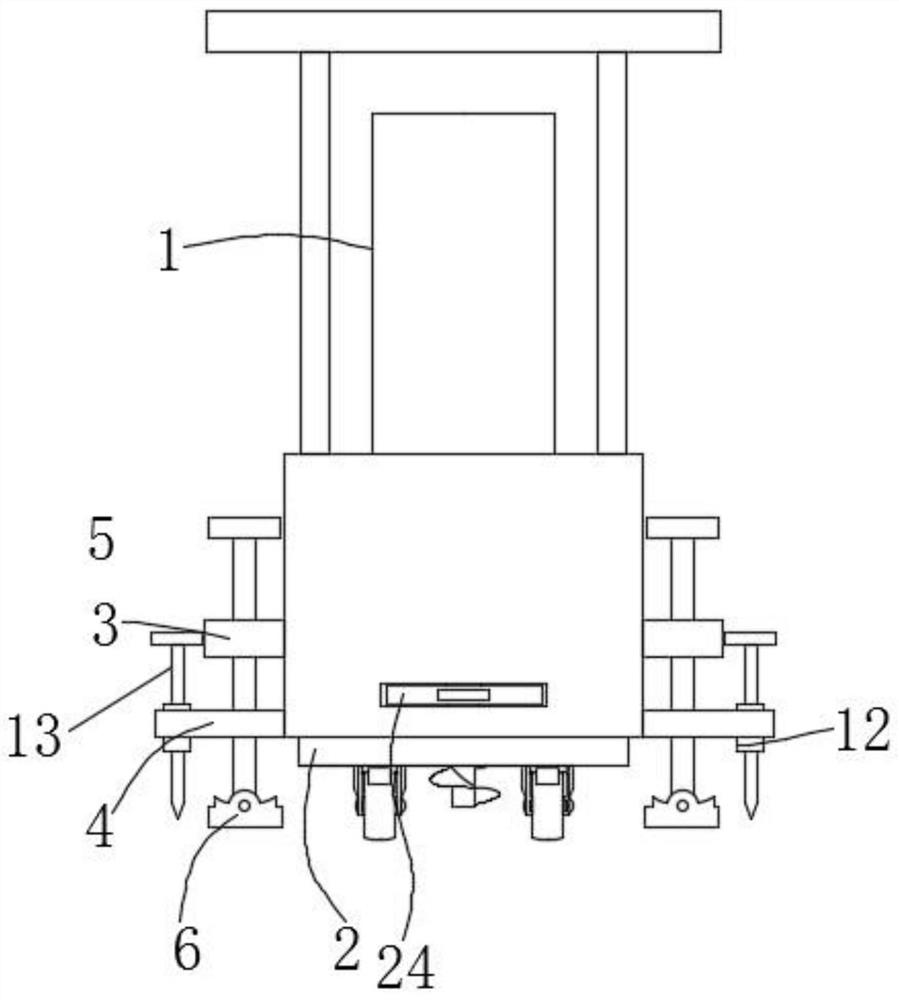

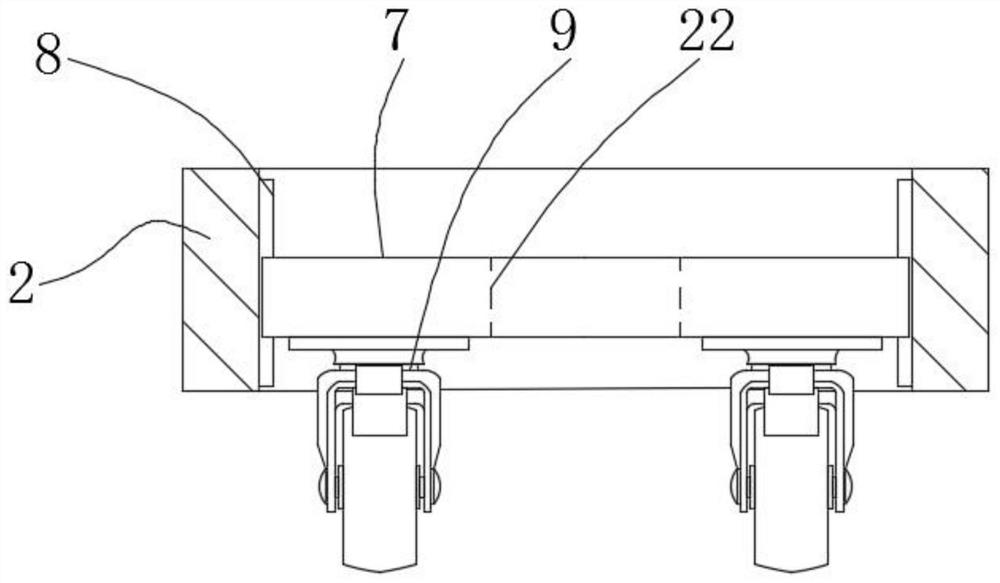

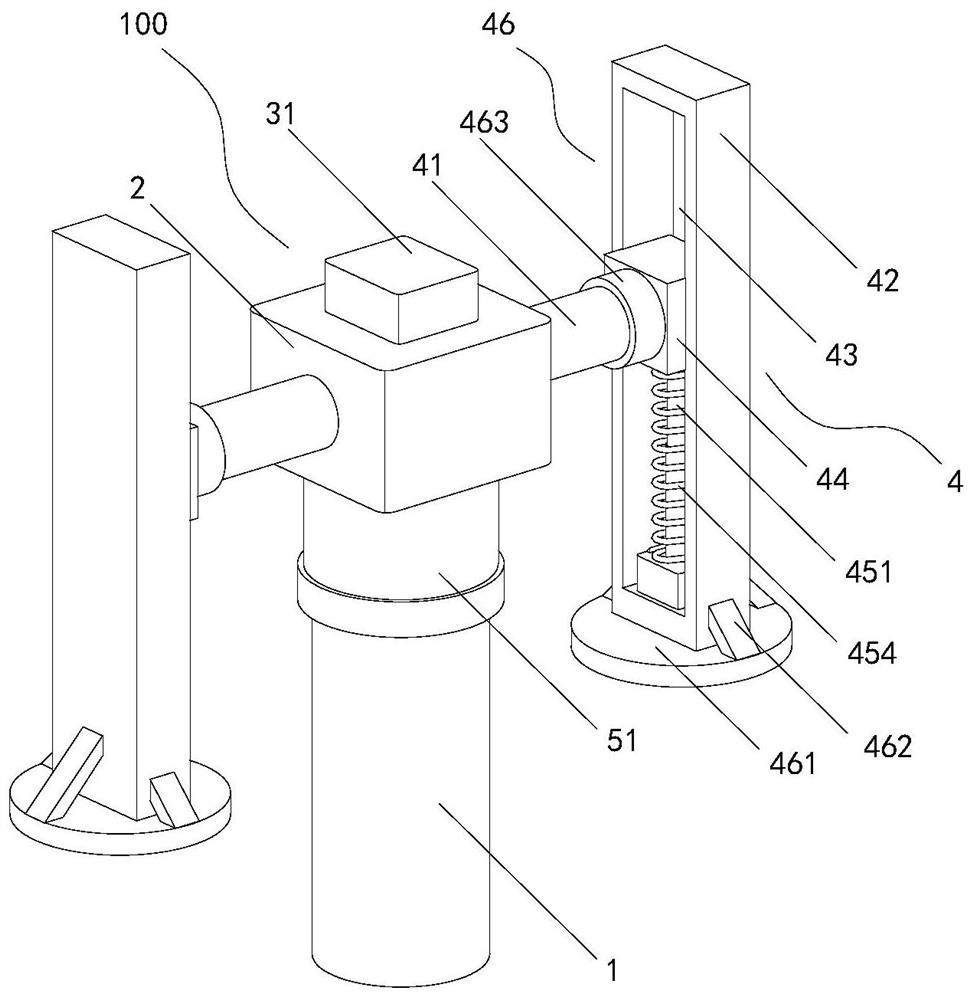

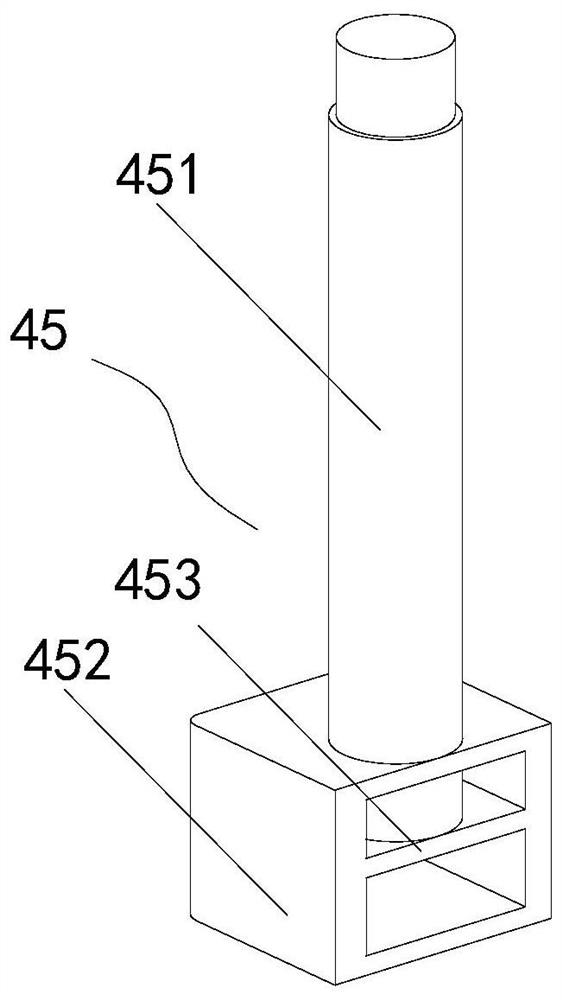

Soil sampling mechanism for geological exploration and using method thereof

InactiveCN112697501AEasy to fixStable samplingWithdrawing sample devicesSoil scienceGeological exploration

The present invention discloses a soil sampling mechanism for geological exploration and a using method thereof. The soil sampling mechanism comprises a working box and a lifting seat fixed in an inner cavity of the working box, the surface of the working box is fixedly connected with a first fixing seat and a second fixing seat from top to bottom, and the top of the first fixing seat is in threaded connection with a supporting rod. The invention relates to the technical field of soil sampling. According to the soil sampling mechanism for geological exploration and the using method thereof, the conveying wheel is retracted through the electric push rod, then the rotating disc on the surface of the supporting rod is rotated, the rotating disc drives the supporting rod to rotate, and the supporting rod rotates in the first fixing base and the second fixing base to move up and down and drive the supporting base at the bottom to move up and down to keep the working box perpendicular to the ground; and the inserting pins are inserted into the ground, and the working box is limited by inserting the inserting pins into the ground, so that the device can be suitable for sampling on the ground with various gradients, the fixation is firmer, the sampling is more stable, and the effect is good.

