Colistin sulfate production method

A technology of colistin sulfate and production method, applied in the field of production of colistin sulfate, can solve the problems of low overall yield, high concentration cost, low purity and the like, achieve system simplification, low valve switching frequency and good operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

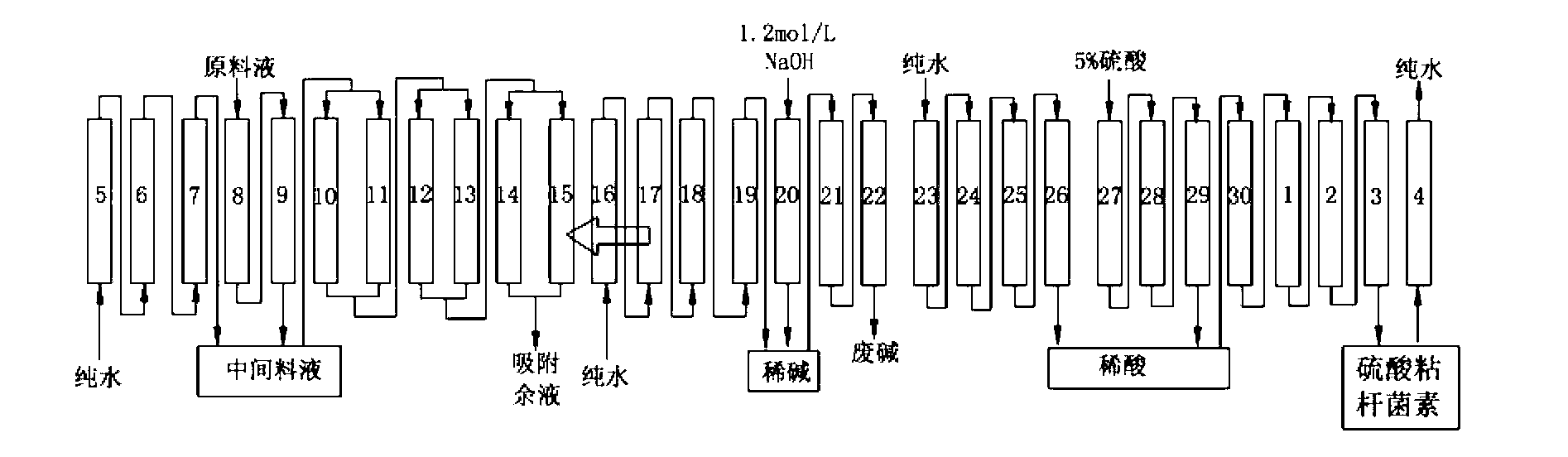

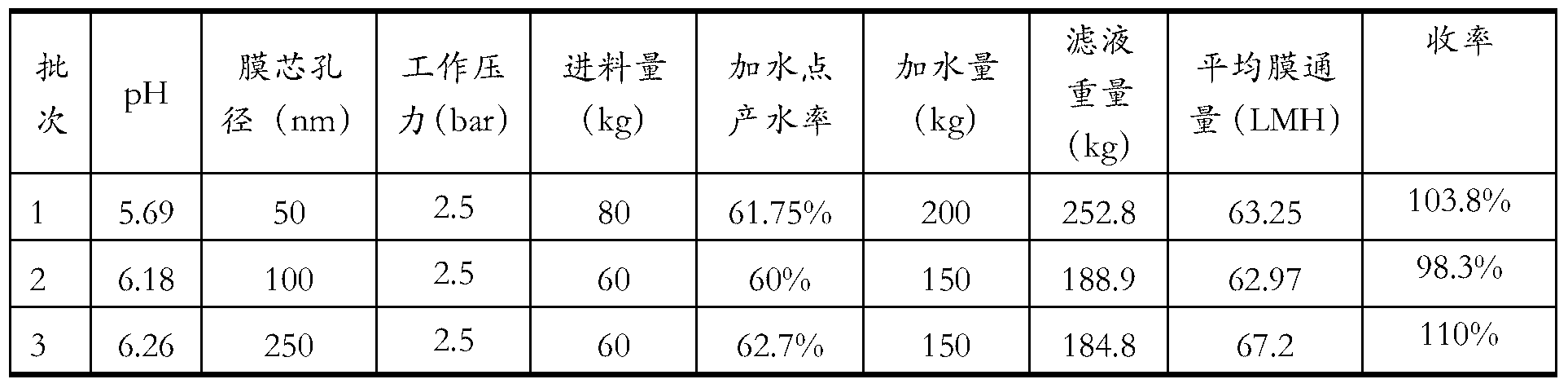

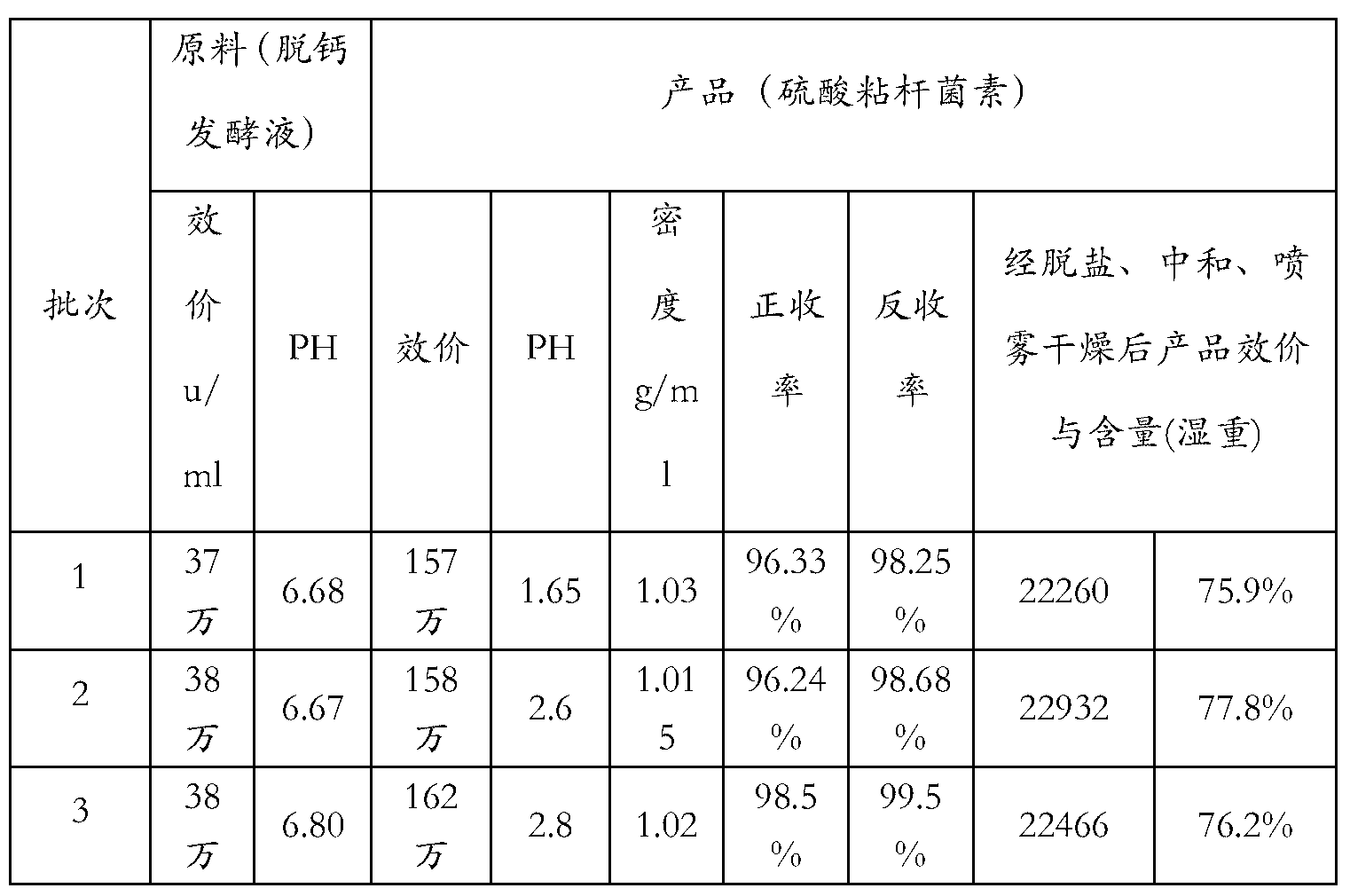

[0040] Embodiment: The raw material liquid is colistin fermentation liquid pretreated by ceramic membrane and decalcified process, the raw material liquid is dark brown, the titer of colistin is between 350,000-400,000 u / ml, and the Ca2+ content is ≤200ppm. The amount of resin filled in each separation unit is 450mL, and the rotation cycle of the equipment is 2100s or 35min. The flow rate of the resin = 450 / 35 = 12.8mL / min, and the feeding amount of the fermentation broth is about 138mL. The amount of resin can be characterized by the ratio of resin volume to feed volume, that is, 12.8:138=1:10.8. In the case of 2100S / rev, the amount of feed liquid that can be processed by a unit of resin is: 10.8ml feed liquid / ml resin; Methods The results of colistin sulfate production are shown in the table below.

[0041]

[0042] It can be seen from the above table that after the raw material solution is treated by the continuous ion exchange system, the product titer is about 1.6 mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com