Patents

Literature

66 results about "Product detector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A product detector is a type of demodulator used for AM and SSB signals. Rather than converting the envelope of the signal into the decoded waveform like an envelope detector, the product detector takes the product of the modulated signal and a local oscillator, hence the name. A product detector is a frequency mixer.

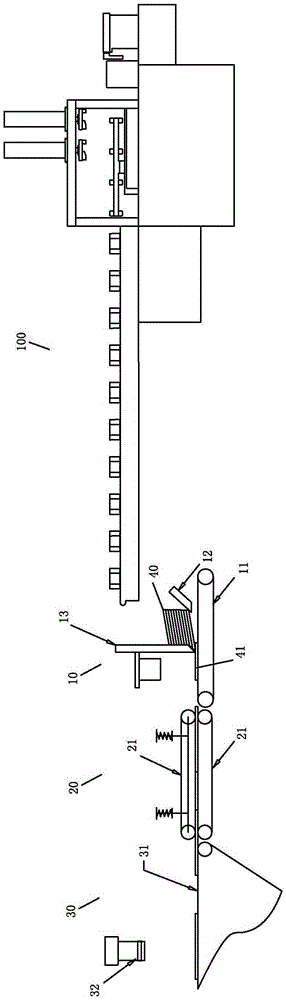

Free flow conveyance system

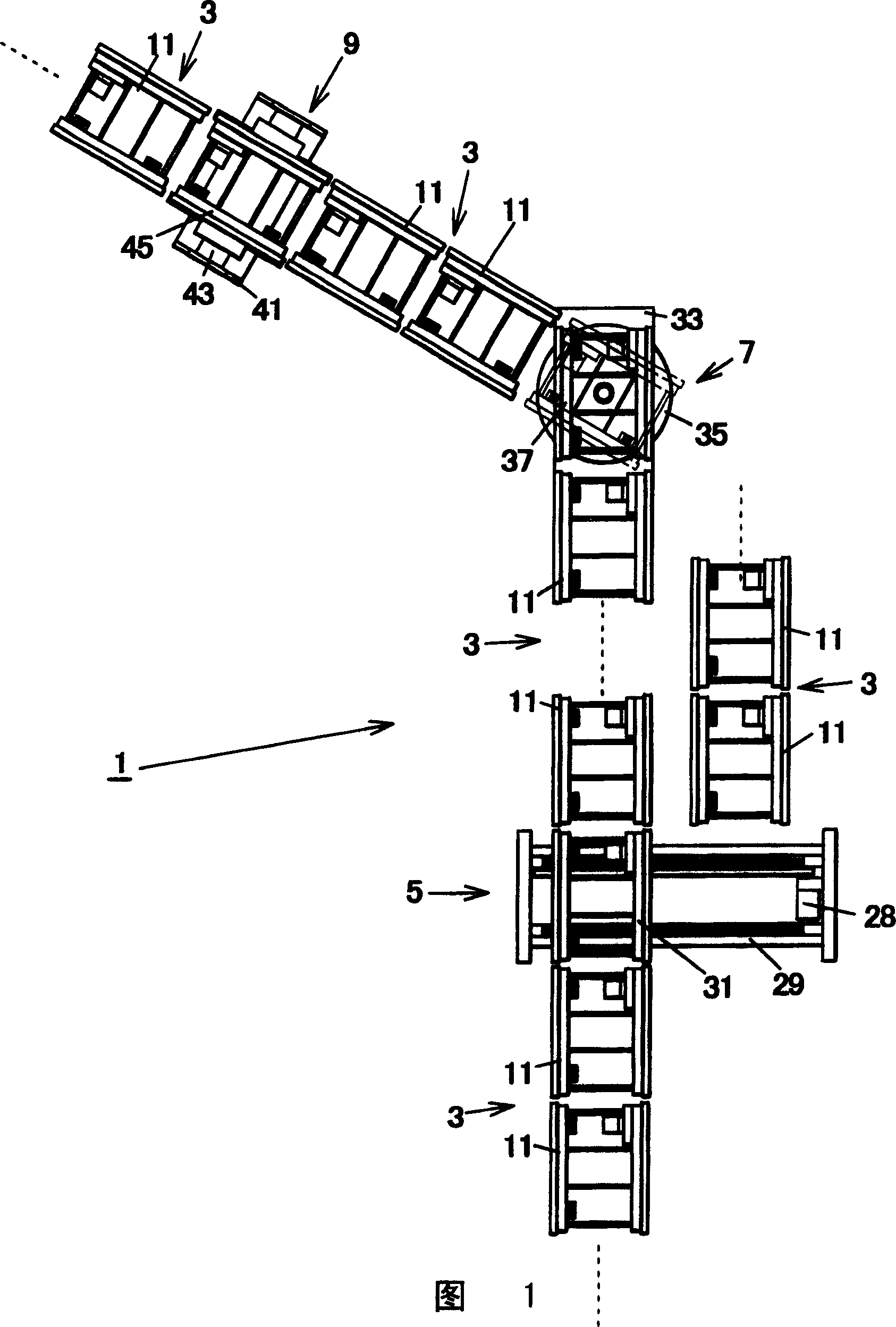

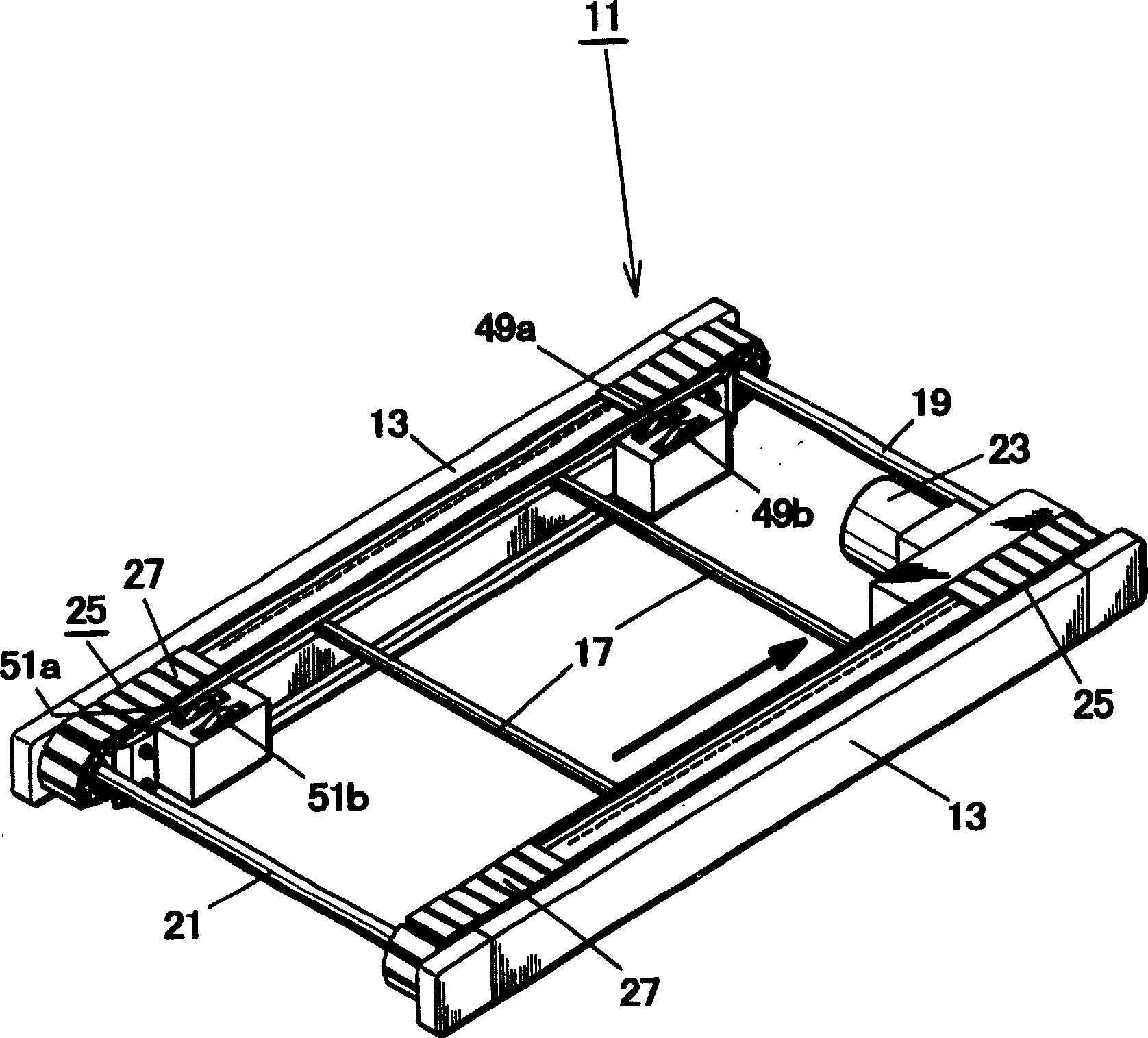

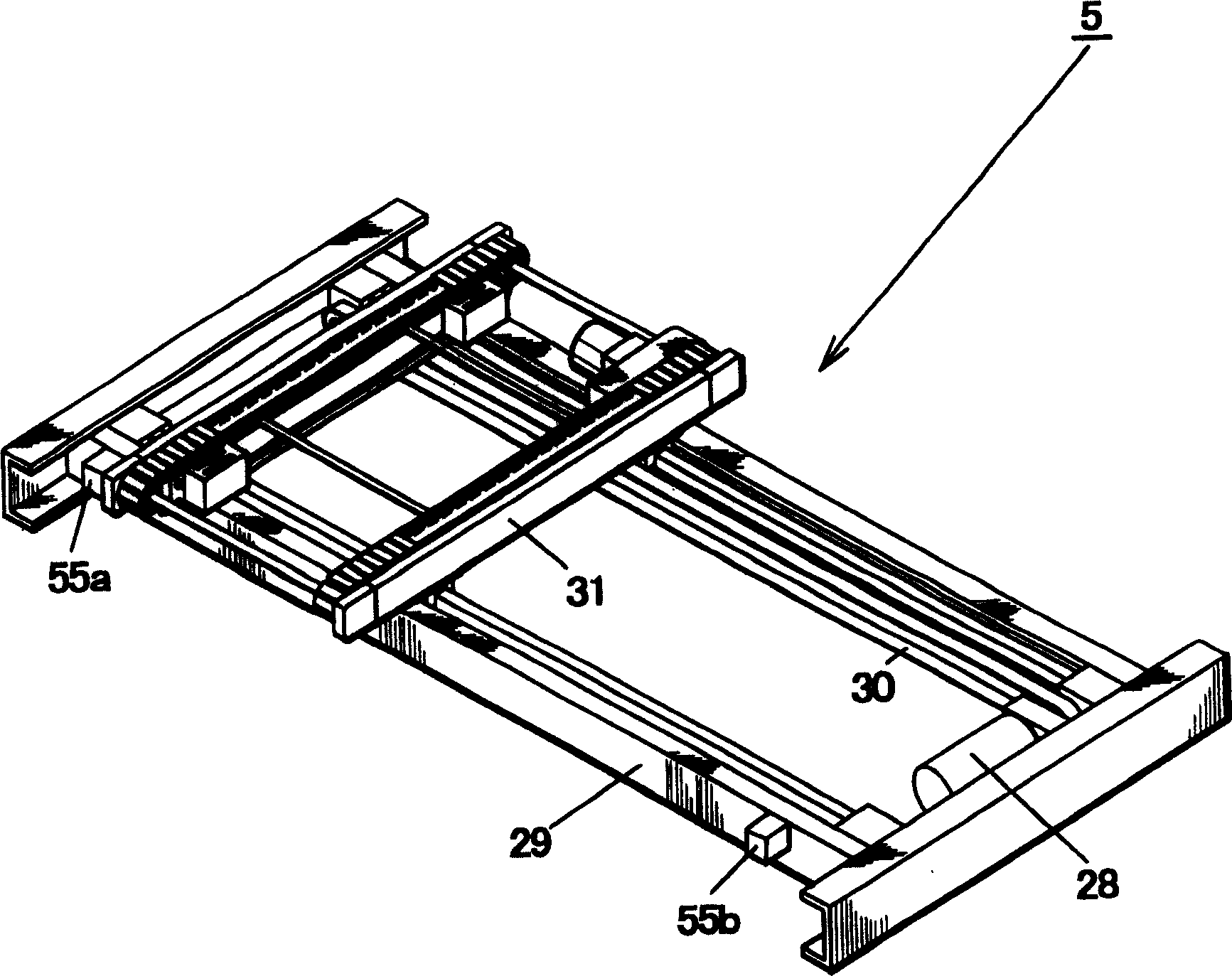

InactiveCN1706733AChanging jobs is simple and easyLow running costControl devices for conveyorsPackagingProduct detectorEngineering

By combining a plurality of linear conveying devices with at least one of the rotating conveying device, lifting conveying device and branch conveying device, the conveying path can be set arbitrarily, and each linear conveying device, rotating conveying device, lifting conveying device and branch Each unit conveying device of the conveying device performs free flow conveying control according to the product detection signals of the product detectors arranged on the input side and the output side of the conveying device.

Owner:STARTECHNO

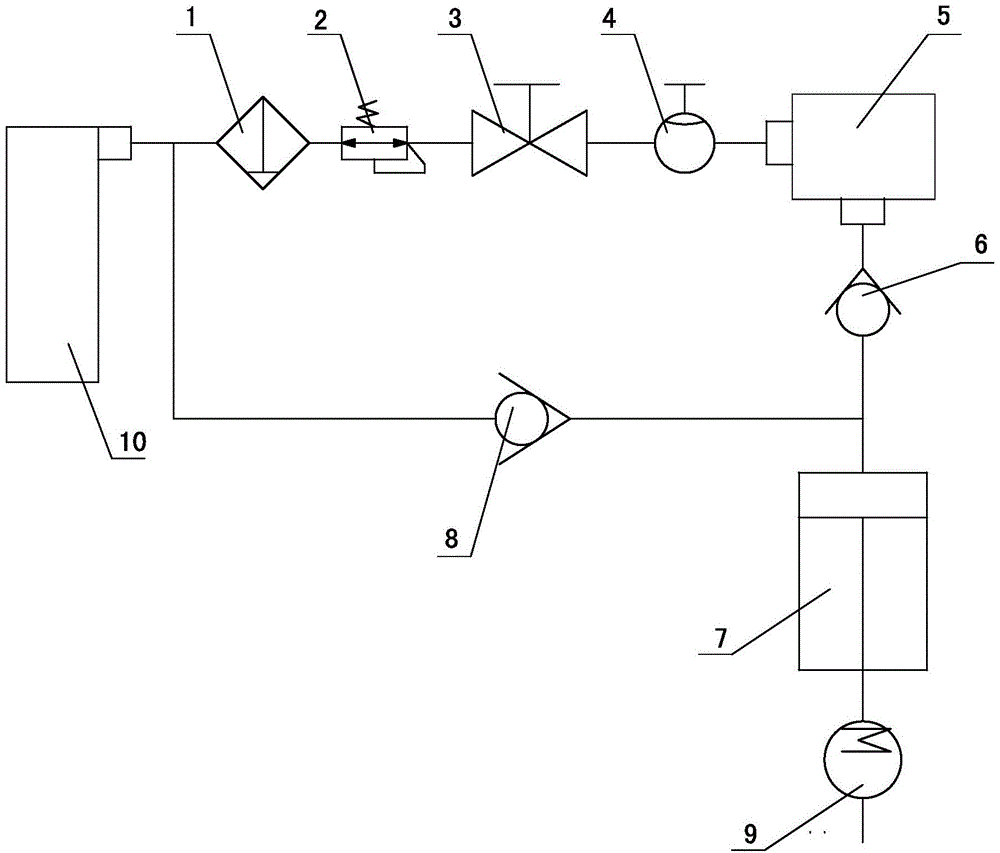

On-line monitoring sampling system for sulfur hexafluoride gas

InactiveCN103558066AAchieving zero emissionsContinuous samplingWithdrawing sample devicesDecompositionSulfur hexafluoride

The invention provides an on-line monitoring sampling system for sulfur hexafluoride gas. The on-line monitoring sampling system is characterized by comprising a filter, an electromagnetic valve, a depressurizing valve, a flow sensor, a sulfur hexafluoride decomposition product detector, a first one-way valve, a cylinder, a second one-way valve and an electric pushing rod, wherein one end of the filter is connected with electrical sulfur hexafluoride equipment, and the other end of the filter is connected with a gas inlet of the sulfur hexafluoride decomposition product detector through the electromagnetic valve, the depressurizing valve and the flow sensor in sequence; a gas outlet of the sulfur hexafluoride decomposition product detector is connected with the cylinder and the second one-way valve respectively through the first one-way valve; the other end of the second one-way valve is connected with the electrical sulfur hexafluoride equipment; a piston rod of the cylinder is fixedly connected with the electric pushing rod. According to the on-line monitoring sampling system, the high-pressure sulfur hexafluoride gas in the electrical equipment can be continuously and stably sampled, and the detection reliability of the sulfur hexafluoride decomposition product detector is ensured; after detection is finished, the sulfur hexafluoride gas can be re-filled into the equipment for cyclic utilization, so that the zero emission of tail gas is realized.

Owner:STATE GRID CORP OF CHINA +1

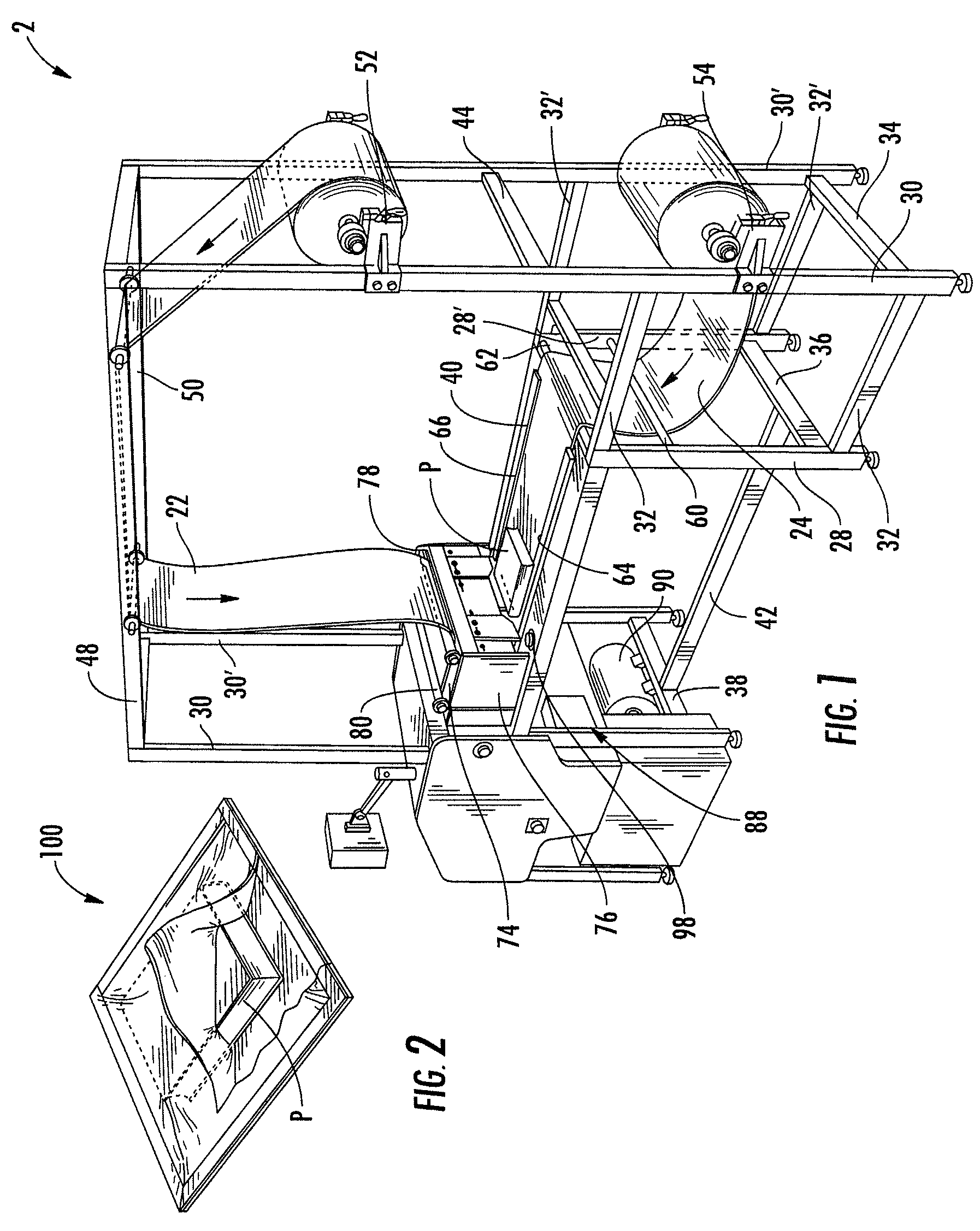

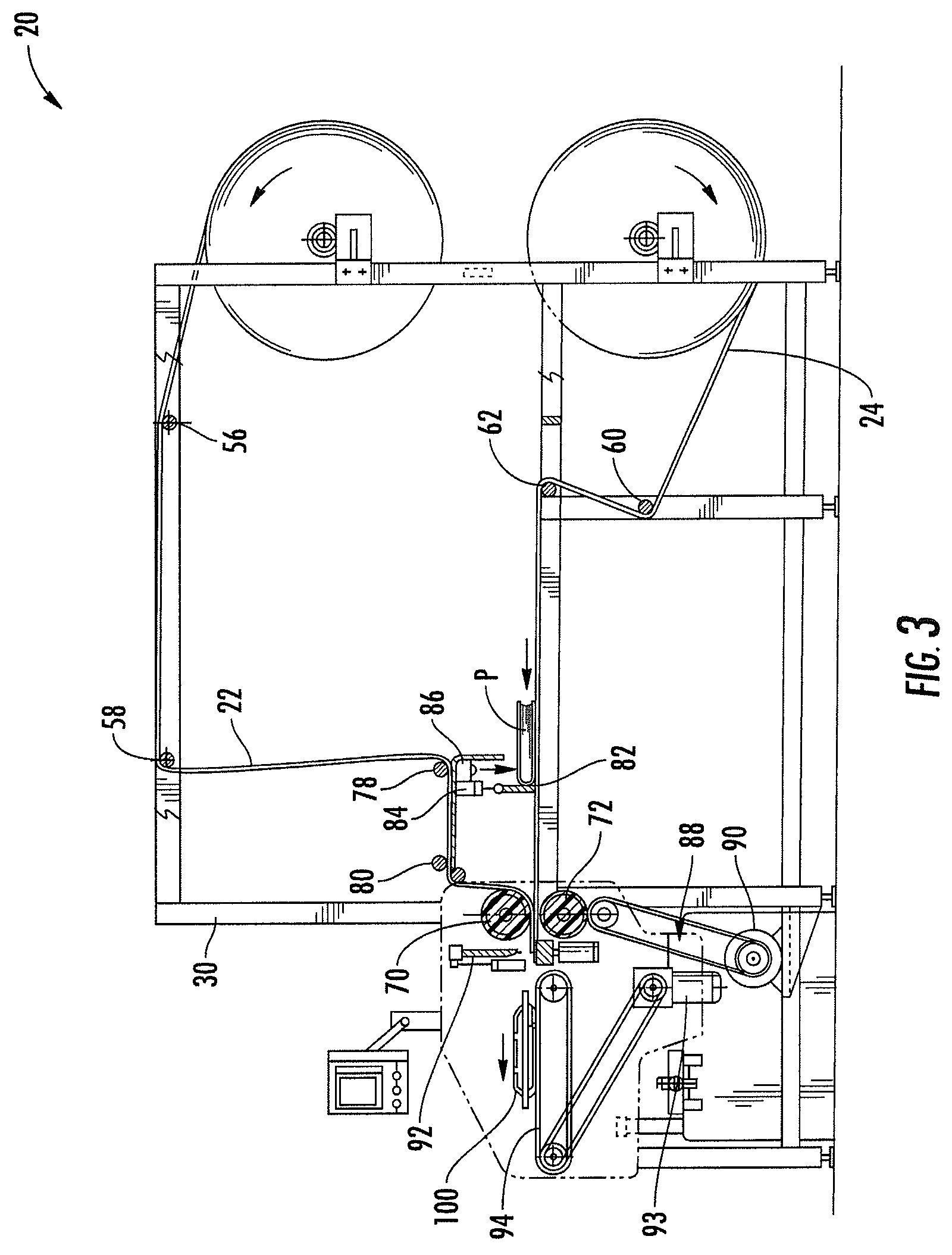

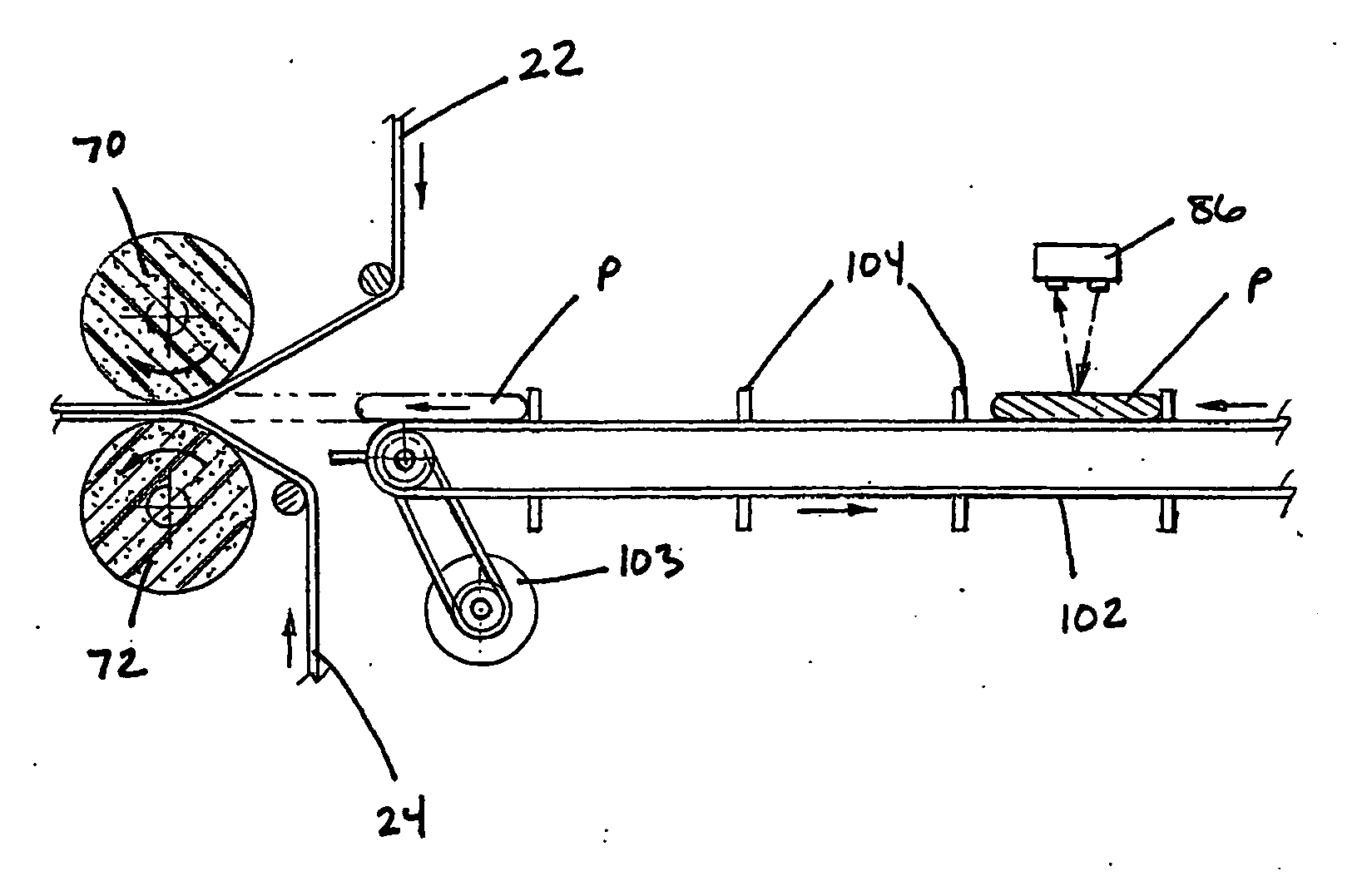

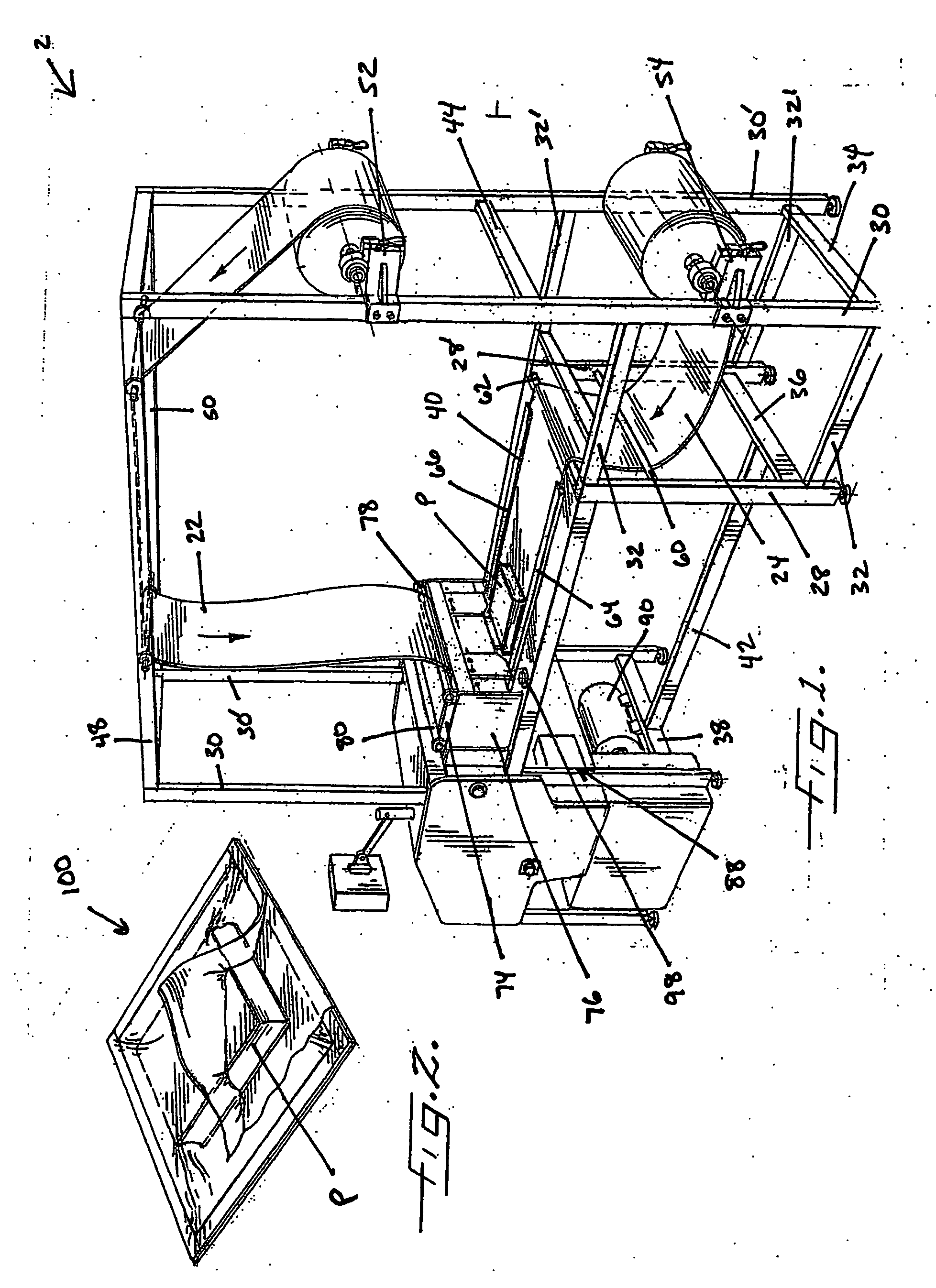

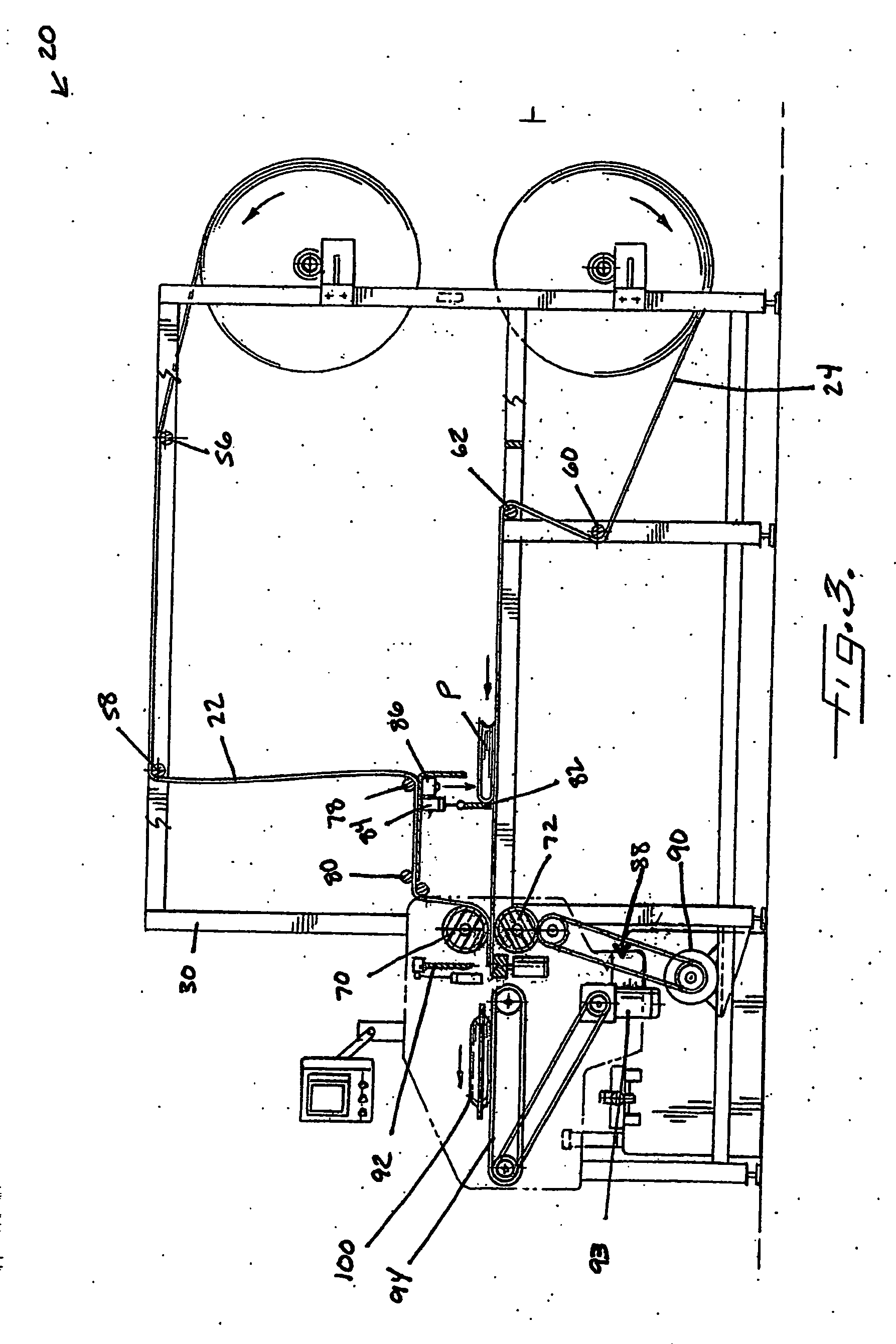

Packaging machine and method

InactiveUS7603831B2Prevents empty cycleAutomate processingPackaging automatic controlSuccessive articlesProduct detectorEngineering

