System and method for separating and purifying flavones and polysaccharide from oldenlandia diffusa

A technology for separation and purification of Hedyotis diffusa, applied in the field of separation of effective components of traditional Chinese medicine, can solve the problems of long process time, complicated operation, cumbersome process, etc., and achieve the effect of simple process, high separation precision and good impurity removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

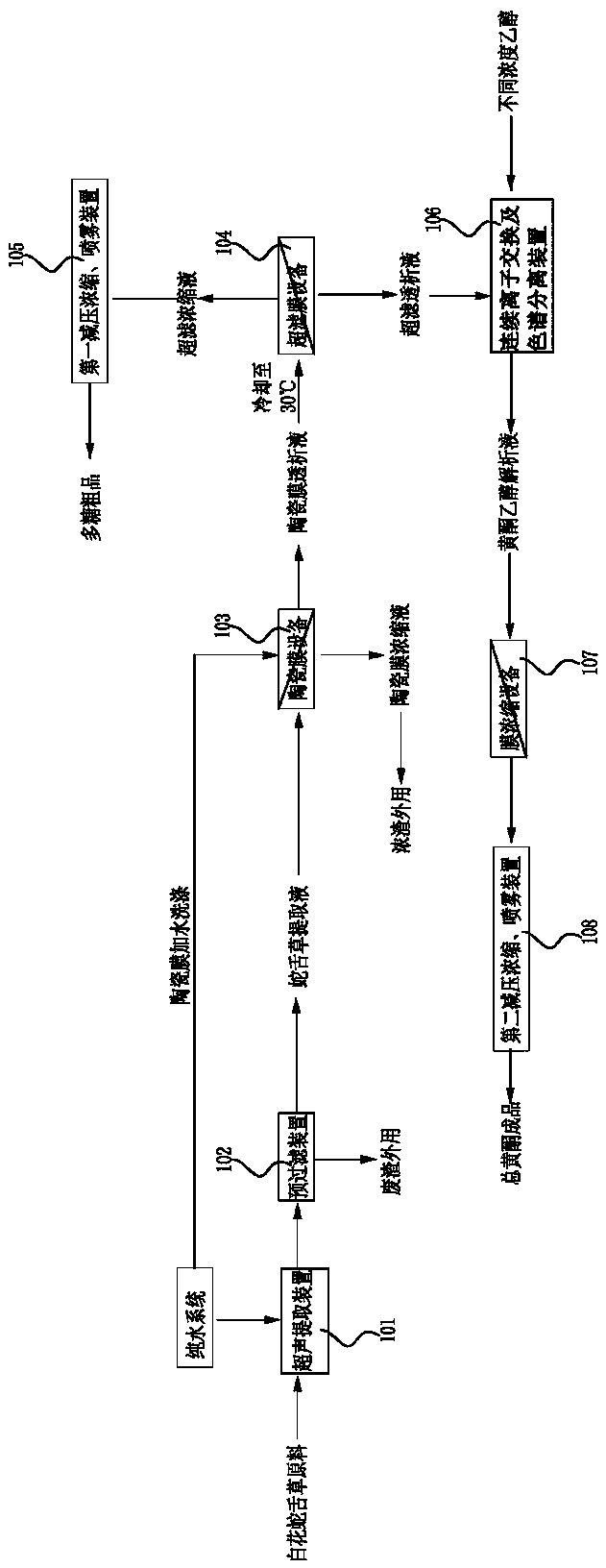

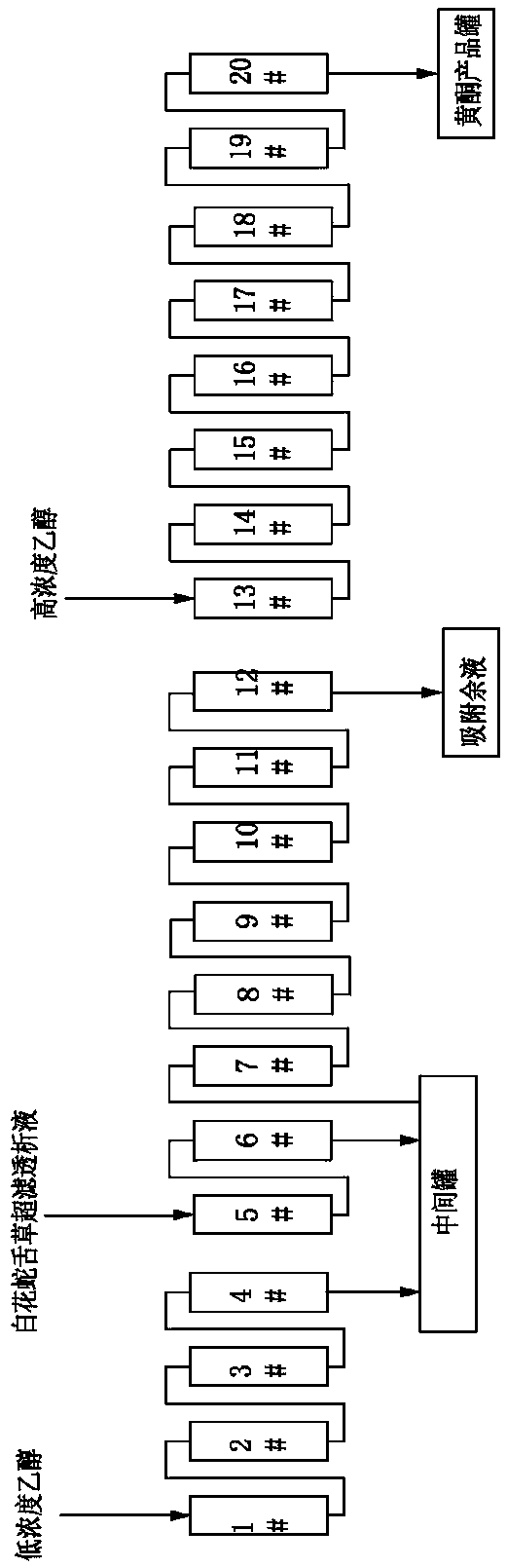

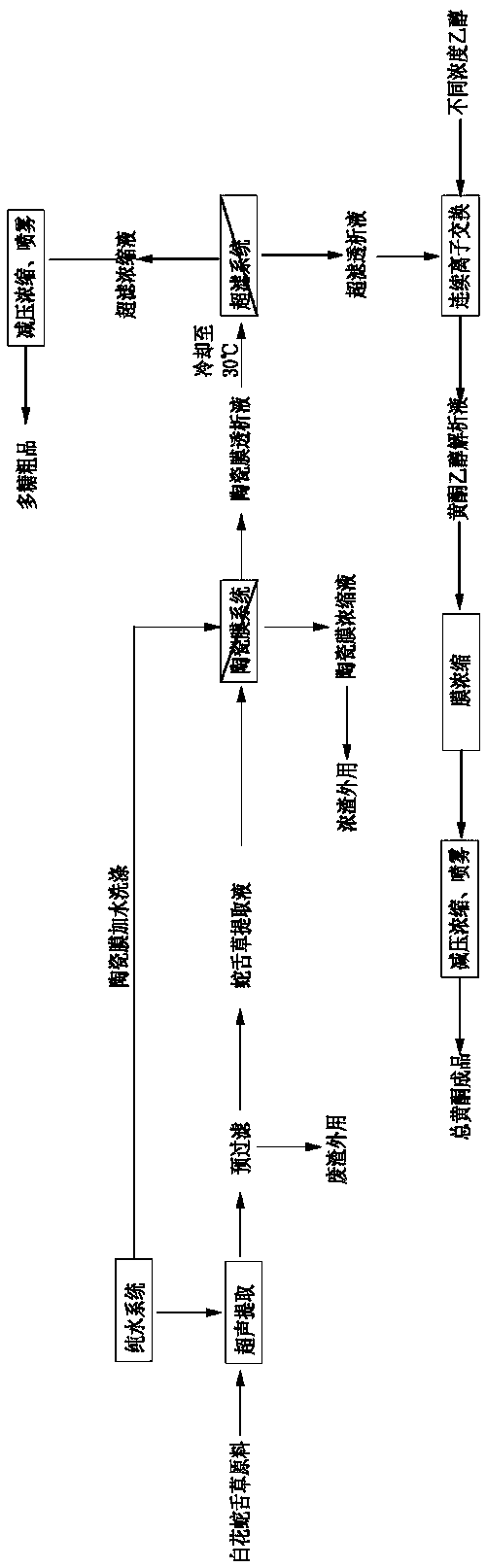

Method used

Image

Examples

Embodiment 1

[0040] Step 1: Weigh 5 kg of pulverized Hedyotis grass powder, add 60 kg of water for ultrasonic extraction for 2 hours, and remove large particles by coarse filtration to obtain 58 L of filtrate;

[0041]Step 2: The filtrate enters the ceramic membrane equipment for clarification and removal of impurities. The membrane area is 0.24 square meters, the pore size is 200nm, the operating pressure is 2.5bar, the operating temperature is controlled within 60°C, and the continuous operation is 540min. During the process, the concentrated solution is washed with water, and the average membrane flux About 51LMH (liter / square meter per hour), get 110L ceramic membrane dialysate;

[0042] Step 3: The ceramic membrane dialysate enters the ultrafiltration membrane equipment for the concentration and separation of polysaccharides. It is equipped with an ultrafiltration roll-type membrane element with a molecular weight cut-off of 2500 Daltons and a specification of 2540. The operating press...

Embodiment 2

[0045] Step 1: Weigh 12 kg of crushed Hedyotis grass powder, add 150 kg of water for ultrasonic extraction for 2 hours, and remove large particles by coarse filtration to obtain 141 L of filtrate;

