Non-excavation two-layer tank reconstruction method and oil product leakage detection method

A double-layer tank and no-excavation technology, which is applied in the direction of layered products, packaged food, packaged item types, etc., can solve problems such as waste of social resources, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

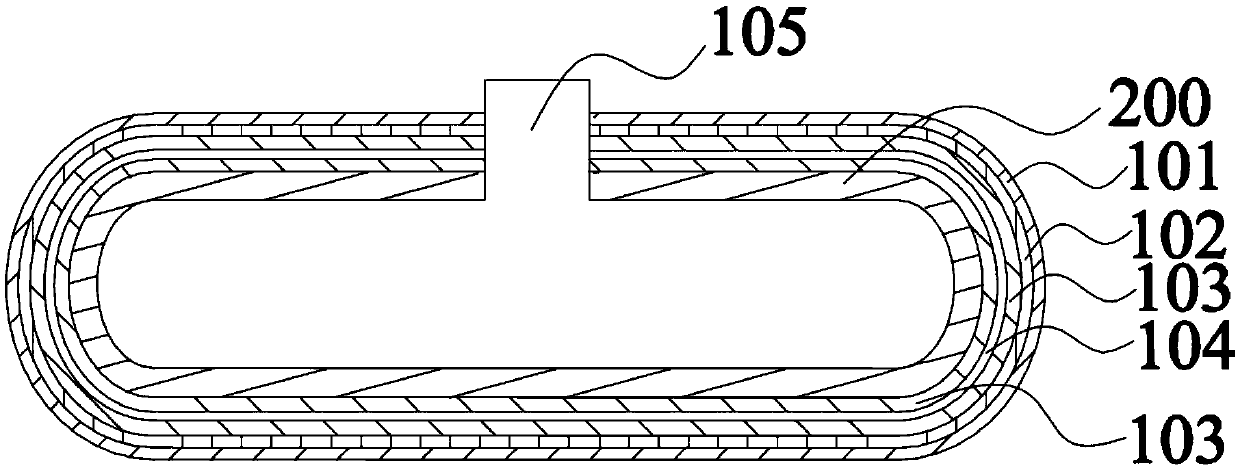

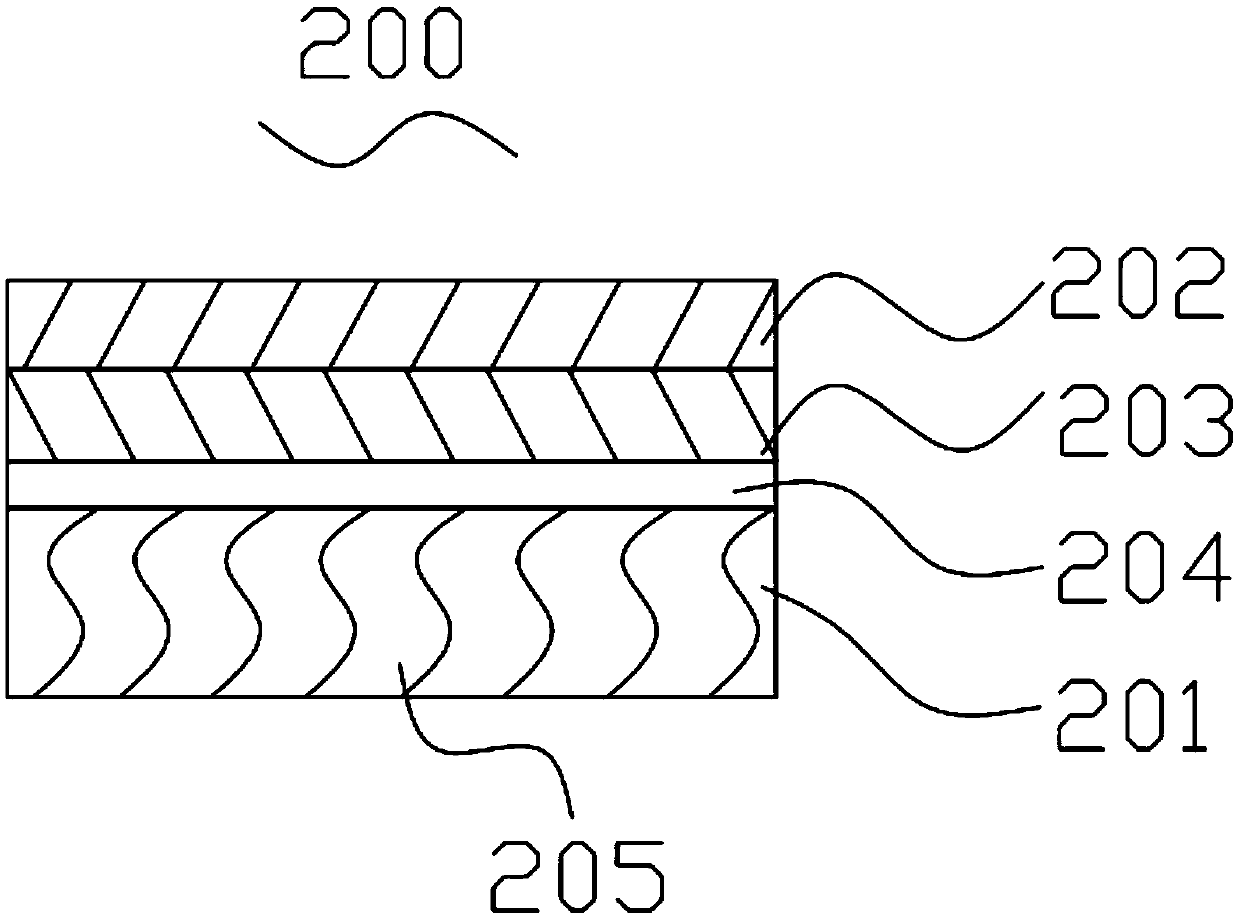

[0028] The following is attached with the manual figure 1 And attached figure 2 The technical scheme of the present invention is described in detail:

[0029] In order to solve the problems existing in the prior art, the present invention provides a method for transforming a non-excavation double-layer tank, and the method for transforming the non-excavation double-layer tank includes steps:

[0030] A: Clean the inner surface of the tank body 101 to be transformed;

[0031] B: gluing the tank body 101 inner surface after cleaning;

[0032] C: immerse the grid cloth 104 into the colloid;

[0033] D: Paste the soft 3D braided composite 200 on the colloid, so that the soft 3D braided composite 200 and the tank body 101 to be transformed form a double-layer tank structure.

[0034] In the technical solution of the present invention, a preferred solution is also provided, including: the transformation method of the non-excavation double-layer tank includes the steps:

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com