Owner:SEALED AIR U S

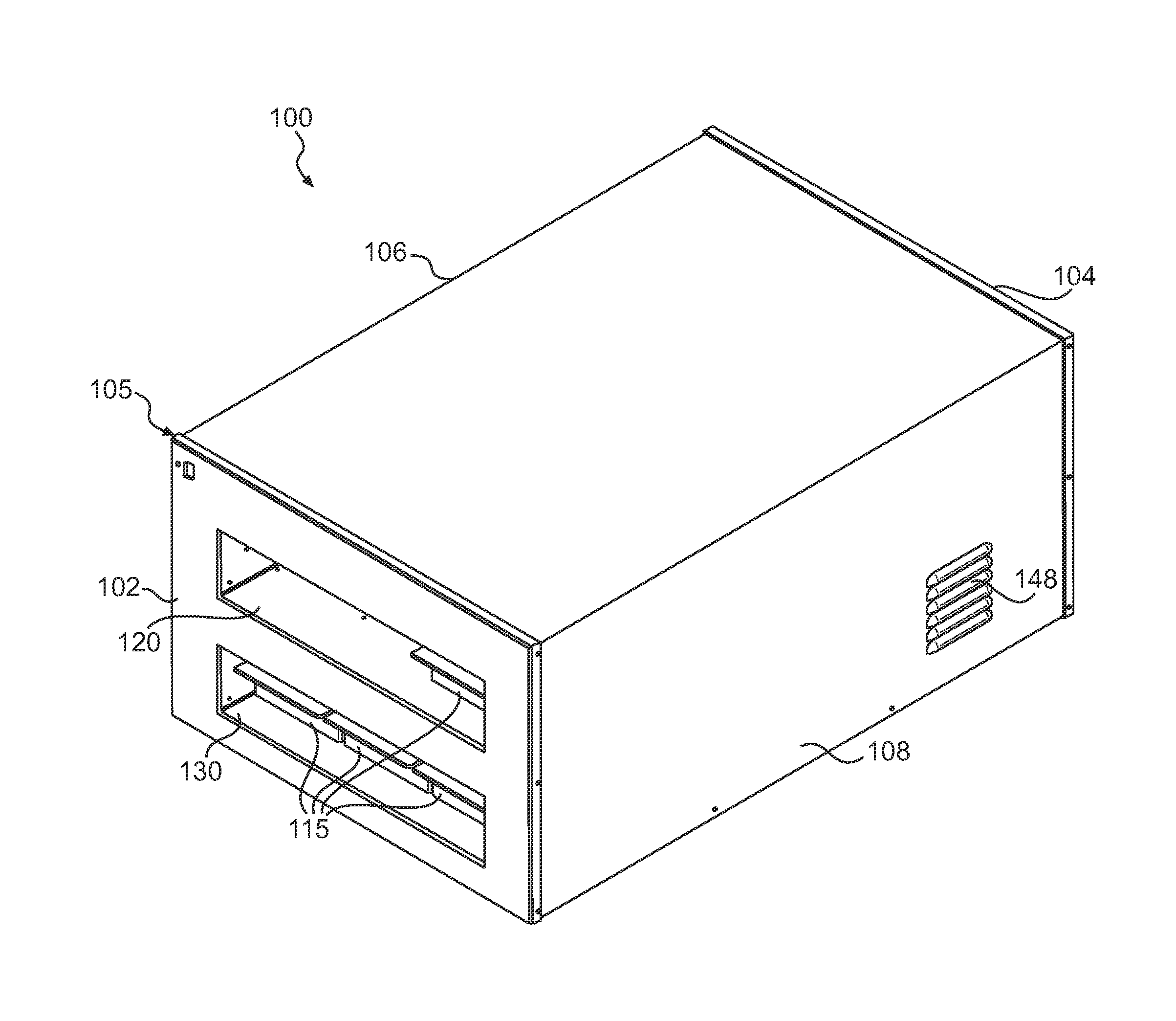

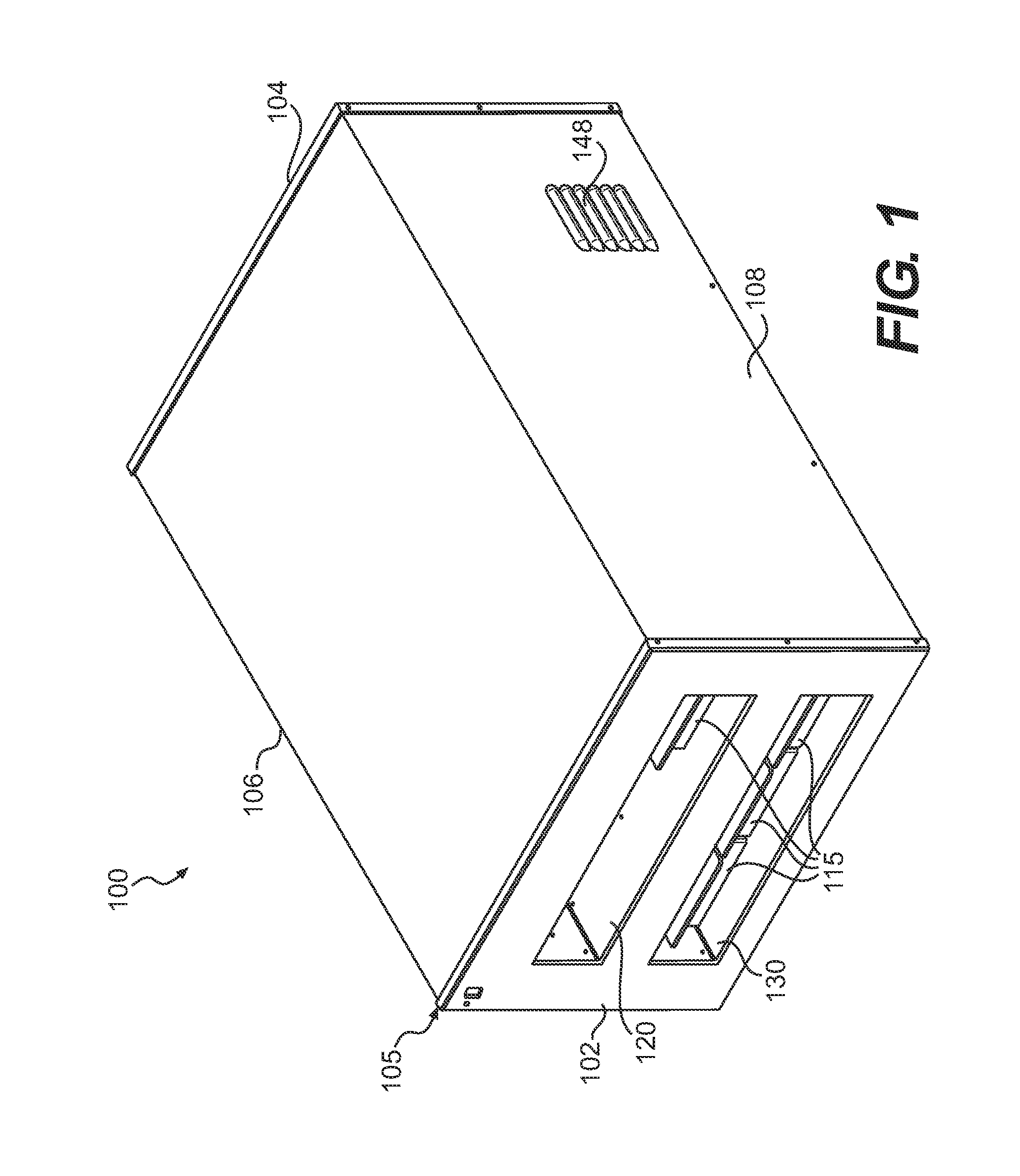

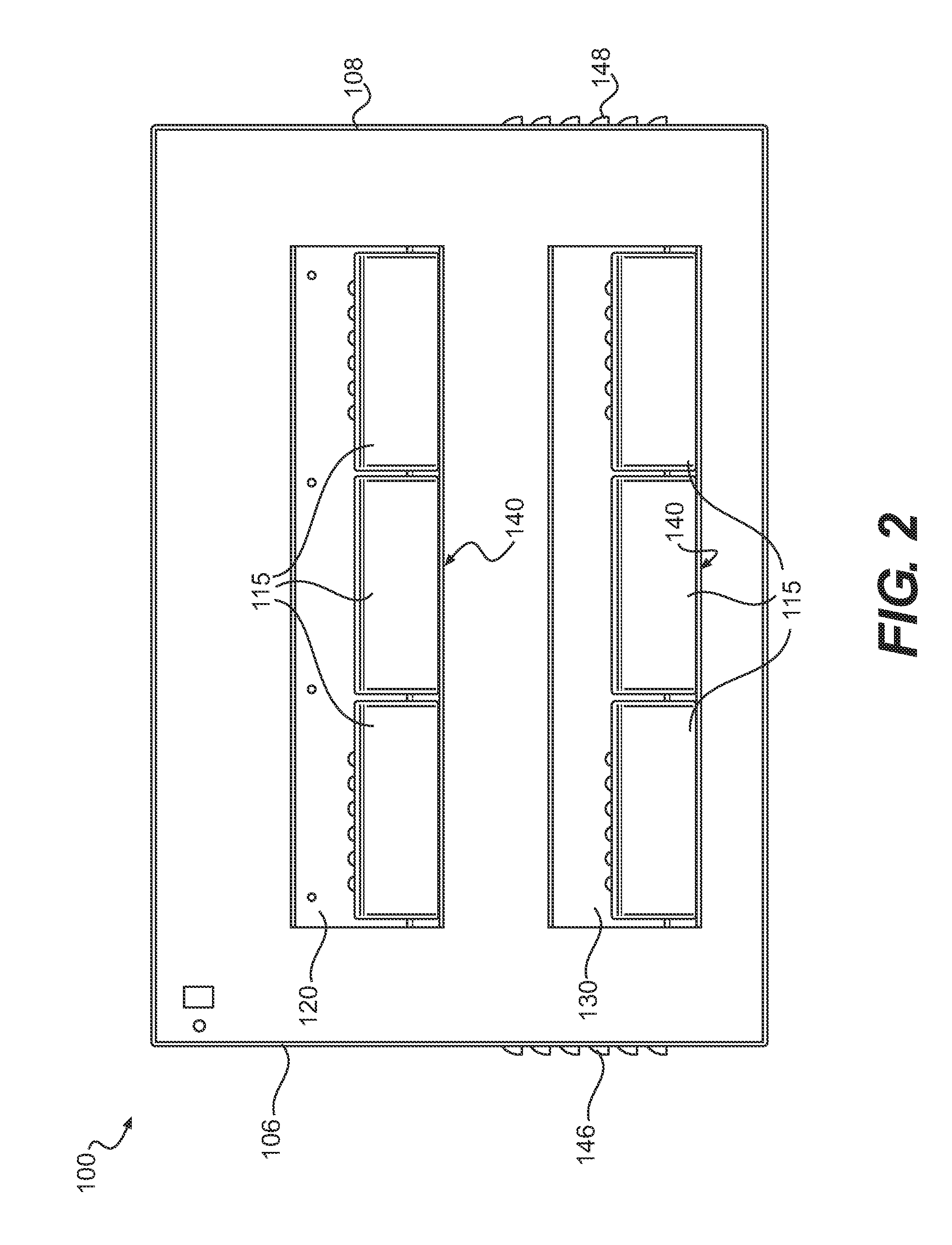

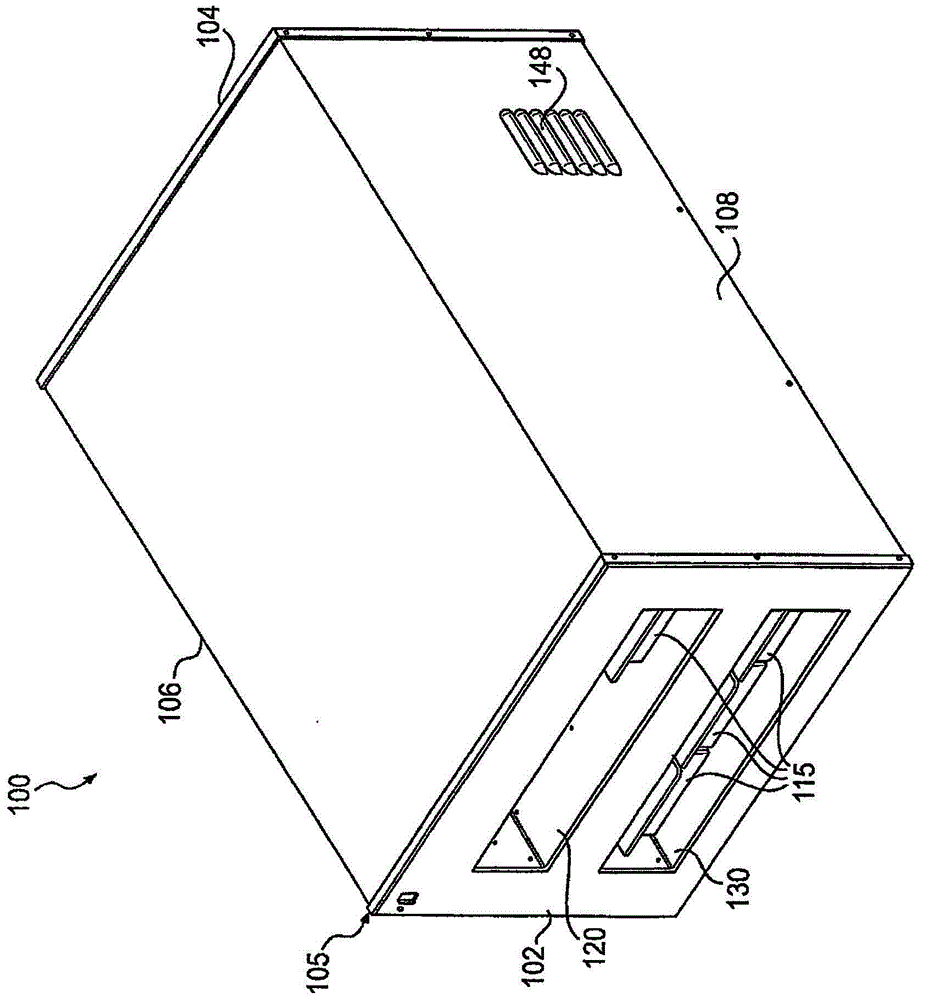

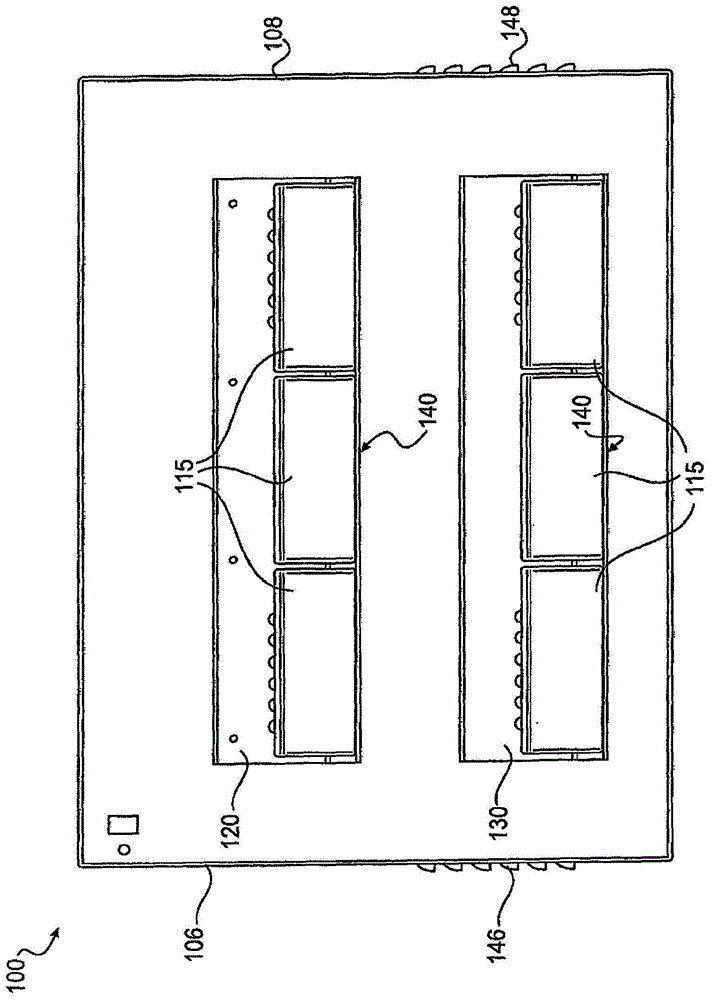

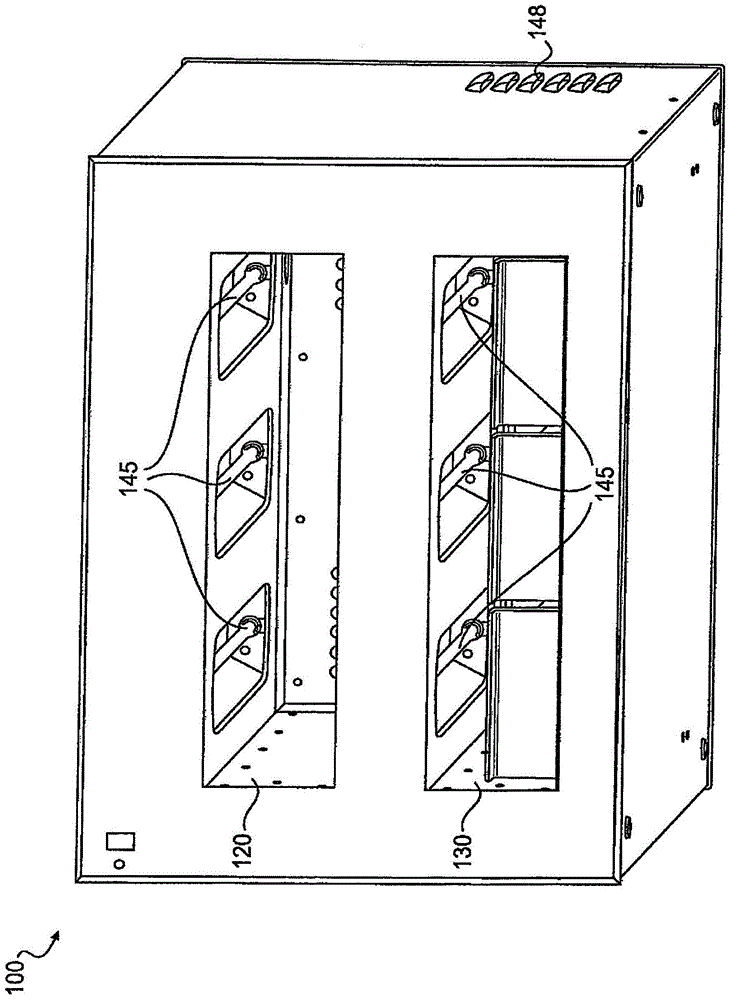

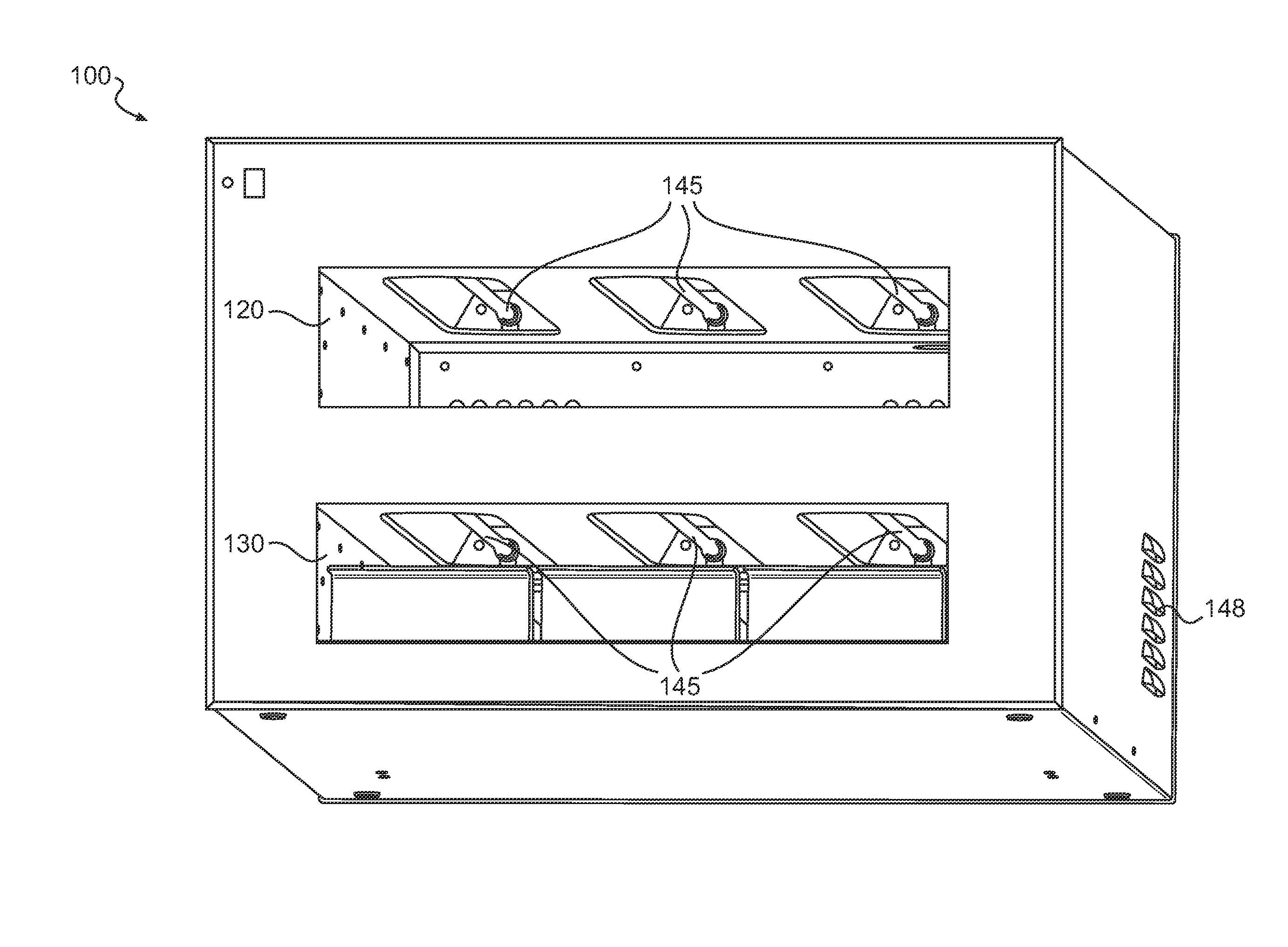

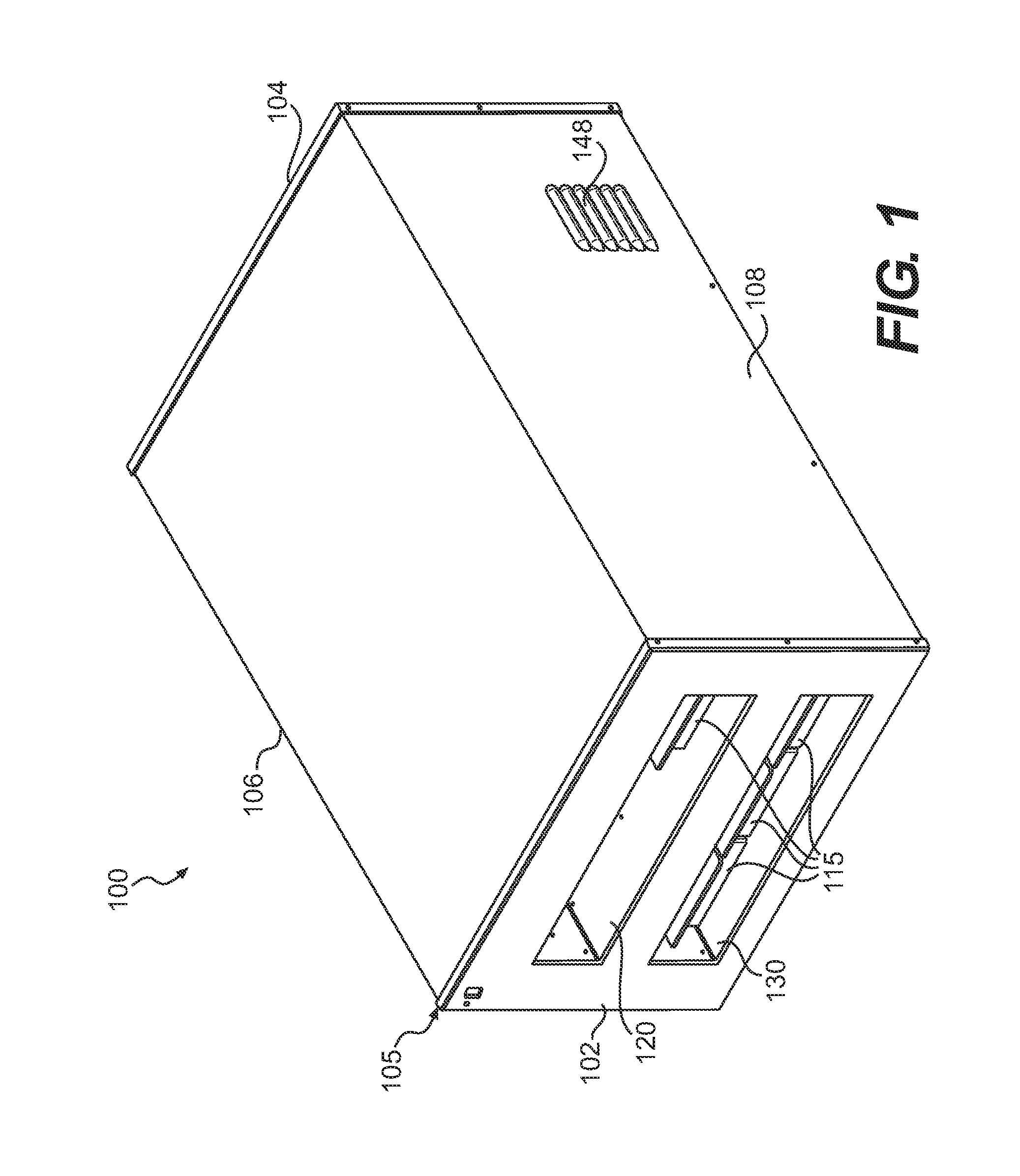

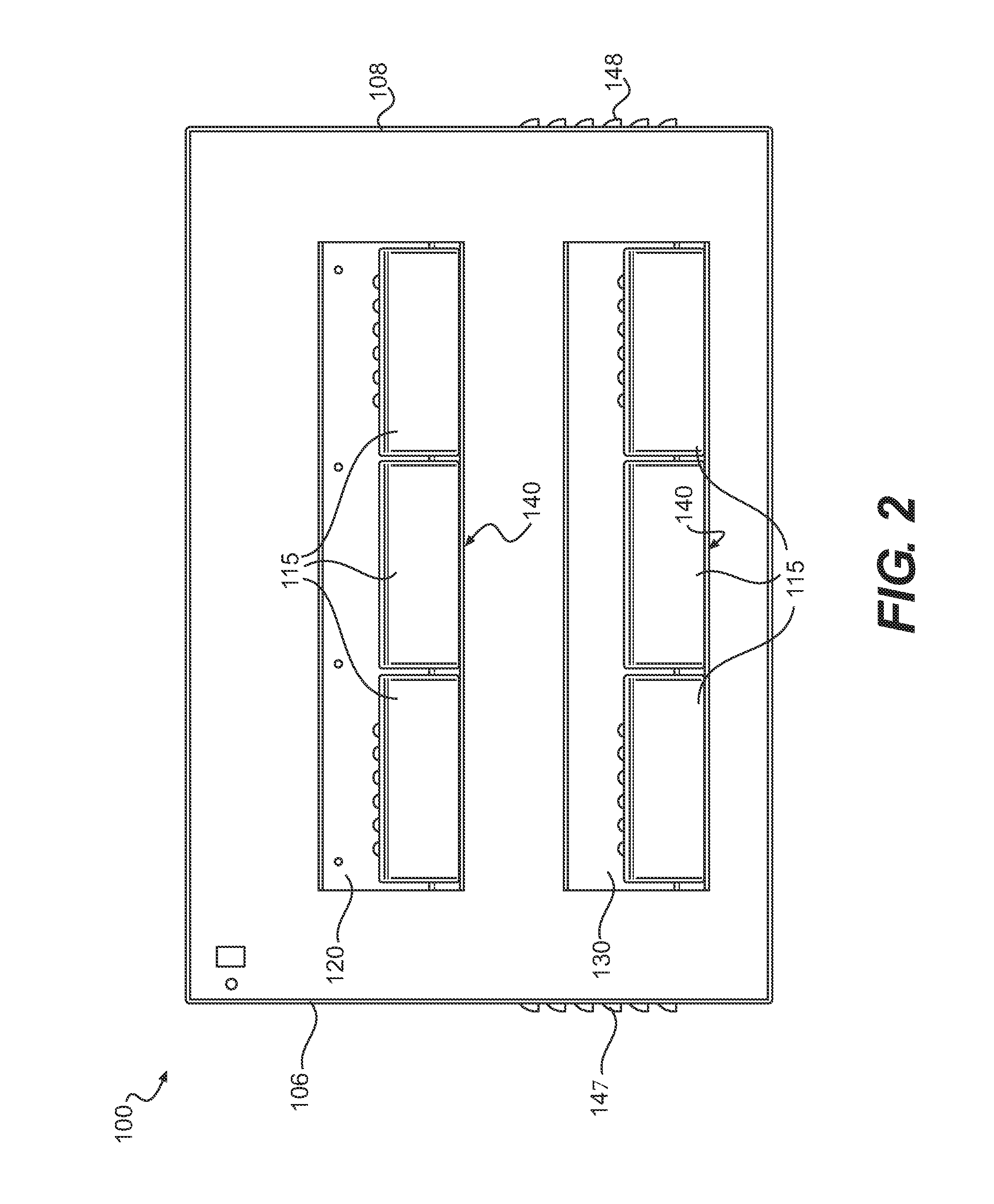

Holding cabinets, methods for controlling environmental conditions in holding cabinets, and computer-readable media storing instructions for implementing such methods

A holding cabinet includes a body defining a holding space and a holding compartment disposed within the holding space for holding a product therein. The holding cabinet further includes a heating source, a steam generator, a temperature sensor, a humidity sensor, a product detector, and a controller. The controller is configured to regulate environmental conditions of the holding compartment according to a determined setpoint, which corresponds to a predetermined temperature and relative humidity. The controller regulates such environmental conditions by acquiring the sensed air temperature, relative humidity, and the detected type of product, and activating and deactivating the heating source and the steam generator in accordance with the acquired air temperature, relative humidity, and the determined setpoint corresponding to the type of product detected and a holding time of the product, to maintain the air temperature and the relative humidity within a predetermined range based on the determined setpoint.