Owner:中国建筑材料工业地质勘查中心安徽总队

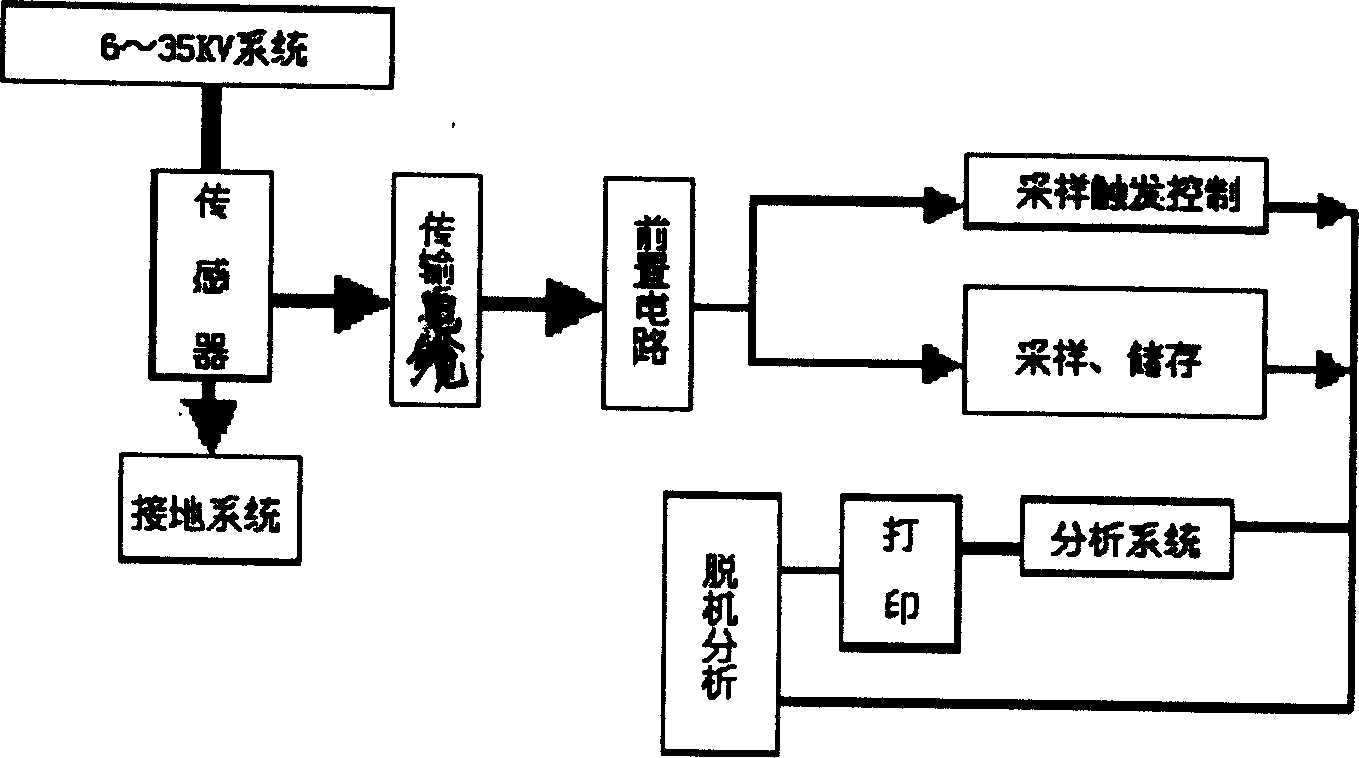

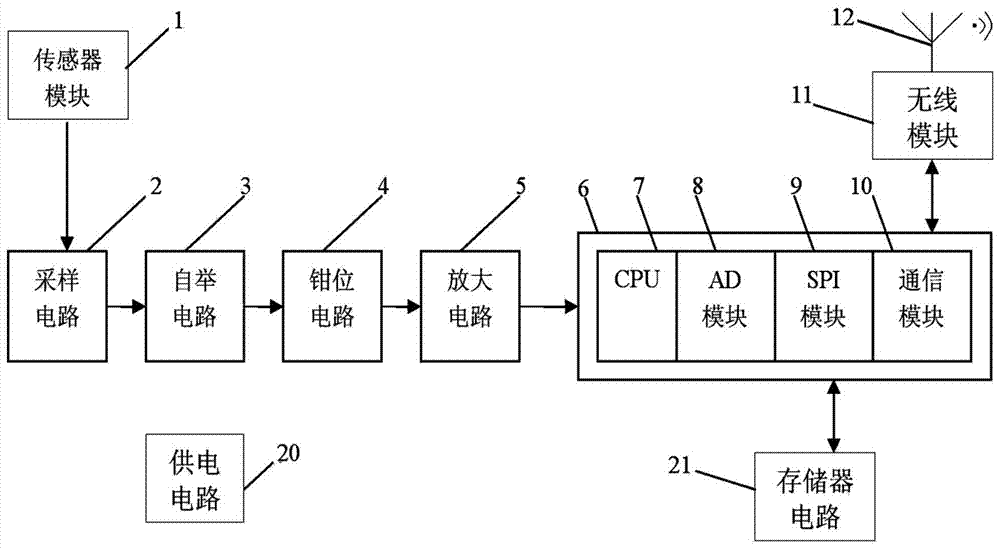

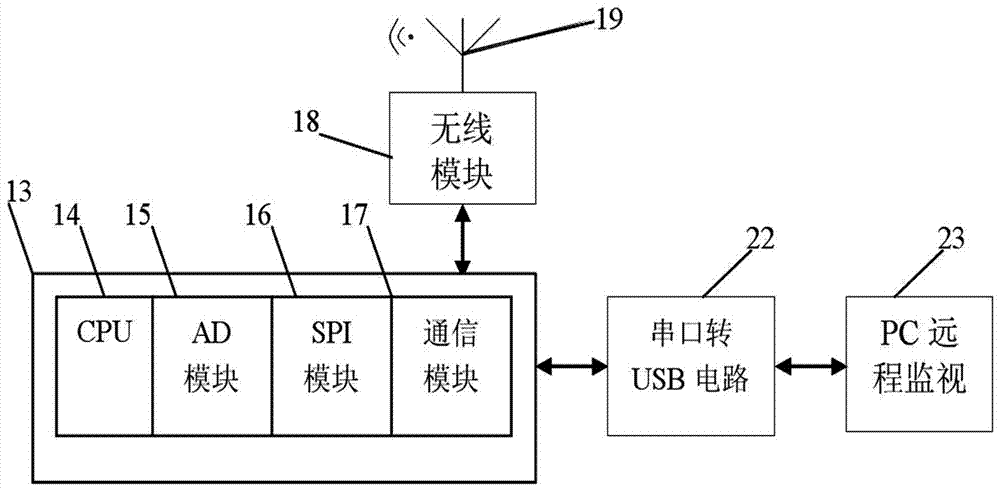

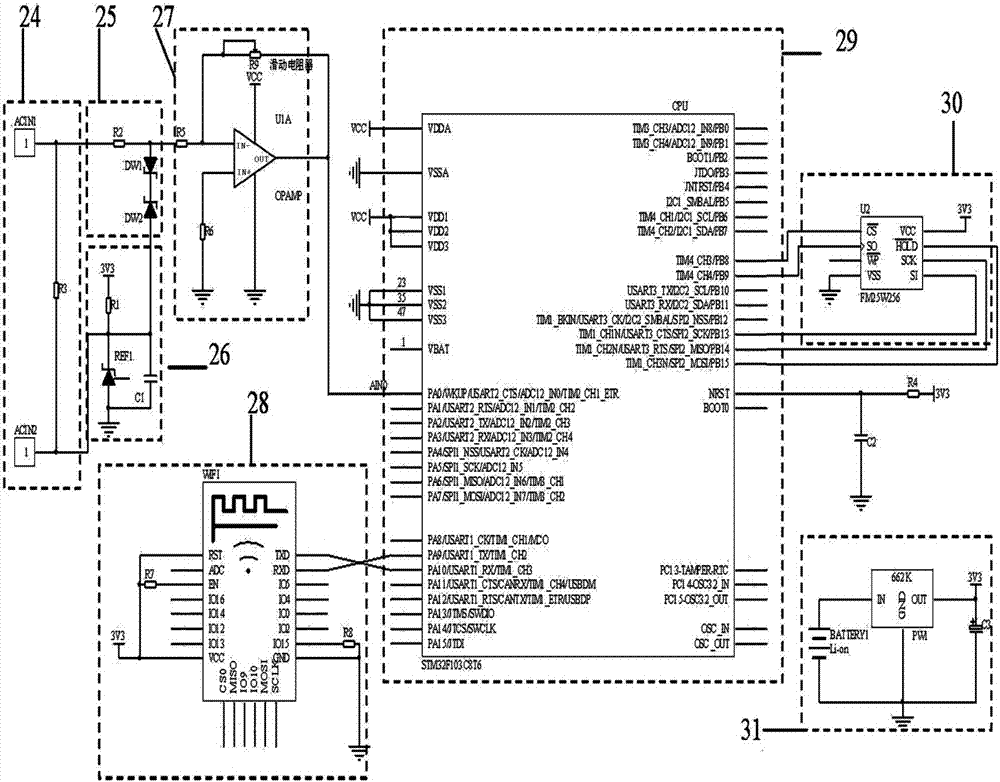

Substation overvoltage monitoring system and method based on wireless acquisition technology

PendingCN107328989AImprove memory depthMeet high-speed signal storageTransmission systemsMeasurement using digital techniquesOvervoltageHemt circuits

The invention belongs to the technical field of electric automatization and especially relates to a substation overvoltage monitoring system and method based on wireless acquisition technology. The system comprises two portions: a test probe portion and a receiving probe portion. Through an AD converter circuit, an analog signal is allowed to be converted into a digital signal stably, and through high-speed analog acquisition in ARM, a good record of detail portions of an original signal is made; stable sampling of an analog sampling circuit is realized; a good energy saving effect is achieved; the system can prevent influence of high-voltage electric field parameter changes, and has good static and dynamic performance; wireless detection of test results is realized, thereby preventing tedious coaxial cable wiring on test sites and preventing the latent possibility of personal electric shock due to wired test of high-voltage equipment; test data is accurate and reliable; an original hardware transformation link of the overvoltage signal is simplified, and flexibility of the whole machine is improved; and the device can be widely produced as a product, and is highly profitable.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

