Separated type actuating mechanism for deep-sea visual sampler

An actuator and separate technology, applied in the field of separate actuators, can solve the problems of inability to replace work tools according to different operation requirements, ROV does not have large weight carrying capacity, ROV working environment is complex and changeable, etc. Power transmission efficiency, easy power adjustment, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

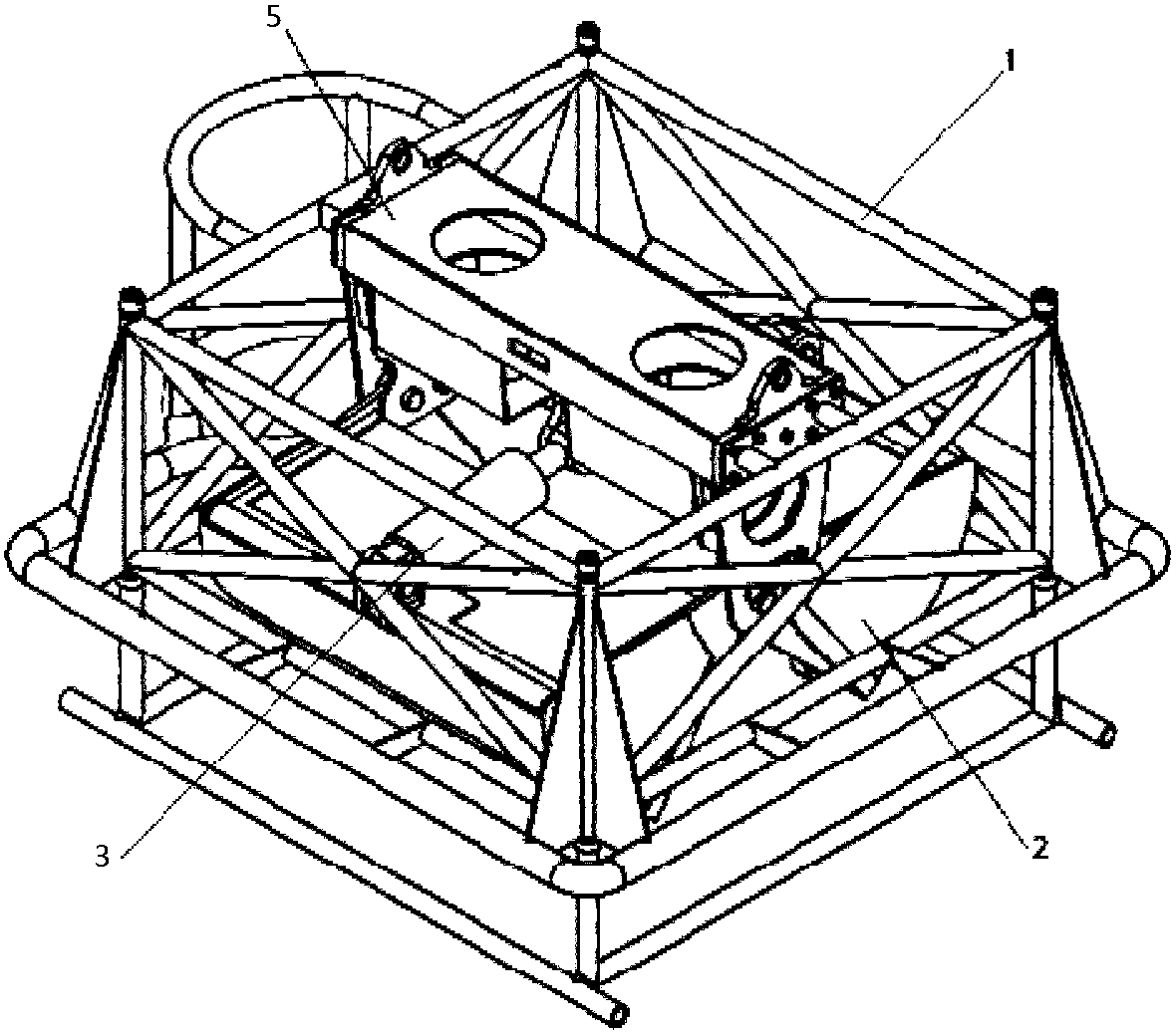

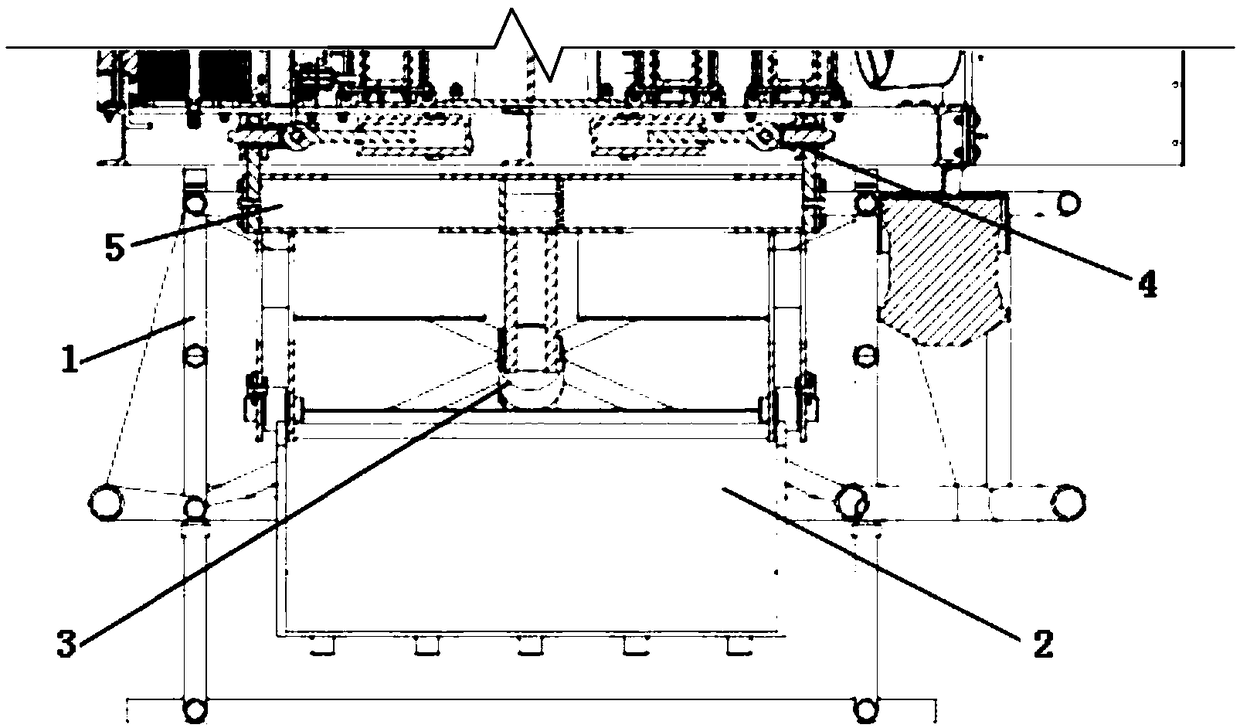

[0029] A separate executive mechanism of a deep-sea visual sampler proposed by the present invention is described in detail as follows in conjunction with the accompanying drawings and an embodiment:

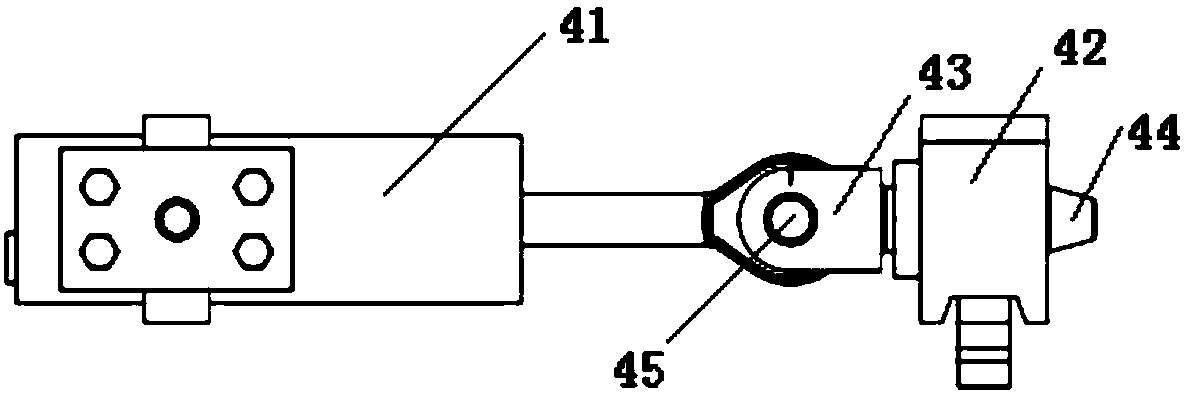

[0030] The separate actuator of the deep-sea visual sampler of the embodiment of the present invention has a structure such as figure 1 , figure 2 As shown, the actuator includes a peripheral non-bearing frame 1, a load-bearing structure 5 located in the frame, a grab bucket 2 and a grab hydraulic cylinder 3; The upper part of the force frame 1 is fixed, and the two bucket-shaped jaws of the grab 2 are respectively driven by a grab hydraulic cylinder 3. The bottom cover of the grab hydraulic cylinder is rotatably connected with the corresponding bucket-shaped jaw. The top end of the piston rod of the cylinder is rotatably connected with the middle part of the bottom end of the load-bearing structure 5; Control system (this control system is the operation control center of thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com