Owner:HENNY PENNY CORP

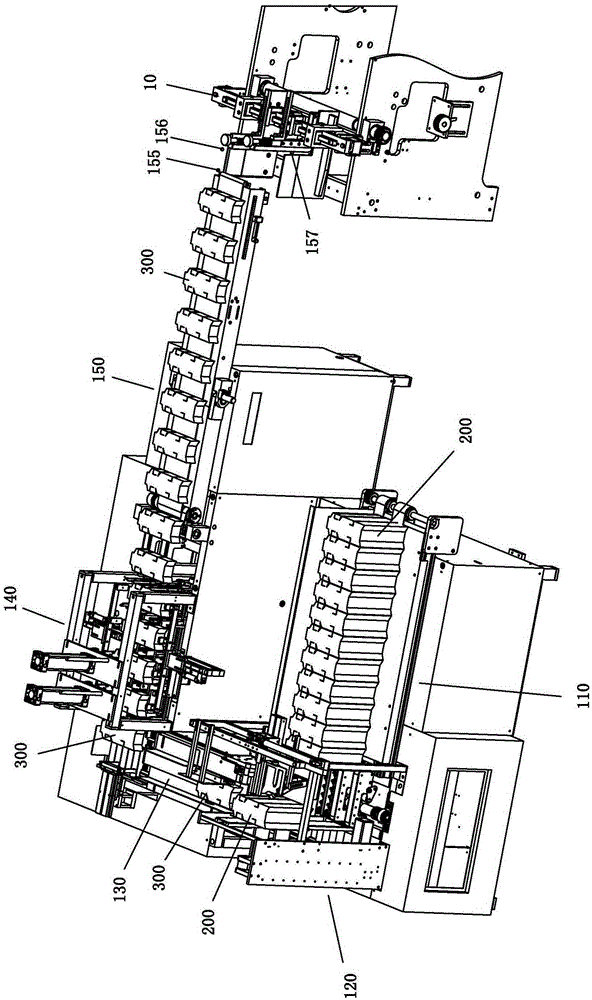

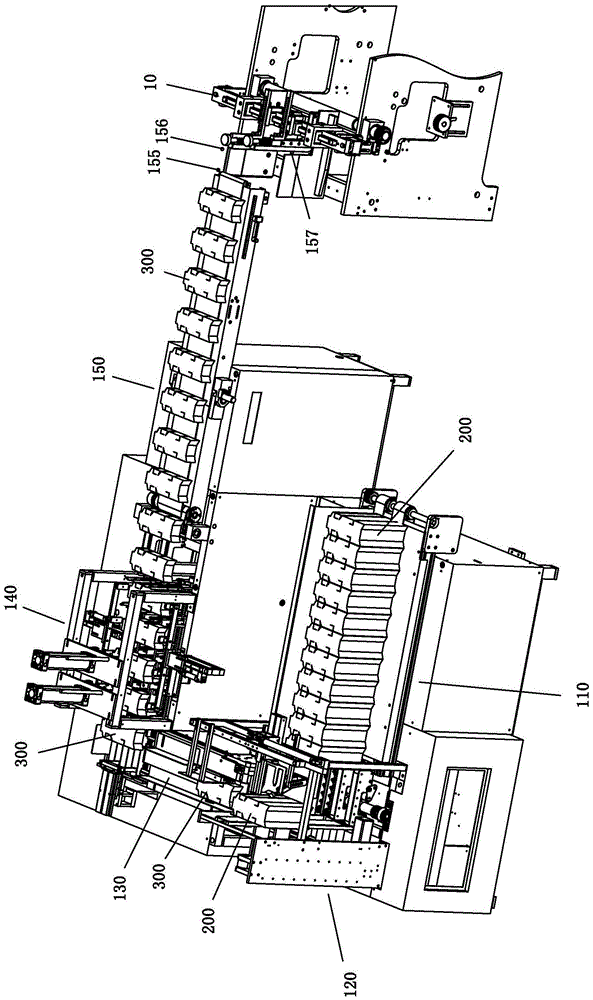

Printed-product detector with printed product in-stack collecting counting device, and operating method thereof

ActiveCN102502325AReduce in quantityAccurate countPile receiversArticle deliveryWaste productPulp and paper industry

The invention relates to a printed-product detector with a printed product in-stack collecting counting device. The printed-product detector comprises a paper feeding part, a detecting part, an in-stack collecting counting part and a waste collecting part, wherein the output end of the paper feeding part is connected with the input end of the detecting part; the output end of the detecting member is connected with the input end of the in-stack collecting counting part; and the in-stack collecting counting part comprises a rejecting cutter, an air blowing device, a layered collection part, a staking part, a stack conveying part and a waste collecting part. An operating method of the printed-product detector comprises the following steps of: conveying printed products to the detecting part for imaging comparison through the paper feeding part pieces by pieces; conveying the printed products to the in-stack collecting counting part for rejecting unqualified printed products and conveying the qualified printed products; conveying the qualified printed products to a first-layer collection part in a parallel manner; lifting the stacking part to a second-layer collecting part after the collection number of the stacking part is up to a preset value; and sequentially carrying out the next-layer stacking operation. The operating method of the printed-product detector, disclosed by the invention, has the advantages of capability of suitably detecting printed-product detectors with high speed, accuracy on counting, direct stacking collection without manual arrangement, and reduced labor number and cost; and in addition, the printed-product detector with the printed product in-stack collecting counting device, disclosed by the invention, has the advantage of simple and convenient combination due to a modular combination.