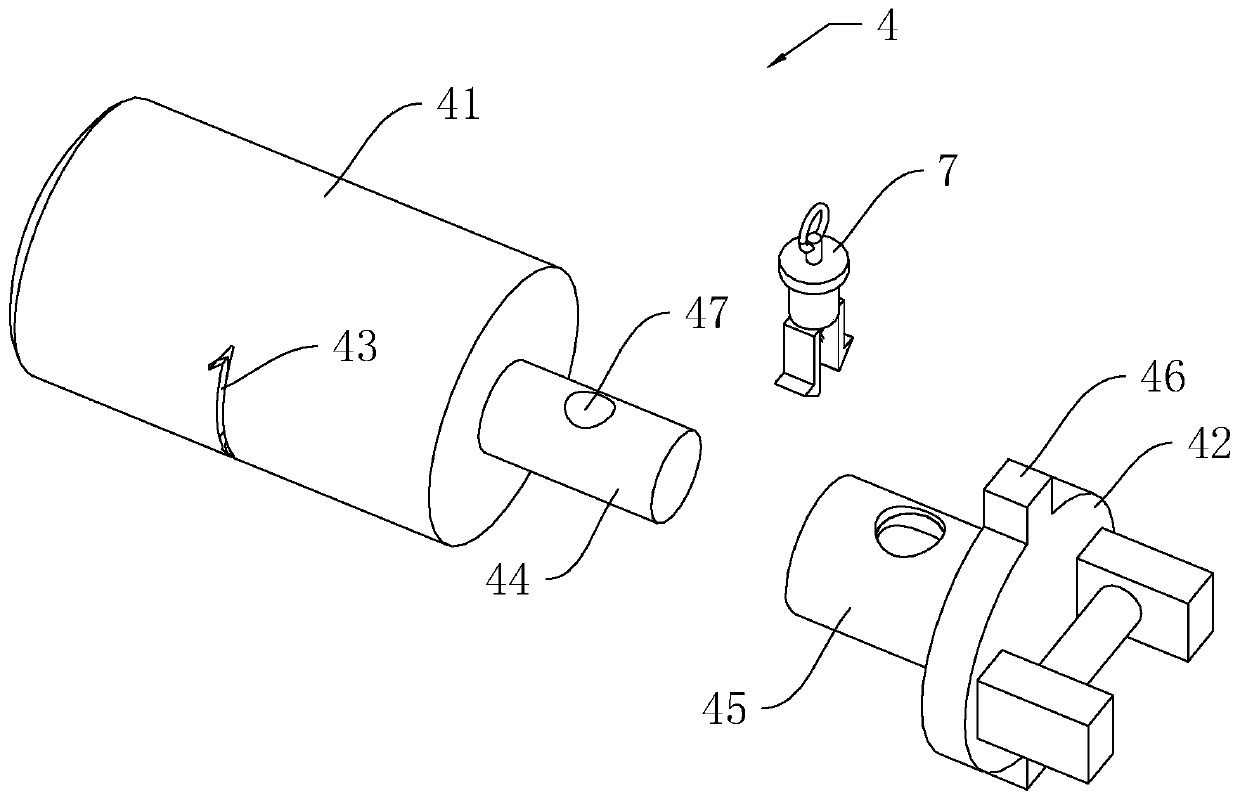

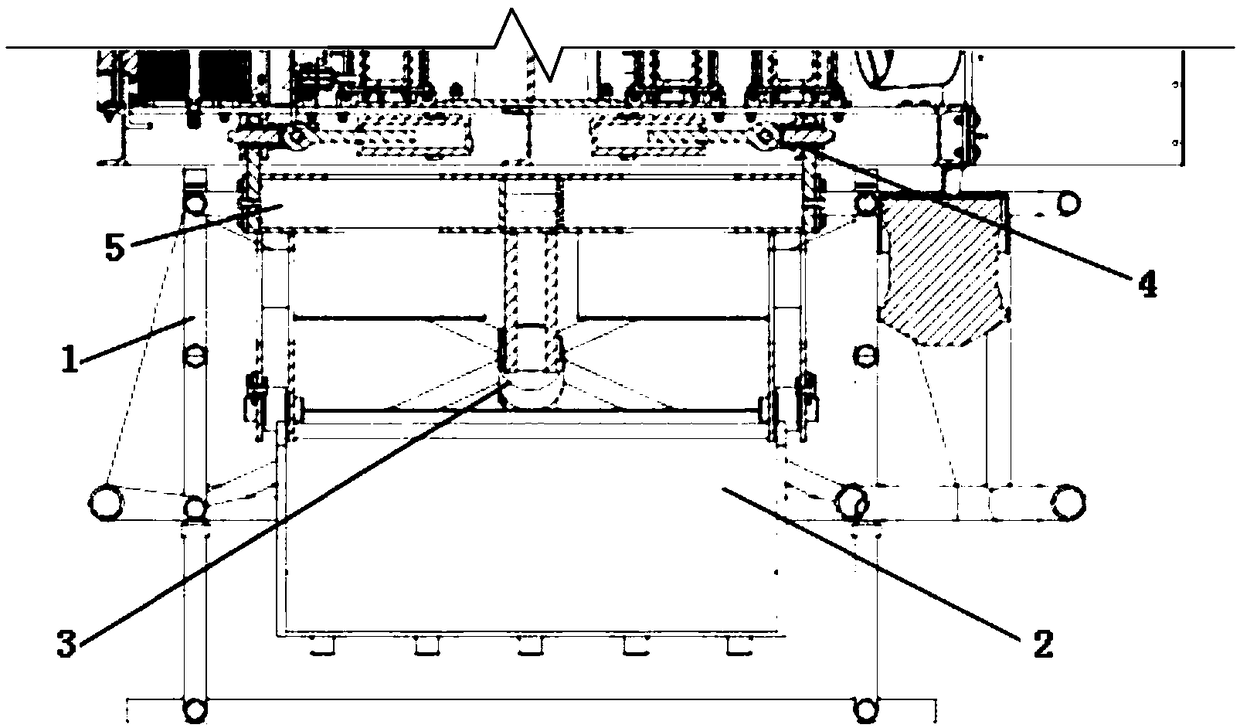

Separated type actuating mechanism for deep-sea visual sampler

PendingCN108489755AImprove efficiencyReduce volumeWithdrawing sample devicesUnderwater equipmentHydraulic cylinderControl system

The invention provides a separated type actuating mechanism for a deep-sea visual sampler and belongs to the technical field of deep-sea hydrothermal area investigating, detecting and sampling equipment. The separated type actuating mechanism comprises a peripheral non-load-bearing framework, a load bearing structure, a grab bucket and a grab bucket hydraulic cylinder, wherein the load bearing structure, the grab bucket and the grab bucket hydraulic cylinder are arranged in the framework; the top of the grab bucket is fixed to the upper part of the peripheral non-load-bearing framework throughthe load bearing structure, two bucket-shaped jaw plates of the grab bucket are respectively driven by the grab bucket hydraulic cylinder, and the top end of a piston rod of the grab bucket hydrauliccylinder is in rotary connection with the middle of the bottom end of the load bearing structure; the top of the load bearing structure is separately connected with a control system of the actuatingmechanism through two separated type lifting point connection mechanisms which are distributed in the direction perpendicular to the axial direction of the grab bucket hydraulic cylinder, and a cameraand a lighting lamp are arranged in the load bearing structure. By means of the separated type actuating mechanism disclosed by the invention, the deep-sea visual sampler can flexibly change operation tools according to target objects when job tasks are executed; thus, functions are expanded, and an operation efficiency is high.

