Product quality inspection method

A detection method and technology for product quality, applied in image data processing, instrument, character and pattern recognition, etc., can solve problems such as affecting the development of enterprises, traditional methods, and easy to cause accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

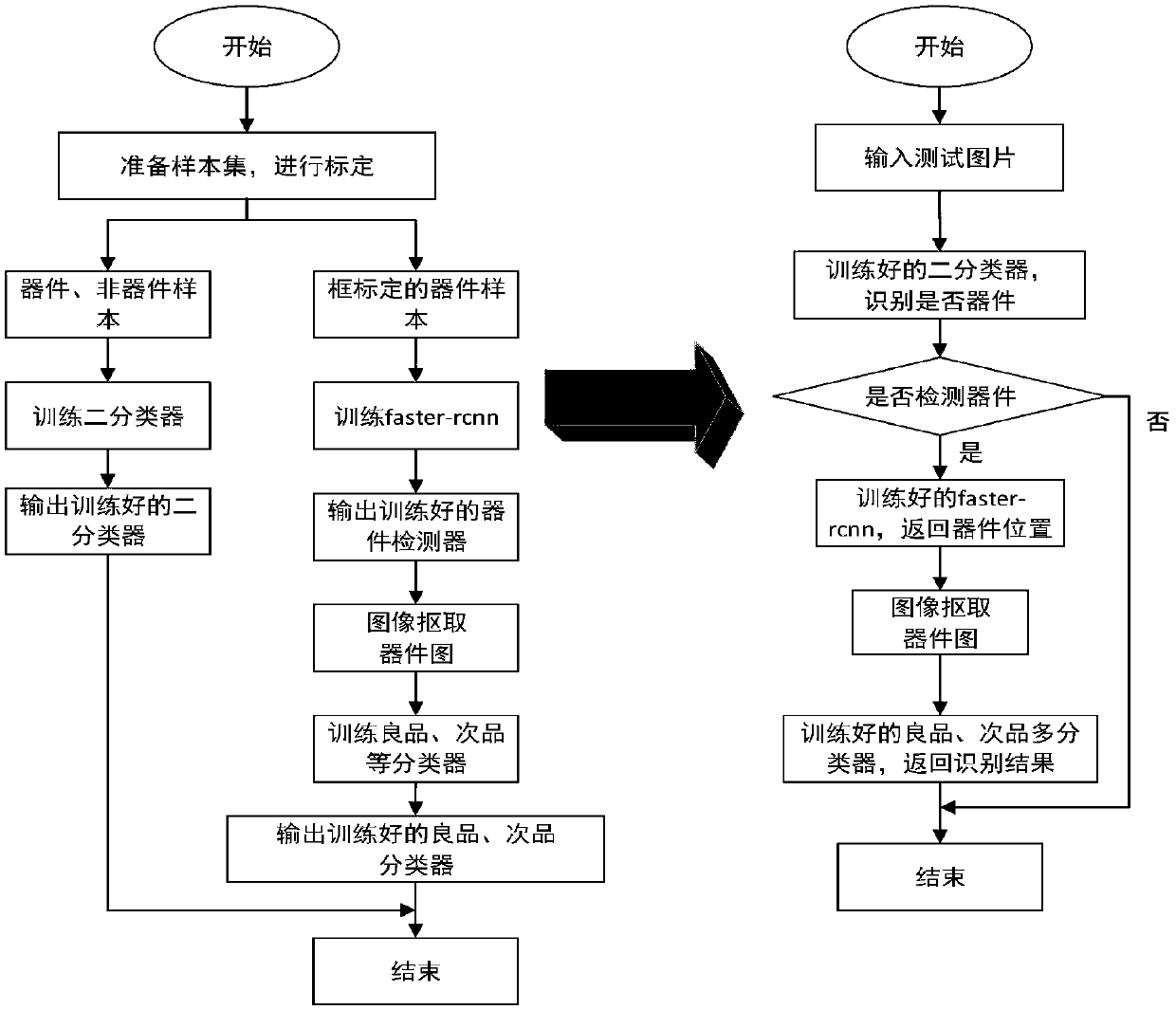

[0023] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the present invention provides a product quality detection method, which includes two parts. The first part is to build a recognizer, and the second part is to use the recognizer to detect the quality of the product to be tested. The recognizer here includes: judging the quality of the product to be tested A binary classifier for detecting whether the object meets the detection category, a product detector for judging the position of the product in the picture, and a multi-classifier for judging the quality of the product; among them, the first part mainly includes the following steps:

[0025] Step 1. Prepare several pictures containing products as product samples, prepare several pictures containing non-products as non-product samples, and calibrate each sample. For product samples,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com