Owner:MASTERWORK GROUP CO LTD

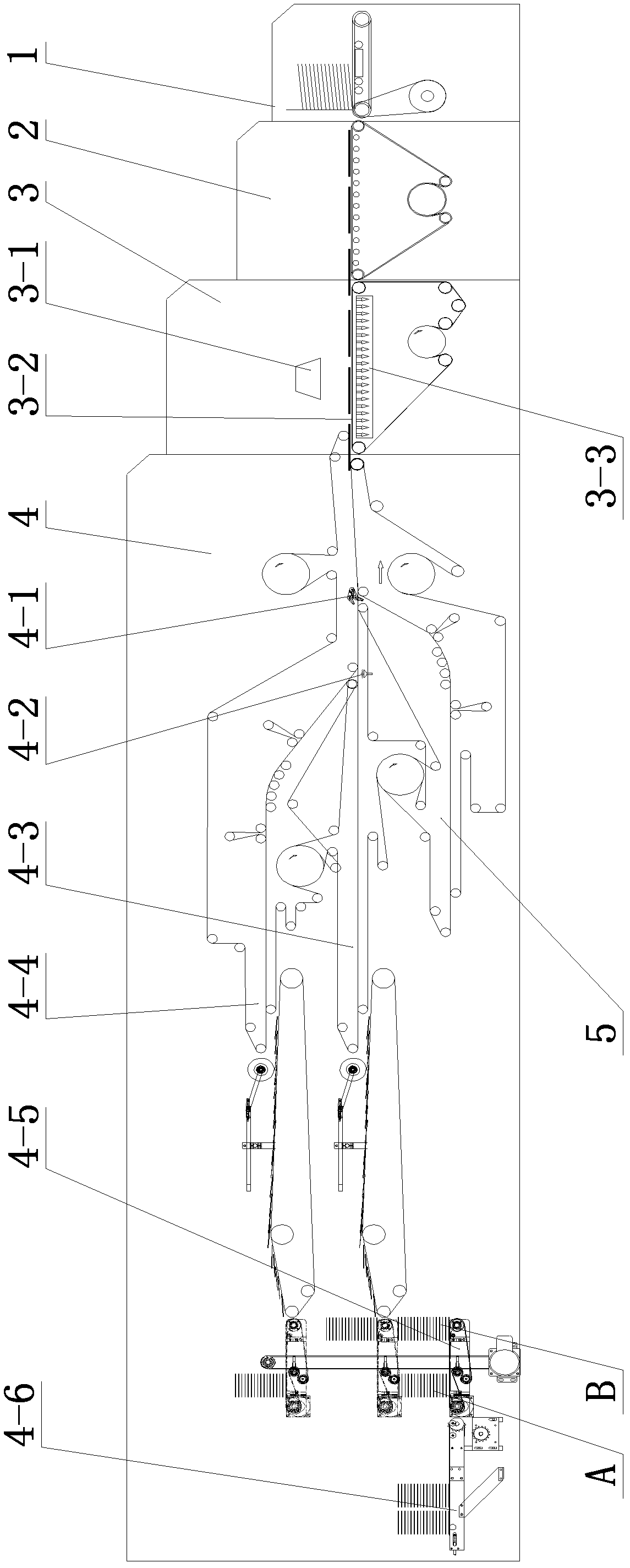

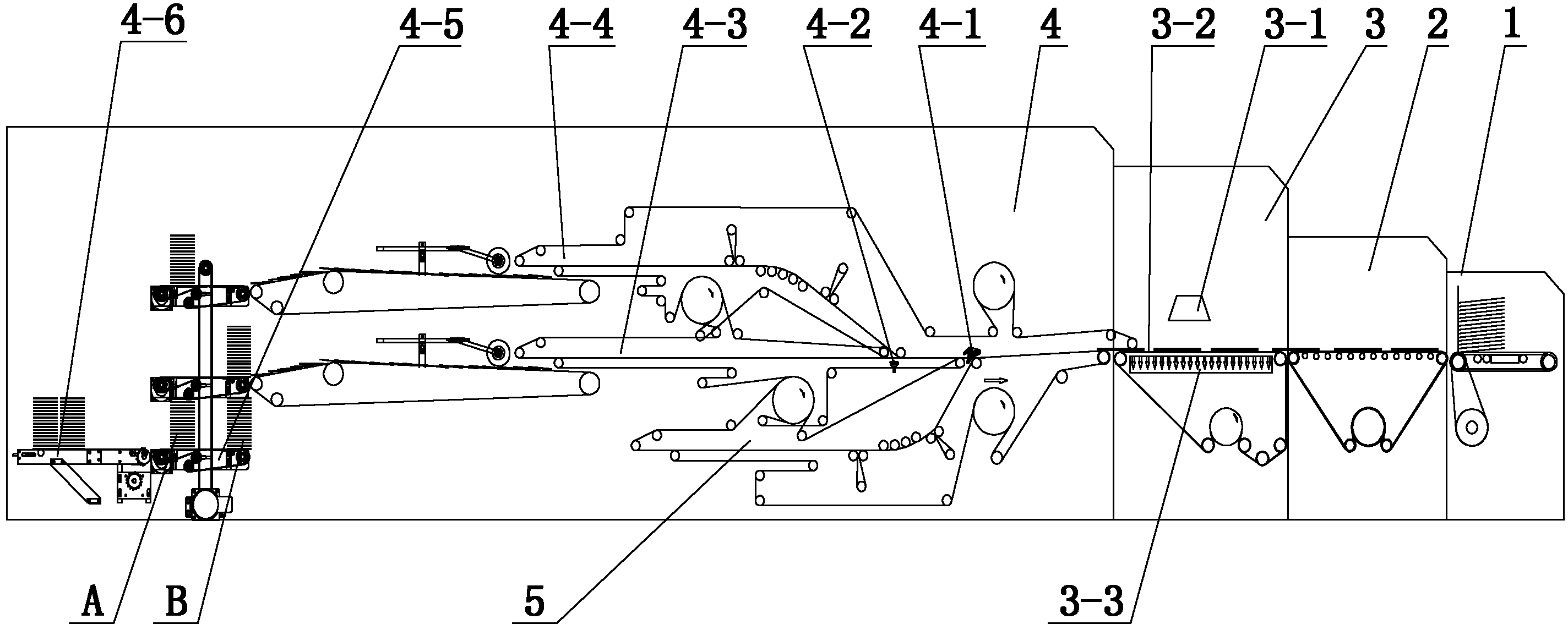

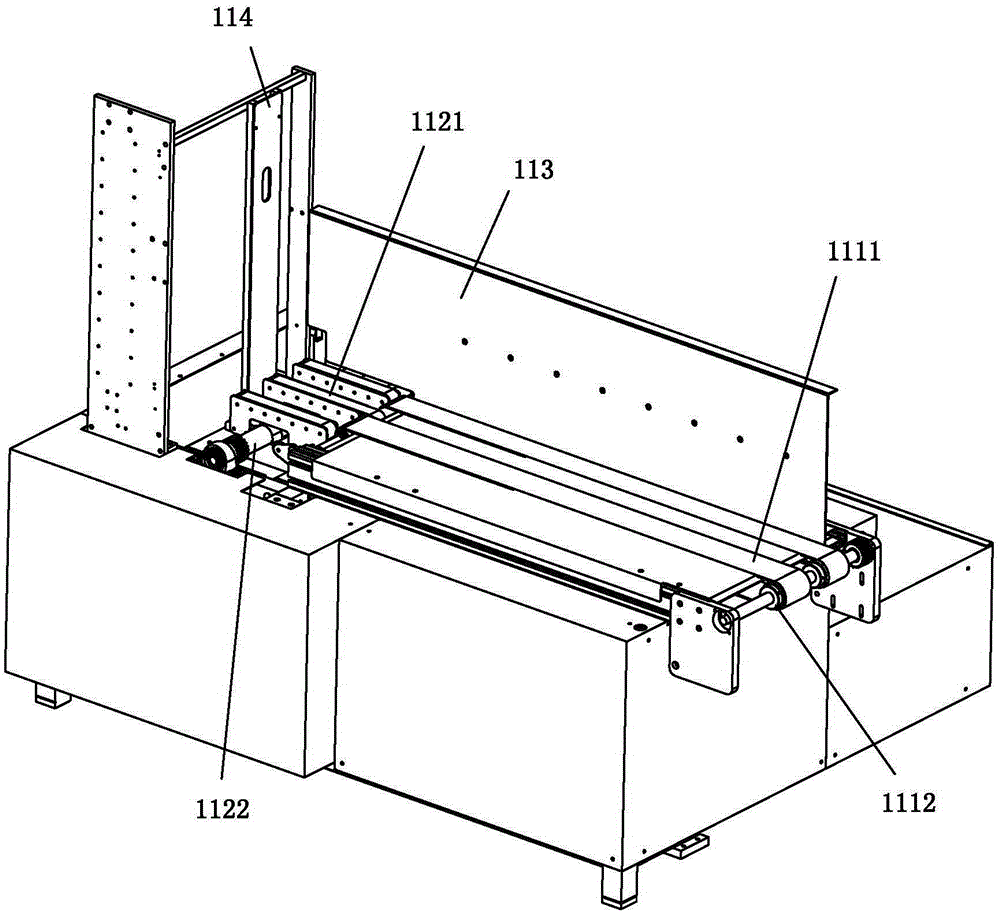

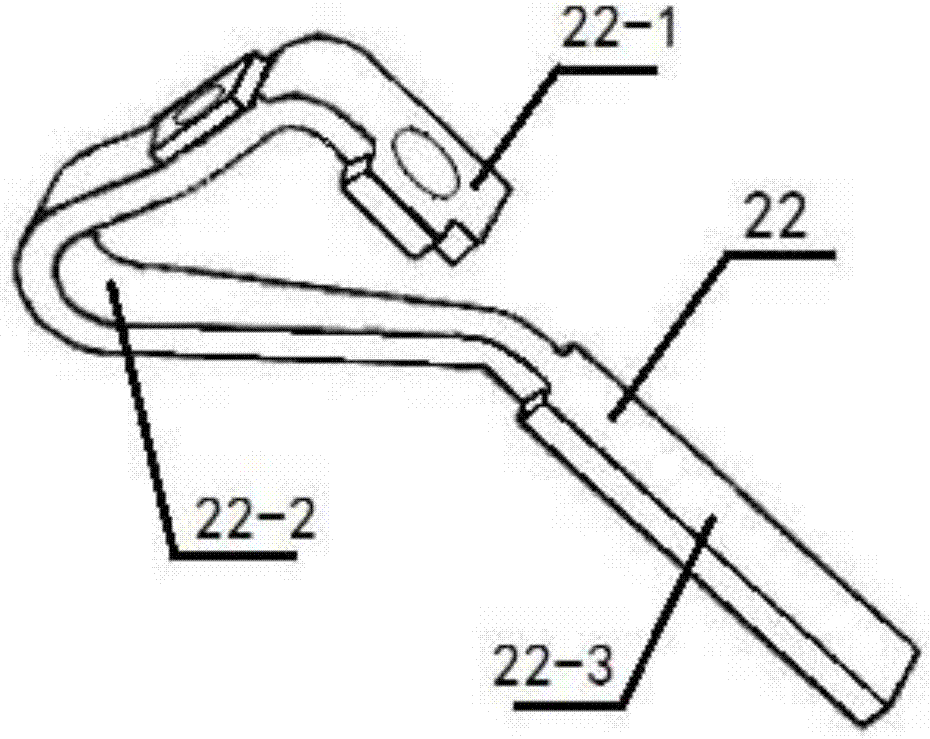

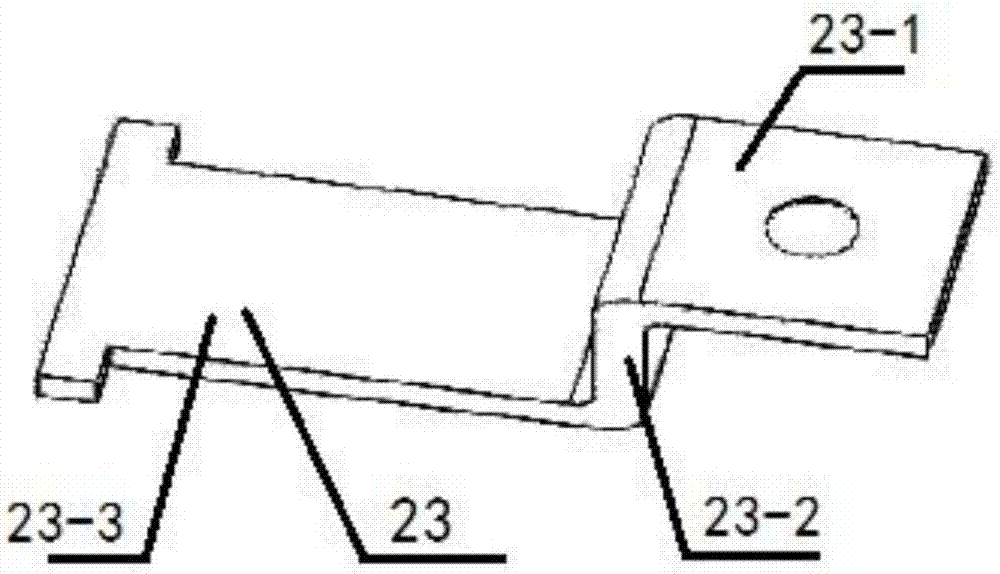

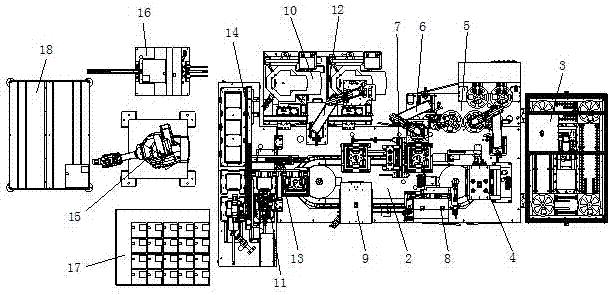

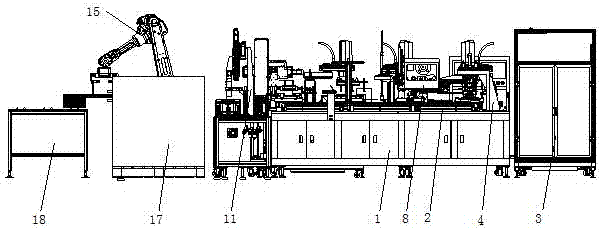

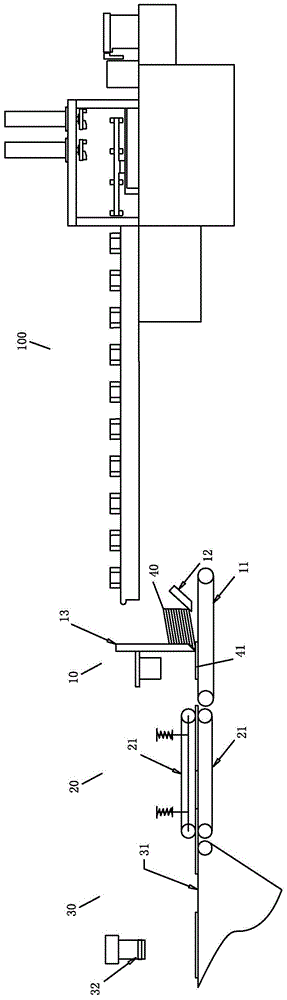

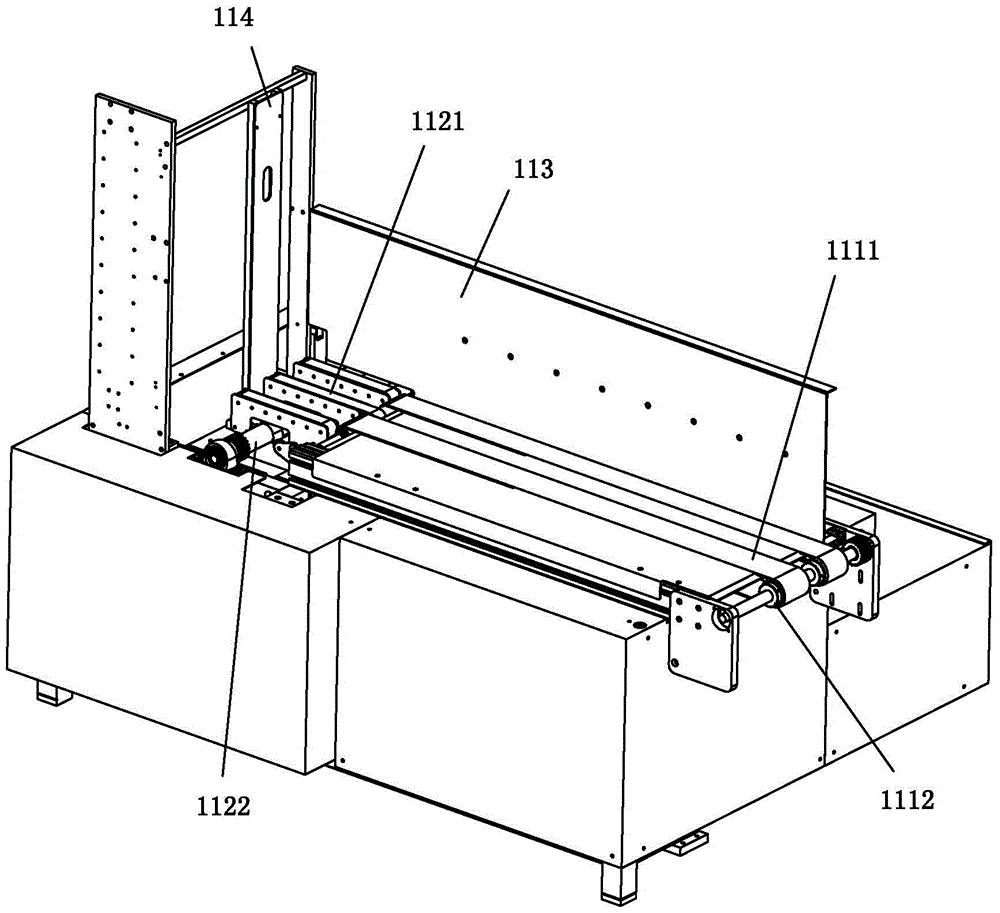

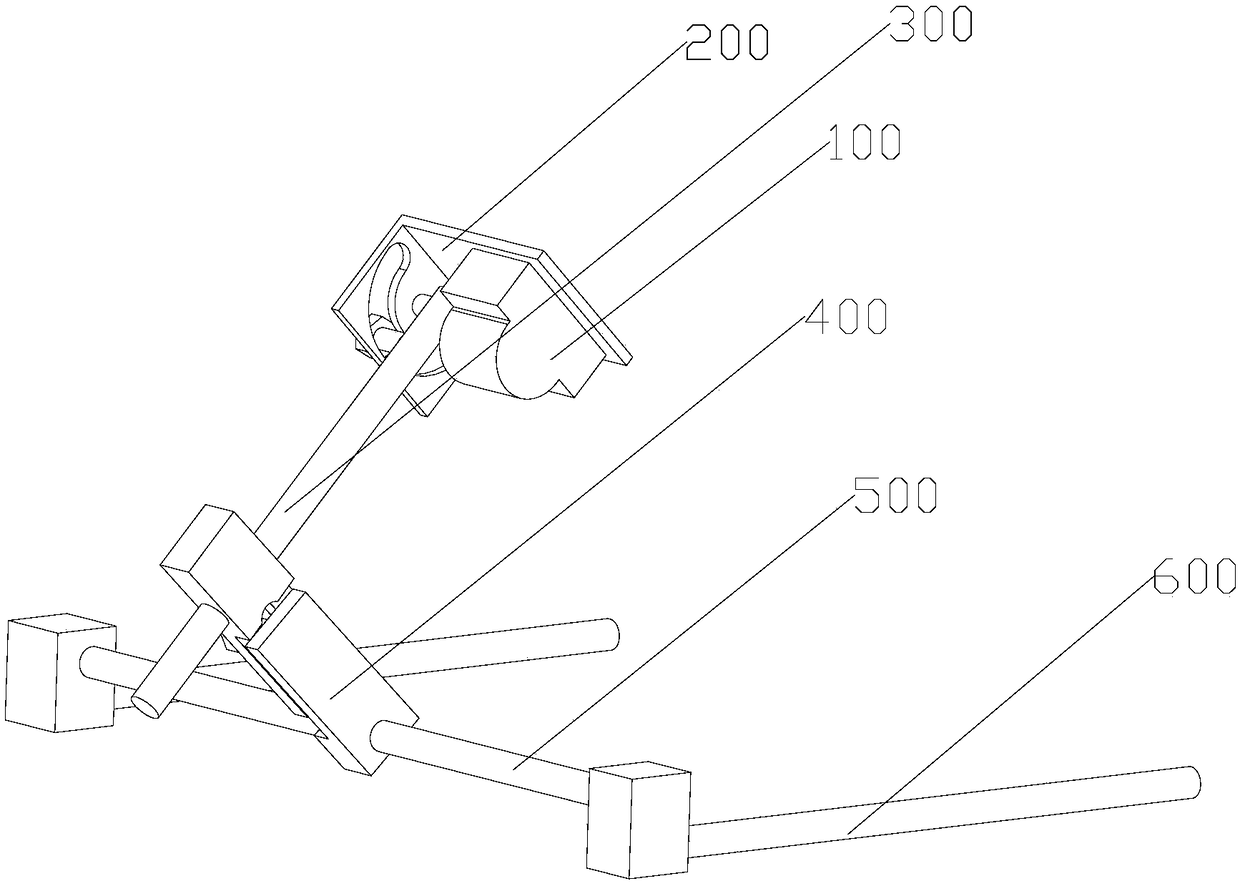

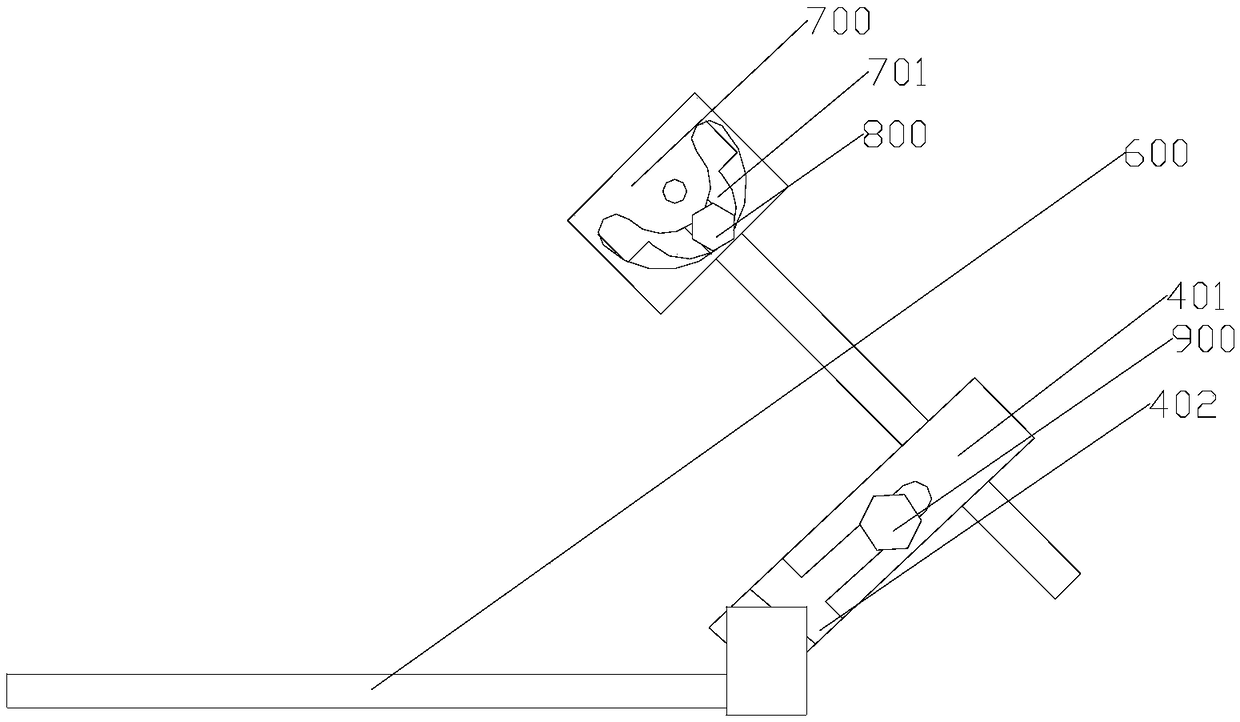

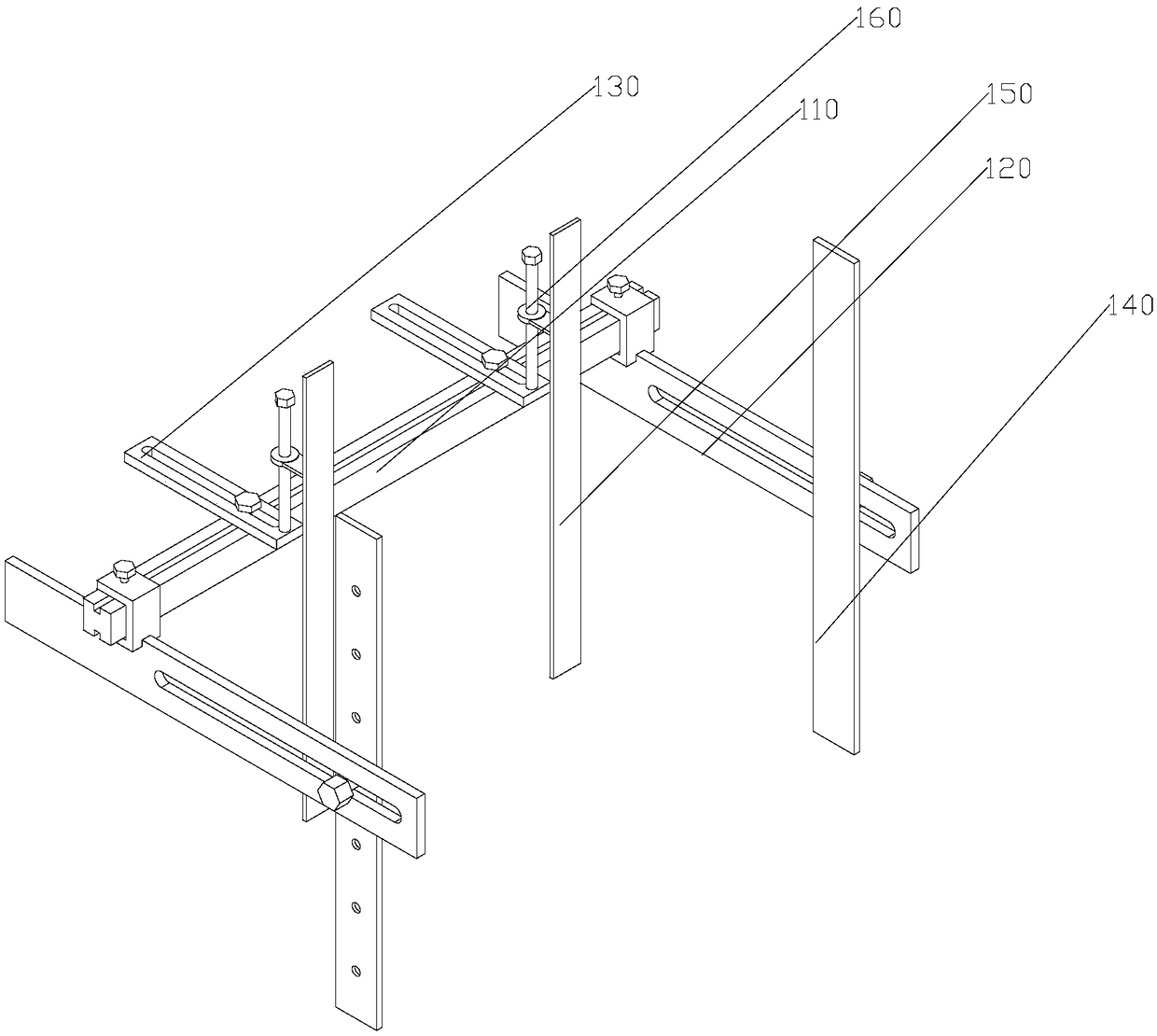

Paper unfolding and loading machine for product detector

ActiveCN105293156AAvoid deformationPrevent being scratchedArticle deliveryProduct detectorPulp and paper industry

The invention discloses a paper unfolding and loading machine for a product detector. The machine comprises a stack piling and paper loading mechanism used for piling up a plurality of thick printing products stacks and conveying the thick printing product stacks, wherein the output end of the stack piling and paper loading mechanism is corresponding to the input end of a lifting and stack dividing mechanism; the output end of the lifting and stack dividing mechanism is corresponding to the input end of a small stack conveying mechanism, wherein the lifting and stack dividing mechanism is used for dividing each thick printing product stack into a plurality of thin printing product stacks as well as conveying out the thin printing product stacks; the output end of the small stack conveying mechanism is corresponding to the input end of a paper unfolding mechanism, wherein the small stack conveying mechanism is used for continuously sequentially conveying each thin printing product stack; the output end of the paper unfolding mechanism is corresponding to the input end of a paper loading and conveying mechanism, wherein the paper unfolding mechanism is used for sequentially performing a paper unfolding work at least twice and a paper releasing work once for each thin printing product stack and then conveying out the thin printing product stacks; the output end of the paper loading and conveying mechanism is corresponding to the input end of a paper feeding mechanism of the product detector, wherein the paper loading and conveying mechanism is used for finishing the paper loading work in a telescopic paper conveying manner. According to the machine, the paper can be continuously fed to the paper feeding mechanism of the product detector after the printing products are subjected to paper unfolding, so that the labor intensity of workers can be greatly reduced, the production efficiency can be improved, and the rate of graded products can be ensured.

Owner:HEBEI TIANYUHENG TECH CO LTD

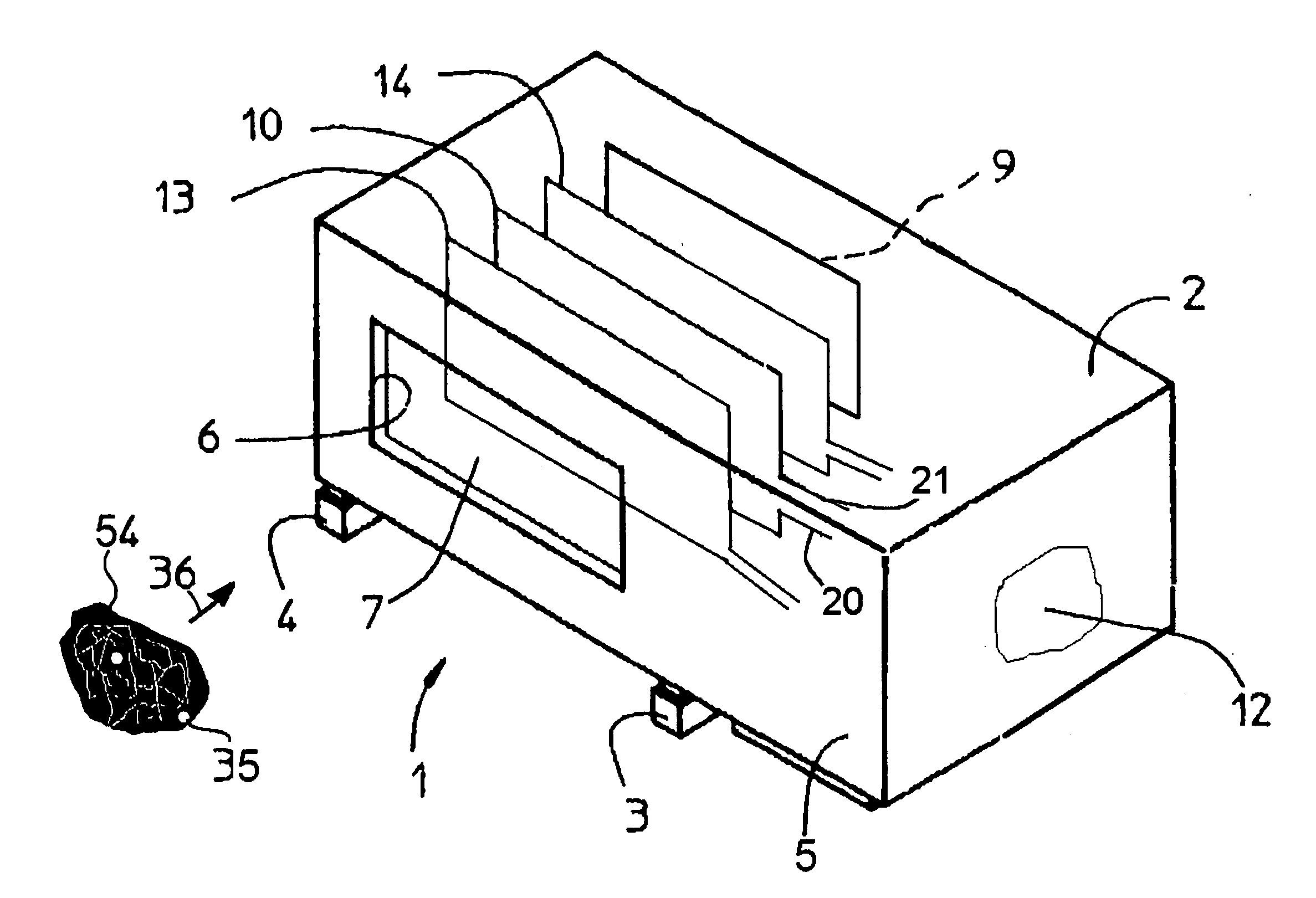

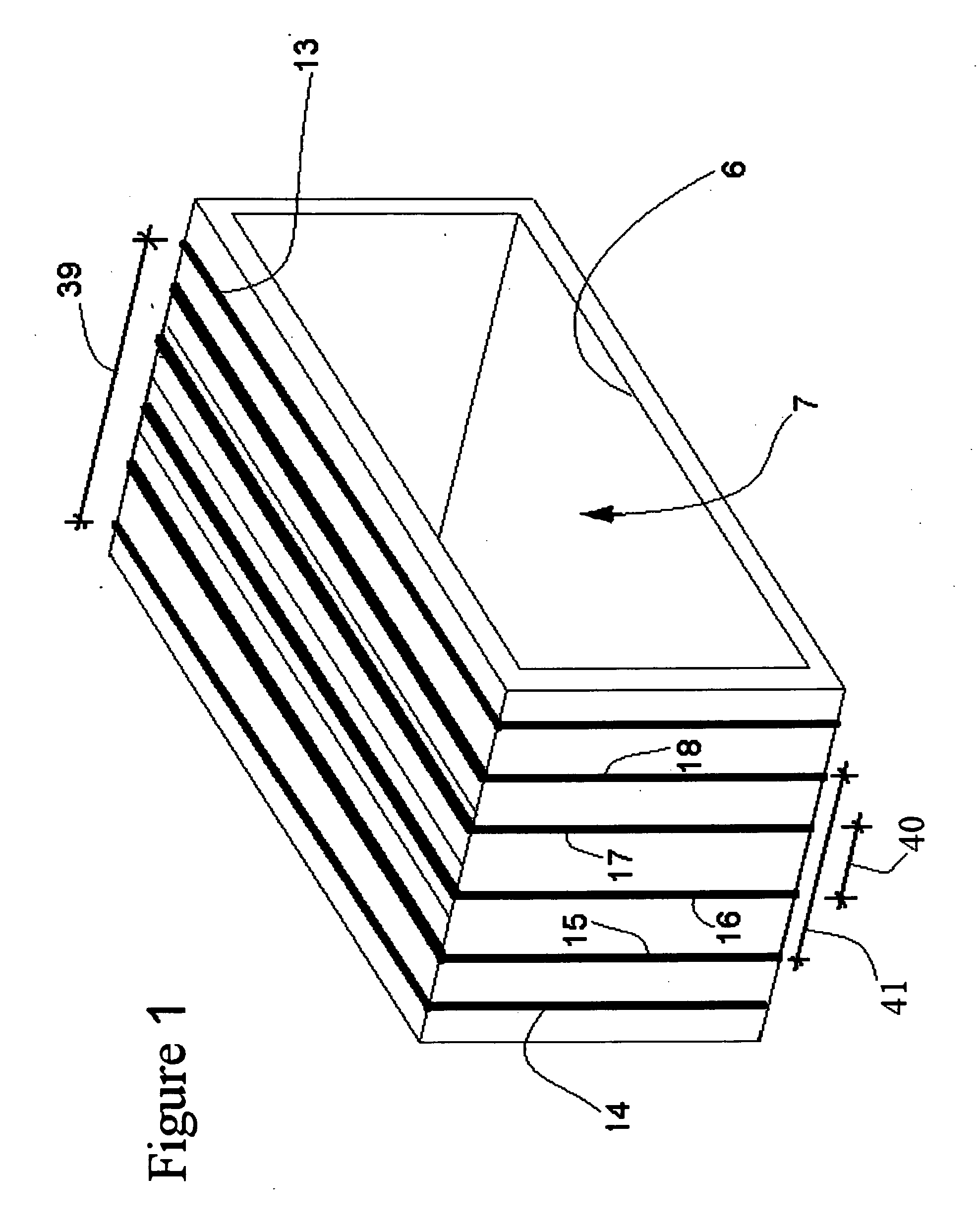

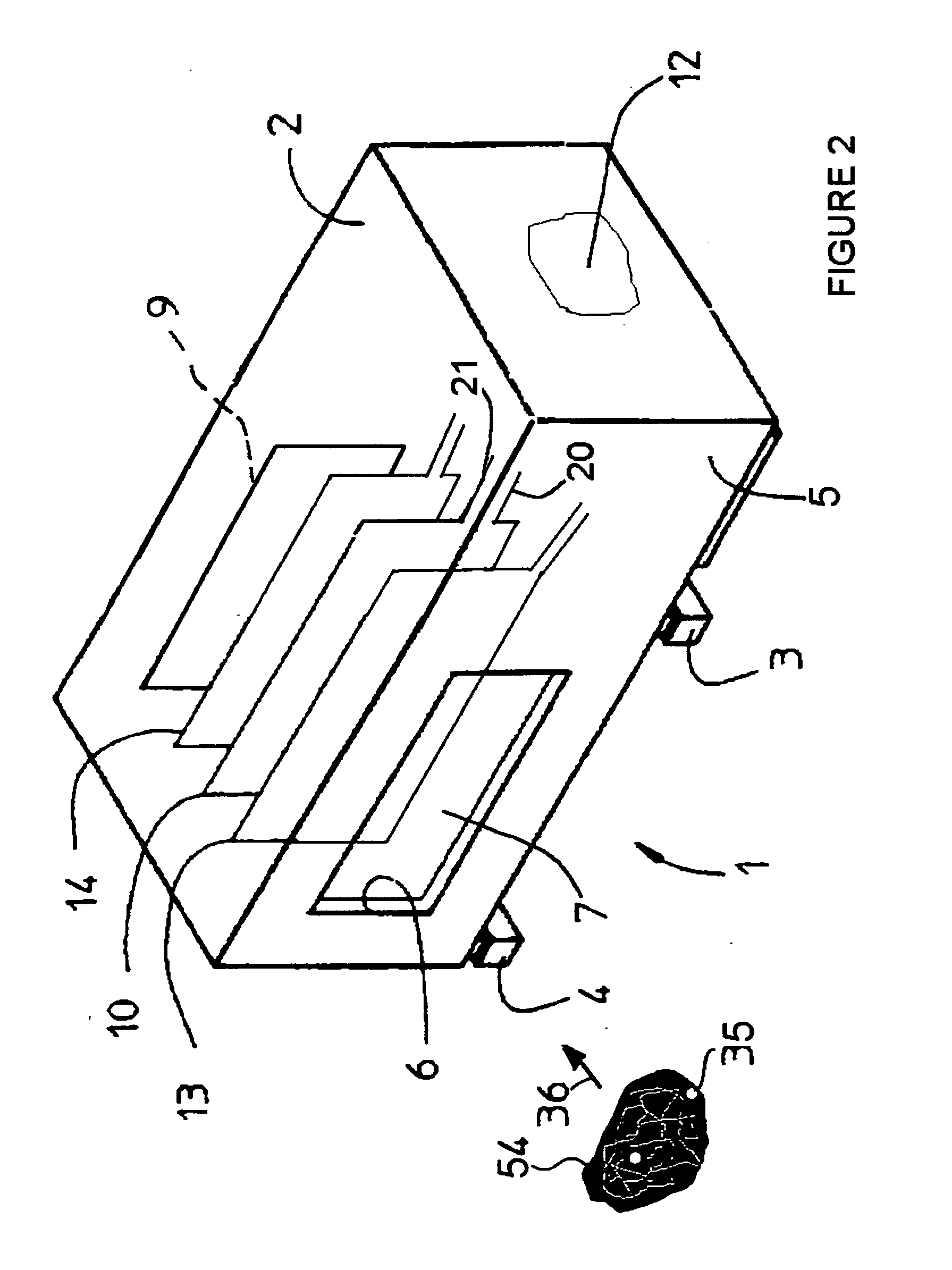

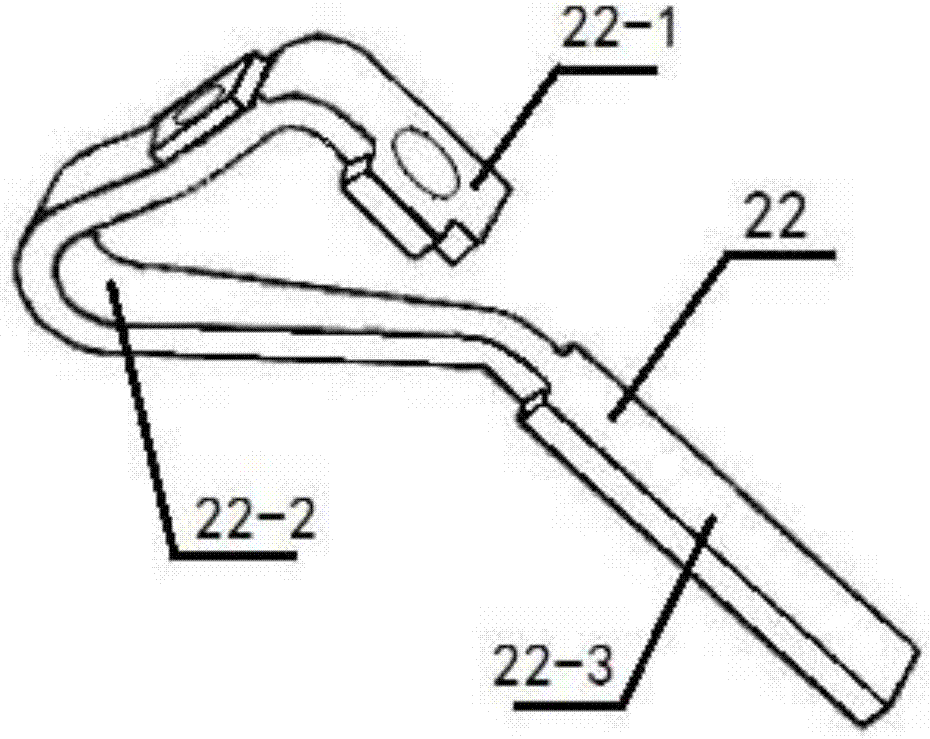

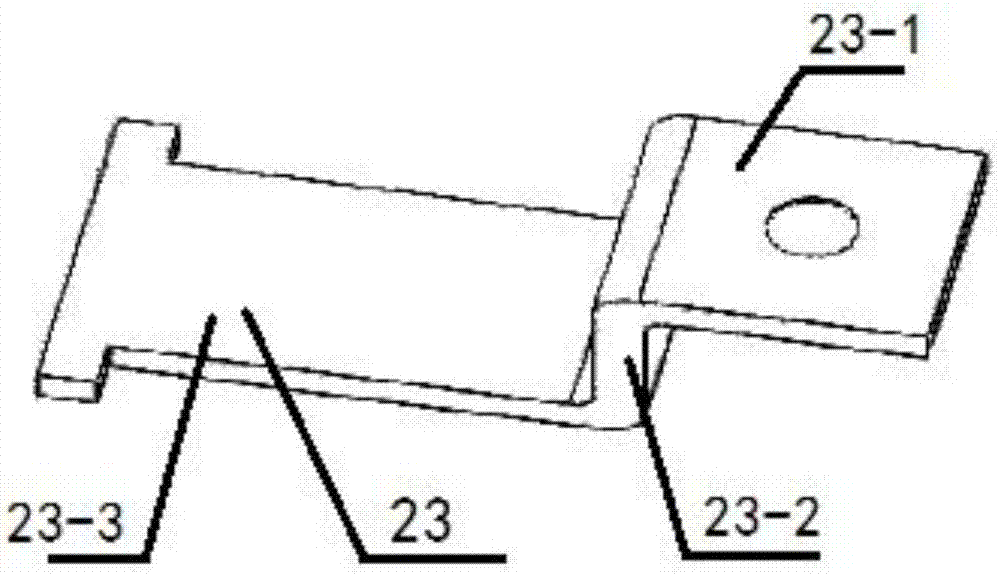

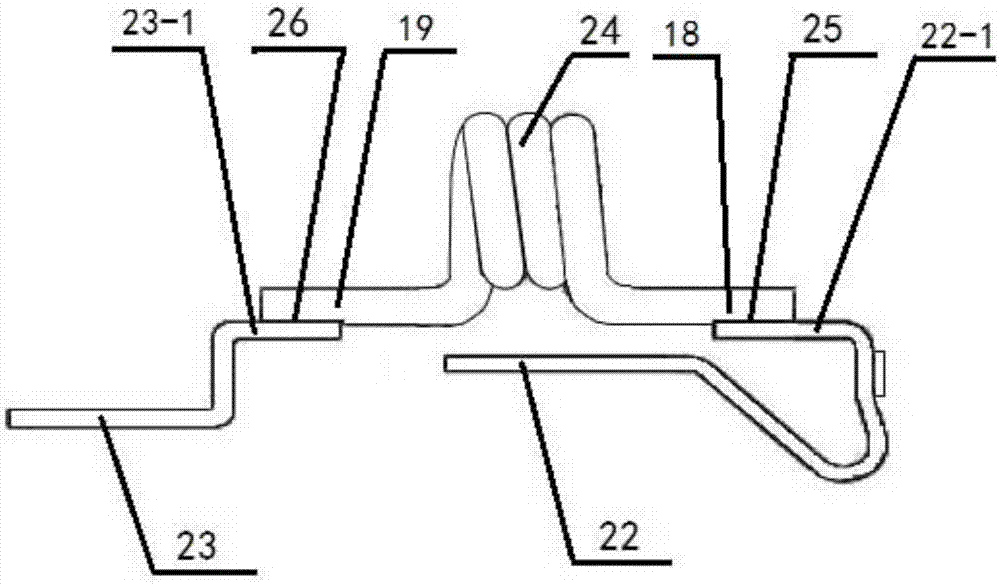

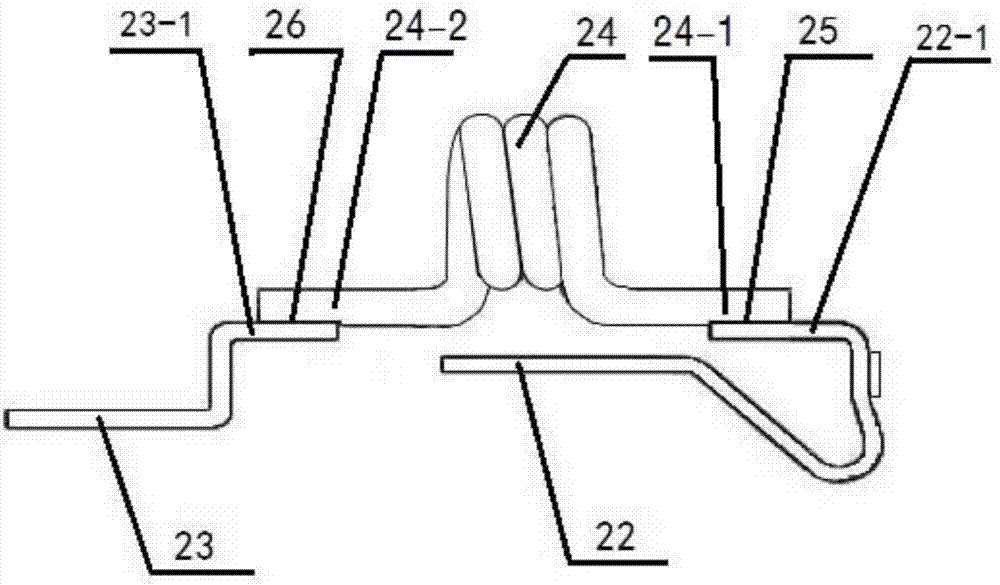

Oscillator coil geometry for radio frequency metal detectors

InactiveUS20080055080A1Increase received signal levelSmall sizeElectric/magnetic detectionBurglar alarm electric actuationRadio frequencyMetal detectors

A metal detector (1) used for identifying contaminants (35) in products (35). The detector (1) includes an oscillator coil assembly (10) that may be formed as a combination of pairs of series wound coils (15, 18) and pairs of parallel wound coils (16, 17). A pair of input coils (13, 14) defines the boundaries of a region (39) within which the oscillator coil assembly (10) resides. A first signal (8) is generated by the first input coil (13) in response to the presence of a metallic object (35) while a second signal (24) is generated by the second input coil (14) in response to the presence of the metallic object (35). By measuring the ratio of the first signal (8) to the second signal (24) the physical location of a metal object within the metal detector cavity (7) can be determined.