Owner:TSINGHUA UNIV

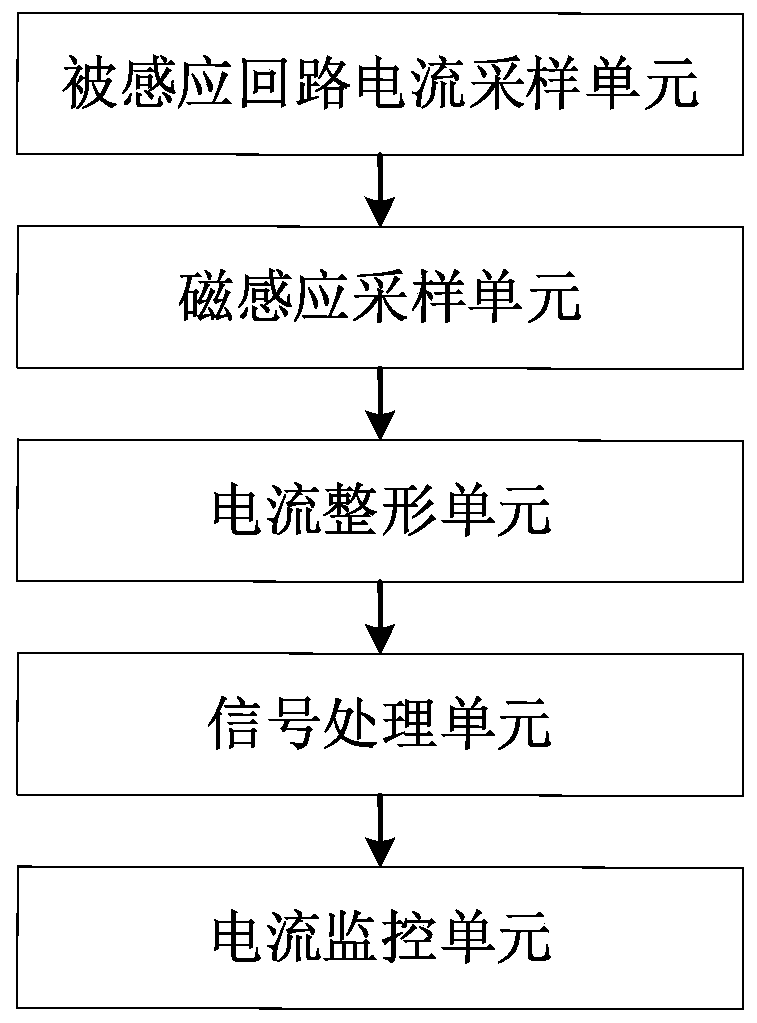

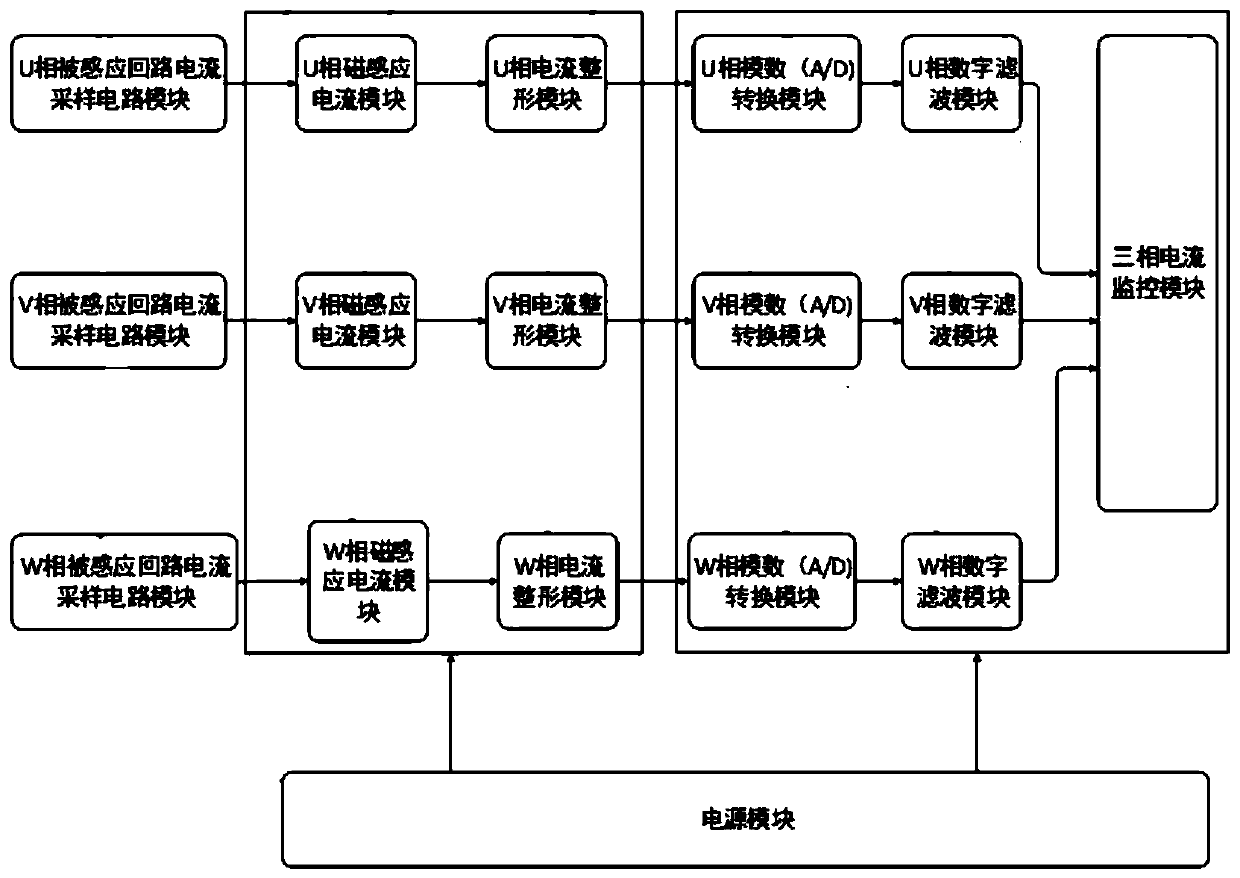

Non-contact three-phase current detection system

InactiveCN111220844AAccurate samplingStable samplingMeasurement using digital techniquesComputational physicsProcessing element

The invention discloses a non-contact type three-phase current detection system. The system comprises an induced loop current sampling unit, a magnetic induction sampling unit, a current shaping unit,a signal processing unit and a current monitoring unit; the magnetic induction sampling unit is a magnetic induction chip and is matched with the current sampling unit, and the magnetic induction sampling unit is used for inducing the three-phase current acquired by the induced loop current sampling unit; the current shaping unit is used for shaping the three-phase current sensed by the magneticinduction sampling unit; the signal processing unit is used for performing analog-to-digital conversion and filtering processing on the shaped three-phase current; and the current monitoring unit is used for verifying the three-phase current processed by the signal processing unit according to a preset current error. The non-contact three-phase current detection system provided by the invention not only is simpler in structure, but also can realize accurate and stable sampling and verification diagnosis of the three-phase current, and is better in performance.

Owner:DONGFENG MOTOR CORP HUBEI

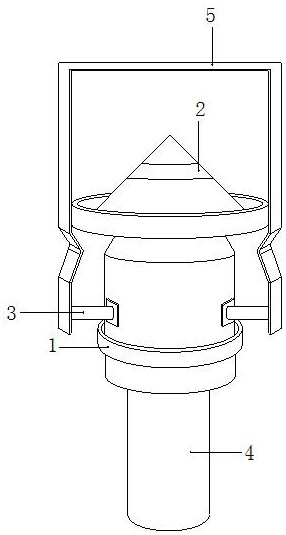

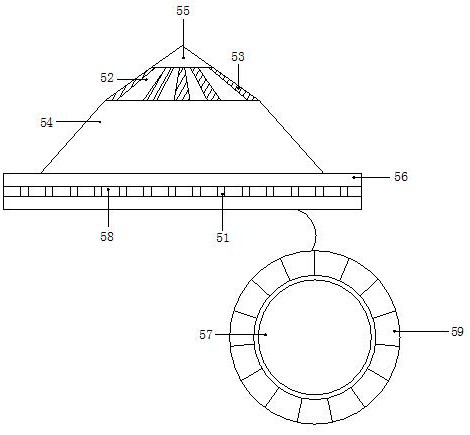

Water quality sampling equipment for environmental monitoring

PendingCN114778188ACaused by condensationEfficient conductionWithdrawing sample devicesTesting waterMoisture condensationWater vapor

The invention discloses water quality sampling equipment for environmental monitoring, which structurally comprises a clamping ring, a connecting rod, a flow guide assembly, a connecting frame and a protective device.When the water quality sampling equipment is used, an adjusting sleeve is immersed into water, water is immersed into the adjusting sleeve from the bottom end of the adjusting sleeve to submerge a sampling pipe, and the sampling pipe is blocked by the adjusting sleeve, so that sampling can be quickly and stably carried out; in the sampling process, most of upward water vapor at the bottom of the adjusting sleeve is intercepted through cooperation of the conical pipe and the ribs, a small part of water vapor vertically penetrates through the frame body and is discharged from the top cover from the top end, ventilation is smooth, it is avoided that the inner wall of the frame body is dewed due to too much water vapor, and part of water vapor is blocked by the separation rods while penetrating through the conical pipe; therefore, water vapor entering the frame body is less, and the effect of avoiding moisture condensation is indirectly enhanced.