[0046] Step 2: The filtrate enters the ceramic membrane equipment for clarification and removal of impurities. The membrane area is 0.24 square meters, the pore size is 500nm, the operating pressure is 3.6bar, the operating temperature is controlled within 60°C, and the continuous operation is 1130min. During the process, the concentrate is washed with water, and the average membrane flux About 62LMH (liter / square meter per hour), get 280L ceramic membrane dialysate;

[0047] Step 3: The ceramic membrane dialysate enters the ultrafiltration membrane equipment for the concentration and separation of polysaccharides, the piped membrane, the roll-type membrane core with a molecular weight cut-off of 5000 Daltons, the operating pressure is 12bar, the operating temperature is controlled ...

Embodiment 3

[0050] Step 1: Weigh 54 kg of pulverized Hedyotis grass powder, add 650 kg of water for ultrasonic extraction for 2.5 hours, and remove large particles by coarse filtration to obtain 610 L of filtrate;

[0051] Step 2: The filtrate enters the ceramic membrane equipment for clarification and removal of impurities. The membrane area is 0.48 square meters, the pore size is 100nm, the operating pressure is 3.6bar, the operating temperature is controlled within 60°C, and the continuous operation is 1080min. During the process, the concentrated solution is washed with water, and the average membrane flux About 69LMH (liter / square meter per hour), get 1220L ceramic membrane dialysate;

[0052] Step 3: The ceramic membrane dialysate enters the ultrafiltration membrane equipment for the concentration and separation of polysaccharides, the piped membrane, the roll-type membrane core with a molecular weight cut-off of 10,000 Daltons, the operating pressure is 8bar, the operating temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com