Owner:BRITTON ANDREW MICHAEL

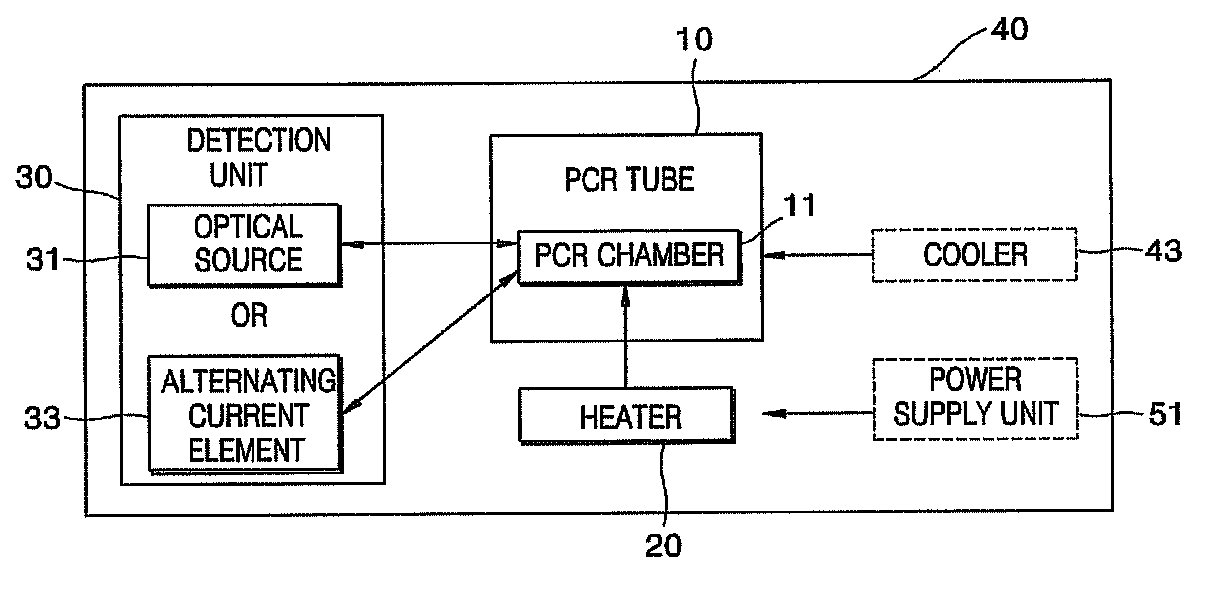

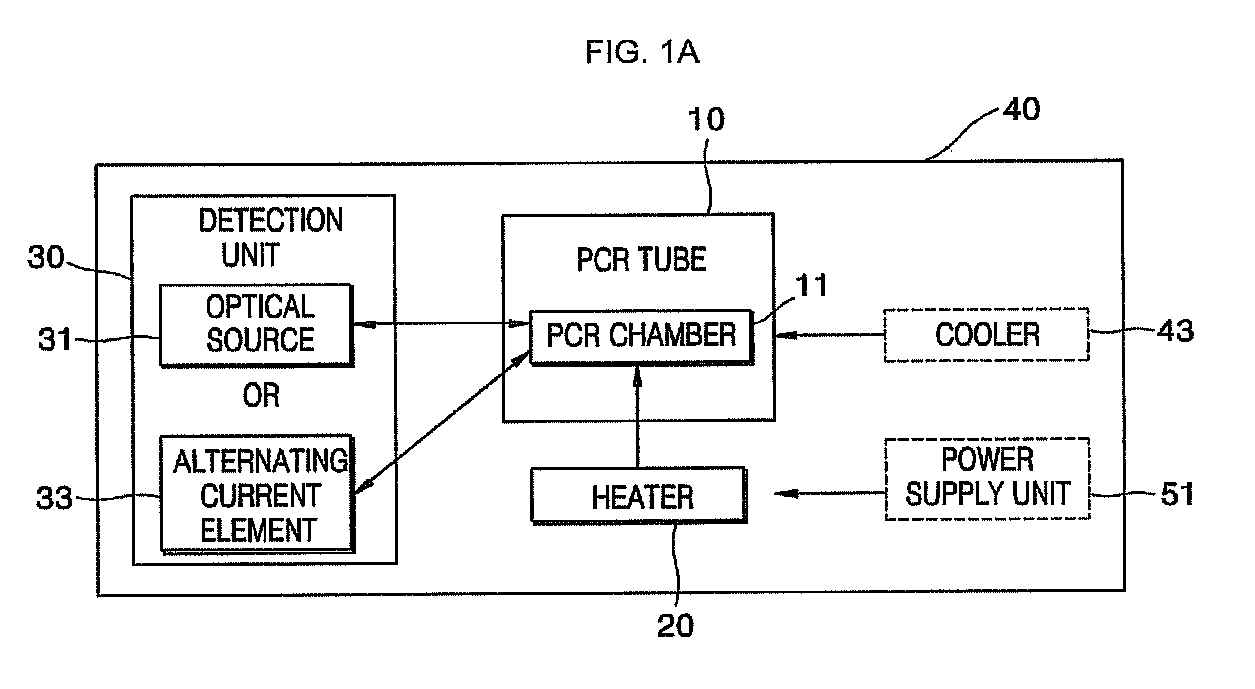

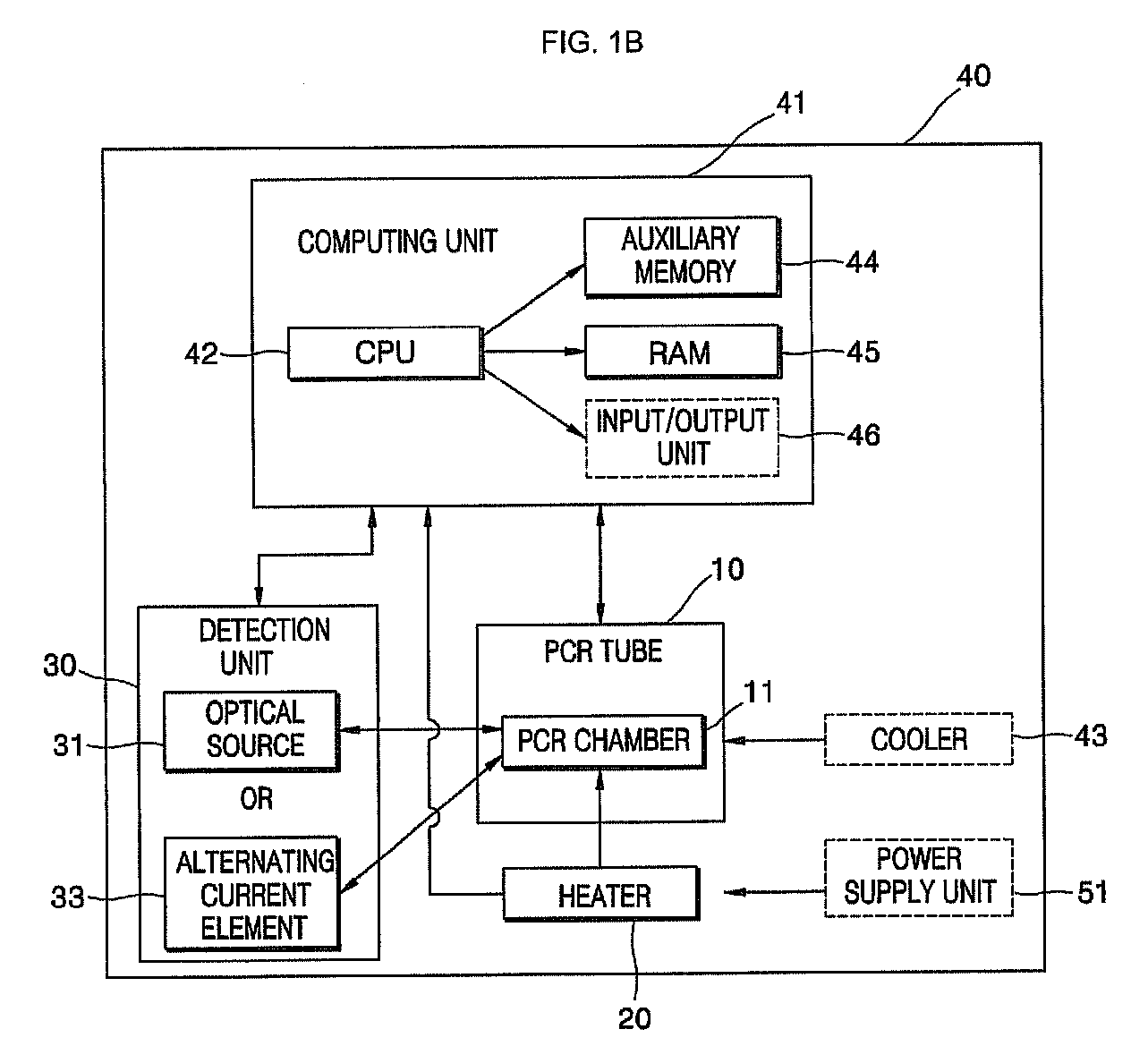

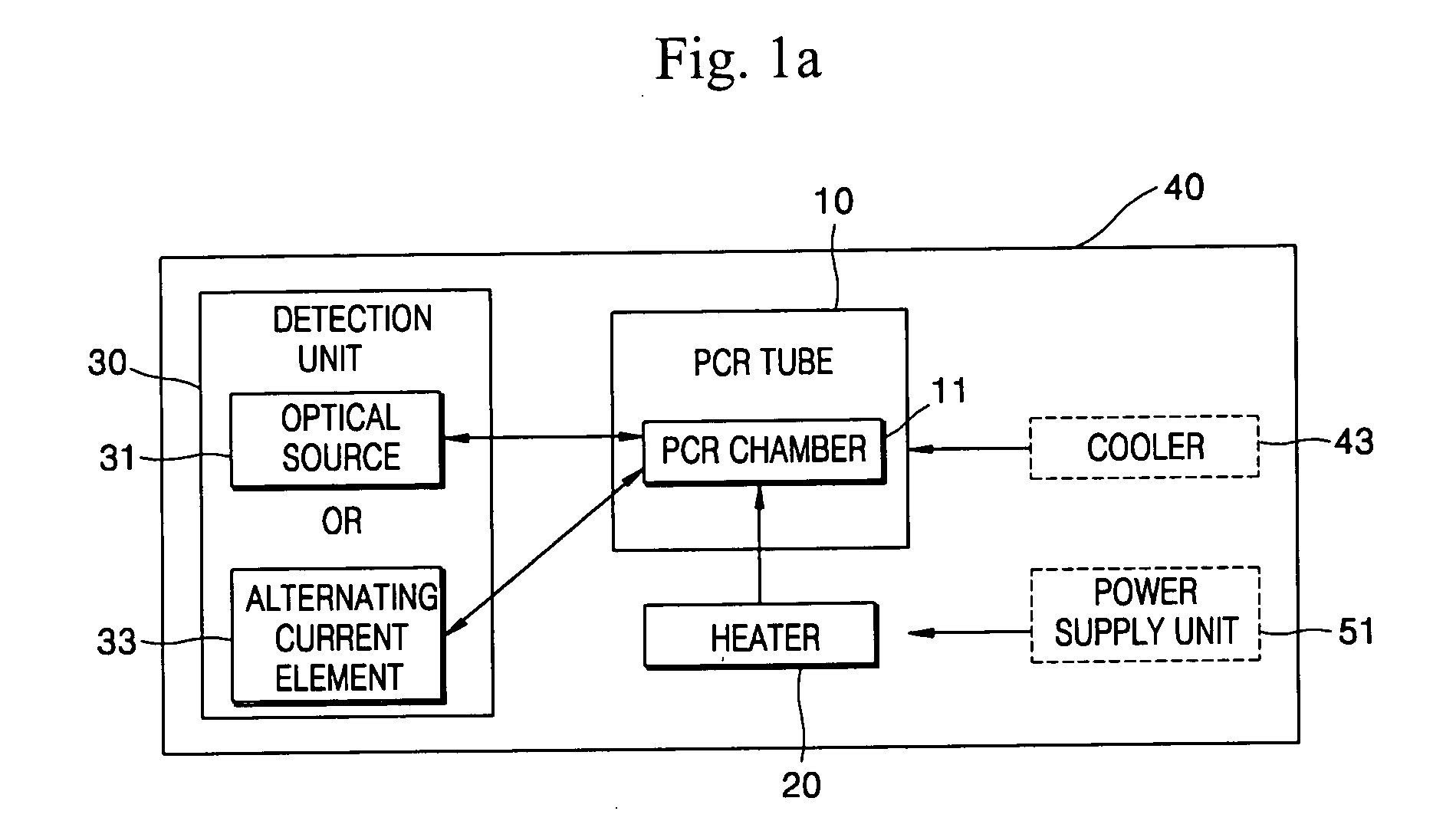

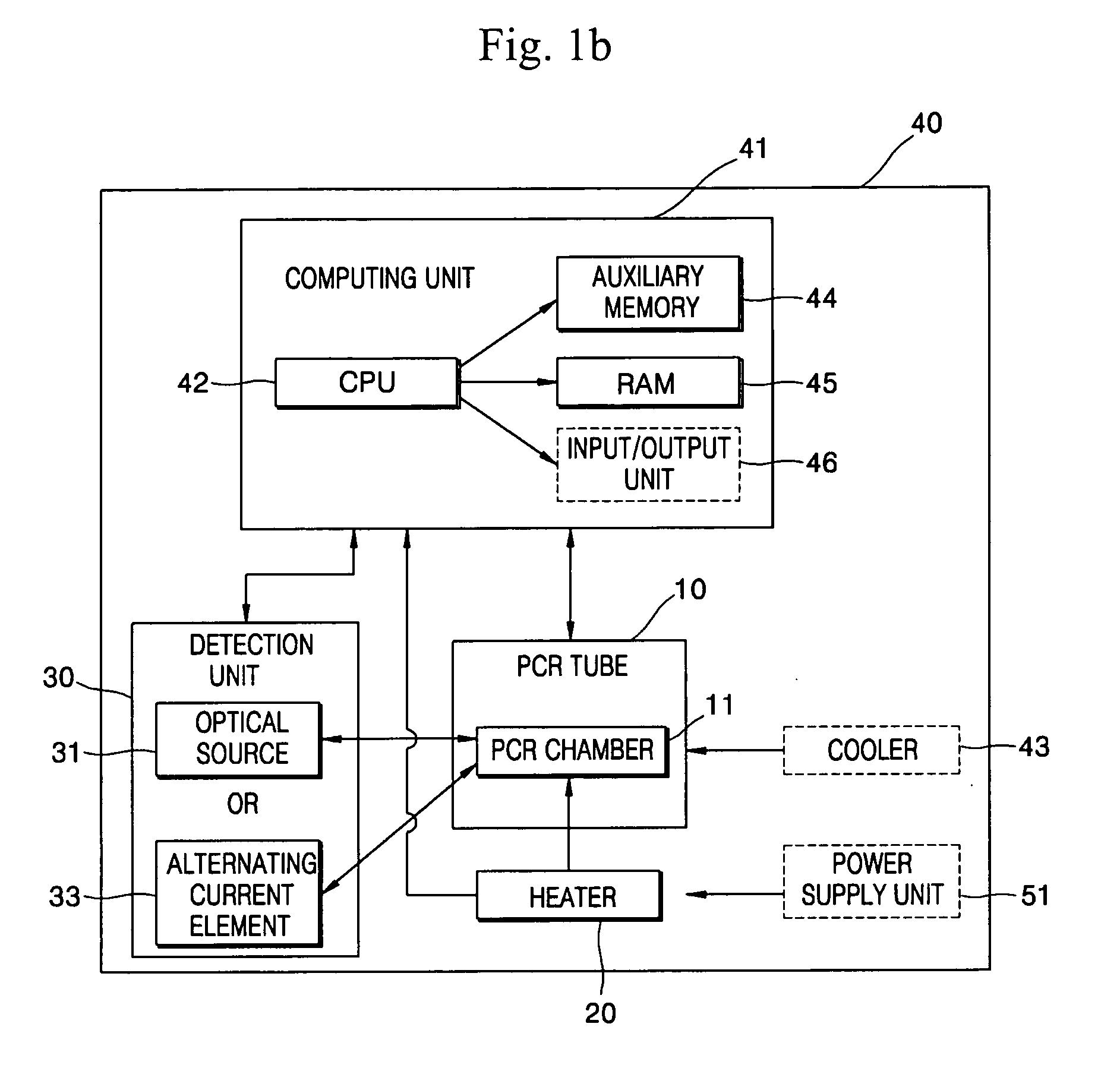

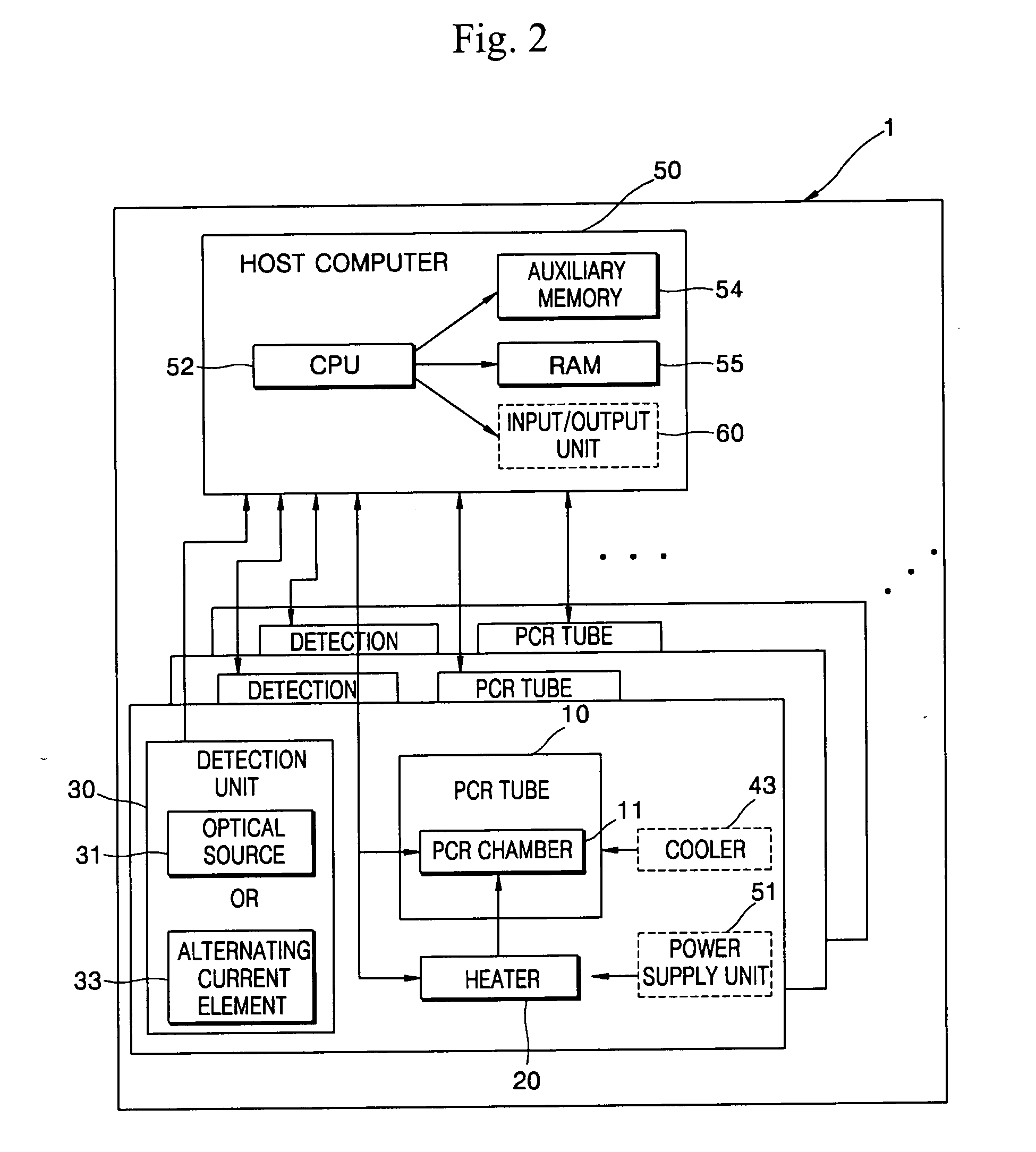

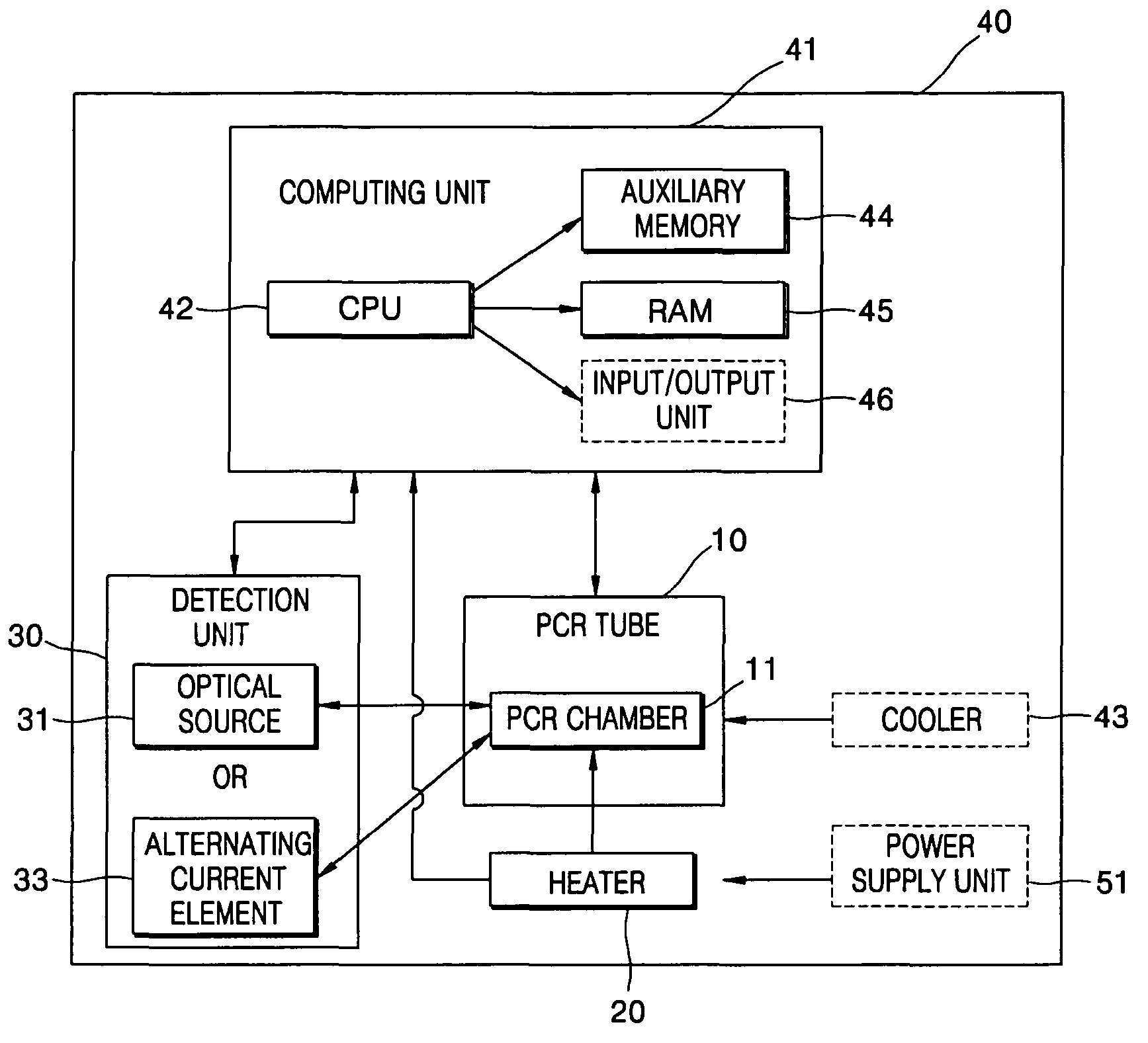

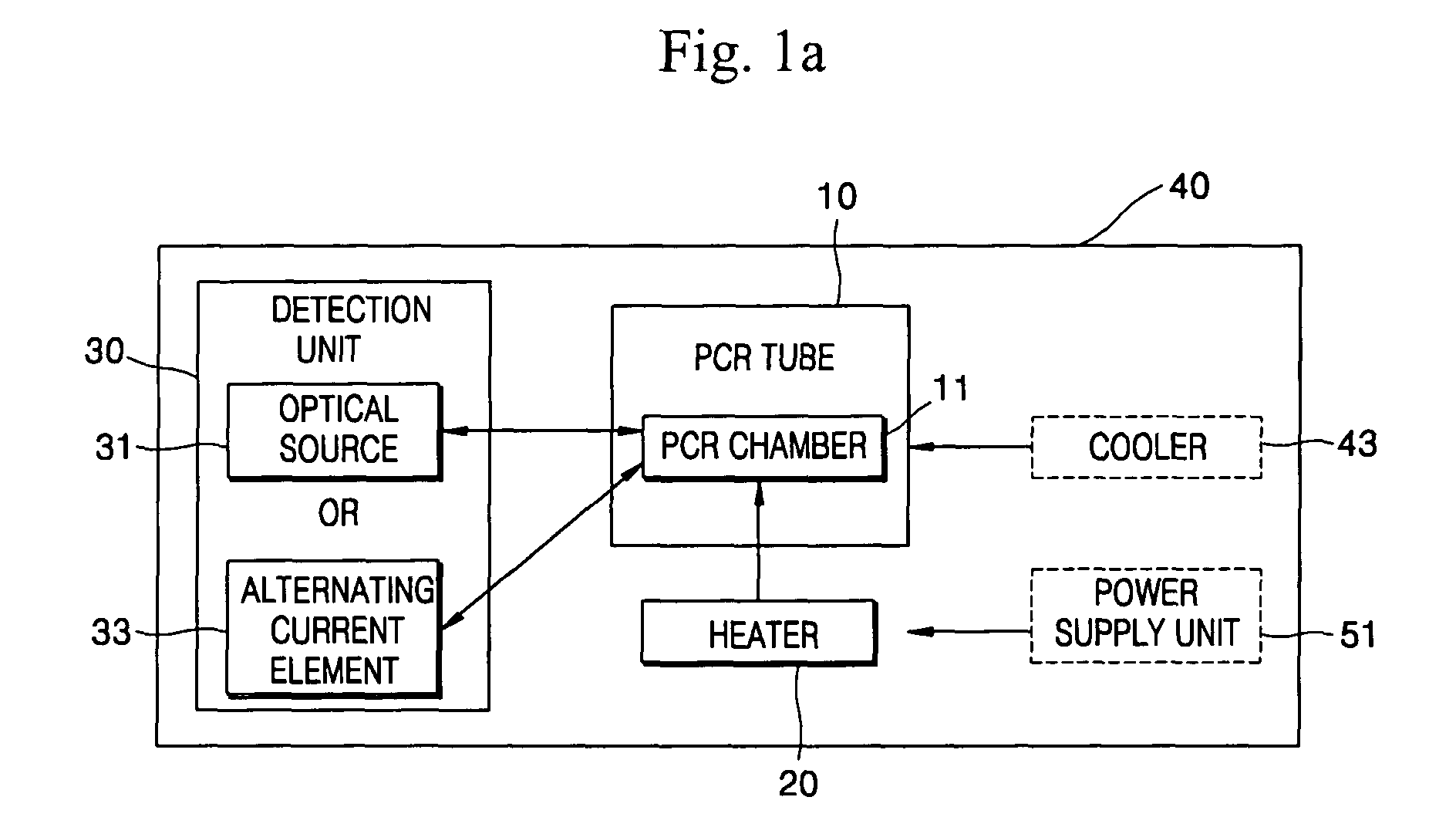

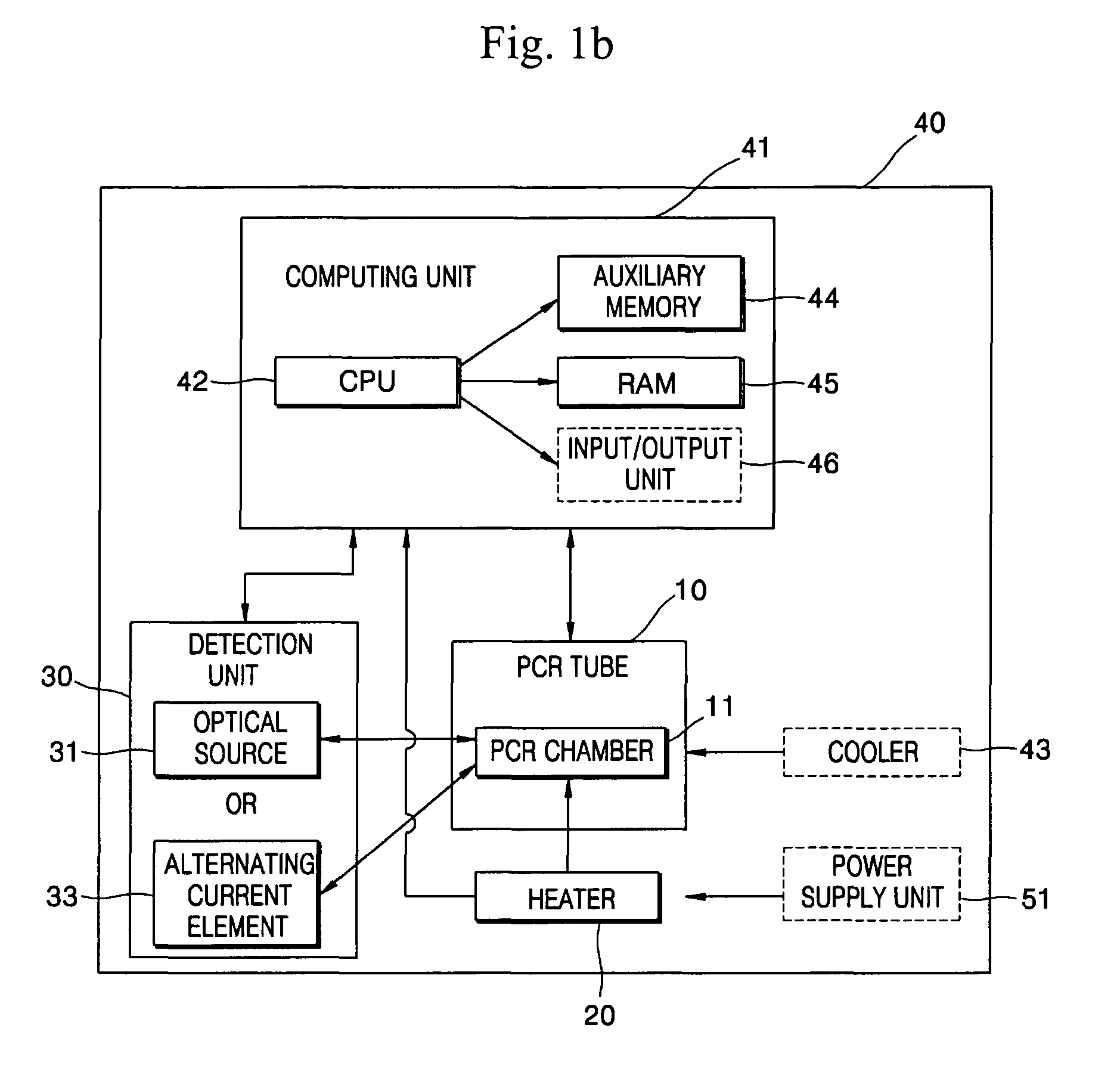

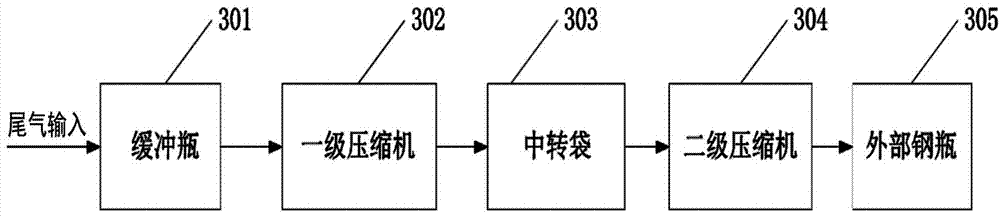

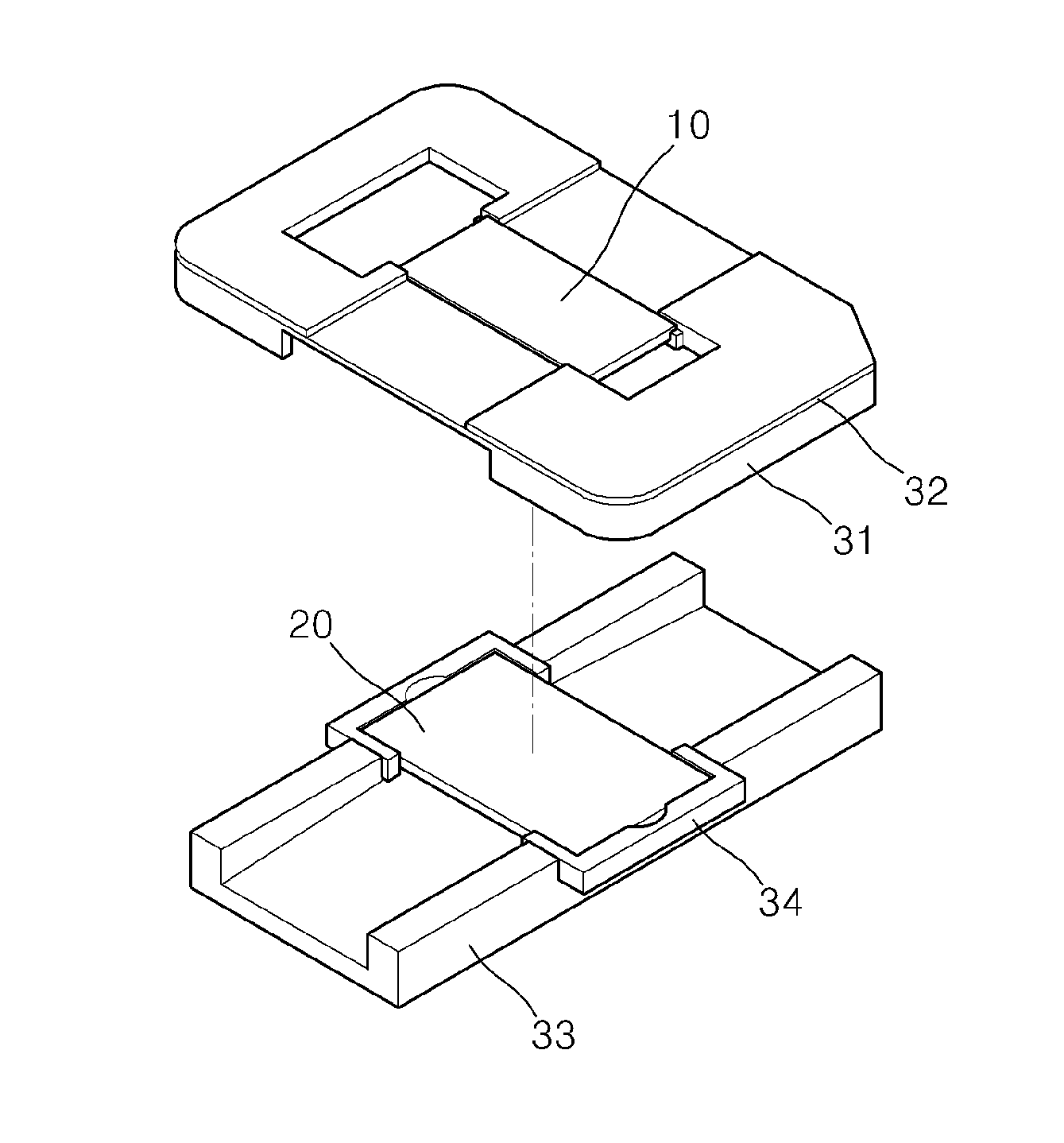

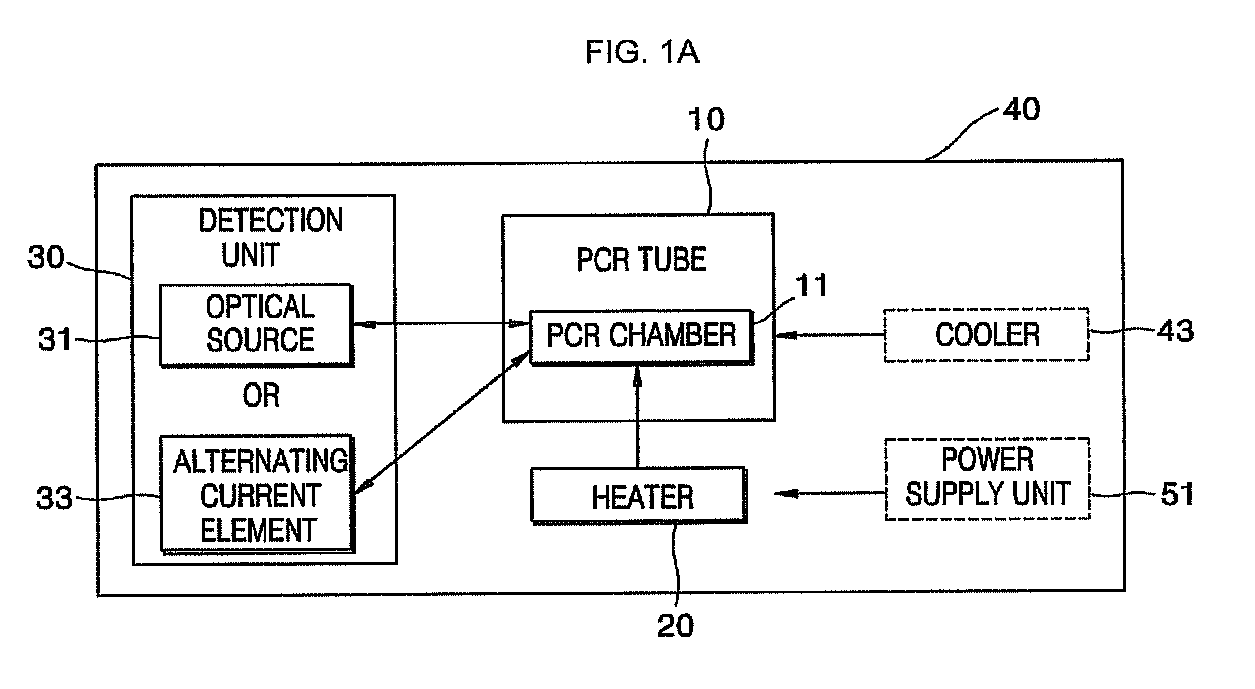

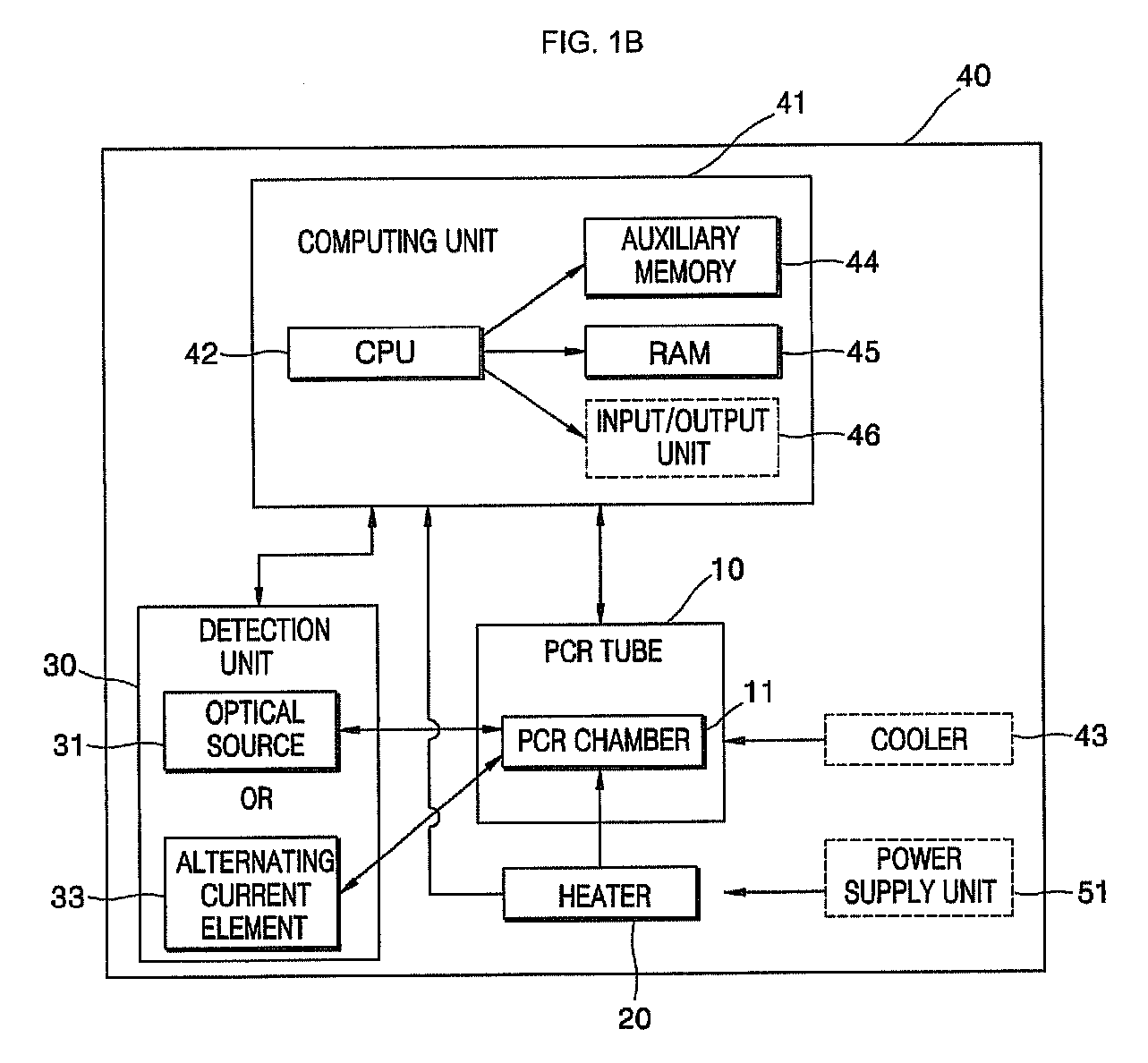

Polymerase chain reaction (PCR) module and multiple PCR system using the same

InactiveUS20100311070A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural scienceProduct detector

Provided are a PCR module and a multiple PCR system using the same. More particularly, provided are a PCR module with a combined PCR thermal cycler and PCR product detector, and a multiple PCR system using the same.

Owner:SAMSUNG ELECTRONICS CO LTD

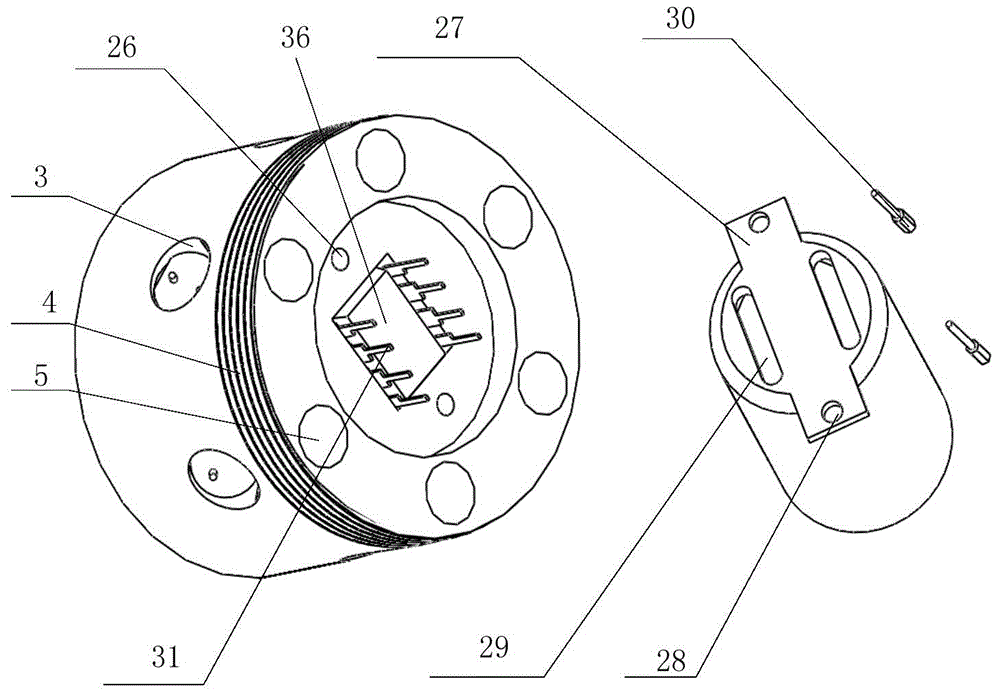

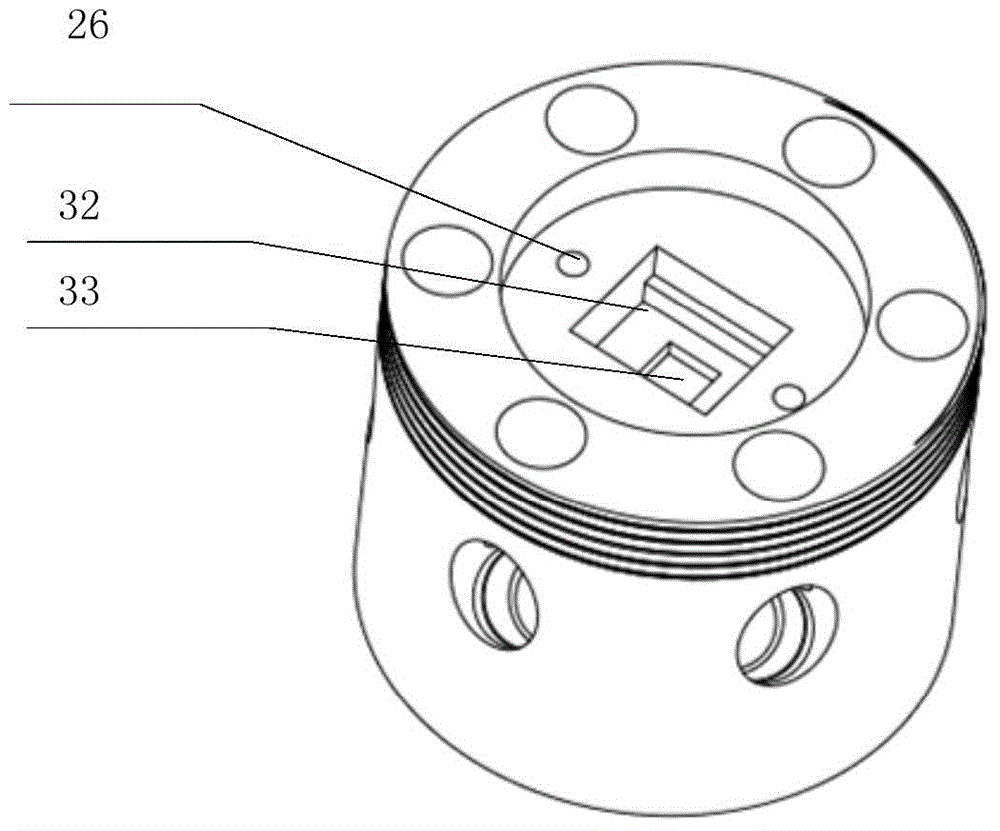

Electromagnetic coil assembly production manufacturing system and manufacturing method

ActiveCN106891113AQuality improvementReduce in quantityWelding/cutting auxillary devicesInductances/transformers/magnets manufactureEngineeringProduct detector

The invention provides an electromagnetic coil assembly production manufacturing system and a manufacturing method. The electromagnetic coil assembly production manufacturing system comprises a vertical plate, an outer rotating disc and an inner disc. A plurality of locking devices are arranged at the edge of the outer rotating disc, and rotation gears of the outer rotating disc comprise the static contact feeding gear, the wiring board feeding gear, the static contact and wiring board detection gear, the coil feeding gear, the coil detection gear, the welding gear, the welding deformation detection gear, the deformation trimming gear, the coil assembly detection gear and the discharging gear. The vertical plate is provided with a static contact and wiring board clamping detector, a coil clamping detector, a welding mechanism, a double-head lifting mechanism, two welding wire feeding mechanisms, a welding deformation detector, a shaping mechanism and a coil assembly finished product detector. According to the electromagnetic coil assembly production manufacturing system and the manufacturing method, the vertical plate, the vertical type rotating disc, the locking devices, the double-welding-head welding mechanism, the shaping mechanism and a detection system are combined together; a plurality of electromagnetic coil assemblies can be produced at the same time; the production efficiency is greatly improved; and the quality of the welded electromagnetic coil assemblies is high.

Owner:嘉兴金日升工具股份有限公司

Polymerase chain reaction (PCR) module and multiple PCR system using the same

InactiveUS20050164281A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural scienceProduct detector

Provided are a DNA PCR module and a multiple PCR system using the same. More particularly, provided are a DNA PCR module with a combined PCR thermal cycler and PCR product detector, and a multiple PCR system using the same.

Owner:SAMSUNG ELECTRONICS CO LTD

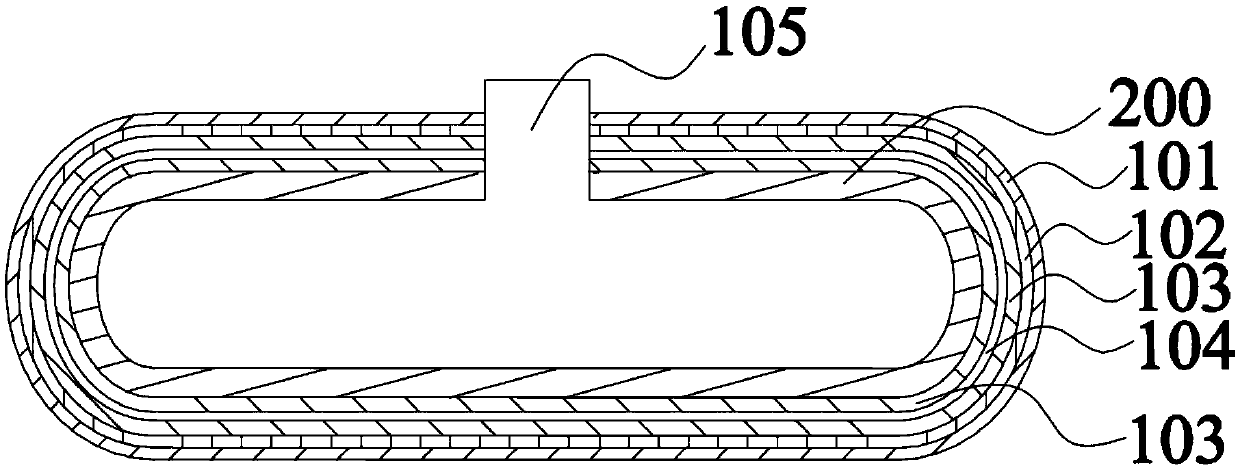

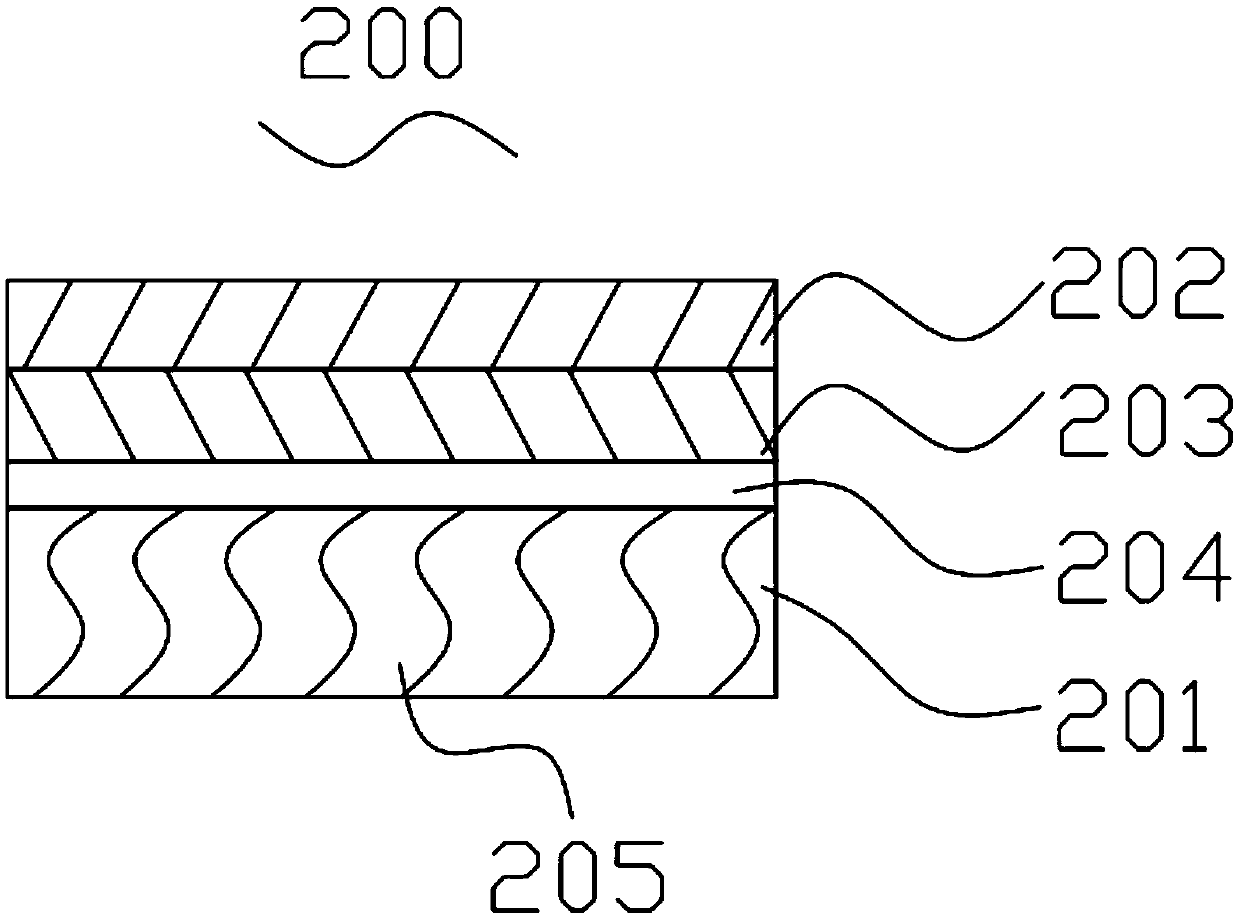

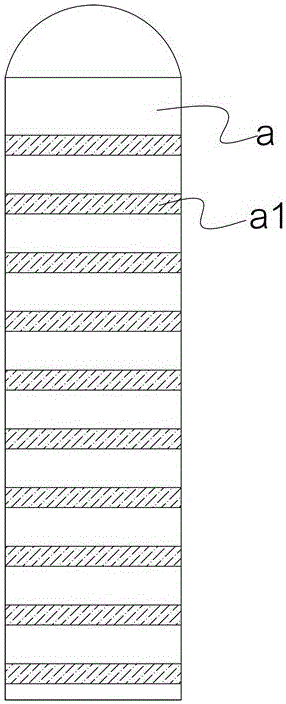

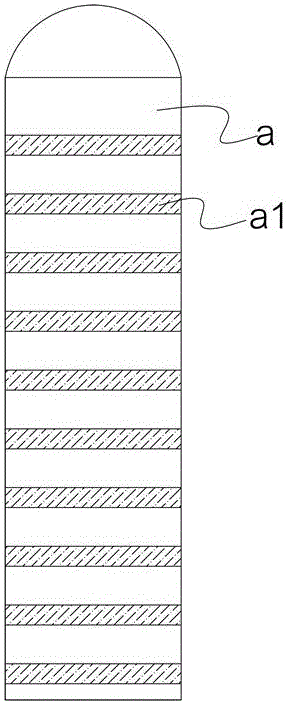

Non-excavation two-layer tank reconstruction method and oil product leakage detection method

ActiveCN105500778AImprove attributesImprove securityMeasurement of fluid loss/gain rateLayered productsStructure of the EarthReconstruction method

The invention relates to a non-excavation two-layer tank reconstruction method and an oil product leakage detection method, especially to a reconstruction method of carrying out non-excavation reconstruction on an original single-layer tank so as to endow the single-layer tank with performance of a two-layer tank. The reconstruction method comprises the following steps: the inner surface of a tank to be reconstructed is cleaned; the cleaned inner surface of the tank is gelatinized; gridding cloth is immersed and buried into the colloid; and a soft 3D woven complex is glued onto the colloid, and after colloid reaction, the soft 3D woven complex and the tank to be reconstructed form a two-layer tank structure. By arranging an oil product detector inside the gap between penetrating layers of the 3D woven layer, whether there exists oil production leakage can be detected at real time. By the method provided by the invention, a single-layer tank buried underground can be reconstructed. Thus, the original single-layer tank buried underground can be reconstructed to have functions of a two-layer tank without excavation. Leakage of oil products can be minimized, and whether oil products leak can be detected at real time. Thus, oil storage safety is greatly raised.

Owner:SHENZHEN BEST TECH CO LTD

Holding cabinets, methods for controlling environmental conditions in holding cabinets,and computer-readable media storing instructions for implementing such methods