Owner:吉林省生态环境监测中心

Geotechnical sampling device for geotechnical engineering

PendingCN112683583AAvoid mixingReduce jitterEarth drilling toolsWithdrawing sample devicesSoil scienceGeotechnical engineering

The invention discloses a geotechnical sampling device for geotechnical engineering, a vertical stand column is installed on the ground through a supporting device, a driving device drives a sampling drilling barrel to conduct rotary sampling, the sampling drilling barrel shakes with rock-soil in the sampling process, then a driving base is driven to shake, a horizontal supporting frame drives a guiding sliding block to slide up and down in the guiding sliding rail, the guiding sliding block extrudes the damping hydraulic rod in the sliding process, and the bottom of the damping hydraulic rod and the buffering piston slide in the buffering air cylinder together. Due to the fact that gas in the buffer air cylinder is extruded through sliding of the buffer piston, sliding of the guide sliding block is slowed down, shaking of the driving base and the sampling drill barrel is slowed down, the rock and soil sampling process of the sampling drill barrel is more stable, and gravel in sampled rock and soil is prevented from being mixed.

Owner:杭州环岩工程技术有限公司

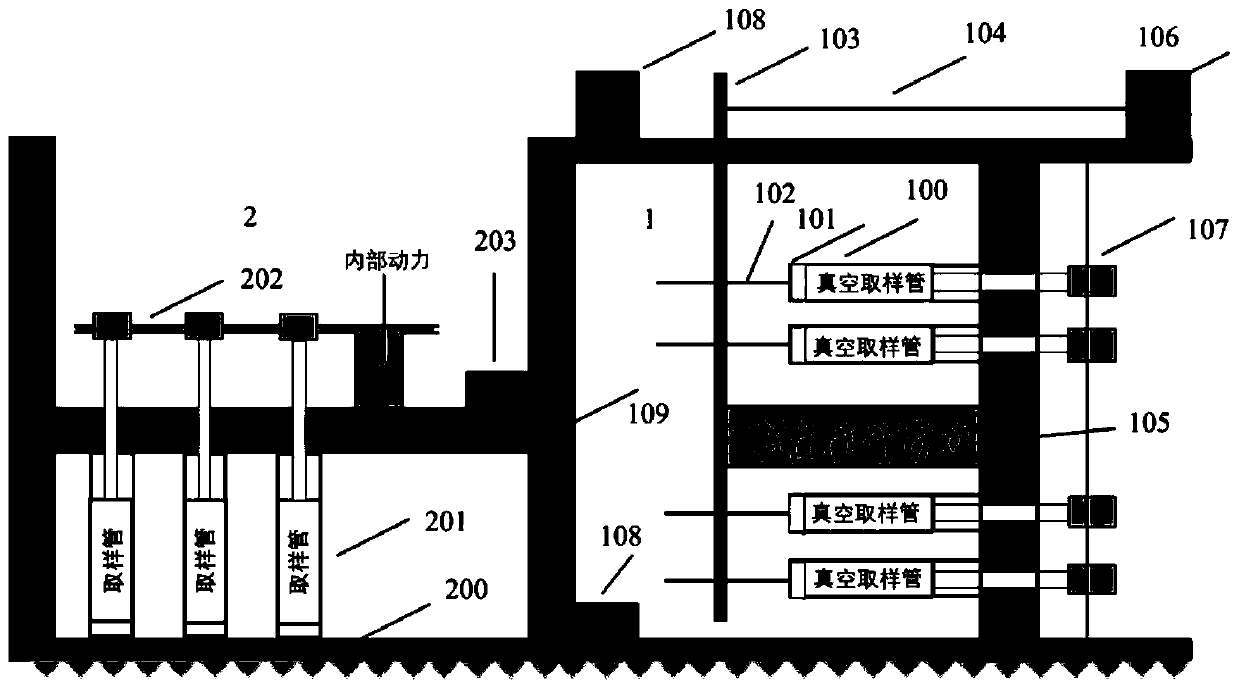

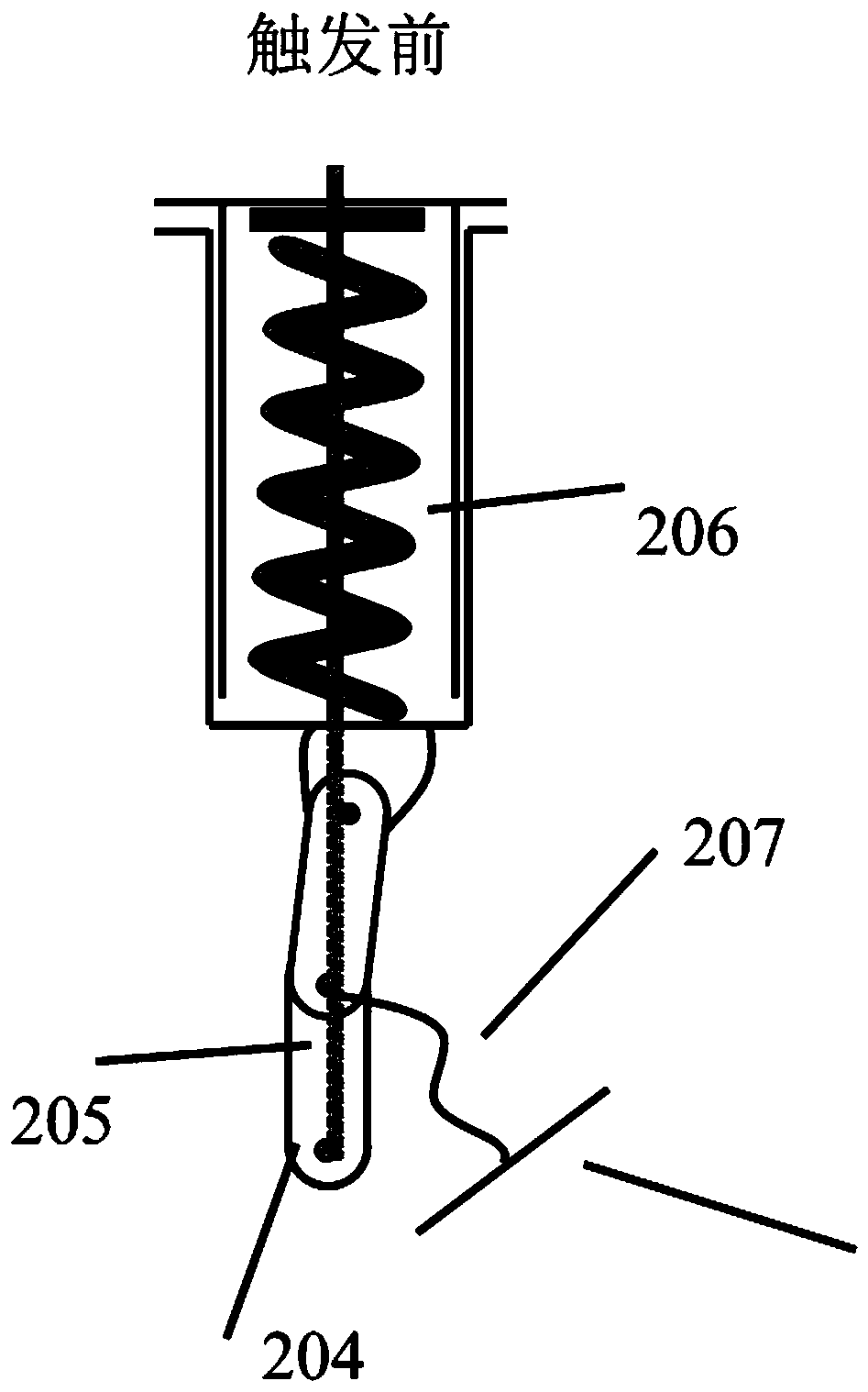

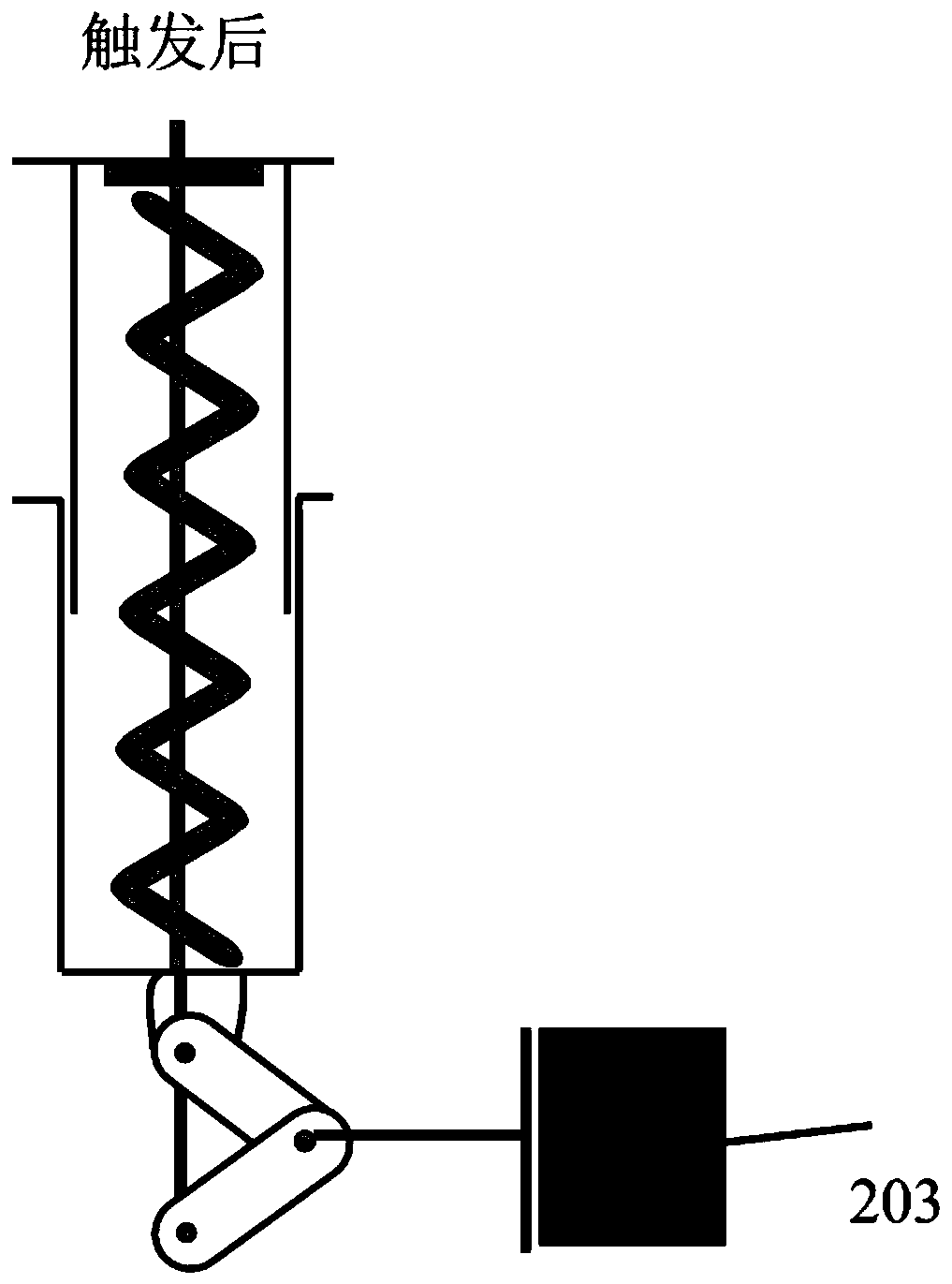

Water-sediment interface water sample sampling system and sampling method thereof

ActiveCN111189673AEnables highly automated samplingMeet the basic power requirements of samplingWithdrawing sample devicesWater samplingElectromagnet

The invention discloses a water-sediment interface water sample sampling system and a sampling method thereof. The water-sediment interface water sample sampling system comprises a surface water bodysampling device and a shallow pore water sampling device, the surface water body sampling device comprises a vacuum sampling pipe for collecting a surface water sample; a filter screen for filtering impurities is arranged at the head of the sampling pipe; a telescopic needle head is connected with the sampling pipe; the needle head is connected and fixed on a vertical iron rod; the top and the middle part of the iron rod are connected with a high-strength rubber band and a compressed spring, the tail part of the sampling pipe is provided with a plug and a wood rod for sealing and stably and vertically distributing the vacuum sampling pipe, a pair of welded electromagnets is arranged on a base and the top of the surface water body sampling device, and a rubber cylindrical mold with two openends is arranged beside the electromagnets. In combination with the mechanical automation principle, simultaneous sampling of water samples (surface water and shallow pore water) on the water-sediment interface is achieved through reasonable structural design, and the device is wide in application, high in automation degree, economical and capable of greatly saving the manual sampling cost.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com