Electromagnetic coil assembly production manufacturing system and manufacturing method

A technology for manufacturing systems and electromagnetic coils, which is applied in the manufacture of inductors/transformers/magnets, manufacturing tools, electrical components, etc., can solve problems such as low product quality, poor welding, and low production efficiency, and achieve high quality and the number of defective products The effect of reduction and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

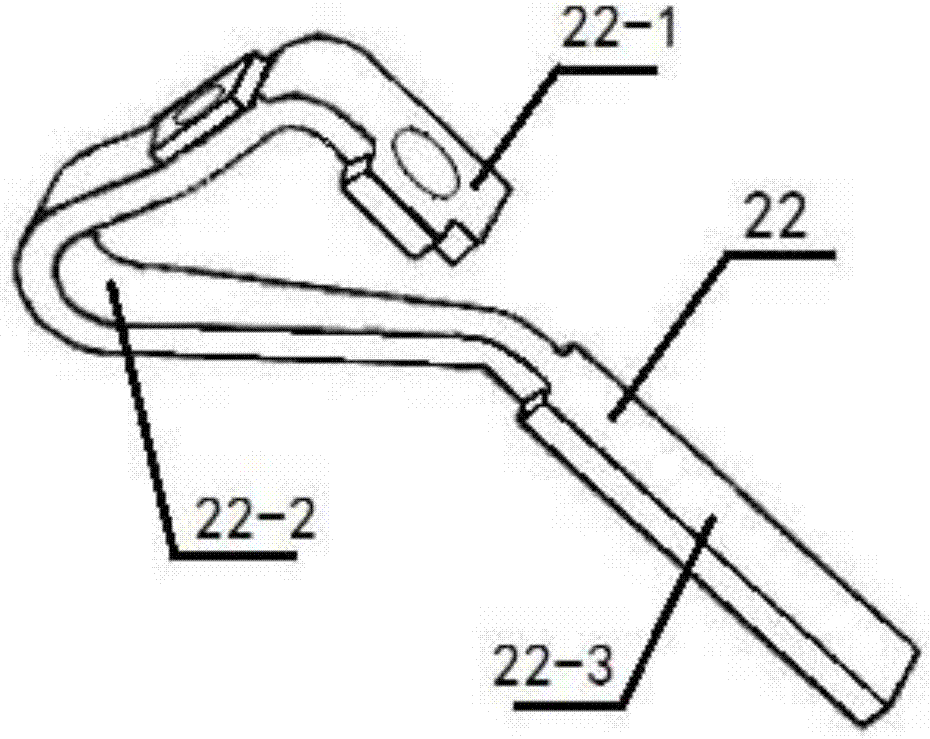

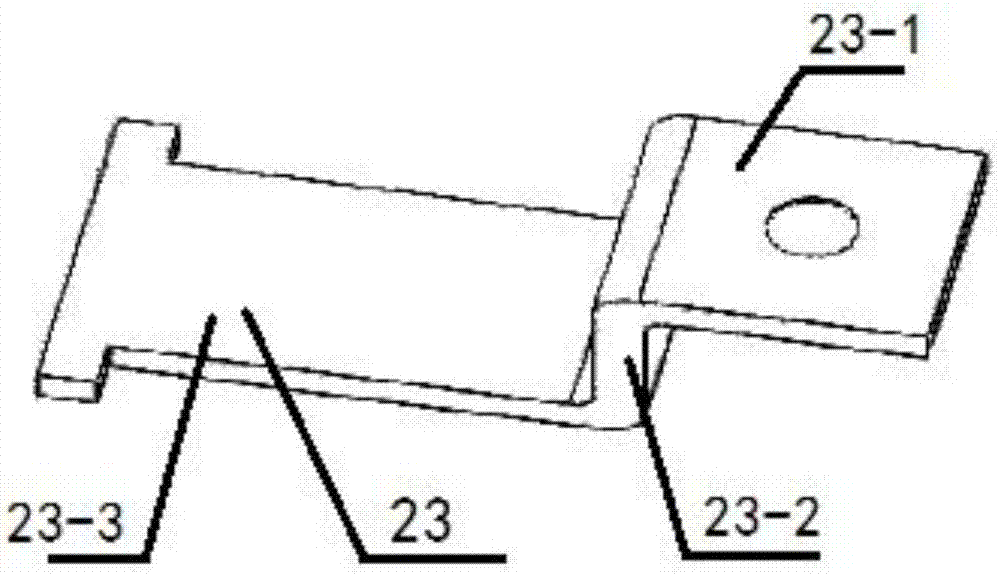

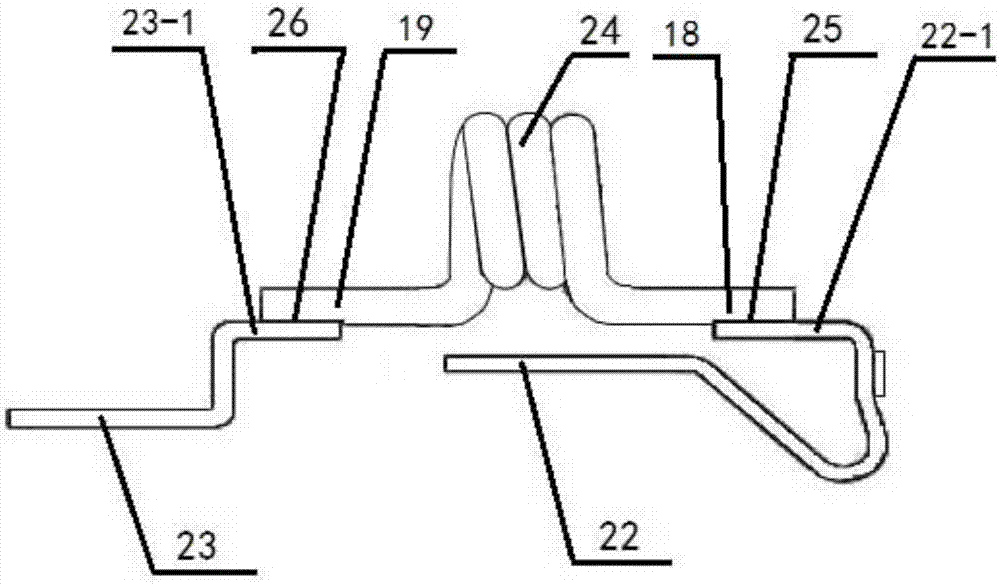

[0054] The electromagnetic coil assembly of the low-voltage circuit breaker is welded by the static contact 22 , the wiring board 23 and the coil 24 . Such as figure 1 As shown, the static contact 22 is composed of a hook head 22-1, an arc handle 22-2 and a straight handle 22-3, and the three are integrated. Such as figure 2 As shown, the wiring board 23 is composed of a first transverse straight plate portion 23-1, a vertical straight plate portion 23-2 and a second transverse straight plate portion 23-3, and the three are integrally structured. Such as image 3 As shown, the first end 18 of the coil 24 is welded with the hook head 22-1 of the static contact 22, and the first welding point 25 is formed at the welding place; The transverse straight plate parts 23 - 1 are welded together, and the second welding point 26 is formed at the welding place.

[0055] The present invention provides a production and manufacturing system for electromagnetic coil components, its func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com