A holding cabinet includes a body defining a holding space and a holding compartment disposed within the holding space for holding a product therein. The holding cabinet further includes a heating source, a steam generator, a temperature sensor, a humidity sensor, a product detector, and a controller. The controller is configured to regulate environmental conditions of the holding compartment according to a determined setpoint, which corresponds to a predetermined temperature and relative humidity. The controller regulates such environmental conditions by acquiring the sensed air temperature, relative humidity, and the detected type of product, and activating and deactivating the heating source and the steam generator in accordance with the acquired air temperature, relative humidity, and the determined setpoint corresponding to the type of product detected and a holding time of the product, to maintain the air temperature and the relative humidity within a predetermined range based on the determined setpoint.

Owner:HENNY PENNY CORP

Polymerase chain reaction (PCR) module and multiple PCR system using the same

InactiveUS7799557B2Bioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural scienceProduct detector

Provided are a DNA PCR module and a multiple PCR system using the same. More particularly, provided are a DNA PCR module with a combined PCR thermal cycler and PCR product detector, and a multiple PCR system using the same.

Owner:SAMSUNG ELECTRONICS CO LTD

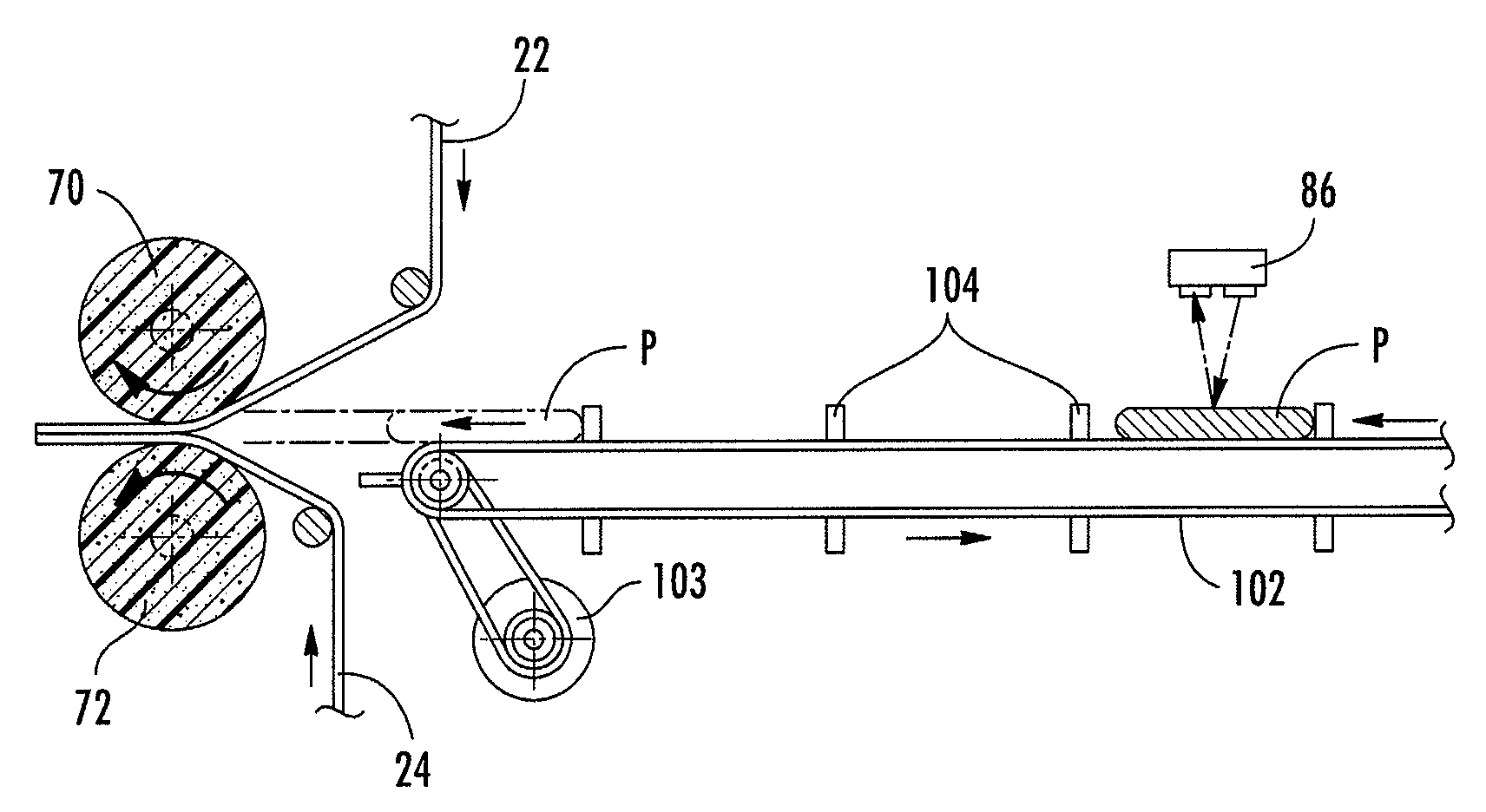

Packaging machine and method

InactiveUS20060218883A1Prevents empty cycleAutomate processingPackaging automatic controlSuccessive articlesEngineeringProduct detector

A packaging method and apparatus wherein each product is packaged by capturing the product in flexible packaging material. The packing apparatus includes a product detector for detecting the presence or absence of a product to be packaged. The detection of the product may cause the advancement of packaging material and the product through a nipping station to form a package. The failure to detect a product may cause the advancement of the packaging material to stop and conserve packaging material until a product is detected. The product detector may be a color sensor trained to detect a color of the first web, a luminescence sensor trained to detect a luminance of the first web, or a light-sensitive sensor trained to detect a difference in light passing through the first web. Also, a luminescence additive may be joined with the lower web to provide a distinct luminance.

Owner:SEALED AIR U S

Welding system and method for electromagnetic coil component

ActiveCN107097011AQuality improvementSmall size and position errorWelding/cutting auxillary devicesAuxillary welding devicesProduct detectorRotating disc

The invention provides a welding system and method for an electromagnetic coil component. The welding system is characterized in that a stationary contact feeding position, a wiring board feeding position, a stationary contact detecting position, a wiring board detecting position, a coil feeding position, a coil detecting position, a stationary contact welding position, a first welding point detecting and finishing position, a wiring board welding position, a second welding point detecting and finishing position, a discharging position and a finished product discharging and detecting position are arranged on an outer rotating disc; and a stationary contact clamping detector, a wiring board clamping detector, a coil clamping detector, a stationary contact welding mechanism, a stationary contact welding wire feeding mechanism, a stationary contact and coil welding forming detector, a first welding point finishing mechanism, a wiring board welding mechanism, a wiring board welding wire feeding mechanism, a wiring board and coil welding forming detector, a second welding point finishing mechanism, a finished product detector and a finished product discharging detector are arranged on a vertical plate. According to the welding system and method for the electromagnetic coil component, the vertical plate, the outer rotating disc, locking devices and the welding mechanisms are combined together, multiple coil components can be produced simultaneously, and the welded coil component is high in quality and precise in dimension.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

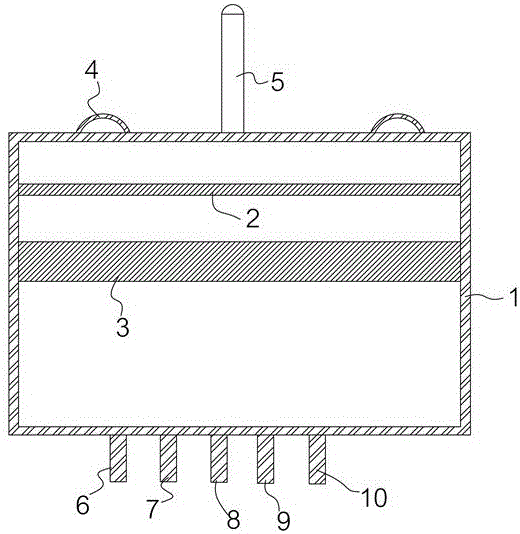

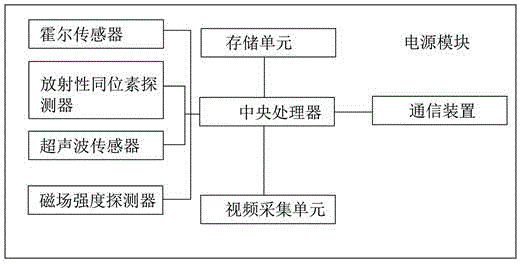

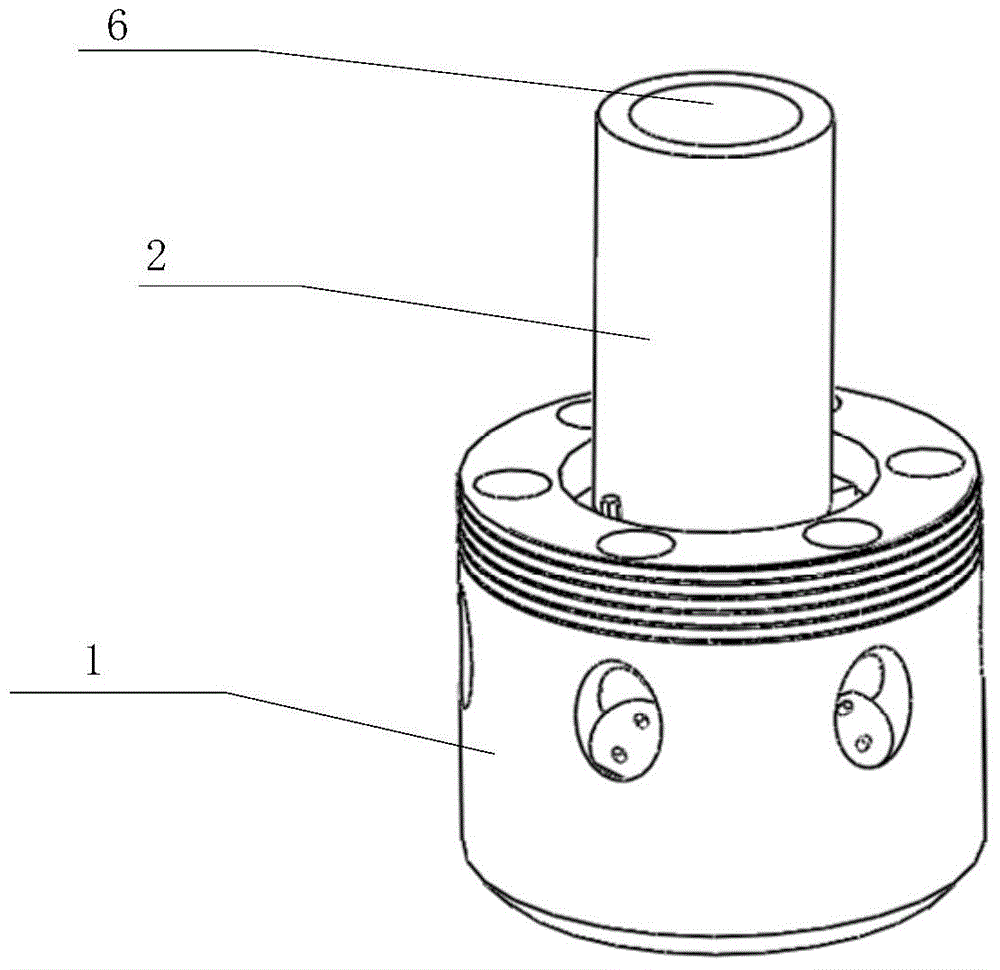

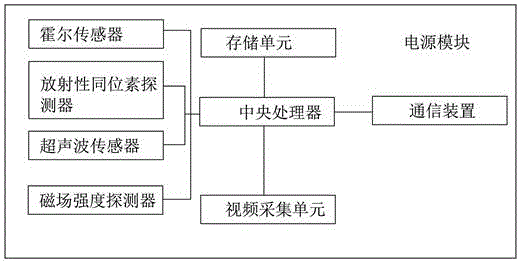

Underground mineral product detector with video acquisition unit

ActiveCN105869372AEasy detectionTransmission systemsClosed circuit television systemsMineral SourcesUltrasonic sensor

The invention discloses an underground mineral product detector with a video acquisition unit. The underground mineral product detector comprises a cylindrical detector body, wherein the detector body is internally provided with a circuit layer and a power supply layer; the underground mineral product detector further comprises a detection circuit arranged in the circuit layer; the detection circuit comprises a central processing unit, a Hall sensor, a radioactive isotope detector, an ultrasonic sensor and a communication device; the Hall sensor, the radioactive isotope detector and the ultrasonic sensor are in signal connection with the central processing unit respectively; the communication device is in signal connection with the central processing unit; the communication device is used for wirelessly transmitting out detected information; the power supply layer is internally provided with a power supply module; the power supply module supplies power to the detection circuit; a lug is arranged at the top of the detector body. By adopting a reasonable structural design and detection of a plurality of probes, a function of conveniently detecting mineral product resources is realized; the underground mineral product detector is simple and convenient and provides portable equipment for underground detection.

