Printed-product detector with printed product in-stack collecting counting device, and operating method thereof

A technology of counting device and product inspection machine, which is applied in stacking receiving device, transportation and packaging, and thin material processing, etc. It can solve the problems of paper jam, inaccurate counting of printed products, disordered paper delivery, etc., and reduce the number of personnel , the combination is simple and convenient, and the effect of counting is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

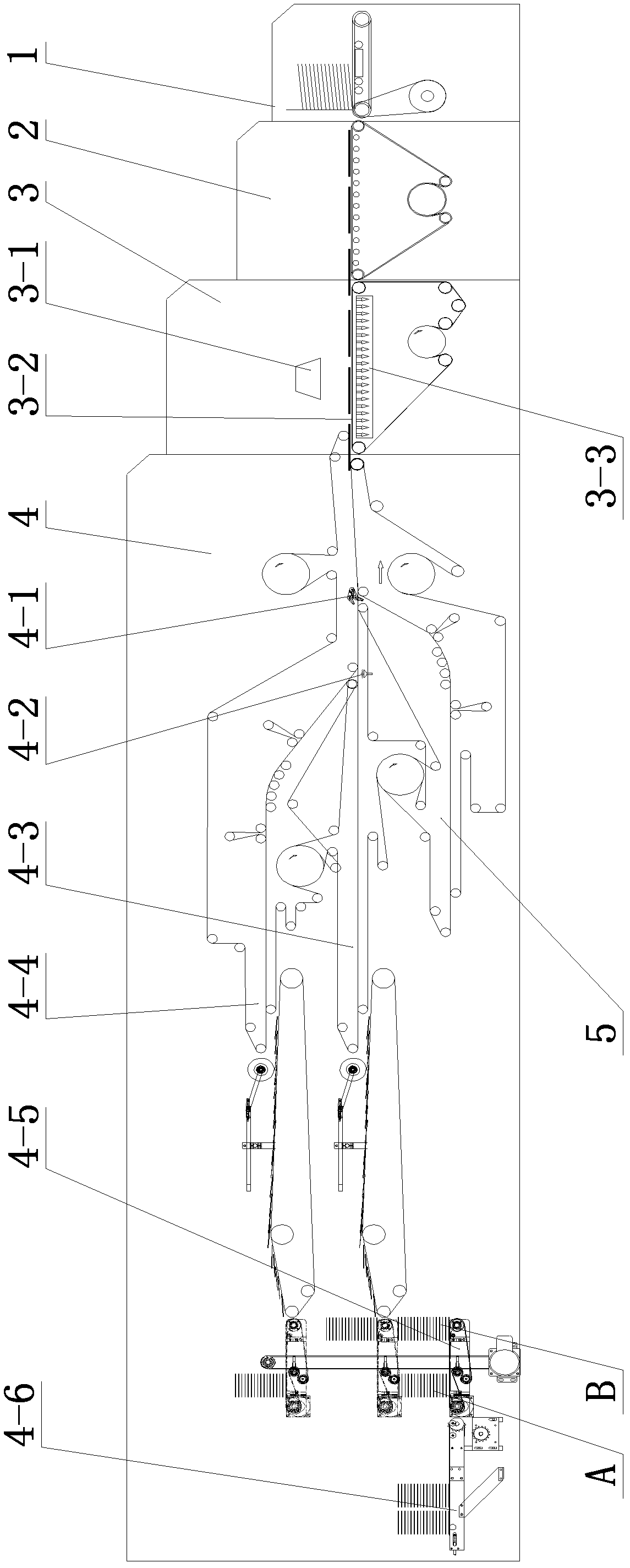

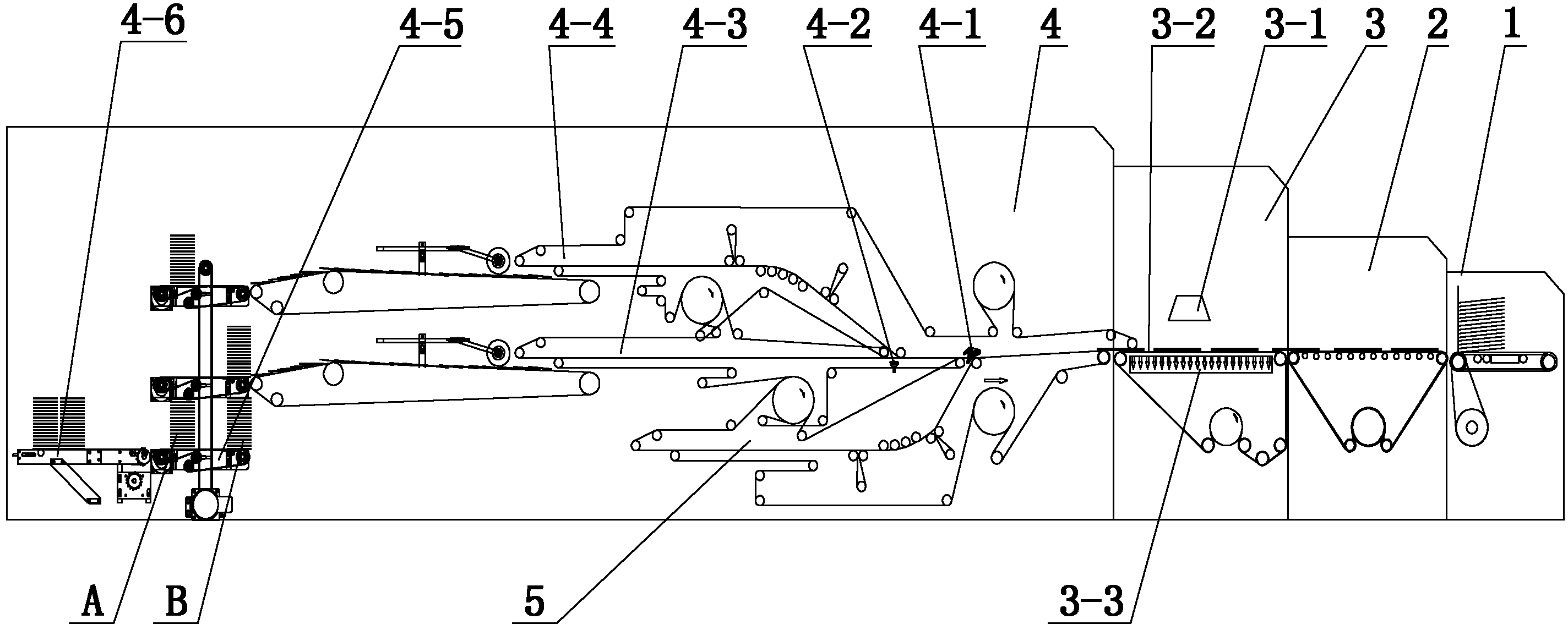

[0026] Embodiment: a kind of product inspection machine (see accompanying drawing) that has printing product separate collection and counting device, it is characterized in that it comprises paper feeding part 1, correction part 2, detection part 3, separate pile collection and counting part 4 and waste product collection Section 5; the output end of the paper feeding section 1 is connected to the input end of the correction section 2; the output end of the correction section 2 is connected to the input end of the detection section 3; the output end of the detection section 3 is connected to the stacking collection and counting section 4 The input end of the pile collection and counting part 4 includes a rejecting knife 4-1, a blower 4-2, a layered collection part, a stacking part 4-5, a stacking conveying part 4-6 and a waste product collection part 5; The waste collection part 5 is placed below the layered collection part; the layered collection part is at least two layers, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com