Method for rapidly separating and detecting mixed explosives

A technology for mixing explosives and explosives, which is applied in the field of trace mixed explosives detection, can solve the problem of unreported mixed explosives and other problems, and achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

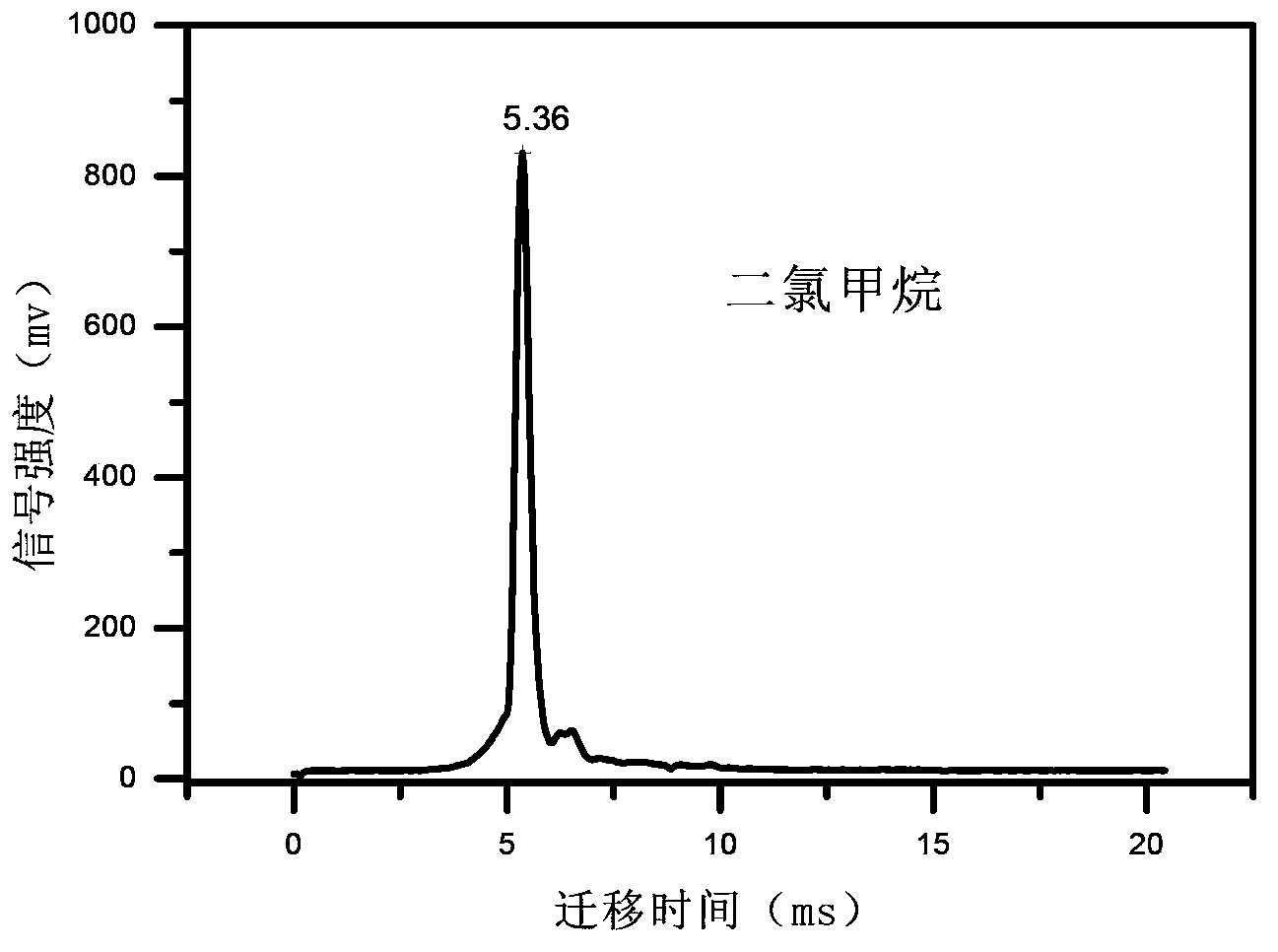

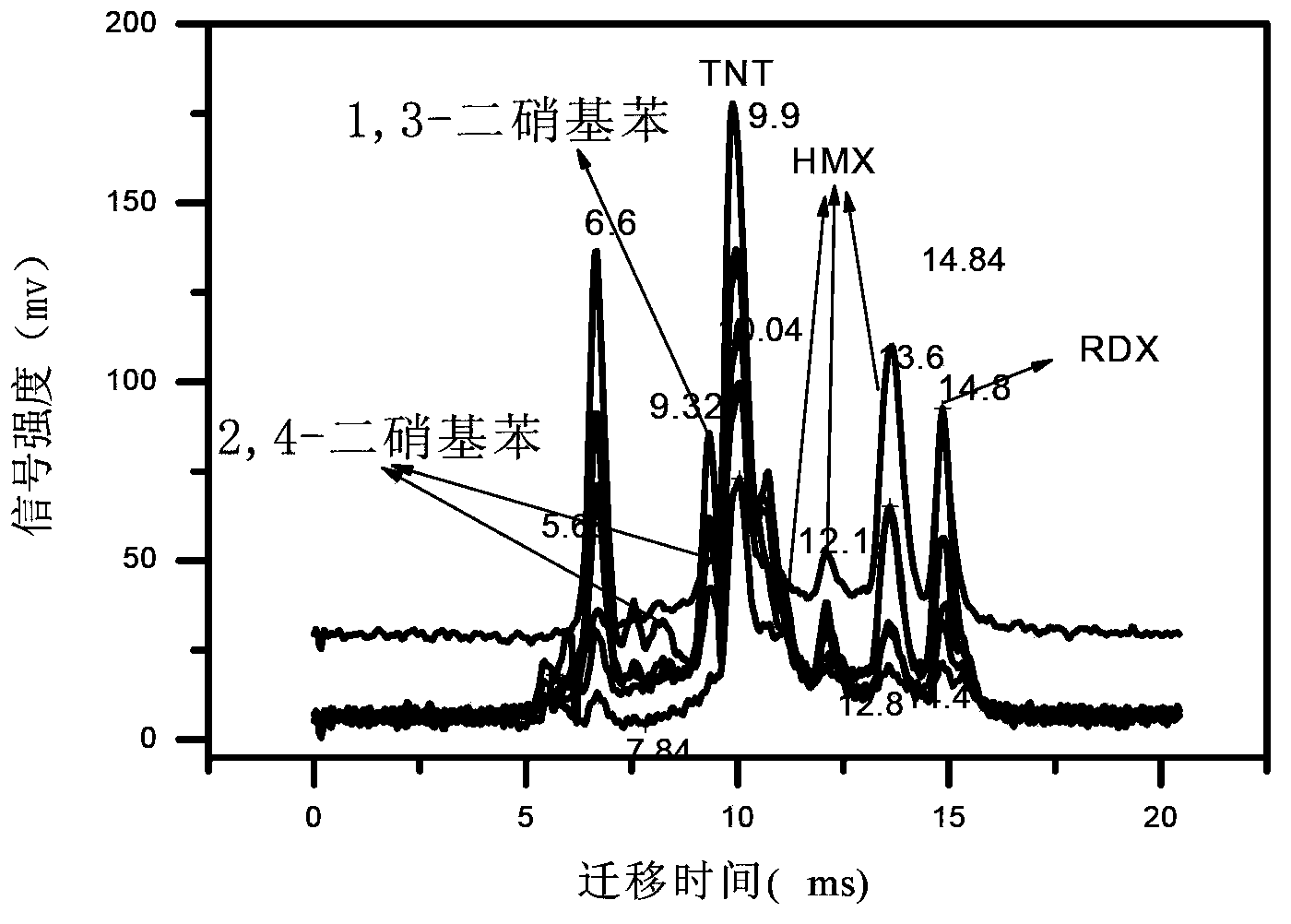

[0021] In order to realize the measurement of explosives, the present invention uses the ion mobility spectrometer as the ionization source as the detection instrument, and the gaseous easily ionizable compound (dichloromethane, concentration 5-100ppm) is passed into the reaction zone in the ion mobility tube of the ion mobility spectrometer, Through the ionization of nickel source, ion mobility spectrometry uses air as carrier gas and drift gas to detect mixed explosives in negative ion mode.

[0022] Different explosives in the mixture have different melting points, for example, the melting point of TNT is 80.6°C, the melting point of dinitrobenzene is 89°C, the melting point of RDX is 204°C, and the melting point of HMX is 276-286°C. The mixed explosives in the examples were purchased from Bailingwei Company, and the concentration of each single component was about 100ppm. The thermal analysis temperature of mixed explosives adopts electric heating technology, and adopts st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com