Owner:QINGHAI QIXIN GEOLOGY & MINERAL EXPLORATION CO LTD

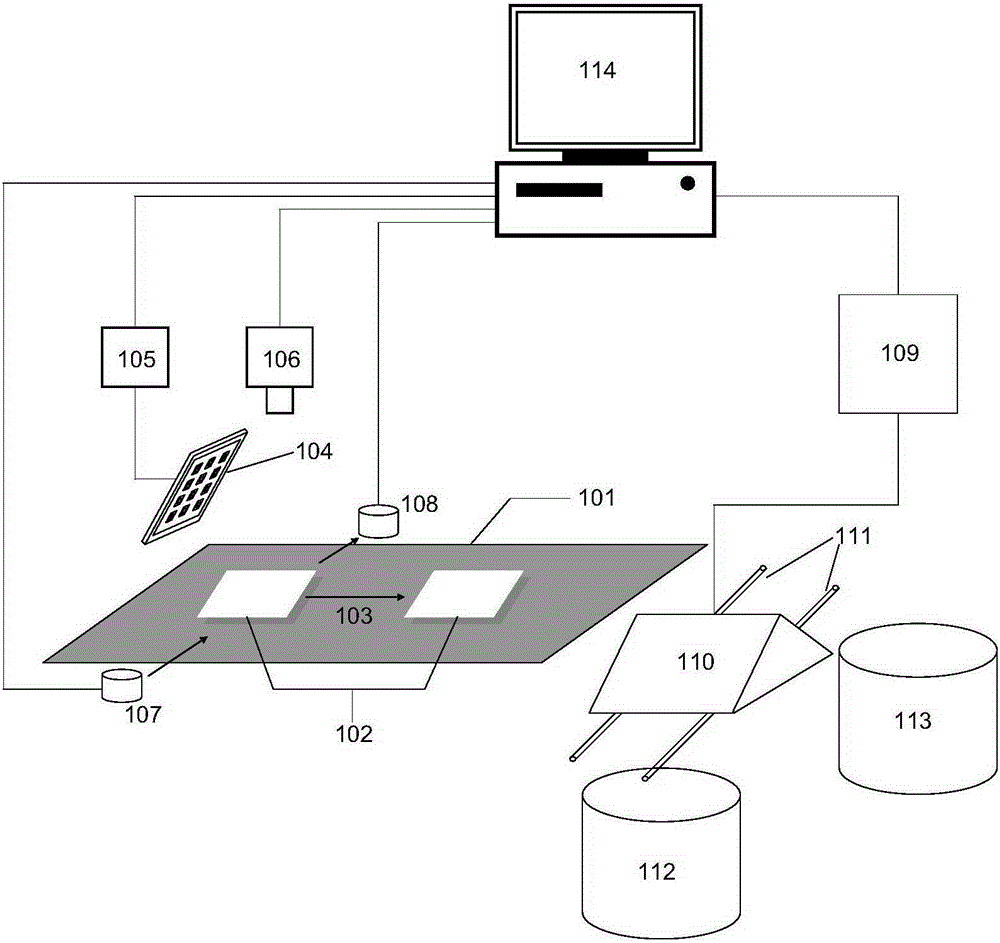

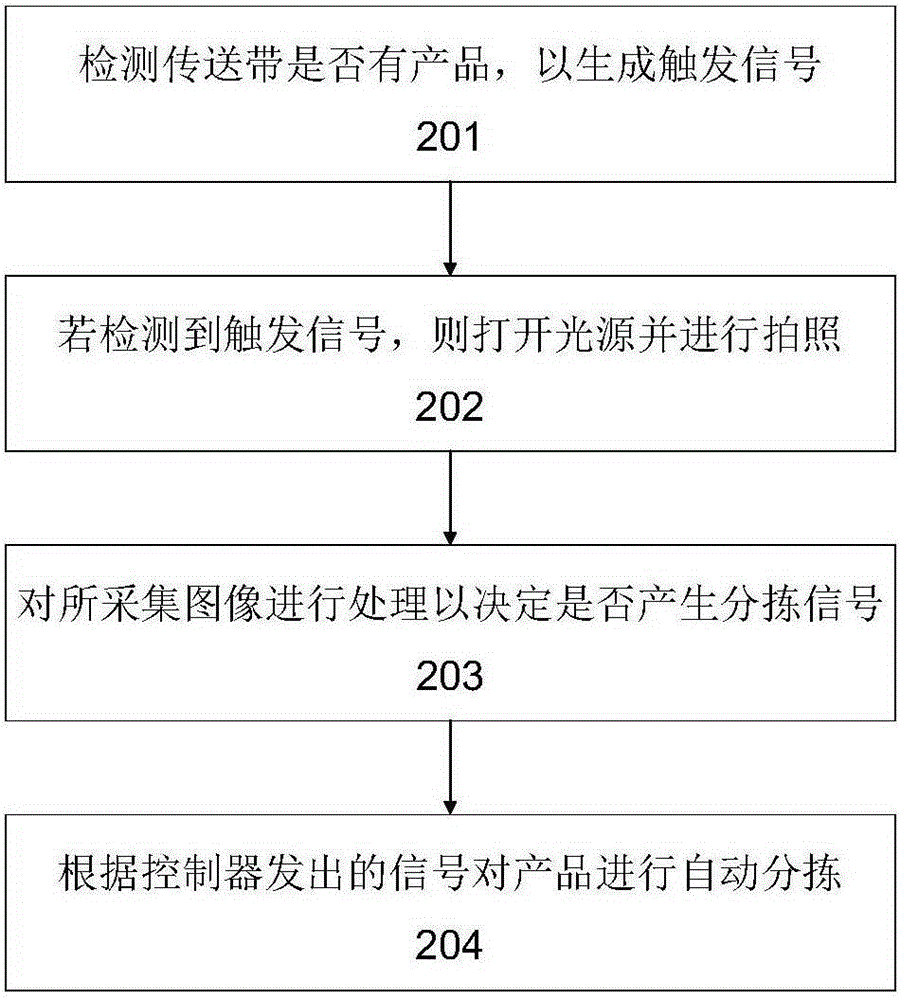

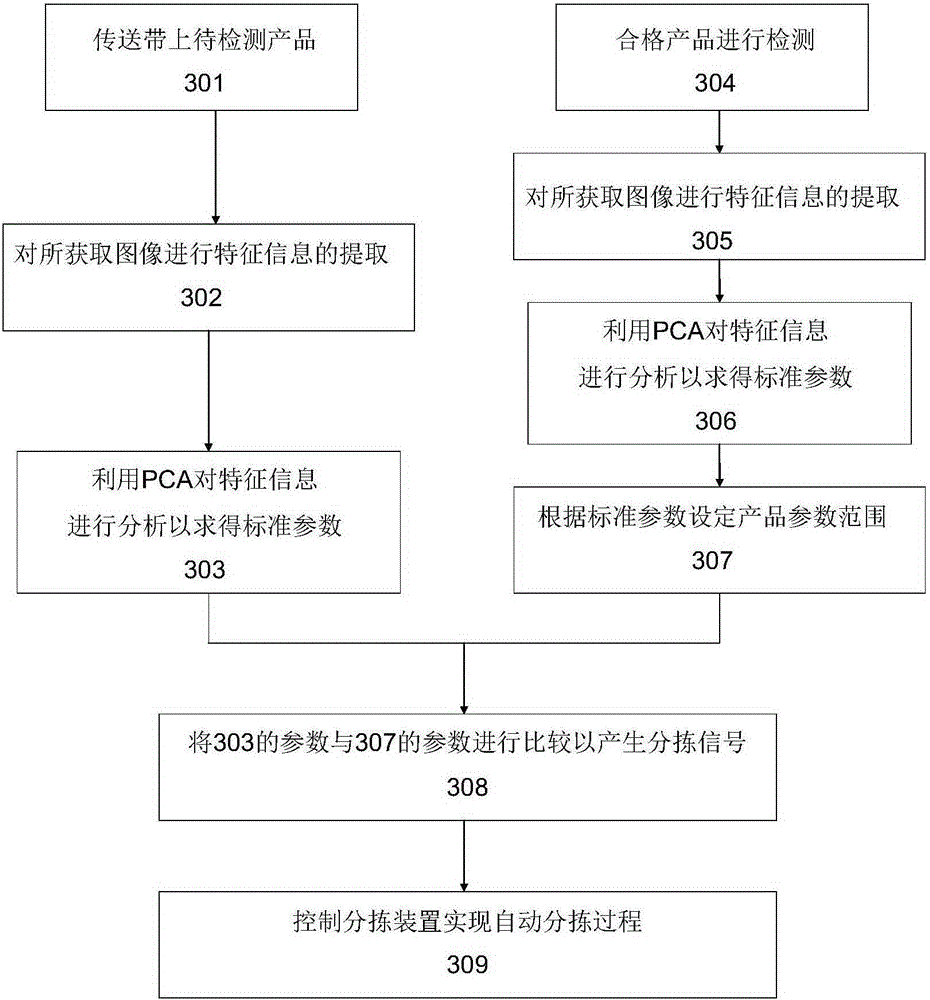

Automatic defective switch socket sorting device and method based on PCA

InactiveCN105214964AImplement automatic detectionEasy to operateSortingProduction lineProduct detector

The invention discloses an automatic defective switch socket sorting device and method based on PCA. The device comprises a product detector, an upper computer, an image acquiring unit, a sorting signal control unit and a sorting executing mechanism. When the product detector detects to-be-detected products conveyed along with a conveying belt, a signal is sent to the upper computer, the upper computer sends an image acquiring command to the image acquiring unit, a returned image is analyzed and processed, and the sorting signal control unit controls the work of the sorting executing mechanism according to the distinguishing result of the upper computer. Automatic detection for the surface quality of switch sockets on a production line is achieved. The method has the advantages of being convenient to operate, high in detecting speed, high in accuracy rate and the like. Meanwhile, the device is wide in application range and can be applied to like products by being slightly modified.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

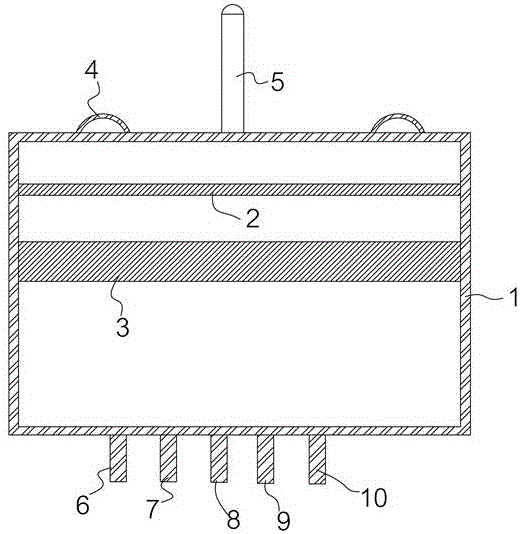

Integrated optical portable agricultural and animal product detector

ActiveCN104897574AReduce volumeImprove detection stabilityScattering properties measurementsMiniaturizationMultiple point

The invention belongs to the technical field of quality detection of agricultural products and particularly relates to an integrated optical portable agricultural and animal product detector. The integrated optical portable agricultural and animal product detector integrates different-waveband LED light sources in a probe and realizes integration of the light sources and detection. The integrated optical portable agricultural and animal product detector comprises probes (34) and a probe mounting shell (7), and each probe (34) comprises a probe surrounding shell (1) and a detecting signal line transmission cavity (2). The probes are combined to detect agricultural products, the different-wavelength LED light sources are integrated together, multiple points of the same sample can be detected at one time, stability and accuracy in detecting are improved, instrument size is reduced, and nondestructive detecting tends to lightness and miniaturization.

Owner:无锡谱视界科技有限公司

Underground mineral product detector provided with magnetic field intensity detector

ActiveCN105759320AEasy detectionTransmission systemsNuclear radiation detectionMineral SourcesUltrasonic sensor

The invention discloses an underground mineral product detector provided with a magnetic field intensity detector. The underground mineral product detector comprises a cylindrical detector body. A circuit layer and a power supply layer are arranged in the detector body. A detection circuit arranged in the circuit layer is also included. The detection circuit comprises a central processor, a Hall sensor, a radioisotope detector, an ultrasonic sensor and a communication apparatus, wherein the Hall sensor, the radioisotope detector, the ultrasonic sensor and the communication apparatus are connected to the central processor in a signal connection mode respectively. The communication apparatus is used for wirelessly transmitting detected information to the outside world. A power supply module is arranged in the power supply layer. The power supply module provides power for a detection circuit. A top of the detector body is provided with a wire lug. Through a reasonable structure design and multi-probe detection, a function of conveniently detecting mineral product resources is realized; the detector is simple and convenient and portable equipment is provided for underground detection.

Owner:黄剑鸿

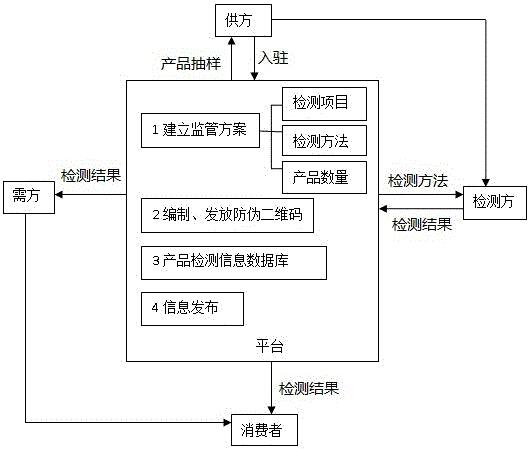

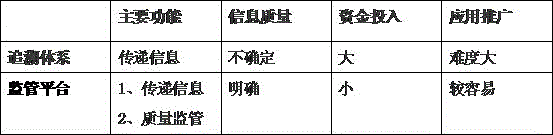

Third-party supervisory platform for food quality information

The invention discloses a third-part supervisory platform for food quality information. The third-party supervisory platform comprises a supplier, a demander and a detector which are connected through the platform, wherein the supplier is an enterprise providing product information, the demander is an enterprise or a customer needing to know product quality information, and the detector is a detection mechanism with detection qualification; the product supplier enters the platform, the platform encodes and issues anti-fake two-dimensional codes, the platform samples supplier products in an online mode, the platform establishes a supervisory scheme and informs the detector, and a sampled sample is sent to the detector by the supplier at the same time; the detector receives and checks the sample according to passwords issued by the platform, the detector provides a detection report for the platform, and the platform provides a product supervisory result for the demander and the customer. The supervisory platform utilizes techniques of network information, anti-fake two-dimensional codes, big data and the like; the product supplier, the product information demander and the product detector are in network connection through a control center, so that the third-party supervisory platform for the food quality information can be formed.

Owner:辛丘岩

Automatic electronic disk packaging line

ActiveCN107089389AIncrease productivitySave time and costTotal factory controlPackaging machinesProduction lineEngineering

The invention discloses an automatic electronic disk packaging line which comprises a base and a main line annular rail. The main line annular rail is installed on the top of the base, the outer side of the main line annular rail is provided with an electronic disk picking and secondary molding mechanical arm, a folding bolt mechanism, a label pasting machine and a CCD finished product detector, a paper skin storing and feeding mechanism and a PASS pasting mechanism are fixedly connected to the top of the base, and a stacking mechanical arm is arranged on one side of the PASS pasting mechanism. According to the automatic electronic disk packaging line, the main line annular rail is installed on the top of the base, materials detected by OCR detecting equipment are processed through the folding bolt mechanism, the materials are subject to box closing operation, labeling operation, CCD finished product detection and PASS pasting operation in sequence on the main line annular rail, at the time, the overall production processes of the finished products are completed, the finished products on the production line are carried away through a stacking mechanism, the overall device is rational in division of labor, manual operation can be replaced, the production efficiency is improved, and time and manpower cost are saved.

