Paper breaking machine for inspection machine

A product inspection machine and paper breaking technology, which is applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of affecting the authenticity rate, high labor intensity, and low production efficiency, so as to improve detection accuracy and reduce labor costs. Strength, labor cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

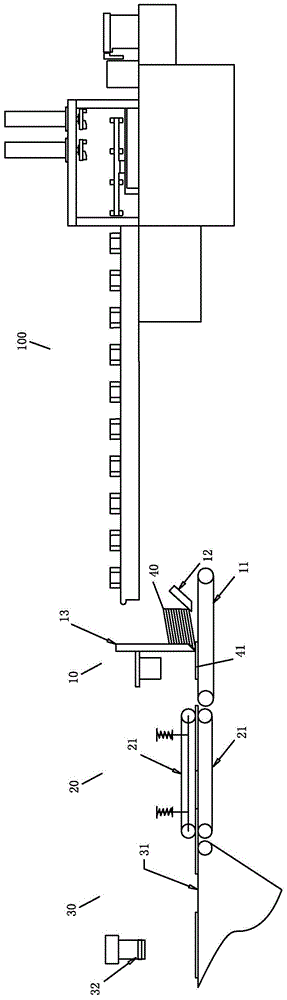

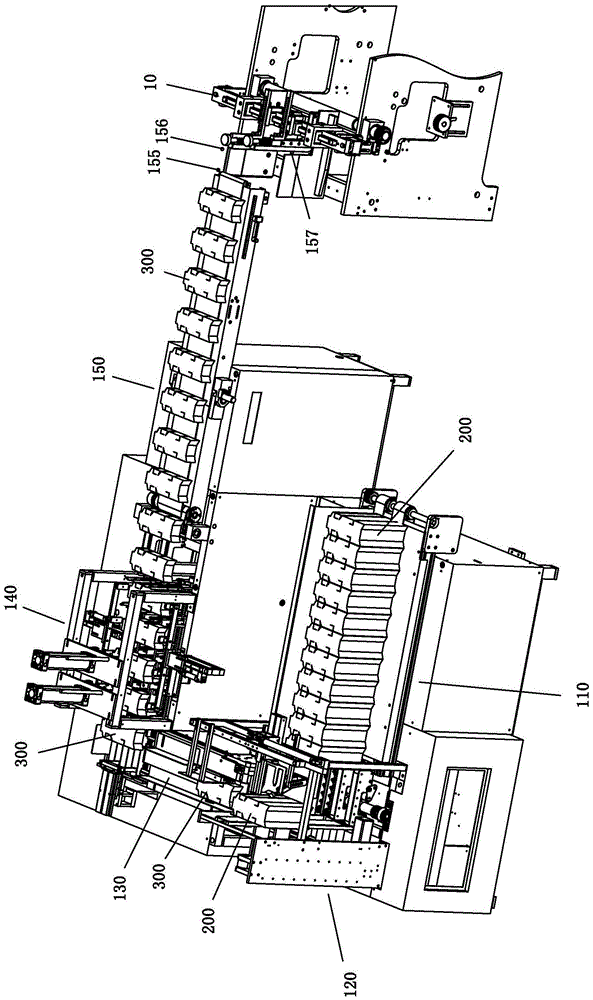

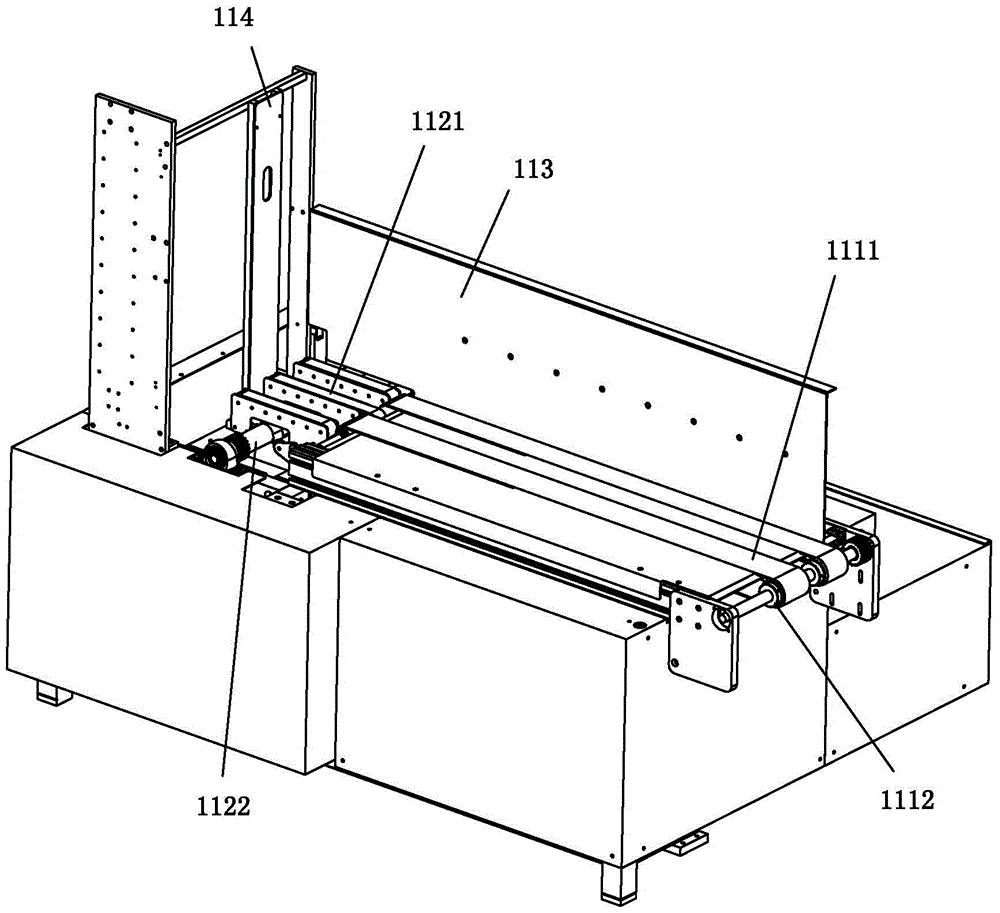

[0036] The paper breaking machine of the present invention is used in a product inspection machine (also known as a small-sheet printed product inspection machine), and is set corresponding to the input end of the paper feeding mechanism 10 of the product inspection machine.

[0037] Existing inspection machines generally include a paper feeding mechanism 10, a deviation correction mechanism 20, and a surface quality inspection mechanism 30, wherein: the paper feeding mechanism 10 includes a paper feeding conveying device 11 and a paper feeding knife 13 and a paper supporting plate 12 correspondingly arranged above it, The deviation correction mechanism 20 includes a pair of deviation correction conveying devices 21 correspondingly arranged up and down, and the surface quality detection mechanism 30 includes a suction detection conveying device 31 and a detection device 32 correspondingly arranged above it. The product inspection machine is an existing equipment in the field, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com