Owner:广东金昇智能数控有限公司

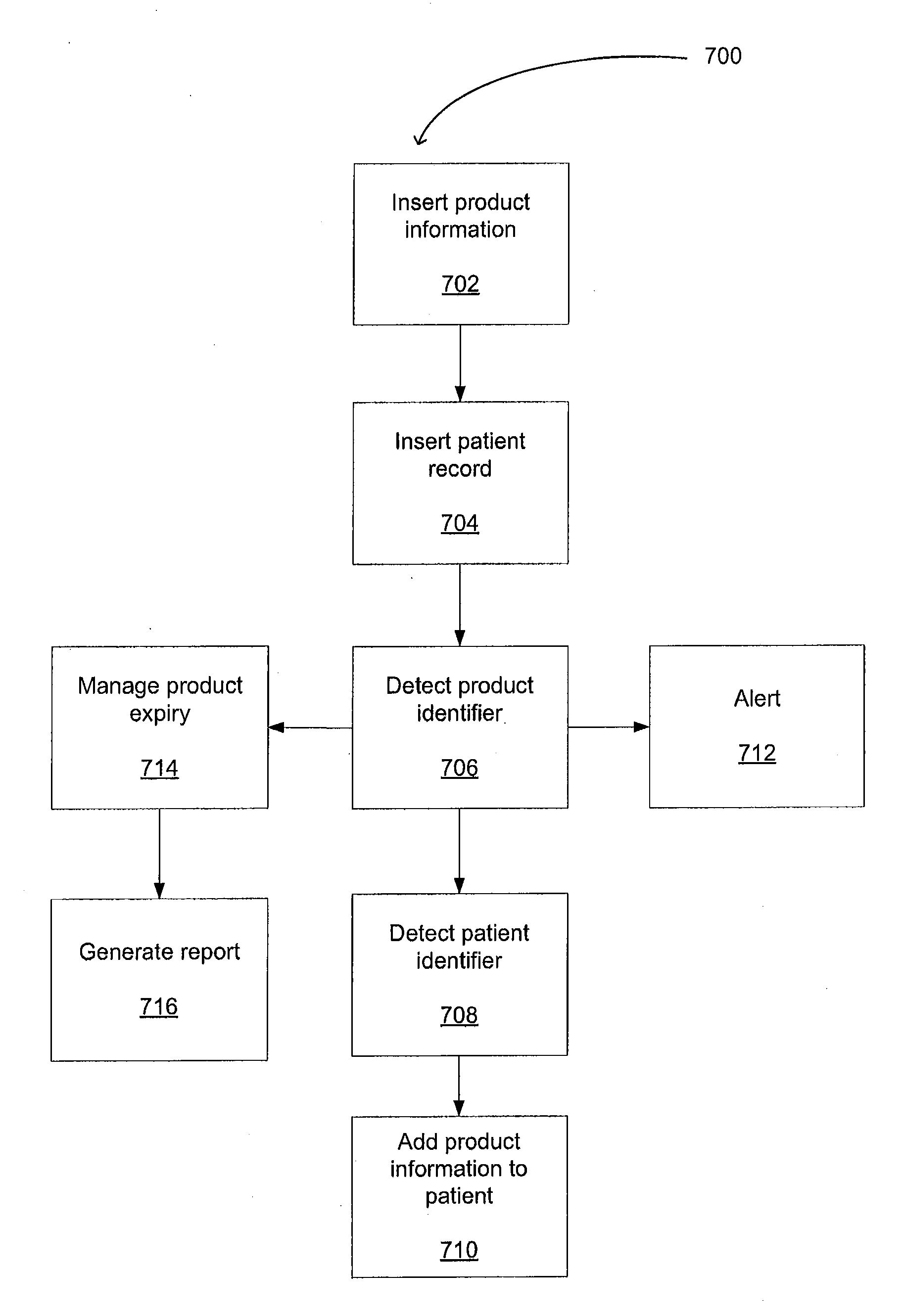

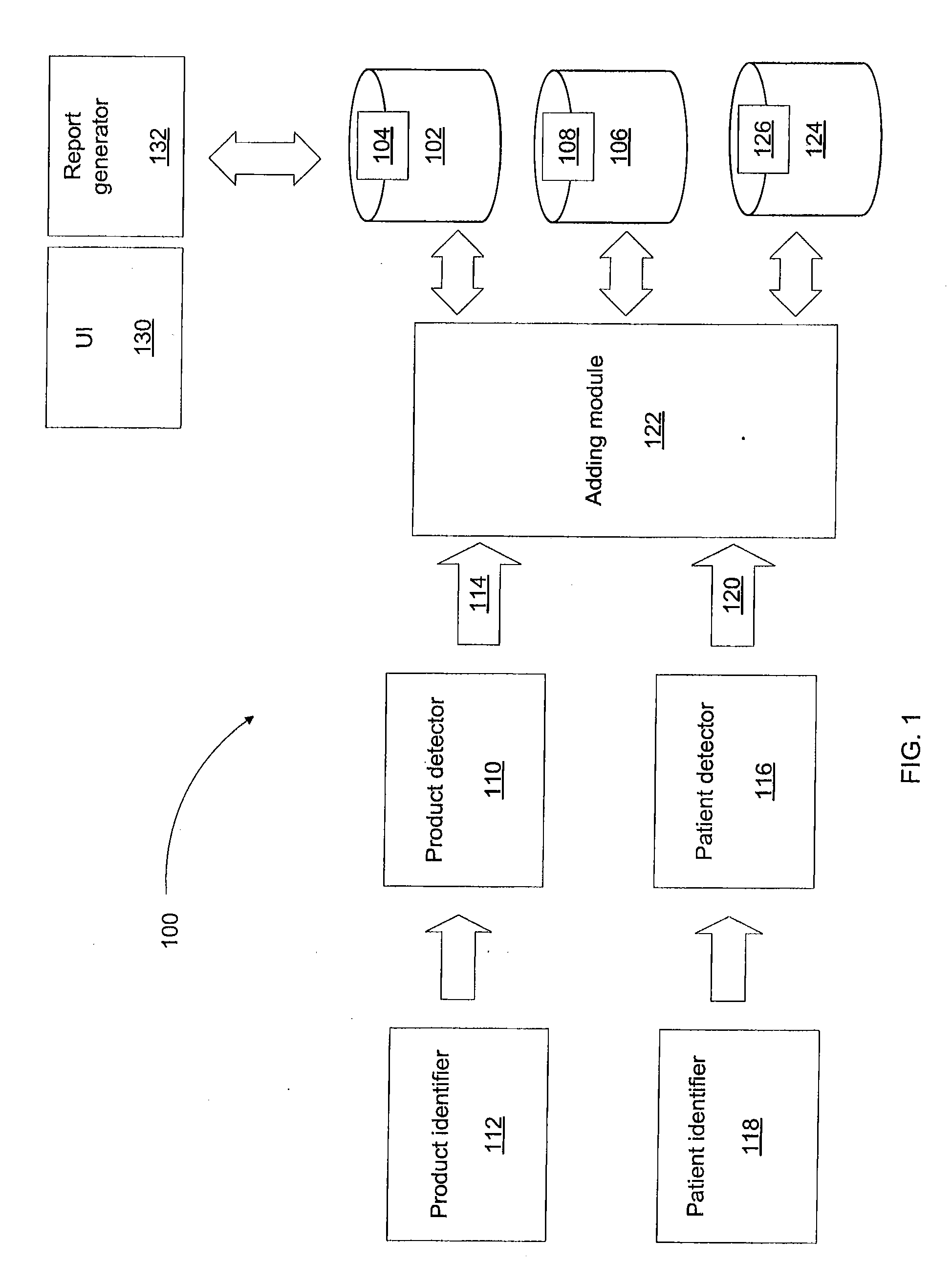

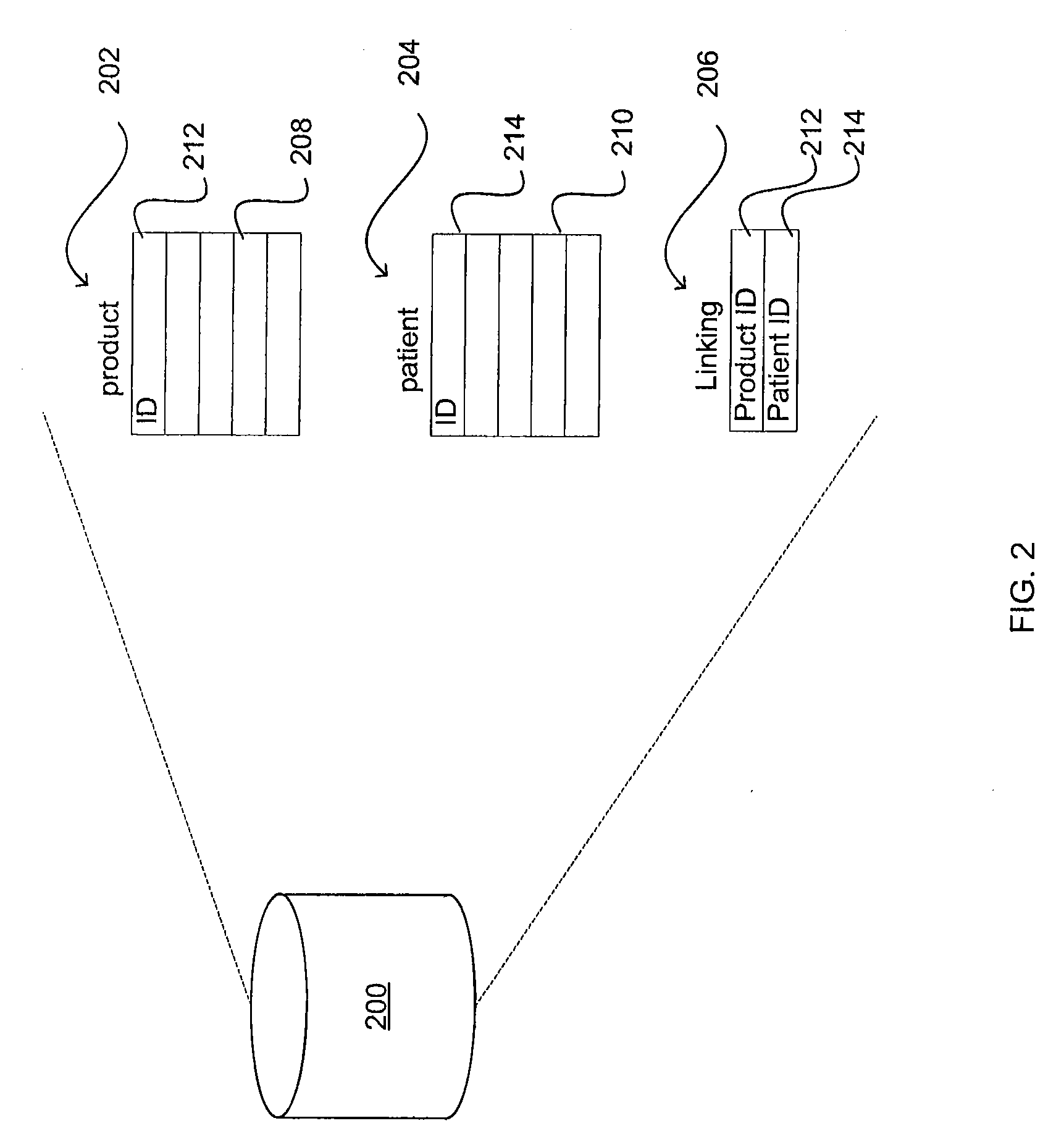

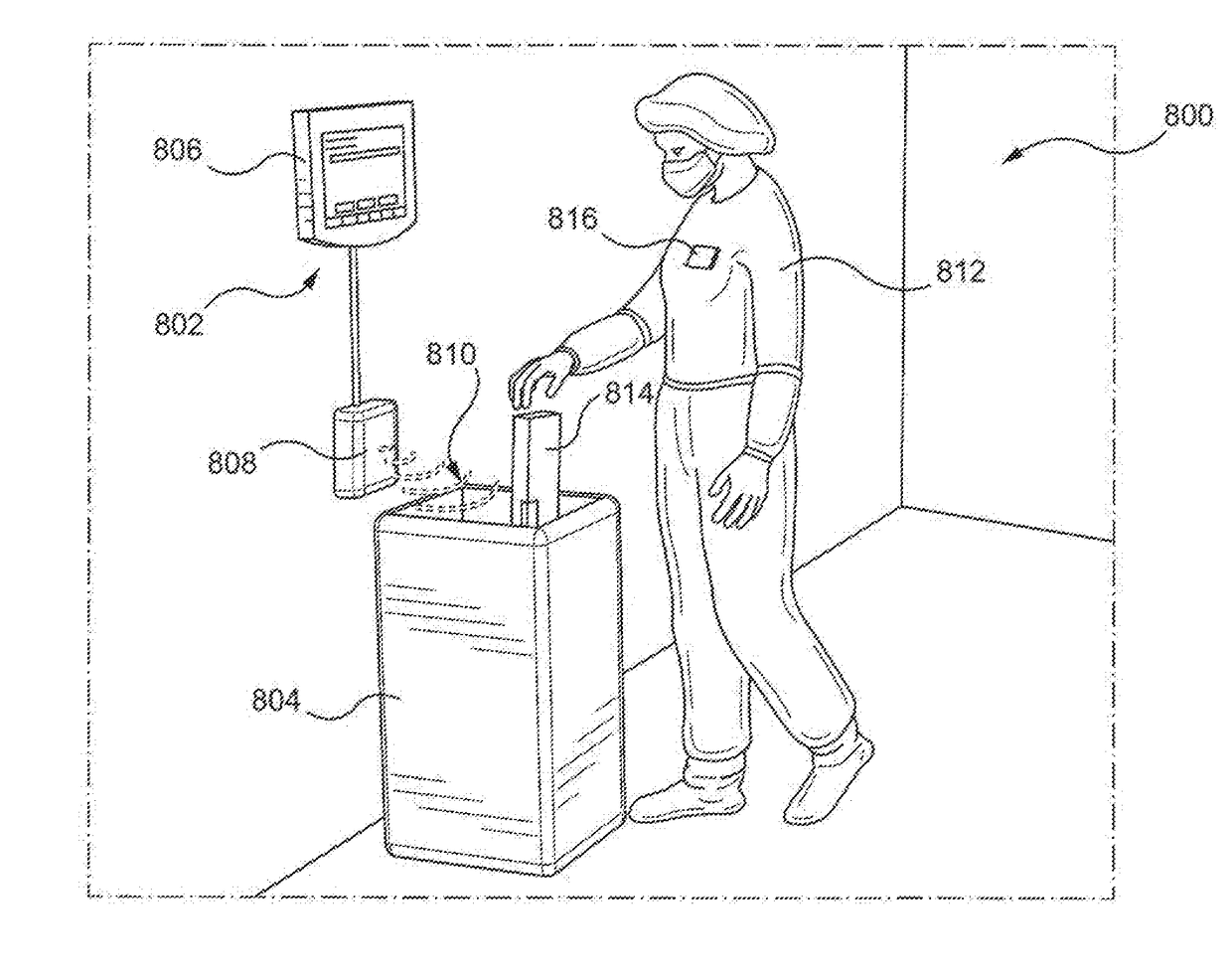

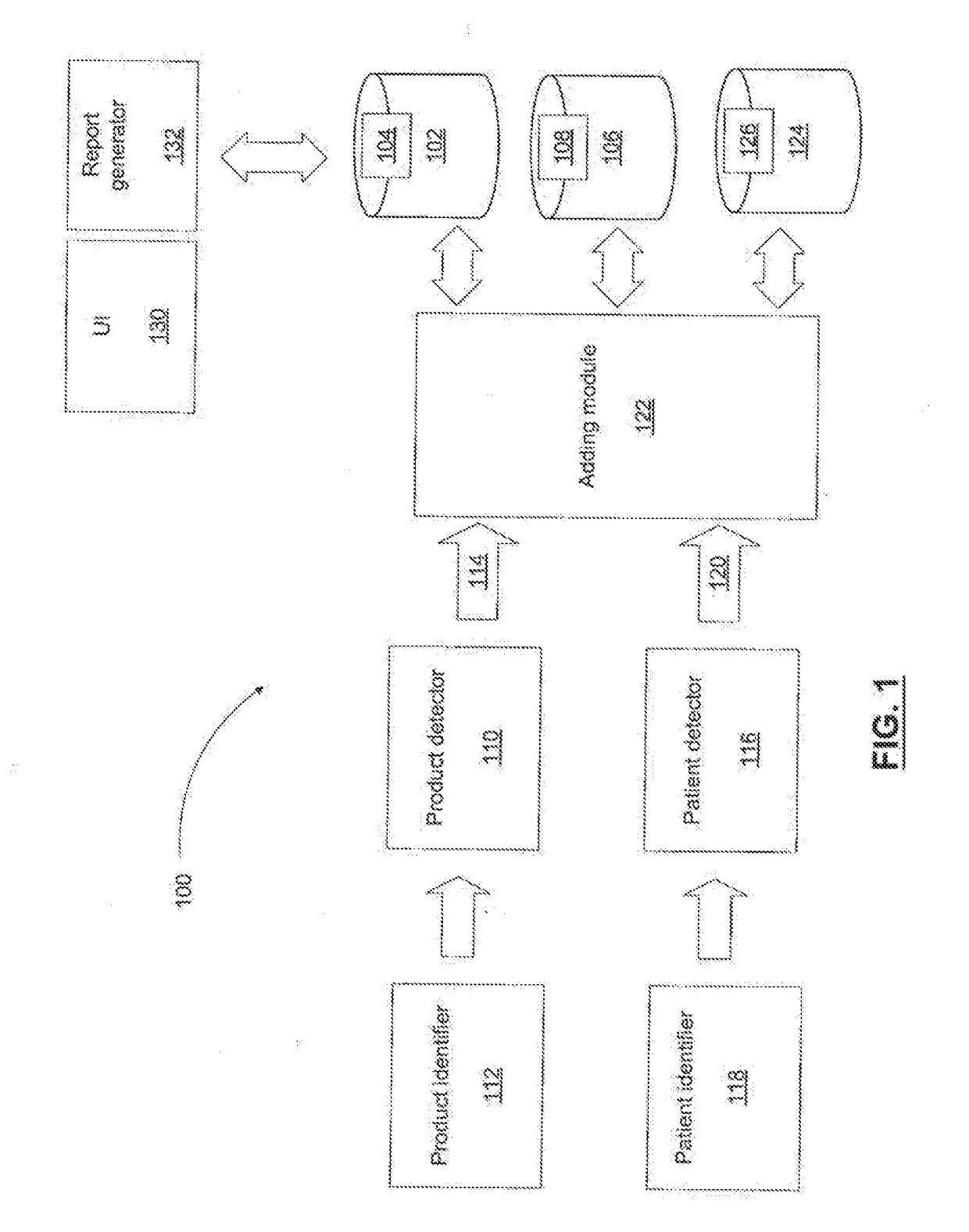

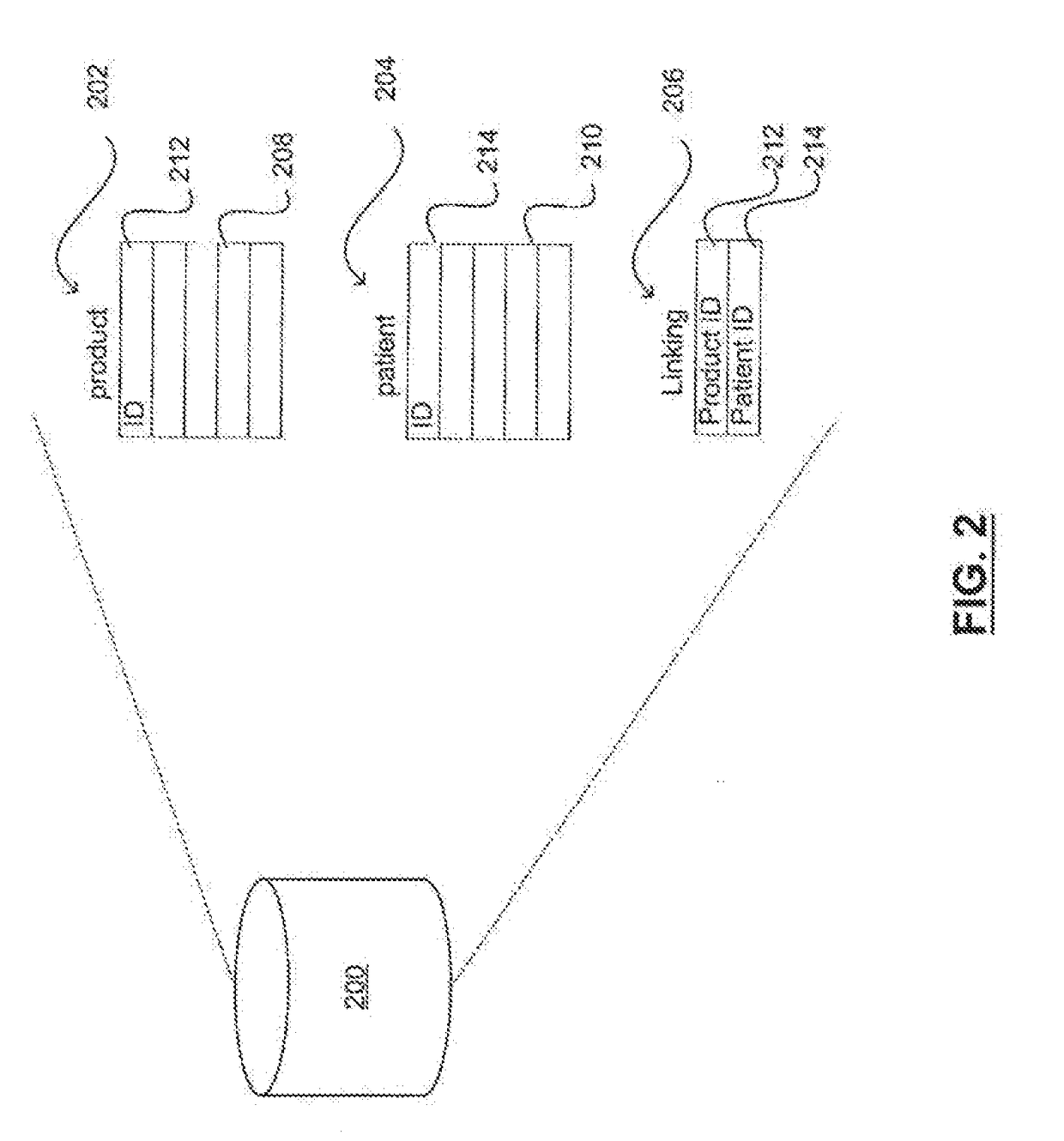

System and method for adding and tracking product information to a patient record

ActiveUS20100274585A1Patient personal data managementOffice automationPatient databaseProduct Identifier

The present system and the method relate to adding product information to patient record. A product database stores the product information corresponding to a product, while a patient database stores the patient record corresponding to a patient. A product detector detects a product identifier corresponding to the product information and generates a product identifier message. The patient detector detects a patient identifier corresponding to the patient record and generates a patient identifier message. An adding module adds the product information to the patient record based on the patient identifier message and the product identifier message.

Owner:LOGI D

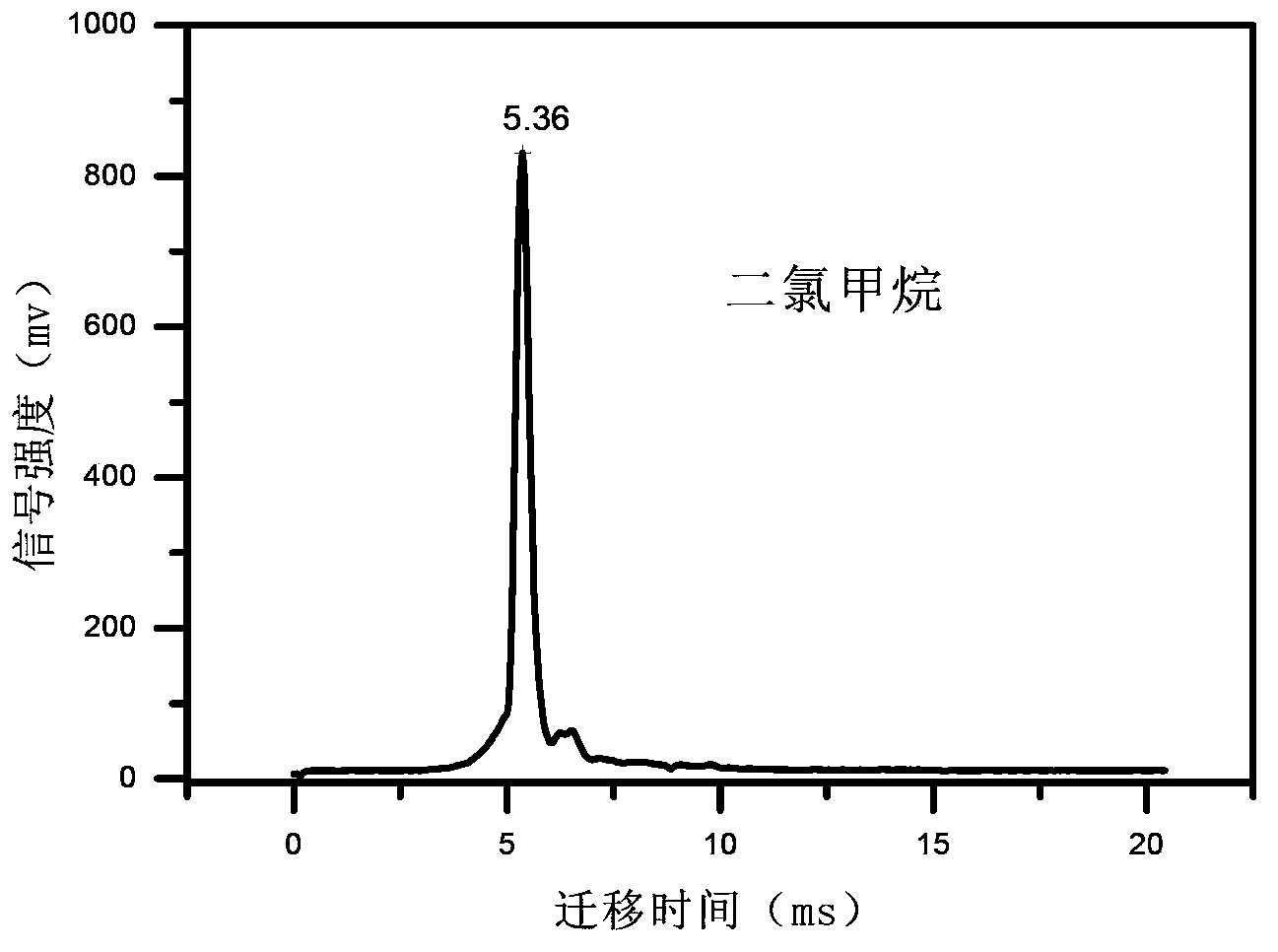

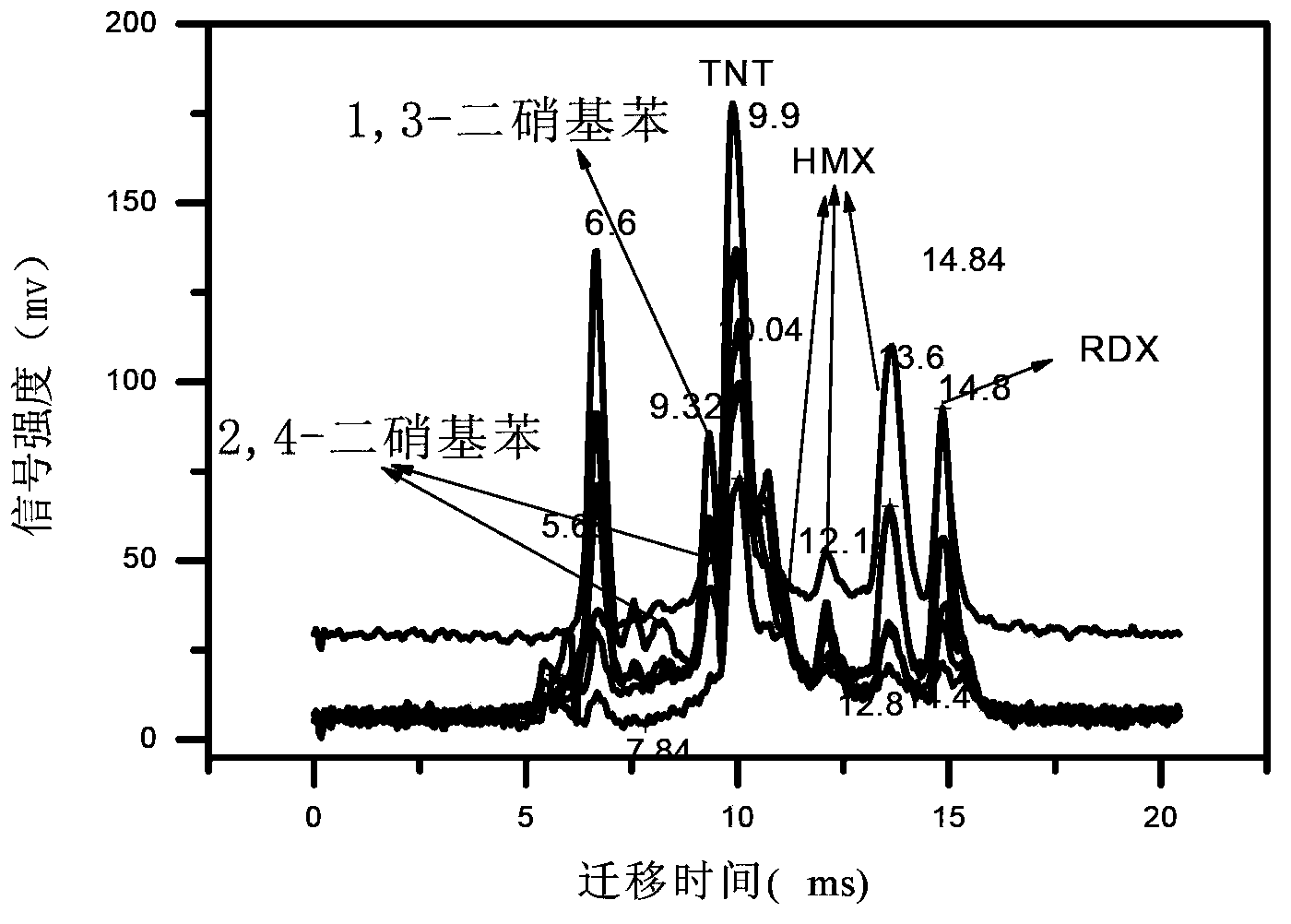

Method for rapidly separating and detecting mixed explosives

InactiveCN103675088AAvoid missingPreparing sample for investigationMaterial analysis by electric/magnetic meansPublic placeBoiling point

The invention discloses a method for rapidly separating and detecting mixed explosives and belongs to the detection technologies of trace mixed explosives. According to the method, the physical characteristics that different explosives have different melting points and boiling points are utilized, an electric heating technology is adopted, and phased continuous temperature rise control is adopted near the melting points or the boiling points, the detection for the mixed explosives is finished in a wider temperature range, and the method is simple in principle and easy to realize. After the technology is mature, a novel light mixed explosive product detector can be formed, has the characteristics of small size, light weight, low cost and portability in use, and can be flexibly used for rapidly detecting various mixed explosives in public places.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Paper breaking machine for inspection machine

ActiveCN105293156BAvoid deformationPrevent inflowArticle deliveryProduct detectorUltimate tensile strength

The invention discloses a paper unfolding and loading machine for a product detector. The machine comprises a stack piling and paper loading mechanism used for piling up a plurality of thick printing products stacks and conveying the thick printing product stacks, wherein the output end of the stack piling and paper loading mechanism is corresponding to the input end of a lifting and stack dividing mechanism; the output end of the lifting and stack dividing mechanism is corresponding to the input end of a small stack conveying mechanism, wherein the lifting and stack dividing mechanism is used for dividing each thick printing product stack into a plurality of thin printing product stacks as well as conveying out the thin printing product stacks; the output end of the small stack conveying mechanism is corresponding to the input end of a paper unfolding mechanism, wherein the small stack conveying mechanism is used for continuously sequentially conveying each thin printing product stack; the output end of the paper unfolding mechanism is corresponding to the input end of a paper loading and conveying mechanism, wherein the paper unfolding mechanism is used for sequentially performing a paper unfolding work at least twice and a paper releasing work once for each thin printing product stack and then conveying out the thin printing product stacks; the output end of the paper loading and conveying mechanism is corresponding to the input end of a paper feeding mechanism of the product detector, wherein the paper loading and conveying mechanism is used for finishing the paper loading work in a telescopic paper conveying manner. According to the machine, the paper can be continuously fed to the paper feeding mechanism of the product detector after the printing products are subjected to paper unfolding, so that the labor intensity of workers can be greatly reduced, the production efficiency can be improved, and the rate of graded products can be ensured.

Owner:HEBEI TIANYUHENG TECH CO LTD +1

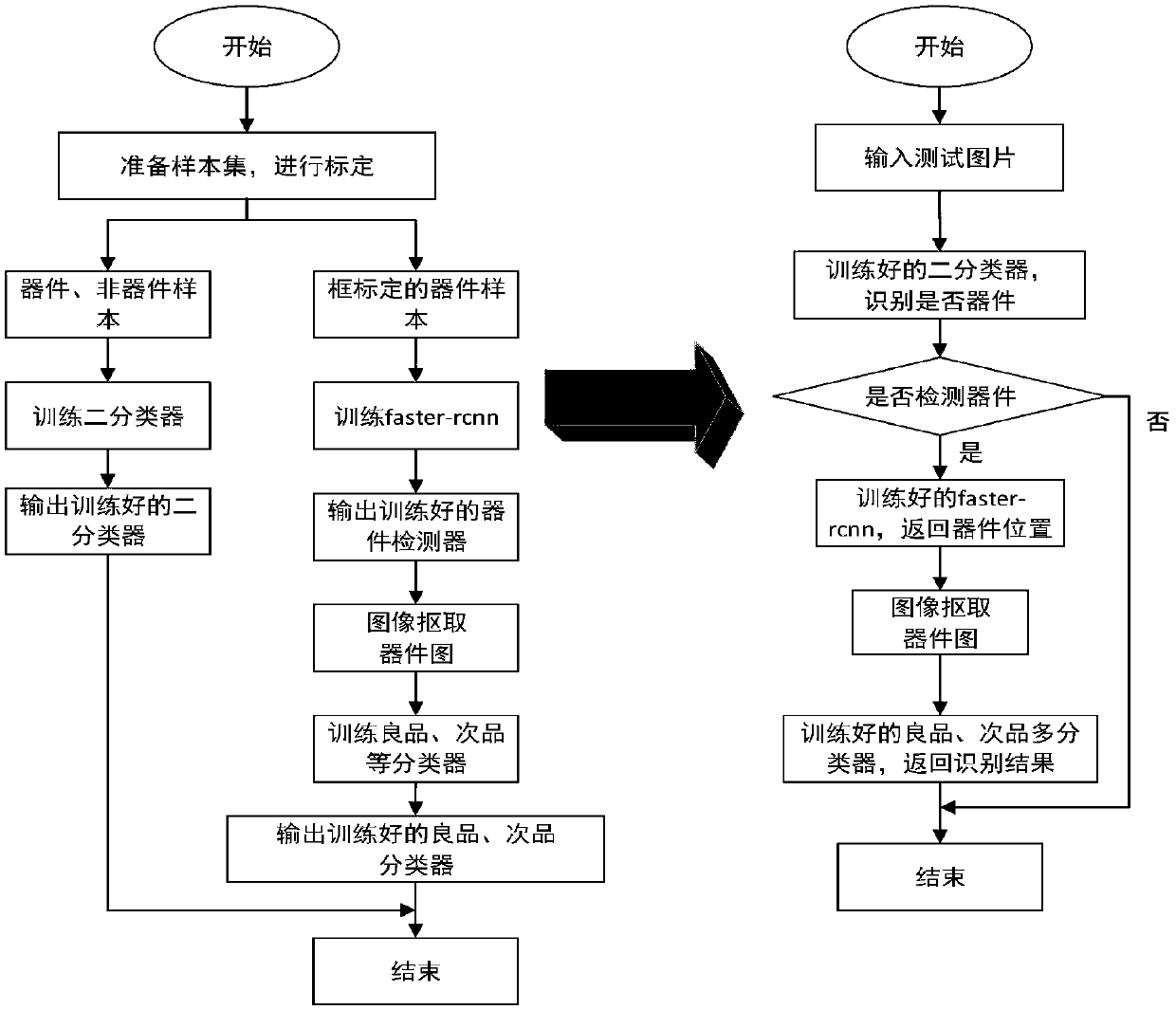

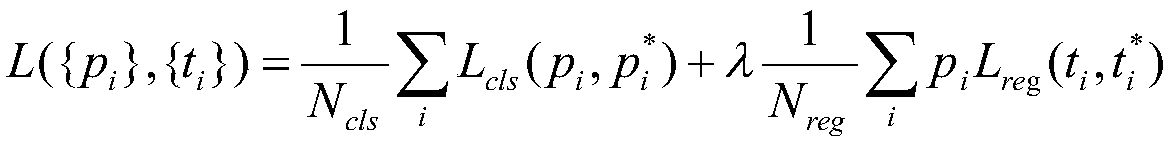

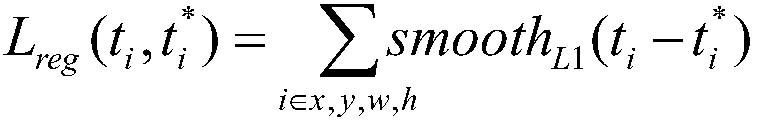

Product quality inspection method

ActiveCN108682003AImprove practicalityImage enhancementImage analysisProduct detectorComputer science

The invention discloses a product quality detecting method. The method comprises two parts, wherein the first part is to construct a recognizer, and the second part is to use the recognizer to detectthe quality of a product to be tested, wherein the recognizer includes a dichotomic classifier which judges whether an object to be tested satisfies the requirements of products in a test category, aproduct detector which judges the position of the product in a picture, and a multi-classifier which judges whether the product is a qualified or a defective product. With the method adopted, whetherthe product is a qualified or defective product can be detected. The method has the advantages of high speed, extendibility and high flexibility.

Owner:睿视智觉(厦门)科技有限公司

Automatic paper discharging device, paper control device and paper product detector

The invention provides an automatic paper discharging device, a paper control device and a paper product detector, and relates to the technical field of paper product detection related equipment. Theautomatic paper discharging device comprises a vibrator and a pushing plate, the vibrator is arranged on the pushing plate, and the pushing plate is used for pushing paper products out. According to the automatic paper discharging device, the paper control device and the paper product detector which are provided by the invention, the automatic paper discharging device can enable the stacked paperproducts to be separated, and each paper product enters the paper product detector from the lower end of a stack of paper products; through the paper control device, the stacked paper products can bein the stacking state, and the effect that only one paper product of the stacked paper products is pushed out by the automatic discharging device every time is ensured; and in this way, the paper product detector provided with the automatic paper discharging device and the paper control device can detect the various paper products, the application range of the paper product detector is widened, and the requirements of an enterprise for multiple kinds of products are met.

Owner:青岛市贤俊龙彩印有限公司

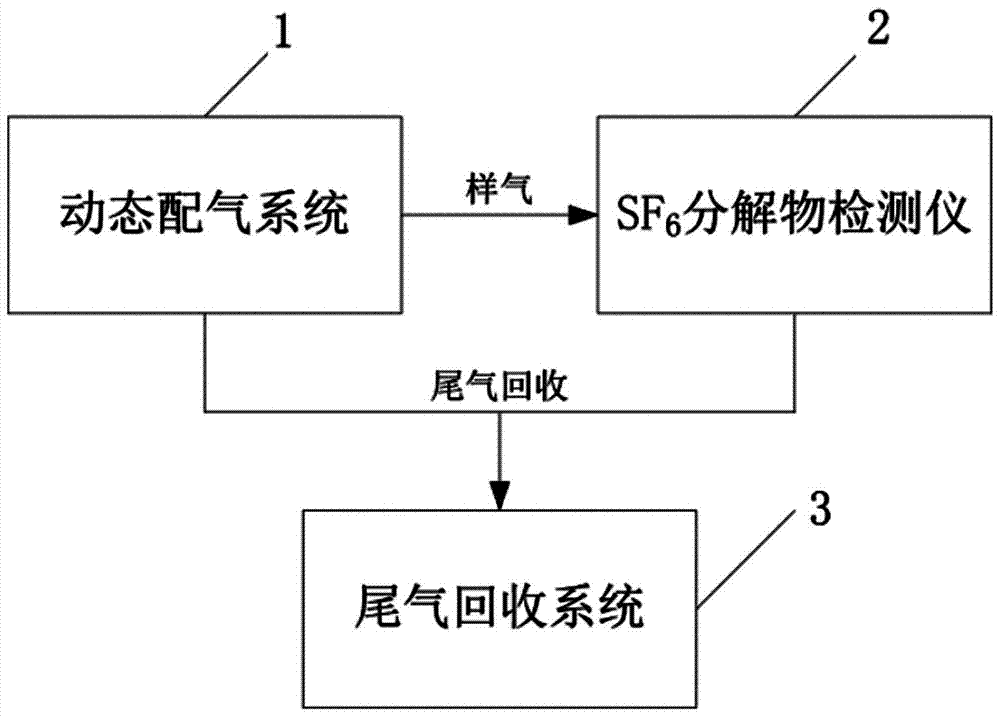

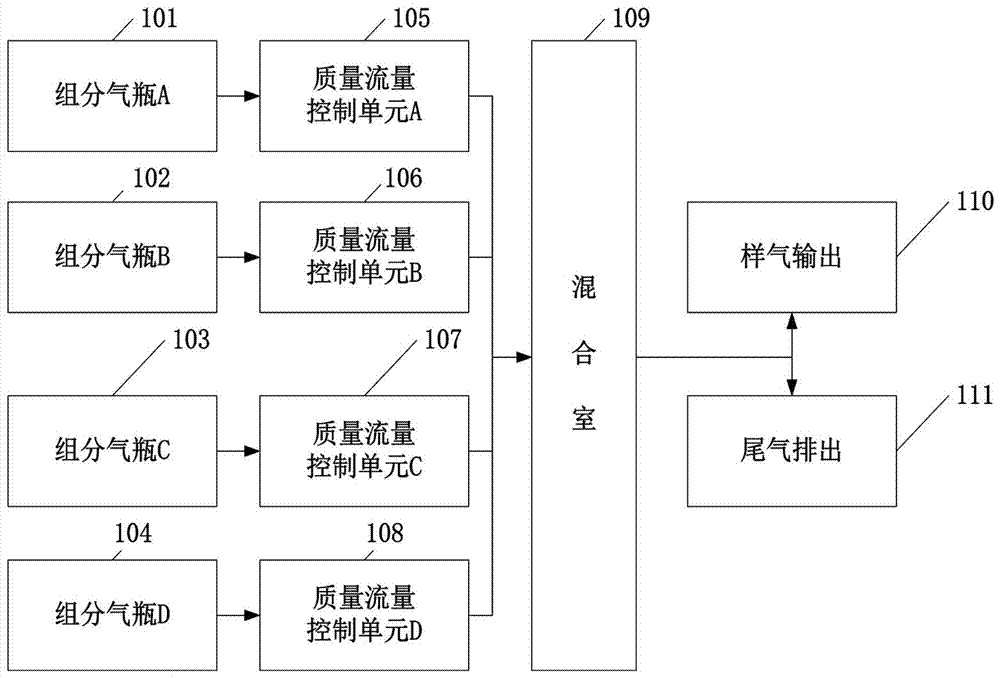

SF6 (sulfur hexafluoride) decomposition product detector calibration device

PendingCN107356712AImprove calibration work efficiencyRealize fully automatic inspectionAnalysing gaseous mixturesEnvironmental resistanceDecomposition

The invention belongs to the technical field of checking of a detection instrument of SF6 (sulfur hexafluoride) electrical equipment, in particular relates to an SF6 (sulfur hexafluoride) decomposition product detector calibration device and specifically relates to the SF6 (sulfur hexafluoride) decomposition product detector calibration device, which adopts a multi-component dynamic gas distribution system. The calibration device comprises the SF6 decomposition product detector; a sample gas output end of the dynamic gas distribution system is connected to a sample gas input end of the SF6 decomposition product detector; tail gas discharging ends of the dynamic gas distribution system and the SF6 decomposition product detector are connected to a tail gas input end of a tail gas recycling system. The SF6 (sulfur hexafluoride) decomposition product detector calibration device, provided by the invention has the characteristics of reasonable design, simple structure, convenience for operation and utilization and the like. According to the SF6 (sulfur hexafluoride) decomposition product detector calibration device, the working efficiency of calibrating the SF6 decomposition product detector can be improved and full-automatic checking and performance estimation of the SF6 decomposition product detector are realized; stable operation of a whole system can also be realized; emission of toxic and harmful gas is reduced and the probability that workers are in contact with the toxic and harmful gas is reduced, so that a zero-emission, pollution-free and environment-friendly working place is provided.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

Polymerase chain reaction (PCR) module and multiple PCR system using the same

InactiveUS8697433B2Bioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural scienceProduct detector

Provided are a PCR module and a multiple PCR system using the same. More particularly, provided are a PCR module with a combined PCR thermal cycler and PCR product detector, and a multiple PCR system using the same.

Owner:SAMSUNG ELECTRONICS CO LTD

Systems and methods for automatically tracking products in a medical facility

According to some aspects, a product tracking, system, including a tracking module adaptedto be affixed to a wall or other mounting location adjacent a receptacle for receiving products therein. The tracking module is operable to track products as they are discarded in the receptacle. The tracking module also includes at least one of a product detector, a patient detector, and an adding module.

Owner:LOGI D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com